All published articles of this journal are available on ScienceDirect.

Review of The Cement-Based Composite Ultra-High-Performance Concrete (UHPC)

Abstract

Introduction:

Ultra-High-Performance Concrete (UHPC) is an advanced type of concrete in the Civil Engineering industry. It is a cement-based composite which exhibits improved mechanical and durable properties showing a high compressive strength of not less than 150 MPa and high tensile strength of not less than 7 MPa.

Objective:

In this article, a review of the use of a different type of supplementary cementitious materials (SCMs) including fibers is made for obtaining the desired UHPC.

Discussion and Conclusion:

For this, it is vital to understand the principles of UHPC. UHPC has several advantages over normal strength concrete (NSC) and high strength concrete (HSC) with some commercially ready UHPC’s available, but the use of it is restricted due to the limited design codes. The influence of the curing type also plays a vital role in the overall performance of UHPC.

1. INTRODUCTION

In concrete technology, there is a highly remarkable type of concrete named Ultra-High-Performance Concrete (UHPC). Just like Normal Strength Concrete (NSC), UHPC is composed of the same standard materials like cement, aggregate, mineral admixture, chemical admixture, and water. The UHPC or Reactive Powder Concrete (RPC) [1], is an elastic material reaching extraordinary strength. The material can reach compressive strengths not less than 150 MPa and tensile strengths of not less than 7 MPa [2-4].

In concrete technology, the development of various types of concrete is considered to be the concrete evolution. Since the early 100, the construction material Normal Strength Concrete (NSC) has been around and responsible for countless civil engineering structures like The Pantheon (Italy, 125), Pont Camille de Hogues (France, 1900), and Hoover Dam (USA, 1935). Around 1970, NSC developed to High Strength Concrete (HSC) a type of concrete which exhibits high compressive strengths (55 MPa or more) [5]. The technological revolution of concrete can be placed around 1980, where HSC has contributed to engineering structures like Water Tower Place (USA, 1970), Two Union Square (USA, 1988), and Petronas Twin Tower (Malaysia, 1997). Around the year 1997, the introduction of Ultra-Hugh-Performance Concrete (UHPC) introduced strengths (compressive) well over 200 MPa along with multiple performance capabilities for concrete. UHPC has been used for Sherbrooke Bridge (Canada, 1997), Shepherds Creek Bridge (Australia, 2005), UHPC girder bridge (USA, 2008), Haneda Airport slabs (Japan, 2010), and Spun concrete columns (Germany, 2012) [6].

UHPC is divided into four essential components; (1) powders and fine materials, which can be Ordinary Portland Cement (OPC), quartz sand, or fine silica sand, (2) superplasticizers (also known as High-Range Water Reducers, HRWR), mostly polycarboxylate ether-based, (3) fibers, usually steel fibers, and (4) of course water [7]. This unique composite material is a combination of superior properties and designs flexibility offering answers with benefits such as reduced construction time, improved aesthetics, excellent durability, and corrosion, abrasion, and impact protection [8-10]. All these lead to reduced maintenance and a longer lifespan for the civil engineering structure. Working with UHPC leads to a reduction in materials (e.g., cross-section, material thickness) and very elastic behavior due to the addition of fibers. In short, some characteristics of UHPC are a low water-to-cementitious ratio (w/c), a high binder content (w/b), and an optimum packing density [2, 11].

For UHPC to be more durable and sustainable, the cement is often wholly or partially replaced by a large quantity of supplementary cementitious materials (SCMs). In order to speed up the chemical reaction with the cement high-temperature curing or pressure curing (autoclave curing) is applied, which considerably results in improved properties of UHPC concrete. Properties include reduced porosity, enhanced strength, improved matrix and aggregate/ fiber bond [12, 13]. Compressive strength of 200 MPa can be reached with eight hours of pressure curing for 3 or 4 percent fiber reinforcement UHPC [13].

There is a distinguished relationship between the micro-scale properties of UHPC and the engineering characteristics of UHPC. The key factor in producing UHPC is the improvement of the micro and macro properties of the material mixture. This enables for a denser packing of the particles and mechanical homogeneity leading to a much denser type of concrete. This ultimately results in a type of concrete with enhanced and improved mechanical and durable properties like high compressive strengths (>150 MPa) and abrasion-resistant, corrosion-resistant, etc. With its improved micro-scale properties, the silica fume (SF) pozzolanic reaction tends to speed up.

Another key point is the investigation of the microstructure and the mechanical properties of UHPC. A method used is by exploring the isothermal mechanism and thermal gravimetric analysis [14]. The investigated activation methods, namely chemical and thermal results in improved microstructural properties. By an accelerated hydration process and increased C-S-H amount formation a porosity decrease is noticeable [15].

The engineering characteristics of UHPC are characterized as having exceptional and enhanced performance capabilities for concrete. The addition of fiber as additional reinforcement in the concrete mixture results in improved mechanical features as strength (compressive, tensile, and flexural), durability features, ductility, and resistance [16].

High-Performance Concrete (HPC) or High Strength Concrete (HSC) is a concrete mixture having more strength and durability compared to Normal Strength Concrete (NSC). The material reaches compressive strengths 55 MPa and more after 28 days of curing and classes as a material requiring special design requirements for the production and testing [17]. In civil engineering, the application of HPC reaches various areas which are not limited to bridges (e.g. long-span bridges), high-rise buildings, and highway pavements.

Structural design guidelines and standards have been written in countries of almost every continent, ranging from Europa (Germany [18]) to Asia (China [3]). The article presents a review of Ultra-High-Performance Concrete (UHPC) and is focused on (1) the principles, (2) supplementary cementitious materials including fibers, and (3) the mechanical and durable properties of UHPC.

2. UHPC PRINCIPLES

There are some basic principles for UHPC as previously identified by several researchers [9, 19-21]. This composite material is based on the following characteristics: (1) a high binder content, reduction of (w/b), (2) reduced porosity, (3) optimized packing density (a close packing of the raw materials), (4) reduced water, < 0.25 (w/c), (5) accelerates early and drying shrinkage due to (temperature, steam or pressure) curing thus improving material properties, and (6) improved ductility due to fibers [2, 4, 12, 13, 18, 22, 23].

UHPC uses a high binder content compared to NSC giving it a reduced (w/b) around 900-1100 kgm-3. By adding Silica Fume (SF) to the binder mix helps fill the voids between the various particle sizes (sand, aggregates) while also improving the workability.

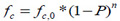

In examining the porosity reduction, the compressive strength (fc) and the porosity have a certain correlation [24], [25] as shown in Eq (1-4). The four models help in forecasting the materials effected through the porosity. Reducing the pores leads to increased compression strength and improved toughness of cement-based materials [26].

Equation of Balshin

|

(1) |

Equation of Hasselmann

|

(2) |

According to the research group, Chen et al. [27]. the predictions with the exponential equation (Ryshkevitch) and the logarithmic equation (Schiller) are almost identical except at 0 percent and 100 percent porosity.

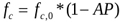

Equation of Ryshkevitch

|

(3) |

Equation of Shiller

|

(4) |

In the equations above fc,0, fc, P0, P, A, B, and D are defined as [4]:

-fc,0 is the strength when the porosity is nil,

-fc is the strength when the porosity is P,

-P0 is the porosity when the strength is nil,

-P is the porosity,

-n is a to be determined coefficient,

-A, B, and D are the empirical constants [4].

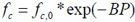

By effectively using the admixture ingredients results in a broader concrete technology process. Normally the concrete strength is controlled by the water/binder ratio (w/b) [18], which is based on the mass. With the introduction of the water/ultrafine particles ratio (w/Fv) (Eq. 5), (Fehling et al., 2014), the combinations of ultrafine particles were effectively used for controlling the strength. This process effectively increases the strength and is based on the volume. The approach also establishes improved UHPC mix designs (extended k+ value, optimized Walz curve) [18].

|

(5) |

where w is the volume-based water, Fv is the ultrafine particle, and Σ is the sum

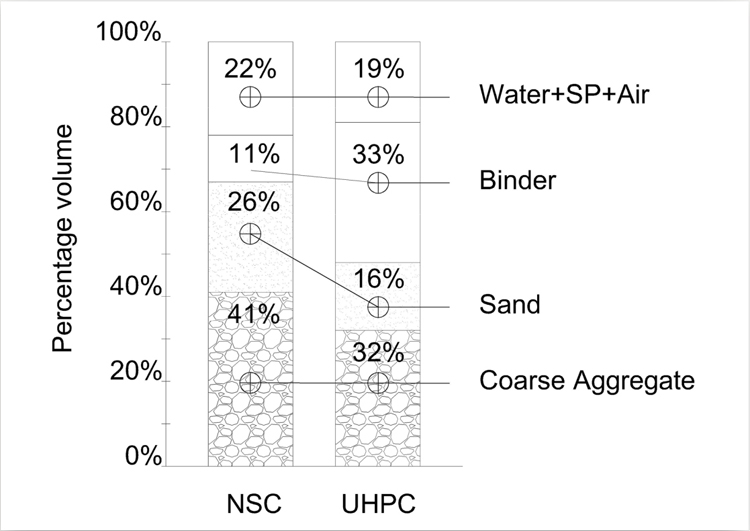

The elimination of coarse aggregate plays a vital role in the composition of UHPC. According to Ma et al. [28], there is a clear difference in the portion of concrete, the time for mixing, and in the autogenous shrinkage. Comparing two UHPC types consisting of the powders Ordinary Portland Cement (OPC), white Silica Fume (SF), and Quartz Powder (QP). To improve the packing density of the powder mixture Quartz Powder (QP) was used as a micro filler. The difference in coarse aggregate size was around 625-670%. Both UHPC compositions had the same sand and superplasticizer (SP), which was polycarboxylate ether (PCE). The PCE ensures a high fluid ability as self-compacting concrete for both UHPC compositions giving it better flowability. Due to the PCE’s chemical structure, it allows water to be reduced up to 40% which enables good particle dispersion with a reasonably small amount (0.15–0.3% by cement weight) [29]. In Fig. (1) the aggregate volume fractions (sand and coarse) for NSC and UHPC is shown.

The type of curing regime plays a vital role in increasing the strength of UHPC (Table 1) as presented by previous researchers [2, 12, 13, 30-33]. As studied by Alsalman et al. [2] the compressive strength showed the highest with curing at 60 °C (two days) followed by 90 °C (three days). The effect of pressure curing (autoclave curing) [30] (0.5 MPa, 1.0 MPa, and 1.5 MPa) and the period (6 h, 8 h, 10 h, and 12 h) showed a maximum increase of 37.5% and 30.3% of the strength. Both the curing regime and the use of mineral admixtures increase the mechanical and environmental performance of UHPC [34].

| Research | Specimen Type | Curing Type | Strength Type | ||||

|---|---|---|---|---|---|---|---|

| Heat / Temperature (oC) | Steam / Autoclave (MPa/ oC) | Compressive Strength (MPa) | Flexural Strength (MPa) | ||||

| Heat | Steam / Autoclave | Heat | Steam / Autoclave | ||||

| Chen et al. (2018) | Beam/ Prism | 20 (room) | - / 0.5-1.5MPa (156-203 oC) | 114-126 | - / 110-168 | 16-20 | - / 16.5-22.5 |

| Alsalman et al. (2017) | Cube/ Cylinder | 21 (room); 60-90 | - | 106-115 (150-180); 105-120 (125-150) | - | - | - |

| Wu et al. (2017) | Beam/ Prism | 20 (room); 90 | 90 / - | 138-150 | 191-201 / - | 27-38 | 30-40 / - |

| Van et al. (2014) | Beam | 20 (room); 65; 90 | - | 170-185; 170-185; 170-190 | - | - | - |

| Yang et al. (2009) | Prism/ Cube | 20 (room); 90 | - | 100-130; 150-180 | - | 16-22 / 21-25 | - |

| Chi and Hu (2003) | Cylinder | - | - / (150-200 oC) | - | - / 34-64 | - | - |

| Aldea et al. (2000) | Cylinder | 20 (room) | 80 / 0.5MPa (175 oC) | 26-60 | 24-48 / 38-46 | - | - |

3. SUPPLEMENTARY CEMENTITIOUS MATERIALS

3.1. Overview

There are several supplementary cementitious materials (SCMs) that contribute to the properties of UHPC. They are added to influence the concrete properties regarding strength, permeability, and more gradually. The SCMs reviewed are (1) Metakaolin, (2) Silica Fume, (3) Fly Ash, (4) Ground Granulated Blast-Furnace Slag, and (5) Copper Slag. In Table 4, an overview of the durable properties is presented in regards to the different SCMs.

3.2. Metakaolin

Metakaolin (MK) is the anhydrous calcined shape of the clay mineral kaolinite. The particle size of MK lies between the cement particles (larger) and the silica fume (SF) particles (smaller). The reaction between the cement and the pozzolans is dependent upon the high-temperature heating, the calcining temperature. Some benefits in using MK powder as an SCM is the improvement of the strength and durability of concrete, the reduction of the autogenous shrinkage, and the refinement of the pore structure. The researchers Tafraoui et al. [35] presented a decrease and increase of both the compressive (-6.7%) and flexural strength (+2.6%) by substituting SF with MK. The availability and low price of MK are much more beneficial for UHPC manufactures, including its white color which can be an aesthetic advantage.

The researchers Rougeau and Borys [36] presented an improved performance using MK and other ultrafine particles in UHPC mixes. Compressive strengths and flexural strengths of 150 MPa and 25 MPA were achieved after 28 days of curing. Using MK as ultrafine particles also resulted in improved durability properties like lower water absorption (1.9%), because of the high compactness. The substitution of SF with MK in the binder mix can contribute to a lower autogenous shrinkage development when cured at room temperature (20oC) at around -200µmm-1 at 0.2916 days [37].

3.3. Silica Fume

A commonly used supplementary cementitious material (SCM) for the production of UHPC is Silica Fume (SF). The material is an ultrafine non-crystalline silica by-product of the production of silicon metals and ferrosilicon alloys that is a highly- reactive pozzolan. The main advantage of SF is the reduction of the concrete by supplementing the cement powder with the silica fume powder either partially or fully.

The production of silicon metal or ferrosilicon alloy produces a waste product, which can be used for the production of concrete, namely Silica Fume (SF). Being an imperative component in the production of UHPC, a typical diameter for SF is about 0.2 μm [4]. In 1995, Richard and Cheyrezy [20] suggested that the SF/PC ratio (silica fume/Portland cement ratio) should be 0.25, around 25%. For excellent bond features, the ideal SF content was found to be 20-30% [38], while some researchers resulted in UHPC strength of 200 MPa with an ideal SF content of 30-35% [38]. As a lower w/c content required a lower SF content, so it can be stated that there is a significant relationship between the two [31]. When SF is not present the swift production of hydration products results in the development of a porous structure and low compressive strength under pressure or autoclave curing conditions [32, 33, 39]. However, there is also a drawback to SF like the variable carbon content, a factor that reduces UHPC’s flowability. Another drawback results in an aesthetic problem caused by the high unburnt coal in SF causing a dark surface colored concrete. Previous studies have shown that other SCMs like Metakaolin (MK), Fly Ash (FA), and Ground Granulated Blast Furnace Slag (GGBFS) are adequate to substitute the silica fume in UHPC [4, 40, 41].

SF plays a major part in the fluidity of UHPC because this type of SCM densifies the microstructure of UHPC [42]. By analyzing several types of SF used as mineral admixture the fluidity property of UHPC is examined. Influence mechanism like the ‘ball effect’ and the ‘plasticizing effect’ contribute to the enhancement of the fluidity [42]. Effect factors like the void ratio, packing density, particle size distribution and the carbon content of SF. By adding about 10-15% SF volume to the UHPC mixture the amount of HRWR needed for the flowability decreases, resulting in a lower viscosity of the mixture. An ideal SF content (5-25%) is also necessary for an optimum fiber-matrix bond of UHPC [43].

3.4. Fly Ash

The production of Fly Ash (FA) is the result of a by-product from the coal power station and consists of spherical particles. Through a double, triple and quadruplicate system the FA is mixed with Steel Slag (SS) powder, SF, and GGBFS. Yazici et al. [40, 41] realized that high compressive strengths of UHPC are obtained consisting of high amounts of GGBFS and FA after different curing regimes. The research showed high strengths from three types of curing, which are (1) standard curing 200 MPa, (2) steam curing 234 MPa, and (3) autoclave curing 250 MPa. The results after all curing regimes can significantly improve the flexural strength and the toughness of concrete by combining FA with GGBFS. However, a disadvantage of replacing the cement with more than 30% is a decrease of modulus of elasticity of UHPC. Peng and his group [44] discovered that by incorporating SS and Ultra-Fine Fly Ash (UFFA) in UHPC resulted in a higher strength concrete. Important is to apply the right amount of SS/UFFA ratio. With three days of 90° C of water curing compressive strengths and flexural strengths were reached of around 189 MPa and 32 MPa. The test specimens were compromised of SS (18%), UFFA (12%), SF (15%), and steel fiber (2%). Because of consecutive hydration and the filling effect of the cementitious ingredients, the UHPC revealed to have exceptional mechanical properties. The use of microscope performed the results. The combination of FA and increasing the autoclave curing duration have resulted in the porosity reduction of UHPC [30]. The mixture of w/c 0.3, FA of 10% and steel fiber of 2% increased the strength (compressive and split tensile) of UHPC [45]. Another benefit of FA is its low cost ($50-$60/T) as supplementary cementitious material [46].

3.5. Ground Granulated Blast-Furnace Slag

Another type of supplementary cementitious material (SCM) is the ground granulated blast furnace slag (GGBFS), which is a by-product of the steel manufacturing process [47]. The research group of Yazici et al. [40, 48] developed a UHPC by replacing the Portland cement (PC) with GGBFS. The result showed an increase in the compressive strength of over 250 MPa after pressure curing. The PC was substituted by percentages of 20%, 40%, and 60%. By applying autoclave curing during setting phases, high compressive strength of 400 MPa was reached. By adding more Ground Granulated Blast-Furnace Slag and Fly Ash, the flowability of the composite material increased. However, under standard curing conditions, the addition of Ground Granulated Blast-Furnace Slag (GGBFS) or Fly Ash (FA) has little effect on the compressive strength of UHPC [13]. Enhancing the durability properties can be achieved with standard curing conditions and a replacement of 50% slag contributed to decreasing the chloride permeability [33]. The researchers Alkaysi et al. [49] achieved improved durability properties regarding the freeze-thaw effect and permeability. A mixture of 50-50 PC and GGBFS resulted in 24.2-44.7 gm-2 mass loss, which is a tolerable freeze-thaw resistance of UHPCs.

3.6. Copper Slag

Copper Slag (CS) or Granulated Copper Slag (GCS) is a by-product material produced from the process of manufacturing copper. For every ton of copper to produce around 2.2–3.0 tons Copper Slag is produced as a by-product material according to Caliskan and Behnood [50], approximately r. Presently the GCS is being used for many purposes ranging from landfilling to grit blasting, which is not very high value-added applications [51]. However, many studies have been conducted regarding the improved mechanical properties (like strength) and the characteristics of concrete using copper slag as a replacement for fine or coarse aggregate. Adding CS or GCS also develops improvement in the workability of concrete and increasing the dosage of slag may lead to reducing the dosage of superplasticizer [48, 50, 52-54].

3.7. Sustainability

The use of Supplementary Cementitious Materials (SCMs) has been a major development in the design, production, and construction of UHPC. A major drawback is a negative impact the process has in terms of energy and resource consumption, carbon consumption, and greenhouse gas (GHG) emissions. As known by researchers worldwide GHG emissions are linked with global climate change giving the latter much more needed attention. There hasn’t been much research conducted on the sustainability of SCMs yet the importance of the topic has been highly overlooked by researchers and engineers alike. In Table 2, some previous work conducted by researchers is summarized.

Ground Granulated Blast Slag or GGBS is an SCM used to substitute the cement amount for the production of UHPC. Initially, a waste product used for landfill sits the material has been developed as an SMC capable of economic and environmental benefits. With a replacement of around 80%, various properties such as flowability, compressive strength, tensile strength, fracture, and durability enhancements are achieved [55].

Copper Slag (CS) improved the workability and compressive strength of Ultra-High Performance mortar (UHPM). One of the reasons for improved workability is the absorption of water by CS, which may cause concern for bleeding. Mixtures with 20% CS reached compressive strengths of 165 MPa [53].

In general, the production of cement (Portland cement e.g. CEMI 52.5R) has a negative impact on the environment as presented in Table 3 [56]. With cement being responsible for around 5% of CO2 emissions (anthropogenic) [57]. More recently, research has been conducted on a more environmental friendly UHPC, or ECO- UHPFRC. The concrete mixture contains a high dosage of mineral admixture and a low clinker content. Eventually, the ECO-UHPFRC has a lower global warming impact compared to traditional methods using the Life Cycle Assessment (LCA) methodology [58]. The use of Silica Fume (SF) or micro-silica is in the production of UHPC. As both Fly Ash (FA) and Silica Fume (SF) are the by-product of the coal power station and silicon metal or ferrosilicon alloys, the environmental impacts of both SMCs are for the transport to the concrete production company [59].

Another type of slag named Phosphorus Slag is employed to design a type of low carbon UHPC material [60]. With a cement replacement of 10-50% and incorporating the revised Andreasen and Andersen particle packing method (section 5), the production of a more fluid and reduced autogenous shrinkage can be achieved. Ultimately the addition of this type of slag can contribute to a more sustainable type of UHPC.

UHPC demonstrates several enhanced durability properties, which include (1) the porosity, (2) freeze-thaw effect, (3) chloride ion penetration, (4) permeability, (5) water absorption, (6) reinforcement corrosion rate, and (7) abrasion resistance. For each property, the effect on UHPC is elaborated as previously mentioned in Table 4. Between all these characteristics there is a certain degree of relationship between them.

| Reference | Researchers | Title | Research Area |

|---|---|---|---|

| [55] | Ganesh and Murthy (2019) | Tensile behaviour and durability aspects of sustainable ultra-high performance concrete incorporated with GGBS as cementitious material |

Ground Granulated Blast Slag (GGBS) |

| [53] | Edwin et al. (2016) | Effect of secondary copper slag as cementitious material in ultra-high performance mortar | Copper Slag (CS) |

| [56] | Müller et al. (2019) | A New Generation of Sustainable Structural Concretes-Design Approach and Material Properties | Sustainable concrete |

| [60] | Yang et al. (2019) | Low carbon design of an Ultra-High Performance Concrete (UHPC) incorporating phosphorous slag | Phosphorus Slag (S) |

| [59] | Sameer et al. (2019) | Environmental assessment of ultra-high-performance concrete using carbon, material, and water footprint | Fly Ash, Silica Fume |

| Material | Global Warming Potential (GWP) | Ozone Depletion Potential (ODP) | Acidification Potential (AP) | Reference |

|---|---|---|---|---|

| (kgCO2kg-1) | (kgR11kg-1) | (kgSO4kg-1) | ||

| CEM II 52.5 | 0.871 | 1.119.10-11 | 1.108.10-3 | [56] |

| SCM | Porosity | Freeze-Thaw Effect | Chloride Ion Penetration | Permeability | Water Absorption | Reinforcement Corrosion Rate | Abrasion Resistance |

|---|---|---|---|---|---|---|---|

| MK | +20% | No information supplied* | No information supplied* | No information supplied* | (-20) – (-25)% | No information supplied* | No information supplied* |

| SF | 2.6-2.8% Limited data provided |

None till 200 cycles Limited data provided |

No data provided* | 4.8-5.3*10-9cmsec-1 Limited information supplied |

No information supplied* | No information supplied* | 0.62-0.65 mm Limited information supplied |

| FA | 2.6-3.0% Limited information supplied |

No information supplied* | No information supplied* | 5.8-5.9*10-9cmsec-1 Limited information supplied |

No information supplied* | No information supplied* | 0.67-0.70 mm Limited information supplied |

| GGBFS | Low. Limited data provided |

24.2 – 44.7 gm-2 mass loss None till 600 cycles |

Very low to High (75% slag)* High (25% slag)** |

<20% (75% slag)** 30 – 55% (25% slag)* |

No information supplied* | No information supplied* | No information supplied* |

| CS | Low. Limited information supplied |

No information supplied* | No information supplied* | No information supplied* | 0.3-0.4% | Fast corrosion. Limited data provided |

+6.7% Enhanced |

**Depends on the curing type (normal, autoclave, steam).

3.7.1. Porosity

One of the factors in improving the durability of UHPC is the reduction of the porosity, leading to an improved microstructure and enhanced homogeneity. A reduction in porosity has a direct effect on the freeze-thawing resistance of UHPC and the water absorption of UHPC. Reducing the porosity leads to reduced water absorption of UHPC [61]. Moreover, the reduction of the porosity has a positive effect on other material properties like shrinkage and creep of concrete. Because of the low porosity, the drying shrinkage will be far less in UHPC, but the autogenous shrinkage may be far more due to the low w/b ratio and cement amount [62, 63].

3.7.2. Freeze-thaw Effect

The high resistance freeze-thaw effect of UHPC is due to the materials three factors, which include (1) the improved homogeneity microstructure, (2) the lower permeability, (3) and the reduced porosity [64]. Depending on the added mineral admixture in the UHPC, the freeze-thawing cycles of 200-500 can be achieved without any signs of degradation on the UHPC structure [65]. This durability property is expressed in terms of relative dynamic modulus (RDM). Several researched have established a decrease in RDM value of around 0-10% only with freeze-thaw cycles of around 300 and 1000 cycles [66, 67].

3.7.3. Chloride Ion Penetration

Another type of durability property of UHPC is chloride ion penetration. The main disadvantage of the chloride ions is the penetration through the network of concrete pores, possibly leading to the corrosion of the steel reinforcement [68]. The higher the chloride ion penetration resistance, the higher the durability property of UHPC. The contributing factors regarding the chloride ion penetration are (1) the water-binder ratio, (2) the curing regime, (3) the type of exposure, (4) and the duration [69]. Comparing the chloride ion penetration value of NSC (1736 coulombs) is far above the value of UHPC value of 22 coulombs [70].

3.7.4. Permeability

The durability property permeability is the ability of UHPC to allow fluids or gasses to flow through. Saturated pumice (0.6-1.25mm), a light porous and dust-form volcanic rock, is effectively used as an internal curing agent for UHPC, which effectively withdraw the deformation of shrinkage in concrete without sacrificing the materials mechanical properties (strength) [71]. Within the concrete, there is an ongoing process of water release from the pumice. The result is an increase of the w/b, which results in an increase in the porosity and water capacity and ultimately raising the permeability of UHPC [72].

3.7.5. Water Absorption

The water absorption of UHPC is one of the durability properties which imposes long term durability achievements. The water absorption capability has a direct relationship between the porosity of UHPC and the permeable pores [73]. Adding the mineral admixtures for the production of UHPC enables a homogeneous microstructure, blocking the flow of water [74]. Along with a lack of permeable pore the water absorption of UHPC ultimately reduces resulting in a more durable material mix. Among all the various SCMs researched the supplementary cementitious material Silica Fume (SF) results in the most effective water absorption reduction of UHPC of about 38-43% [73]. An interesting aspect is the activity of SF and superabsorbent polymers (SAP), an internal curing agent for concrete, which rapidly absorbs the fresh concrete water. The reaction weakens to endure the further hydration process [75].

3.7.6. Reinforcement Corrosion Rate

The reinforcement corrosion rate of UHPC is related to the steel corrosion within the material. In most cases, a visual inspection is required in order to detect the physical deterioration of the material. Along with methods as potential or polarization resistance measurement equipments, there is a need for some more methods to detect early stages of corrosion activity [76, 77]. A type of sensor studied is the fiber Bragg grating (FBG) sensor, which allows strain measurements to be made where conventional sensors are not possible [78].

3.7.7. Abrasion Resistance

The abrasion resistance of UHPC is another property regarding the durability of concrete. This property is defined as the ability of a surface to resist being worn away by rubbing and friction [79]. Several studies have shown that factors like the strength (compressive and tensile) and Supplementary Cementitious Materials (SCMs) affect the abrasion resistance of UHPC. The replacement of cement with different SCMs leads to a denser Interfacial Transition zone (ITZ) created by a better pre refining effect [80, 81]. For UHPC the abrasion resistance mass loss is 3-7 times lower compared to the abrasion resistance mass loss of NSC [82].

4. FIBERS

The use of fibers has a positive effect on UHPC, mainly on the ductility and the impact resistance. Several factors affect the mechanical performance of UHPC by adding fibers. Table 5 presents the influence of fibers on the strength performance of UHPC. The most common type of fibers used is steel fibers having a tensile strength of 2500 MPa or beyond [64]. Adding a volume fiber ratio between 0-5 percent has the most positive effect for increased strength. The testing results of cubical and cylindrical specimens increased by 4% and 8% [34] with an addition of 3 percent fibers as presented by the research group Alsalman et al. [2]. The research group Pyo et al. [83] achieved compressive strengths of 150 MPa by adding between 0.5-2 percent amounts of steel fiber volume.

Another factor is the addition of two or three different types of fibers taking into account the fiber length [4]. The initial placement of the fibers parallel to the longitudinal direction instead of transversely gave a 61% larger flexural strengths of UHPC and a 5.5% larger initial cracking of UHPC. The use of steel fiber also increases the compressive and splitting tensile strengths, along with enhancing the compression tension ratio [84].

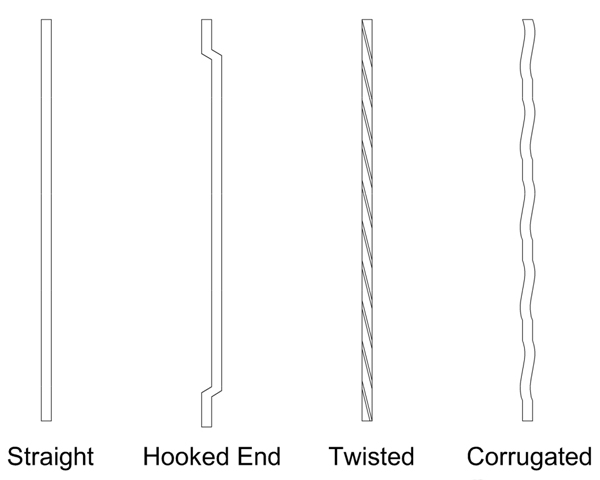

By adding steel fibers, the compressive strength improves working as an enhancing material to UHPC [45] (28 days curing). The fibers (Figs. 2 and 3). can be divided into (1) deformed fibers, mostly hooked or twisted, (2) straight or smooth fibers, and (3) the length of the fibers short or long. It is worth mentioning that steel fibers have a high resistance in an alkaline environment, shows high strength, and a high elastic modulus [85].

5. METHODS, MATERIALS, AND COMPOSITION

In recent years, there have been three generations of mix design methods developed for UHPC, namely (1) the Linear Packing Density Model (LPDM), (2) the Solid Suspension Model (SSM), and (3) the Compressible Packing Model (CPM) [86, 87]. Most researchers have developed the UHPC mix designs based on the CPM concept (empirical concept) [20, 88-90]. However, UHPC also contains small particles (on a microscopic level) in order to improve the packing density. Research has discovered that there are surface forces (electrical charges, steric- and van der Waals forces), which influence the interaction of these small particles [4, 91]. Therefore, for microscopic particles, using the CPM method to predict the particle packing can considerably result in differences compared to the experimental results. The mixtures containing fine particles cannot be used to predict the behavior by CPM [92] accurately. Since the UHPC mixture is made of various components of non-identical classes, the CPM mix design method only contemplates packing the packing of monosized classes [91].

A typical UHPC mixture proportion is given in Table 6 where the cement is taking around 28.5% only of the mixture.

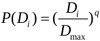

With the particle packing model of Andreasen and Andersen [93], the allocation of the UHPC grain size can be established. The particles allocation is calculated according to Eq (6), where coarse mixtures are realized when 0.5>q and small particles are realized when q <0.25 [85, 93].

|

(6) |

In Eq (6) P(Di) is the fragment of the concrete parts less than the specified diameter Di; Dmax is the maximum particle diameter; q is the distribution modulus, which relies on the kind of concrete.

| Research | Specimen Type | Fiber Type | Strength Type | ||

|---|---|---|---|---|---|

| Length/ Diameter (mm/ mm) | Volume (%) | Compressive strength (MPa) | Flexural strength (MPa) | ||

| Richard and Cheyrezy (1995) | Cylinder | 13 / 0.15 | 2.0 | 170-230 | 30-60 |

| Schmidt and Fehling (2004) | Cylinder | 17 / 0.25 | 2.5-3.0 | 165-225 | - |

| Graybeal (2006) | Cube / Cylinder / Prism | 12.7/ 0.2 | 2.0 | 112-210 | 28-36 |

| Shi et al. (2015) | - | 0-4 | 0-4.0 | 200-800 | 30-141 |

| Kanagalakshmi et al. (2016) | Cube | 13 / 0.8 | 1.0; 1.5; 2.0 | 74.5; 84; 98 | - |

| Alsalman et al. (2017) | Cube / Cylinder | 12.7 / 0.2 | 3.0 | 106-180 | - |

| Pyo et al. (2017) | Cubes | 19.5 / 0.2 | 0.5-2.0 | 142-169 | 9-21 |

| Buttignol et al. (20017) | Cube/ Prism | 13 / 0.2 | 1.0-5.0 | - | - |

| Material | Quantity (kgm-3) | Weight (%) | Average Diameter (µm) | Material | Amount (kgm-3) |

|---|---|---|---|---|---|

| Total Binder (PC and SF) | 943 | 37.8 | n/a | Total Binder (PC and SF) | 943 |

| Portland cement | 712 | 28.5 | 15 | Portland cement | 712 |

| Silica Fume | 231 | 9.3 | <10 | Silica Fume | 231 |

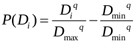

A revised form of the Andreasen and Andersen model (Eq. 6) is shown in Eq. (7), which introduces a minimum particle size (Dmin). Enhancing concrete mix designs for NSC and lightweight concrete has been well accepted by this equation as well as UHPC [85, 90].

|

(7) |

As studied by previous researchers a wide range of materials is compared. The raw materials for the UHPCs consisted of the following binder powder composition: Ordinary Portland Cement, the SCMs (Metakaolin (MK), Silica Fume (SF), Fly Ash (FA), Slag (Ground Granulated Blast furnace Slag (GGBS) and Copper Slag (CS)); the filler compositions variables were: quartz and sand; the superplasticizer, which was Polycarboxylate Ether (PCE) based enables to reduce the water content of the mixture and steel fibers.

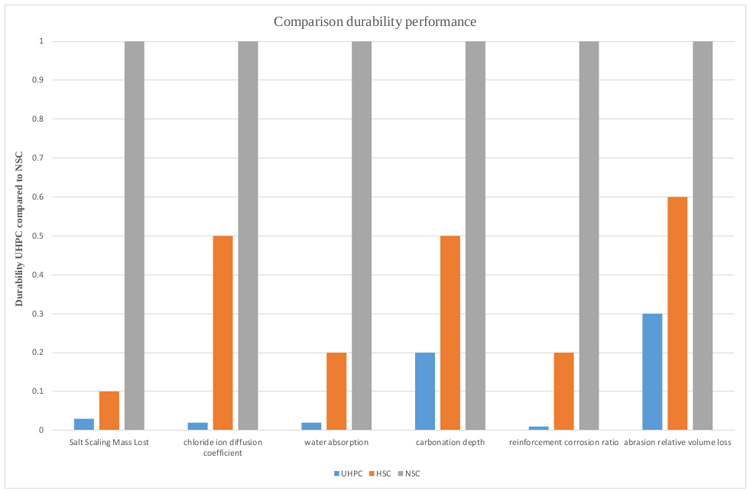

The research of Vande Voort [94] highlighted the durability properties of UHPC (including fibers), HSC, and NSC. The results showed a significant improvement in the durability of UHPC compared to HSC and NSC. The indicators in Fig. (3) are the salt scaling mass lost, chloride ion diffusion coefficient, water absorption, carbonation depth, reinforcement corrosion ratio, and abrasion relative volume loss and are relative to NSC.

The information in Table 7 outlines the chemical properties of some Supplementary Cementitious Materials (SCMs) as researched by Wu et al. [13, 51, 95].

For the production of UHPC, it is important that the composition improves the material properties on a micro and macro scale. The mixture will guarantee mechanical consistency, maximum particle packing density and minimum size of flaws [19, 96, 23]. For that reason, the composition of UHPC should both emphasize on selecting suitable materials with physical and chemical characteristics as well as the different grain sizes. In Table 8 there are some commercially available UHPC mixtures presented [64, 97]. These cement-based composites are known as BSI, Ductal, and Dura and are further elaborated. As the table shows the composition of UHPC is based on powder cement, SF, and sand. As the cost for the production of UHPC still surpasses that of Normal Strength Concrete (NSC) it is impeccable to reduce the material cost of UHPC and still produce a high-quality product.

Because UHPC has a high autogenous shrinkage, the addition of SCMs in UHPC mixture has a positive effect on it. However, studies have shown that the proportions of the UHPC mixture were mostly assumed instead of designed, and the replacing PC and SF by SCMs were tested [91]. Moreover, it is noticeable that Fly Ash or Slag can replace Silica Fume, temperature curing accelerates the hydration process, and the mechanical properties can be enhanced by using straight long or deformed (hooked and twisted) long steel fibers [98].

| CaO (%) | SiO2 (%) | Al2O3 (%) | Fe2O3 (%) | SO3 (%) | MgO (%) | Na2Oeq (%) | K2O (%) | C (%) | |

|---|---|---|---|---|---|---|---|---|---|

| Cement | 62.49 | 21.18 | 4.73 | 3.41 | 2.83 | 2.53 | 0.56 | – | – |

| MK [45] | 0.20 | 51.85 | 43.87 | 0.99 | - | 0.18 | 0.01 | 0.12 | - |

| SF | 1.85 | 93.90 | – | 0.59 | – | 0.27 | 0.17 | 0.86 | 1.06 |

| FA (class C) | 4.63 | 42.52 | 32.62 | 9.35 | 1.21 | 0.73 | – | – | – |

| GGBS | 39.11 | 33.0 | 13.91 | 0.82 | – | 10.04 | – | – | – |

| CS [95] | 1-3.5 | 27-33 | <3 | 55-60 | - | - | - | - | - |

5.1. BSI

BSI (Beton Special Industrial) is a UHPC developed by the French Contractor Eiffage Group and Swiss company Sika Corporation in 1996 [99]. The UHPC material is marketed by the Lafarge Company and is much coarser compared to other UHPC products available. In Tables 9 and 10, the material properties of BSI are presented (mechanical and durability properties). The BSI material reached high compressive strengths of around 220 MPa and containing around 2.5% steel fibers (length 20 mm, diameter 0.3 mm) by volume [18, 100].

5.2. Ductal

Ductal is a commercially available UHPC mix marketed by the company Lafarge Inc. and Bouygues. This UHPC product is distributed to costumers in three components namely the dry materials pre-mixed in bulk bags, the steel fibers, and the chemical admixtures. The cost of Ductal is amount dependent and varies around $980/m3 in the United States [101]. Ductal UHPC exhibits higher strength capabilities (compressive (152-207 MPa) and flexural (35-50 MPa)) and better durability properties like abrasion, freezing and thawing, carbonation, and chloride ion penetration (chloride ion penetration < 0.02x10-12m2s-) [102]. In Tables 11 and 12 some material properties of Ductal are presented marketed by Lafarge Inc. Company.

5.3. Dura

In 2006/2007 Dura was introduced in Malaysia by the Dura Technology Sdn. Bhd. as a ready-mixed UHPC material. Dura UHPC exhibits high strength of 150/160 MPa (compressive strength) and 30 MPa (flexural strength). In Table 13, some enhanced durability properties of Dura UHPC are presented.

6. STANDARDS AND RECOMMENDATIONS

As UHPC is a relatively new construction material, there have not been available standards and recommendations for long. In 2014 Germany, Fehling et al. [18] published the English version of Beton-Kalender regarding UHPC guidelines standards, which highlighted the fundamentals, design, and some UHPC examples. With the German Committee for Structural Concrete (DAfStb – Deutscher Anschluss für Stahlbeton) working on UHPC guidelines focusing on the design, technology, and quality [104]. In France (2016) the technical guidelines and recommendations for UHPC were replaced for the French national standards for UHPC [105]. In previous years, the design and production of UHPC, as well as researchers, referred to the French Interim Recommendations [106] and the Japanese Recommendation [107] for guidance.

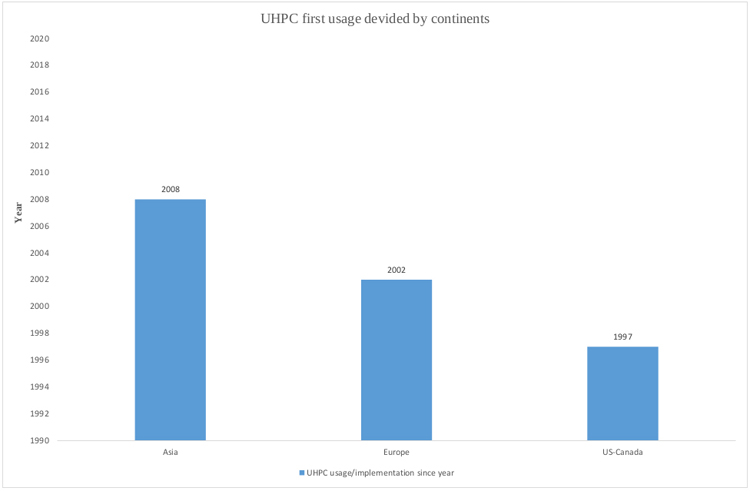

With a rise in popularity of UHPC several countries have started to work on their standards and guidelines like the Chinese standards [3]. On the American continent (Canada and the USA) an Emerging Technology Report (ETR) gives an overview of the Structural Design of Ultra-High Performance Concrete by the subcommittee ACI 239C [108] (in 2013). The report marks as a beginning for the understanding of design methodologies for UHPC and briefly introduces these concretes, their properties and design principles for their use. For several years the FHWA - Federal Highway Administration (USA) has published reports [109] regarding UHPC, which provides a framework for understanding, developing and using UHPC. In Fig. (4), a comparison of the first usage of UHPC divided by continents is presented in Fig. (5).

7. RESEARCH SIGNIFICANCE - NEW FINDINGS

As most of the available literature review is well known among researches, there are still some major essentials in order to fully commercialize Ultra-High Performance Concrete (UHPC). Along with the materials unique and desirable characteristics suitable in a variety of constructions [110-112], challenges like (1) lack of sufficient design codes, guidelines and standards, (2) producing sustainable UHPC (less CO2 emission), (3) requirement of high cement content.

(1) The concrete industry has always provided sufficient and adequate design codes, guidelines and standards for concrete, which are regularly updated when needed. These official documents are on a continental level as well as a country level (e.g. China, Germany, etc.). However, for UHPC proper documentation regarding the operations, maintenance, and inspection still are needed.

(2) The need to produce more sustainable UHPC is gaining more attention among researchers and engineers alike. As many countries realize the negative impact that the concrete industry has in terms of energy and resource consumption, carbon consumption, and Greenhouse Gas (GHG) emissions. As known by researchers worldwide GHG emissions are linked with global climate change giving the latter much more needed attention.

(3) There is more research needed for UHPC in the concrete industry in terms of developing and producing more sustainable as well as economical UHPC. A proper balance between the benefits and the financial costs of UHPC should be accurately researched. This will enable to commercialize this high-performance type of concrete more, making it more attainable and favorable for future engineering structures.

| Materials (kgm-3) | BSI | Ductal | Dura |

|---|---|---|---|

| Portland Cement | 1114 | 712 | 911 |

| SF | 169 | 231 | 225 |

| Fine Sand | 1072 | 1020 | 911 |

| Ground quartz | - | 211 | - |

| Accelerator | - | 30 | - |

| Fiber (steel) | 234 | 156 | 173 |

| SP | 40 | 30.7 | 38 |

| Water | 211 | 109 | 200 |

| Mechanical Properties | Test Data | |||

|---|---|---|---|---|

| Mean | Unit | Design Value | Unit | |

| Compressive strength | 140 | MPa | 100 | MPa |

| Flexural strength | 30 | MPa | - | MPa |

| Tensile strength | 8 | MPa | 5 | MPa |

| Young’s modulus | 50 | GPa | 45 | GPa |

| Durability properties | Test data | |

|---|---|---|

| Value | Unit | |

| Abrasion | 1.2 | - |

| Freeze-thaw (300 cycles) | 100 | % |

| Carbonation | 0 | mm |

| Chloride ion diffusion | 0.2 | m2s-1 |

| Post curing shrinkage | 0.10-6 | - |

| Durability Properties | Test Data | |

|---|---|---|

| Value | Unit | |

| Chloride permeability | <200 | Coulomb |

| Chloride ion diffusion | 0.05 – 0.1x10-6 | mm2s-1 |

| Carbonation | <0.1 | mm |

| Abrasion | <0.03 | - |

| Water absorption | <0.2 | % |

CONCLUSION

This article reviews the application of various Supplementary Cementitious Materials (SCMs) and fibers in order to obtain the desired UHPC. The substitution of the SCMs showed enhanced mechanical and durable properties and reviewed several segments of UHPC, like (1) the (compressive, tensile, flexural) strength, (2) the flowability, and (3) the toughness. From the conducted analysis and comparison, the following conclusions are summarized:

- The curing applied (high temperature and pressure) on UHPC resulted in improved durability properties. The use of high-temperature curing can decrease the drying shrinkage, while the use of pressure curing results in 30-38% growth of the compressive strength. Because of the porosity reduction, UHPC shows better water absorption. The result in Fig. (3) shows a better performance in the durability of UHPC compared to HSC and NSC.

- Both the curing regime and the use of mineral admixtures in the form of SCMs increases the concretes mechanical and environmental achievement (200 MPa strength). In its solid phase, the effects of the type of curing environment, aggregate, mineral admixtures, the properties of the fiber, the size of the specimen, and strain-rate all influence the mechanical performance of UHPC. The use of chemical admixture, PCE, allows a water reduction of 40% resulting in a better flowability of UHPC.

- The steel fiber is used as an improving material to UHPC and by adding steel fiber to the mixture the compressive strength (at 28 days) becomes larger. Adding 1% of fiber volume reaches compressive strengths well over 150 MPa. Fiber volume of 2% also allows a reduction of the autogenous shrinkage by 14-15%. Comparing UHPC to normal strength concrete (NSC) the compressive strength is higher by adding 4-8% of steel fibers, which acts as an enhancement material. The placement of the fibers also affects the performance of UHPC. Placing the fibers parallel to the longitudinal direction results in 61% larger flexural strengths.

- Moreover, it is noticeable that (1) the SCM Fly Ash or Slag can replace Silica Fume; (2) curing with high temperatures speeds up the hydration process, leading to higher strengths by Fly Ash, Slag. Also (3) the mechanical properties of UHPC are enhanced using steel fibers, which are long deformed (hooked and twisted) or straight.

- By replacing the Portland cement and the Silica Fume with the SCMs Metakaolin (flexural strength +2.6%), Fly Ash (200-250 MPa strength), and Ground Granulated Blast-Furnace Slag (250 MPa) result in the production of UHPC with similar or better mechanical and durability properties. Another positive effect is reducing UHPC’s autogenous shrinkage (40-60%). Using the SCM Metakaolin in the production of UHPC also gives a more aesthetically pleasing result with its white color.

- Understanding the UHPC principles is one step closer in developing and producing the desired UHPC. As guidance, most studies have used the compressible packing model (CPM) to produce UHPC. This mix design method is not the most reliable, because the CPM method only considers monosized classes packing as proven UHPC mixtures consist of different size classes, which makes this method a debatable precision regarding the behavior of UHPC. Another point is the fact that UHPC contains fine particles, and the CPM concept does not take specific forces into account (electrical charges, steric- and van der Waals forces).

- Because of the limited design codes available (only several countries have their standard and recommendation), the application of UHPC is not as fast as NSC. However, with a rise in popularity of UHPC several countries have started to work on their standards and guidelines.

CONSENT FOR PUBLICATION

Not applicable.

AVAILABILITY OF DATA AND MATERIALS

The authors confirm that the data supporting the findings of this study are available within the article.

FUNDING

The provided funding for conducting the study has been provided by Shanghai Municipal Engineering Design Research Institute Co., Ltd.) and Huazhong University of Science and Technology.

CONFLICT OF INTEREST

The authors declare no conflict of interest, financial or otherwise.

ACKNOWLEDGEMENTS

Declared none.