All published articles of this journal are available on ScienceDirect.

Compressive Behavior of Recycled Mortar After Exposure to High Temperatures

Abstract

The possibility of using fine recycled concrete aggregate as a substitute for natural sand are relatively limited. In order to promote it for engineering application, this paper reports the effect of elevated temperatures from room temperature to 600oC on the compressive behavior of mortars containing recycled fine concrete aggregate was investigated. It is found that no obvious relation between the color change and the recycled mortars replacement percentage.And the mass loss of recycled mortars is larger than that of normal mortars.The compressive strength of recycled mortars declines significantly as the temperature rises. The elastic modulus of recycled mortars decreased with the increase in temperature, and the decrease is much quicker than the decrease in compressive strength.

1. INTRODUCTION

In recent years, considerable effort have been directed towards investigating the possibility of using coarse recycled concrete aggregate (RCA) as a substitute for natural coarse aggregate (NCA) in concrete construction. This had led to a deeper understanding of the ways and means of processing demolished concrete, mixture design of RAC, its physical and mechanical properties for an exhaustive treatment of various aspects of this material [1]. But the possibility of using fine recycled concrete aggregate as a substitute for natural sand is relatively limited.

The use of recycled fine concrete aggregate as sand in concrete had been studied by several other researchers [2-4]. Their works revealed that recycled fine aggregate lowers the quality of the concrete in mechanical strength and durability. Buyle-Bodin et al. [5] found that recycled fine aggregate increased porosity and permeability of the concrete.

Zhao et al. [6] studied the properties of mortars containing fine recycled concrete aggregates, including fresh properties, mechanical properties and interfacial transition zone (ITZ) microstructure.

Studies on properties of masonry mortars manufactured with fine recycled concrete aggregates revealed that a replacement ratio of fine recycled concrete aggregate up to 40% was a viable alternative for producing environmentally friendly masonry mortar [7].

In this study, the effect of elevated temperature on the compressive behavior of mortars containing recycled fine concrete aggregate was investigated.

2. EXPERIMENTAL DETAIL

2.1. Materials and Mix Proportions

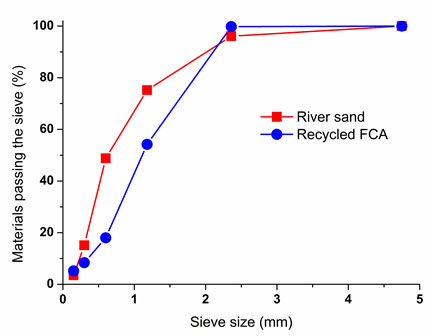

Two types of fine aggregate were used in this research. One of the fine aggregate was natural river sand, which met Chinese Standard “GBT14684-2011” [8].The second type was recycled fine concrete aggregate (FCA) obtained from crushing waste concretes from curbs and sidewalks in Nanchang, PR China. The physical properties of fine aggregates are shown in Table 1. Fig. (1) presents the size grading of the aggregates. Ordinary Portland cement with a 28d compressive strength of 32.5 Mpa was used in this investigation, which was compatible with Chinese Standard “GB175-2007” [9]. The chemical composition of ordinary Portland cement is stated in Table 2.

| Type of fine aggregates | Fineness modulus | Bulk density (kg/m3) | Apparent density (kg/m3) |

Silt content (%) | Water absorption (%) | Crushing value (%) |

|---|---|---|---|---|---|---|

| River sand | 2.6 | 1460 | 2610 | 1.56 | 4.3 | 11.1 |

| Recycled sand | 3.2 | 1280 | 2480 | 2.5 | 6.6 | 18.7 |

| Lime (Cao) | Silica (SiO2) | Alumina (Al2O3) | Iron oxide (Fe2O3) | Sodium oxide (Na2O) | Magnesium oxide (MgO) | Potassium oxide (K2O) |

Sulfur trioxide (S03) |

|---|---|---|---|---|---|---|---|

| 56.52 | 23.18 | 7.06 | 3.32 | 4.25 | 2.05 | 0.89 | 1.98 |

Three mortar mixtures consisting of 0%, 50%, 100% recycled fine concrete aggregate as a partial replacement for sand were prepared. These mixtures were used to investigate the effect of recycled aggregate on the mechanical properties of mortar exposed to elevated temperatures. Details of the mortars mixtures are given in Table 3. Due to high water absorption of recycled fine concrete aggregate, the water of the mortars mixtures included mixing water and added water. This may make the proportion w/c high.

| Mix | Recycled aggregate content (%) | Cement | Recycled fine aggregate | Natural sand | Mixing water | Added water |

|---|---|---|---|---|---|---|

| NM | 0 | 240 | — | 1500 | 320 | 0 |

| RM50 | 50 | 240 | 730 | 730 | 320 | 35 |

| RM100 | 100 | 240 | 1430 | — | 320 | 70 |

2.2. Test Methods

Prism mortar specimens (70.7×70.7×212 mm) were cast for each mixture and prepared to determine the effect of different temperatures on mass loss, compressive strength and modulus of elasticity. After casting, the mortar specimens were kept in their moulds for 24h at room temperature (20±2°C). After 24h, the specimens were demoulded and cured in a fog room (20±2oC, 95% relative humidity) for 28 days, and then dried at room temperature for 7 days. The mortar specimens were heated in an electric furnace to temperatures of 200, 400, 600oC. In order to ensue that the temperatures in the center of the mortar specimens also reached the target temperatures, the temperature was maintained at 200, 400, 600oC for 3h respectively. After completion of the heating regimes, specimens were removed from the furnace and the mass losses of specimens for each temperature were measured. The heated mortar specimens were then cooled to room temperature. The uniaxial compressive behavior of mortar specimens for each mix proportion were tested according to JGT/T70-2009 [10]; the tests were conducted at 0.0025mm/s. The loading setup was a YAW-3000 microcomputer controlled electro-hydraulic servo tester.

3. RESULTS AND DISCUSSION

3.1. Visual Observations

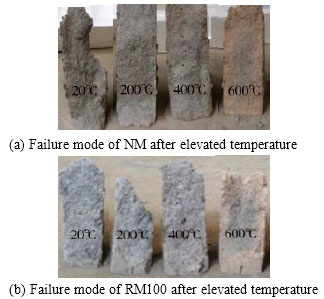

During the process of heating, no explosive spalling was seen for all the mortars. It may indicate that recycled mortar has a good resistance against explosive spalling. So it may behave well when exposed to fire. No crack was observed for recycled mortars after exposure to 200°C. When the temperature was at 400°C, there were a few hairline cracks on the surfaces of the recycled mortars; at 600°C, most cracks crossed the cross-section of recycled mortars.

After exposure to elevated temperature, the heated recycled mortars had different colors. When the temperature was below 200°C, the surface of recycled mortars was gray; at 400°C and 600°C, it was turned to light red and red, respectively. And it seems that no obvious relation between the color change and the recycled mortars replacement percentage. It may be attributed to the changes in chemical of recycled mortars after exposure to elevated temperature.

3.2. Mass Loss

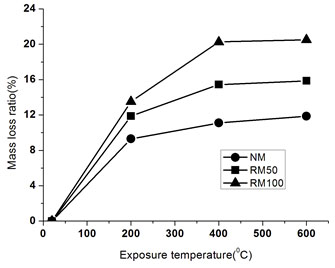

The mass of each mortar specimen was measured before and after the exposure to elevated temperature, and the percentage mass loss (i.e. ratio of mass loss to mass of mortar at room temperature) is shown in Fig. (2). The Fig. (2) shows that mass loss increased gradually with the increase in exposure temperature and that mass loss was affected by the recycled mortars replacement percentage. With the same elevated temperature, the higher the recycled mortars replacement percentage, the bigger the mass loss.The mass loss was obvious when the exposure temperature increased from 20°C to 200°C, due to the evaporation of abundant free water and capillary water. Up to 400°C, the mass loss was not affected significantly. Fig. (2) shows that the mass loss of recycled mortars is larger than that of traditional mortars because recycled mortars contain more evaporable water than the traditional mortars due to the larger water absorption of the former than the latter.

3.3. Compressive Strength

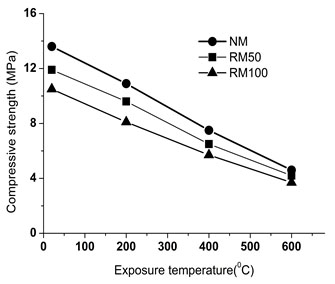

Table 4 shows the residual compressive strengths of all mortars. And the variation of the residual compressive strengths with temperature is shown in Fig. (3) for recycled mortars. It is shown that the compressive strength of recycled mortars declines significantly as the temperature rises.

| Mix | Compressive strength (MPa) | Elastic modulus (GPa) | ||||||

|---|---|---|---|---|---|---|---|---|

| 20°C | 200°C | 400°C | 600°C | 20°C | 200°C | 400°C | 600°C | |

| NM | 13.6 | 10.9 | 7.5 | 4.6 | 18.2 | 11.5 | 6.1 | 2.4 |

| RM50 | 11.9 | 9.6 | 6.5 | 4.2 | 13.6 | 8.6 | 4.5 | 1.8 |

| RM100 | 10.5 | 8.1 | 5.7 | 3.4 | 11.7 | 7.4 | 3.9 | 1.5 |

The compressive strength at 200°C was 80.7% and 77.1%, of the original compressive strength (at 20°C) for RM50, RM100, respectively; at the same temperature for NM that was 80.1%. The slight decrease in mortars strength in the temperature range from 20 to 200°C is attributed to the softening of the cement gel or attenuating the surface forces between gel particles. When the temperature range from 200 to 400°C, the compressive strength of mortars dropped rapidly. At 400°C, the compressive strength for all mortars was about 55% of that at 20°C. Above 400°C, the mortars had a larger compressive strength loss. The reason is that the dehydration of the cement paste results in gradual deterioration of the mortar microstructure. With further increase in temperature up to 800°C, the residual compressive strength of NM, RM50, RM100 was 33.8%, 35.2%, 32.3%, respectively. The recycled sand content has certain effect on compressive strength of the mortars. At the same temperature, the compressive strength of recycled mortars declines with the increase of the recycled sand content.

3.4. Elastic Modulus

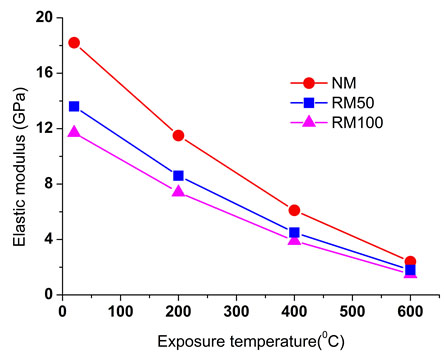

Fig. (4) shows the effect of elevated temperature on elastic modulus of recycled mortars. As it can be seen from Fig. (4), for all mortars, the elastic modulus decreased with the increase in temperature, and the decrease is much quicker than the decrease in compressive strength. The reason why elastic modulus of mortars after exposure temperature is decreased may be debonding between aggregate and hardened cement paste, thermal degradation of aggregate. At 200°C, the residual elastic modulus of all mortars was about 63.2%. For RM100 specimens, it was further reduced to 33.3% and 12.8% after exposure to 400°C and 600°C, respectively. Above all, the losses in elastic modulus of recycled mortars were larger than the losses in compressive strength for the same temperature.

3.5. Failure Mode

Fig. (5) shows the failure modes of recycled mortars after elevated temperature.With the same elevated temperature, the failure process and modes of recycled mortars (specimens NM, RM50, RM100) were similar. When the load on the mortars was close to the peak load, the first crack appeared in the mortars while the cracking sound could be heard. After the peak load, the crack propagated along the oblique direction of recycled mortars. The load decreased quickly, and accordingly the failure process was rapid. Then the specimen was broken with splitting mode. As can be seen from Fig. (4), the angle of failure plane of recycled mortars after elevated temperature was different. The higher the elevated temperature was, the bigger the angle of failure plane.

CONCLUSION

- After exposure to elevated temperature, the heated recycled mortars had different colors. No obvious relation between the color change and the recycled mortars replacement percentage.

- Mass loss of recycled mortars increased gradually with the increase of exposure temperature and that mass loss was affected by the recycled mortars replacement percentage. With the same elevated temperature, the higher the recycled mortars replacement percentage was, the bigger the mass loss.

- Compressive strength of recycled mortars declines significantly as the temperature rises. The recycled sand content has certain effect on compressive strength of the mortars. At the same temperature, the compressive strength of recycled mortars declines with the increase of the recycled sand content.

- The elastic modulus of recycled mortars decreased with the increase in temperature, and the decrease is much quicker than the decrease in compressive strength because the elastic modulus is more sentive to high temperature.

CONFLICT OF INTEREST

The authors confirm that this article content has no conflict of interest.

ACKNOWLEDGEMENTS

This work was supported by the Chinese National Natural Science Foundation (No. 51368001), the Natural Science Foundation of Jiangxi Province (20142BAB216002), the Technology Support Project of Jiangxi Province (20151BBG70012), the Open Project Program of Jiangxi Engineering Research Center of Process and Equipment for New Energy, East China Institute of Technology (No. JXNE-2014-08) and the Opening Project of Guangxi Key Laboratory of Disaster Prevention and Structural Safety (No. 2013ZDK01), which are gratefully acknowledged.