All published articles of this journal are available on ScienceDirect.

Exploring the Soil-water Retention Characteristics for Unsaturated Soil Using Coconut Shell Waste for Subgrade Improvement

Abstract

Introduction

Suction distribution has a major impact on the stability of unsaturated soil because it affects seepage and shear strength. The Air Entry Value (AEV) and Residual Water Content (RWC) variations determine the Soil-Water Characteristic Curve (SWCC), which is a crucial component of suction distribution. The subgrade is submerged in water during a flood event, which has an impact on the AEV and RWC, and lowers their performance. Crushed Coconut Shell (CCS), a waste product, has been recycled in this study and used as an addition to increase subgrade strength by enhancing AEV and RWC. Currently, researchers abroad confirm that CCS improves subgrade performance. Nevertheless, the optimum content of the soil-CCS mixture varies based on the soil type of the respective regions. Moreover, there is a lack of scholarly research examining the enhancement of AEV and RWC affected by CCS following a flood occurrence.

Aim

This research study sought to determine the deviations of AEV and RWC for the optimum CCS content of unsaturated soil in Malaysia.

Methods

In this research, control samples and soil mixed with 0.5, 1.0, 1.5, 2.0, and 2.5% of CCS were used. The pressure plate extractor equipment and analysis generate SWCC, which characterises the AEV and RWC parameters and quantifies the performance of submerged subgrade because of a flood event.

Results

The outcome revealed a significantly higher AEV for mixed soil as compared to the control sample. The AEV for the control sample was 10 kPa, whereas that for the optimum mixture of soil-CCS of 0.5% was 25 kPa. Therefore, it has been confirmed that the use of CCS has a positive impact on AEV and RWC. This, in turn, is expected to improve the overall performance of the subgrade when subjected to submersion in water.

Conclusion

The objective of this study was to assess the characteristics and potential applications of hazardous waste by transforming it into a soil improvement agent. This research supports Chapter 8 of the 12th Malaysia Plan 2021–2025: Environmental Sustainability: Improving Resilience to Climate Change and Disasters, and Chapter 6 of the Green Technology Master Plan Malaysia 2017–2030: Waste.

1. INTRODUCTION

A subgrade refers to a foundational layer that is specifically prepared to support the construction of roads or railways [1]. The primary objective of the subgrade is to provide structural support to roadways, pavements, or railway tracks, ensuring that they can withstand applied loads without experiencing severe deformation. The main characteristic that determines subgrade materials is their ability to resist deformation under external loads, therefore indicating their strength or stiffness. In a general context, it can be observed that the greater the deformation resistance exhibited by a subgrade, the higher the level of load support it provides, until it approaches a critical deformation threshold [2]. According to a study conducted earlier [3], it has been observed that the subgrade has a significant role in the occurrence of pavement problems, which are attributed to the presence of unstable and weak soil. Another issue that develops is the problem of long-term subgrade settlement, which can be attributed to various factors, such as heavy traffic, the presence of wetted soft clay, compaction of coarse-grained materials, cycle periods, confining pressure, moisture content, and the dynamic characteristics of subgrade filler. Therefore, it is crucial to strengthen the subgrade in order to maintain its function and avoid potential disasters. The phenomenon of road distress increasingly contributes to the degradation of road infrastructure, necessitating constant repair and maintenance. The subgrade features have been reported to impact the pavement layers, including both economic and natural factors [4].

Besides the need for reinforcing, it is crucial for the subgrade to have the ability to efficiently drain rainwater or floodwater that may accumulate underneath it. Before starting construction, it is crucial to carry out ground improvement procedures, especially when the soil exhibits signs of settlement, low bearing capacity, or deformation. In order to comply with construction guidelines, the soil is altered with the purpose of improving its mechanical and hydraulic properties. The soil's condition can be improved by implementing either soil modification, soil stabilisation, or a combination of both methods [5].

The occurrence of unstable and poor soil poses significant challenges in the field of construction, particularly in periods that involve flooding. Hence, the utilisation of stabilised soil is crucial for ensuring the subgrade's ability to endure the stress imposed by flood occurrences. In order to address the previously mentioned problem, it is common practice to use additives for the purpose of enhancing and stabilising the soil, as well as enhancing the subgrade's resistance to submersion or collapse [6]. According to a previous study [7], the increasing expenditures associated with cement and the environmental issues associated with its production have resulted in a perceived reluctance to use additives, like cement or lime, in the stabilisation of expansive soils. Therefore, the endeavour to find materials that exhibit the characteristics of being advantageous, economical, and environmentally sustainable for soil stabilisation requires careful and persistent work. The utilisation of waste materials to modify the soil's characteristics in this context represents a highly efficient and economically viable approach for soil stabilisation. The stabilisation of subgrade typically involves the addition of cement, lime, and fly ash, a method known for its high efficacy. However, it should be noted that this approach necessitates a longer curing period in comparison to chemical stabilising agents [8]. In addition, the utilisation of charcoal and biochar as means to enhance soil water capacity has proven to be successful. Nevertheless, it is crucial to acknowledge that the regular requirement for specialised modifications in order to use this strategy may make it impracticable [9].

Subgrade without a good Air Entry Value (AEV) and water release gives an extra load to hold and eventually submerges the road structure, leading to instability of the soil. There are two strategies that can be employed to reinforce the subgrade during periods of flooding: increasing the soil's mechanical strength and improving its hydraulic properties. One potential method for stabilising the subgrade is the use of strengthening chemicals, which can be employed to gradually enhance the subgrade's structural integrity and hydraulic characteristics. Several modifications have been implemented to enhance the strength and hydraulic characteristics of the soil, including the incorporation of a mixture of marble dust and rice husk [10].

The concept of hydraulic conductivity is a fundamental aspect of soil mechanics, denoting the soil's capacity to facilitate the movement of water through its linked void spaces. The optimal hydraulic conductivity of soil is achieved when water can permeate through it without inducing any deformation in the underlying subgrade. According to F. A. Kechik et al. [11], the soil's failure can be attributed to its hydraulic and strength characteristics.

The hydraulic characteristics of a material have a direct impact on the mechanical behaviour of the subgrade [12]. The bimodal water retention curve can be employed as a variable to facilitate a comparison of water retention in relation to volumetric water content and matric suction. This analysis reveals a direct relationship between matric suction and volumetric water content, whereby an increase in matric suction corresponds to a decrease in volumetric water content [13]. Furthermore, A. Satyanaga et al. [14] have clarified that when measuring the water retention curve, it is crucial for the water volume to attain a state of equilibrium before increasing the matric suction to a higher level. The experiment demonstrated that a significant reduction in water volume is occasionally not consistent with the air entrance value of the specimen in terms of suction.

The investigation of soil reinforcement through the incorporation of additives has been the subject of extensive research conducted by numerous scholars. Various materials have been examined, with particular emphasis on those employed to improve the subgrade. Contemporary research attempts have been made to employ waste materials as supplementary components to have a beneficial influence on the natural environments. The use of waste in construction materials leads to cost reductions and environmental protection measures. Efforts to recycle various waste materials and integrate them into construction sites aim to reduce the potential environmental impacts [15].

In the present study, wasted crushed coconut shell has been employed as a constituent to enhance the performance of the subgrade. The coconut shell is released as a by-product in many processes within the food sector. Businesses face a significant issue with storing waste goods because of the huge amount of space they occupy. The environmental repercussions of accumulation and open storage are anticipated to be primarily challenging.

Crushed coconut shell, classified as a nano-carbon substance, is derived from agricultural processes, and is considered a byproduct. A study was conducted to investigate the impact of soil water penetration on nanocarbon content levels [9]. The study observed that the cumulative infiltration curves for all nanocarbon concentrations exhibited a smooth pattern, resembling that of homogenous soils without nanocarbon. The composition of the fine soil matrix remained consistent throughout the study. The presence of nanocarbon has been seen to enhance the micropores within soil particles through partial filling due to its substantial specific surface area and nanoscale dimensions. The modification of the pore-size distribution can be performed by diminishing the ratio of larger pores and increasing the ratio of smaller pores. At low-pressure heads, water exhibits a preference for passing through larger pores. As the pressure head increases, the water within the macrospores is expelled, resulting in the retention of just the smaller pores. Thus, greater suction forces are observed in the smaller holes. Consequently, the soil containing nanocarbons exhibits a reduced rate of water outflow compared to the homogeneous soil lacking nanocarbons. Consequently, the incorporation of nanocarbons has the potential to slightly augment the soil's capacity for water retention [9].

The optimal water content for crushed coconut shells was examined in a previous study through the execution of a Proctor test. The findings indicated that the optimal water content ranged from 16.13% to 18.44% as the coconut shell content increased. The maximum dry density exhibited a drop from 1.865 Mg/m3 to 1.785 Mg/m3, respectively. The findings of the study can be utilised to provide suggestions, such as modifying the dimensions and morphology of coconut shells to enhance their reactivity in soil [16].

According to a study conducted earlier [17], the inclusion of coconut shell charcoal has been found to enhance the maximum dry density of soil. Specifically, the addition of 8% coconut shell charcoal has been observed to yield a maximum dry density value of 1.175 g/cm3. However, it is worth noting that exceeding this optimal percentage of coconut shell charcoal can lead to a reduction in the maximum dry density of the soil. The observed outcome could be attributed to the presence of an excessive quantity of coconut shell charcoal within the soil. The abundance of charcoal was reported to inhibit the exact adhesion of soil grains, primarily due to the uniform size of the coconut shell charcoal particles. The study also revealed that the swelling value decreased to 0.24% following the incorporation of 4% coconut shell charcoal. Using a concentration of coconut shell charcoal beyond 4% may result in ineffectiveness due to an increase in the swelling value of the soil. This may make the soil unstable and susceptible to modifications caused by water. Conversely, the addition of coconut shell charcoal with a concentration below 4% can yield effectiveness. The incorporation of coconut shell charcoal at a concentration of 4% has been seen to result in a significant reduction of 53.8% in the soil's initial swelling value.

The main goal of this study was to find out how the specimen additive and air entry value affect the hydraulic properties and how experimental investigations can help improve geotechnical design. The air entry value is a parameter that describes the capacity of a soil to retain or release air in response to changes in its moisture content. When the soil is moist, water infiltrates into its pores. As the soil undergoes desiccation, the process of air infiltration occurs, wherein air enters the soil pores to displace the water present. The air entry value refers to the quantification of the suction pressure or tension required for the initiation of air movement that displaces water from the pores within the soil. The measurement pertains to the soil's capacity to retain air across different levels of moisture. The matric potential, a parameter that quantifies the energy required for water extraction from the soil, is commonly employed to represent the air entry value. Pressure units, such as kilopascals (kPa), are commonly employed for its measurement. Soils with lower air entry values exhibit a larger tendency to release air when the moisture content declines. Conversely, soils with higher air entry values possess a better ability to store air, even when moisture levels are relatively low [18]. The primary aim of this study was to ascertain the air entry value of a soil mixture composed of crushed coconut shell and soil. This has been accomplished using a plate pressure extractor in a controlled laboratory setting. Additionally, the air entry value of the soil mixture has been compared to that of control samples. This comparative analysis may serve to enhance and validate the hydraulic properties of the soil mixture.

2. MATERIALS AND METHODS

2.1. Preparation of Soil Samples and CCS

Soil samples have been collected near the Universiti Pertahanan Nasional Malaysia (UPNM) campus. To conduct the experiment, both disturbed and undisturbed samples were collected for testing purposes. To preserve their initial condition, the samples were stored in vacuum-sealed bags. Subsequently, the soil sample was subjected to crushing and sieving processes to get a reduced grain size suitable for subsequent testing. The CSS waste utilised in this study was procured from commercial sources, as indicated in Fig. (1). The CCS was fragmented into particles of 5 to 8 mm in size prior to its mixing into the soil sample.

2.2. Basic Soil Properties

The Unified Soil Classification System D2487-06 (USCS) was used to divide the crushed coconut shell that customers purchased from a store into groups [19]. This was done using sieve analysis.

2.3. Soil Hydraulic Conductivity (Ksat)

In this study, the saturated hydraulic permeability was measured using the constant head permeability method described in ASTM D 2434: Standard Test Method for Permeability of Granular Soils (Constant Head) [20]. This experiment was exclusively applicable to the control sample.

The soil samples were positioned on filter paper, which was held by a funnel to collect the water that penetrated through the soil. Subsequently, the soil samples were carefully inserted into an acrylic tube measuring 76 mm in diameter, which was positioned in an elevated manner above the filter paper and funnel. The experiment was initiated by introducing water into the acrylic tube, which was then allowed to run through the soil sample. The measurement of the volumetric flow rate (Q) was conducted to determine the quantity of water moving through the sample within a certain time interval. The experiment was carried out at various water depths, namely 2, 4, 6, 8, and 10 cm. Ensuring a consistent water level over the duration of the experiment was important. The experiment was conducted over a period of 10 minutes and repeated until the effluent measurements achieved stability for a minimum of three readings. The saturated hydraulic conductivity, Ksat, was obtained by employing Eq. (1):

|

(1) |

Where,

Q = Discharge of water, mL/min

z = Height of water in the mold, m

A = Cross-sectional area of the section, mm2

H = Height of soil sample and water, m

2.4. Soil Water Characteristic Curve (SWCC)

The soil samples were obtained by removing the upper layer of the site and conducting excavation efforts up to a depth of 0.5 m to get representative samples. Prior to initiating the experiment, a 24-hour period was allocated for the immersion of all samples to attain saturation for both control and soil-CCS mixture soils.

The SWCC experiment employed a pressure plate extractor apparatus, shown in Fig. (2), in accordance with the standards specified in the ASTM D6836-02 standard, which is used for determining soil water characteristic curves for pressure plate extractors [21]. The experimental setup consisted of two chambers that were designed to sustain high pressures of 5 and 15 bars, respectively. The size of the sample ring was 50 mm in diameter and above.

The experiment was initiated by introducing a ceramic plate into the chamber, followed by the application of a pressure ranging from 0.01 to 15 bar. The length for which the samples needed to be kept in the chamber varied depending on the applied pressure, with each pressure level requiring a specified duration ranging from 24 hours to 4 days. During the experiment, water was suctioned out from the chamber due to the applied pressure. Subsequently, the samples were subjected to weighing prior to the further application of pressure.

Upon the conclusion of the experiment, the mass and composition of gravitational moisture present in each sample were measured. The moisture content of the volume (θv) was determined by utilising Eq. (2):

|

(2) |

where,

Wa = Sample weight before each pressure is applied

Wb = Sample weight after each pressure is applied

ρb = Bulk density

Following this, correlation curves were constructed to illustrate the relationship between the moisture content of the volume and the suction matrix. Additionally, a comparative analysis was performed to assess the consistency between the empirical findings and the application of Van Genuchten's (1980) [22] equation by the utilisation of the regression technique outlined in Eq. (3):

|

(3) |

where,

Se = Normalised water content

|ϕ| = Suction pressure, [L] or cm of water depth

α = Inverse value of air entry suction

n = Function of the pore-size distribution

2.5. Soil-CCS Mixture Test

A total of six samples were developed for the experiment on the Soil Water Characteristic Curve (SWCC). These samples included samples designed with a mixture of soil-CCS, as well as a control sample. To ascertain the most favourable combination and concentration of soil treated with CCS, six distinct mix design percentages were considered: 0%, 0.5%, 1%, 1.5%, 2.0%, and 2.5% by dry weight of soil. These percentages were determined based on prior research. Table 1 shows the names of the soil-CCS mixture samples and their corresponding CCS percentages.

| Name | Soil Percentage (%) | CCS Percentage (%) |

|---|---|---|

| C0 | 100 | 0 |

| CCS05 | 95 | 0.5 |

| CCS10 | 90 | 1.0 |

| CCS15 | 85 | 1.5 |

| CCS20 | 80 | 2.0 |

| CCS25 | 75 | 2.5 |

3. RESULTS AND DISCUSSION

3.1. Basic Soil Properties and Hydraulic Conductivity (k)

The soil composition, consisting of gravel, sand, silt, and clay, has been reported to be 5.1%, 91.3%, 3.0%, and 0.6% respectively. The soil of Bukit Gemilang has been identified as poorly graded sand, SP, as presented in Table 2 and Fig. (3). The value of hydraulic conductivity, ksat, indicates the control sample, that is, sandy soil. The presented data illustrate the distribution of soil particles in the control sample.

3.2. Soil Water Characteristic Curve (SWCC)

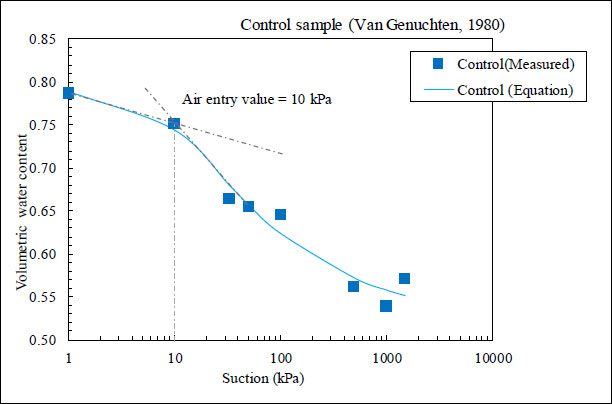

The Soil Water Characteristic Curve (SWCC) of all soil samples included in this study was developed by experimentation using a pressure plate extractor apparatus. Upon the completion of the laboratory experiments, the obtained results were subsequently analysed and fitted with the equation proposed by Van Genuchten in 1980. Figs. (4 and 5) show the behavior of controlled soil sample and soil-CSS mixture, respectively. The data presented illustrate the Soil Water Characteristic Curve (SWCC) values for both control samples and mixtures of soil-CCS. From Fig. (4), it can be clearly seen that the AEV for the controlled soil sample obtained was 10 kPa. The graph presented in Fig. (5) demonstrates the pattern of all mixtures in comparison to the control sample, which shows significantly increased AEV.

| Parameter | Unit | Value |

|---|---|---|

| Soil composition | - | - |

| Gravel | % | 5.1% |

| Sand | % | 91.3% |

| Silt | % | 3.0% |

| Clay | % | 0.6% |

| Soil classification | - | SP |

| Poorly graded sand | ||

| Hydraulic conductivity, ksat | cm/sec | 0.0124 |

Table 3 presents the parameters derived from the fitting performance of the Van Genuchten (1980) model. The R2 value was used to evaluate the quality of the collected data. Based on the provided information, the R2 value suggests that the fitted data corresponded closely to the measured data. Additionally, the air entry value of the soil-CCS mixtures was noted to be greater in terms of volumetric water content when compared to the control sample. The results indicated the use of CCS to contribute to enhanced water retention in soil, with optimal water release compared to the control sample.

The addition of crushed coconut shell at 0.5% into the soil led to a significant rise in the air entry value, elevating it from 10 kPa to 25 kPa. The air entry value of the mixed samples exhibited a progressive drop from 25 kPa to 20 kPa upon the addition of crushed coconut shell at an incremental rate of 0.5%. The air entry value remained constant at 13 kPa for soil-CCS mixtures of 1.5%, 2.0%, and 2.5%. This finding suggests that the incorporation of an acceptable percentage of crushed coconut shell into the mixture resulted in a significant deviation in the air entry value. Other than that, the use of CCS also led to an increment in volumetric saturated water content (θs) and volumetric residual water content (θr).

According to the findings presented earlier [16], the use of a smaller-sized crushed coconut shell may potentially lead to reduced effectiveness in the mixture due to its potential impact on the durability, toughness, and abrasion resistance of the coconut shell. The use of a sieve size larger than 14 mm has implications for the surface area of each individual crushed coconut shell, the distribution of crushed coconut shell within the sample, and possibly the air entry value of the mixture. In this study, the use of 5-8 mm size of CCS increased the AEV result and indicated that the soil-CCS mixtures can be used as an alternative for subgrade performance.

| Parameter | Soil-CCS Mixture | |||||

|---|---|---|---|---|---|---|

| 0% | 0.50% | 1.00% | 1.50% | 2.00% | 2.50% | |

| Sample label | C0 | CS05 | CS10 | CS15 | CS20 | CS25 |

| Volumetric saturated water content, θs | 0.79216 | 0.81105 | 0.79216 | 0.81424 | 0.7815 | 0.83256 |

| Volumetric residual water content, θr | 0.51596 | 1.00E-10 | 0.51596 | 0.57201 | 0.54961 | 0.61216 |

| Inverse to air entry suction, α | 0.093808 | 0.039078 | 0.093808 | 0.075049 | 0.073148 | 0.069256 |

| Pore size distribution, n | 1.413 | 1.0525 | 1.413 | 1.4997 | 1.4928 | 1.7493 |

| R2 | 0.972 | 0.9690 | 0.9720 | 0.9889 | 0.9759 | 0.9770 |

| Air entry value | 10 | 25 | 20 | 13 | 13 | 13 |

The results indicated that maintaining a consistent particle size and achieving a uniformly distributed crushed coconut shell in the sample can enhance water retention capabilities. The use of crushed coconut shell as a soil amendment has been observed to effectively fill the voids within the soil structure, hence contributing to a slight enhancement in its overall strength [16].

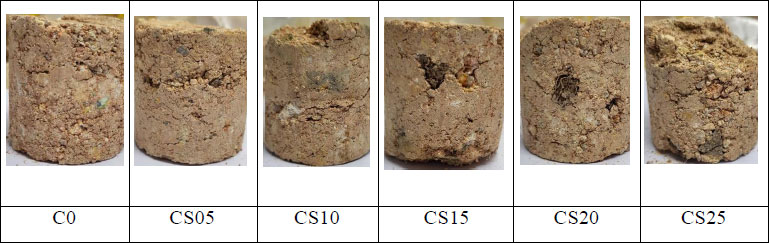

Fig. (6) presents a comparison between the control sample and the soil-CCS mixture following a 24-hour period of oven drying. The observed CCS-soil sample exhibited a higher degree of brittleness in comparison to the control sample. The changes in the soil structure also could be seen as the additive modified the surface structure of the soil. However, despite the degree of brittleness in the soil surface structure, the increased AEV exhibited by the additive indicated a significant potential for using CCS as a subgrade improvement additive.

CONCLUSION

In conclusion, the soil used for all the samples was poorly graded and sandy. The soil was classified using the Unified Soil Classification System (USCS) based on the data obtained from sieve analysis. The experiment conducted through the SWCC revealed that the SWCC graph exhibited a pattern indicating an increase in volumetric water content at desirable suctions. The enhancement of the SWCC graph was verified by the increase in the measured AEV. The AEV value exhibited a substantial enhancement in all soil-CCS mixes when compared to the control sample. It can be inferred that the use of 0.5% coconut shell may provide optimum AEV for control soil samples, enhancing their quality. Significant deviations were also evident in the volumetric saturated water content (θs) and volumetric residual water content (θr). It can be implied that the R2 result strongly supported the finding of the laboratory data being in line with the equations, indicating the laboratory work to be performed successfully.

This study showed the soil and CCS mixture to have the ability to improve the hydraulic properties of submerged subgrade conditions. Furthermore, given the demonstrated capability of CCS to enhance the subgrade performance under flood conditions, it is recommended to perform further research to examine the effects of integrating CCS into soil compositions, particularly in relation to shear strength assessments, including the California Bearing Ratio (CBR). In addition, it is of utmost importance to conduct Field-Emission Scanning Electron Microscopy (FESEMF) for microstructure tests for the optimum mixes.

The hydraulic behaviour observed throughout this experiment may offer a further understanding of the complexity of the unsaturated soil behaviour. A precise assessment of hydraulic characteristics is essential for forecasting the failure of embankments or subgrades caused by flooding resulting from intense rainfall. Incorporating waste material for soil stabilisation is not only beneficial for the environment, but may also allow for the material to be reinvented for beneficial usage.

LIST OF ABBREVIATIONS

| CCS | = Crushed coconut shell |

| SWCC | = Soil water characteristic curve |

| AEV | = Air entry value |

| RWC | = Residual water content |

CONSENT FOR PUBLICATION

Not applicable.

AVAILABILITY OF DATA AND MATERIALS

The data and supportive information are available within the article.

FUNDING

None.

CONFLICT OF INTEREST

The authors declare no conflict of interest, financial or otherwise.

ACKNOWLEDGEMENTS

The support provided by the Faculty of Engineering, Universiti Pertahanan Nasional Malaysia (UPNM), to this study is highly appreciated.