All published articles of this journal are available on ScienceDirect.

The Impact of Schedule Compression Techniques on Construction Project Timelines: A Case Study in Basrah, Iraq

Abstract

Introduction

Project managers always compete to finish their projects on time. However, certain circumstances force them to use schedule compression techniques - such as activity crashing, overlapping, and method substitution, to address unplanned delays.

Methods

These techniques offer practical means to accelerate project timelines; however, their degree of effectiveness can vary widely across different projects and contexts. Nevertheless, such circumstances make compressing construction project schedules an important consideration for avoiding financial losses and protecting stakeholders' interests.

Results

The paper aims to evaluate the effect of schedule compression techniques on a construction project located in one of Basrah’s oil fields in Iraq. A case study approach is followed for discussing time-cost trade-offs, challenges, and outcomes with such techniques, including their financial implications, strategies for mitigating risks, and the management of resources.

Conclusion

The results provide insights that are useful in the optimisation of project schedules while ensuring that constraints for cost, safety, and operation are met.

1. INTRODUCTION

Construction projects are dynamic in nature, with tight schedules, strict budgetary constraints, and limitations in resources. It is extremely important to meet project milestones and deliverables within time for satisfactory completion of a project for all the stakeholders involved [1]. However, most of the time, such goals are pretty hard to be realized, rather calling for strategic measures toward expediting the timelines of a project without any compromise on its quality and cost efficiency.

There are techniques for compressing project schedules, which project managers might initiate in their attempt to improve efficiency and reduce the time tied to project delivery [2]. The techniques could be activity crashing, overlapping, and substitution of construction methods, among others, which refers to a unique way of shortening the project delivery schedule [3]. However, the practical application of schedule compression techniques is predicated on complete comprehension of all related implications on project results and stakeholders' interests as well [4]. Finding a balance between the need for speeding project delivery and maintaining project cost, quality, and risk tolerance is an important aspect of effective project management [5].

This paper, hence, aims to explore the impact of schedule compression techniques on the compliance of construction projects with approved/requested time frames based on a case study carried out in Basrah, Iraq. Real data and experiences are discussed through this research, serving as valuable insights for project managers, stakeholders, and researchers who share the same challenge in managing construction projects. This research work attempts to advance the best practices in construction project scheduling and management through deeper analysis of the schedule compression techniques applied and their implication within a practical project environment.

2. LITERATURE REVIEW

Construction projects, by their nature, are beset with quite a sizeable number of challenges that make the completion of work very difficult. Among these many challenges, schedule slippage is one of the major concerns to a contractor and a project stakeholder because it has the potential to cause a tremendous financial loss on the project invested in by them [1]. It is in the wake of these challenges that the concept of compression of schedules has emerged as a strategy for increasing the pace of a project and reducing the effect of delays.

Schedule compression involves a set of methods that work to reduce project durations without reducing the quality of the projects or may even improve it along with project effectiveness. The most common technique for schedule compression is called activity crashing—that is, adding more resources to critical activities in order to finish them as quickly as possible [6, 7]. A project manager applies additional resources like labourers and equipment to reduce the duration of activities on the critical path so as to compress the overall project schedule [6, 8, 9].

Activity overlapping is yet another method of compressing the schedule of a project. It refers to the parallel execution of activities that are normally sequential in nature. It helps reduce the idle time between activities and allows them to overlap; therefore, a project will be completed in a much shorter time than it would have taken if the activities were not overlapping. Although activity overlapping may produce quite a degree of saving time, it also brings in certain complexities and risks to the project, such as higher needs for coordination and rework [3, 4, 10, 11, 12].

Apart from activity crashing and overlapping, activity/method substitution is also another method of schedule compression. According to a study [5], it replaces one activity or a series of activities with different construction approaches or the use of available construction technologies that are more effective or productive. There are many ways in which project managers can work to speed up the schedule of the project using different efficient or innovative construction methods without affecting the performance or quality of the project [11, 13].

Despite the many advantages of the schedule compression techniques, their implementation mostly suffers from a share of challenges and risks. One of the key challenges is that there are inherent trade-offs amongst time, cost, and quality, as schedule compression for a project will more often require extra resources and, thus, increase cost [2]. Furthermore, an additional challenge facing project managers is selecting the suitable technique to compress a schedule, which requires them to carefully consider several factors, including project complexity, risk tolerance, and stakeholder preferences, among others [11, 14, 15, 16].

It is, therefore, noted in the existing literature that the importance of conducting an empirical study on the practical application and outcome of schedule compression techniques in construction projects cannot be overemphasised. This kind of study shall go a long way to provide valuable lessons, including how best to achieve success, the challenges involved, and best practices in schedule compression within the contexts of varied construction projects based on real-time data and experiences [5, 9, 17]. Thus, the findings in this area contribute to bridging the gap between theoretical knowledge and practical implementation and, as a result, help project managers and stakeholders make informed decisions and optimise project schedules toward timely completion [3, 7].

A focus on schedule compression has also seen new developments in fast-tracking and modular construction as ways of shortening on-site time and increasing the efficiency of construction, especially for projects with limited access to logistical space [12, 13, 14]. These studies highlight increasing reliance on off-site fabrication and precast technologies, not only because they decrease direct labour needs on construction sites but also because they reduce the risk of accidents in risky conditions [11]. Moreover, research into the financial risks of schedule compression has been rising significantly, especially in the open book contracting models where the contractor and the client are open to the risks of the timescale of delivery, which has been considered the main key of work [13, 18]. The literature also reveals the importance of effective resource allocation and logistical management to execute fast-tracking and method substitution strategies [17, 19].

The adoption of so-called schedule compression techniques is a successful strategy for handling project delays and lessening their impact. They should, however, only be applied carefully, in accordance with stakeholder requirements, and the complexity and risk tolerance of the project. Schedule compression techniques can, therefore, be used effectively by project managers and stakeholders to get satisfactory project completion and project success through empirical research and real-world experience.

3. RESEARCH METHODOLOGY

The goal of this paper is to evaluate the impact of these schedule compression techniques on a construction project of a company in Basrah, Iraq. This part details the methodologies employed when investigating the effect that these schedule compression techniques have on the construction project duration, especially in the context of the WP Foundation Work project in Basra, Iraq. We will study these techniques using both qualitative and quantitative research methods.

3.1. Research Design

This is a mixed-method paper in which the researcher collects qualitative and quantitative data and then analyses project schedules, performance metrics, interviews, and observations [20, 21].

3.2. Case Study Approach

A careful case study of the WP Foundation Work project is conducted to study the application and consequences of different schedule compression techniques, thus allowing for an in-depth examination of real-world practices based on this detailed project case study [21, 22].

3.3. Data Collection Methods

Data for this paper were collected using the following approaches:

Document Analysis for:

3.3.1. Project Schedules

A review for detailed project schedules before and after compression drawn from Primavera P6 or other scheduling methodologies taken from the organisation together with the activity durations and sequences.

3.3.2. Project Reports

This includes reviewing changes in schedule, resource utilisation, and the approach used during schedule compression.

3.3.3. Interviews

This includes conducting semi-structured interviews aimed at understanding the project’s stakeholders’ perception of the efficiency and effectiveness of schedule compression strategies alongside resource management [23].

3.4. Data Analysis

The data analysis combined qualitative and quantitative techniques:

3.4.1. Quantitative Analysis

3.4.1.1. Schedule Comparison Before and After

Primavera P6 was used to carry out detailed schedule comparisons. This is to highlight differences in durations and dates. The changes were then compared using a Gantt chart and incorporated in the results.

3.4.1.2. Performance Metrics

The key performance indicators analysis has covered project duration, percentage of task completion, safety and quality statistics.

Primavera P6 was used to schedule and compress the project using the methods described in the study. The software provided real-time updates as schedule modifications were implemented and enabled the modelling of activity time, resource use, and timing. The choice of Primavera P6 was critical in assessing the practicality of various scenarios for overlapping the activities and fast-tracking, as well as in terms of reallocation of resources to reduce the proposed schedule of the project from 15 to 11 weeks.

3.5. Qualitative Analysis

3.5.1. Thematic Analysis

Based on analysis of interview transcripts and observation notes to identify common themes [24].

3.5.2. Content Analysis

Analysis of project reports and documents for cross-verification of data from interviews and observations [22].

3.6. Data Triangulation

Data triangulation ensured reliability and validity by cross-verifying information from documents, interviews, and observations:

3.7. Ethical Considerations

Ethical considerations included:

3.7.3. Transparency

The research process was conducted transparently.

The study employed a mixed-method approach, integrating case studies and qualitative and quantitative techniques, offering a well-rounded understanding of how schedule compression affects construction project timelines. The findings contribute to best practices in construction project management, with a focus on optimising schedules.

3.8. The Selected Case Study

The selected construction company is located in Basrah city, and it has more than 20 years of experience working in the construction field, where they have implemented many projects out there and one of them was selected to be the study sample. The working environment in this oil field is extremely different from other green working zones, where extra HSE, security and quality requirements must be addressed to ensure smooth and continuous work on site. Therefore, every construction task planned to be completed onsite must have an approved method statement that passes the HSE and security requirements. Thus, project managers normally require planning in advance for resources required to access the site. This includes completion of a health check, specific HSE training, complete site induction for personnel and initiating the material approval process (MAR) for each item to be used on site. These steps are normally time-consuming and any error and change in staff can cost the projects a considerable delay. Therefore, the process of applying schedule compression techniques, discussed below, had to take this into account to ensure better results under such conditions. A brief description of this case study project is provided below:

4. DATA COLLECTION, ANALYSIS AND RESULT

4.1. Project Before Schedule Compression

This project involves a number of civil works and is programmed for 15 weeks starting in October 2022. This project is planned with a BAC = $841,796.16 USD before profit. The project was awarded to the company by a reputable international oil company operating in Basrah.

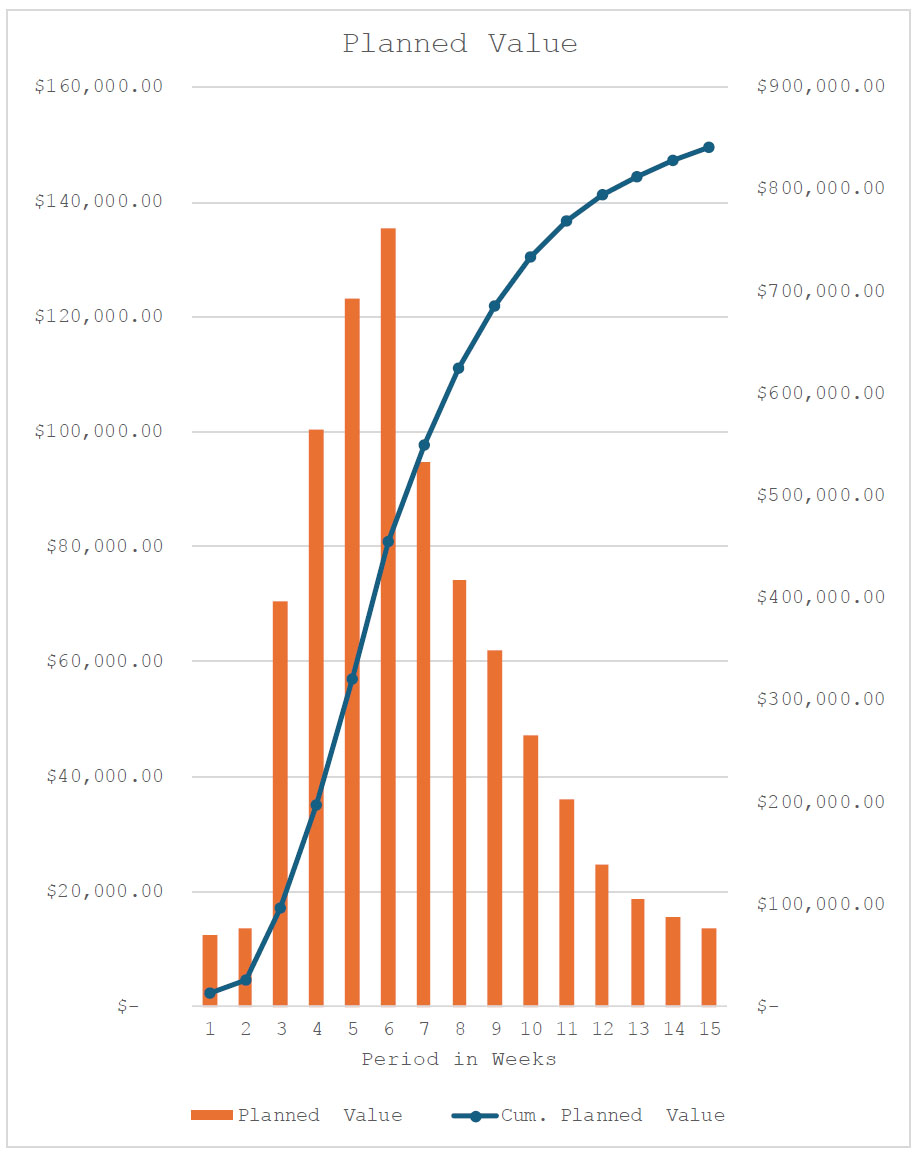

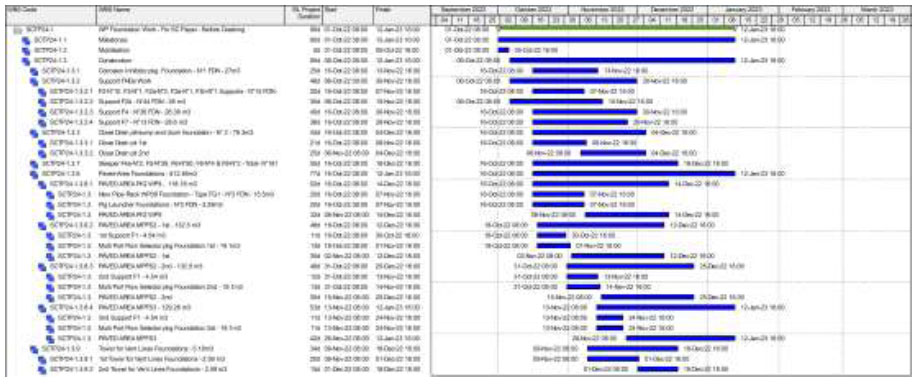

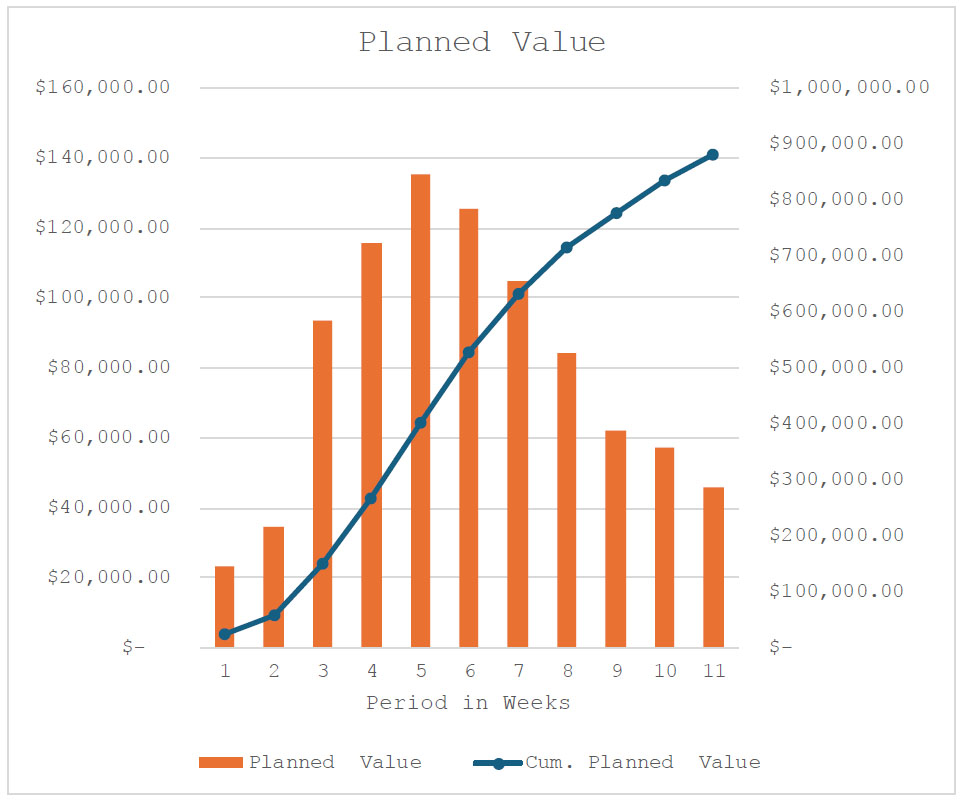

In alignment with the approved schedule, weekly values have been computed, and both a histogram of weekly planned values and an S-curve illustrating the cumulative weekly planned values for the original schedule have been generated, as depicted in Fig. (1). Furthermore, all work packages were planned to be executed on-site as per the agreed schedule and were scheduled to start and finish, as illustrated in Fig. (2).

Original S-curve of planned values of project before compression.

Original high-level schedule.

The project contains six major work packages as follows:

- Corrosion Inhibitor pkg. Foundation

- Support Foundation

- Close Drain pit/sump and drum foundation

- Sleeper Foundations

- Paved Areas Foundations

- Tower for Vent Lines Foundations

The paved area foundations represent the longest work package to complete, as it involves constructing concrete paved sections consecutively, as shown in Fig. (2).

4.2. Project After Schedule Compression

Two weeks before the planned start, the client requested the company to try to complete the project before the start of January to allow the client to operate the well pad in early January 2023. The client offered the company a financial reward and considered the company for an award for another similar contract in the field.

In response to the client’s request to compress the project schedule from 15 weeks to 11 weeks, the project team implemented multiple techniques to meet the new deadline while maintaining safety and efficiency. The incentives offered by the client motivated the contractor to explore different methods to compress the schedule.

4.3. Schedule Compression Techniques Used

4.3.1. Activity Overlapping

The initial design called for the concrete paved areas to be built in sequential order, with two MPFS2 paved areas and one MPFS3 paved area scheduled for completion one after the other. This sequential method caused a delay in completion since, as Fig. (2) illustrates, each phase had to be completed before the next could start, with very little overlap. Each of these paved areas includes pipe supports coded as F1, a multi-port flow selector foundation, and the main concrete paved area. The construction process required the F1 and multi-port flow foundations to be completed first, followed by the main paved area. In the original schedule, the F1 and multi-port flow for the first paved area had to be finished before starting the F1 and multi-port flow for the second paved area and similarly for the third one.

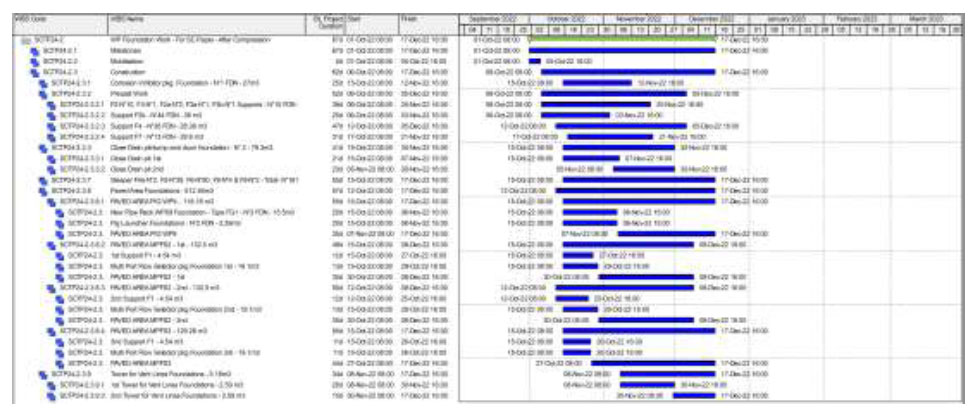

To shorten the timeline, the project team employed activity overlapping, allowing all three paved areas to be constructed simultaneously. Accordingly, this has allowed multiple teams to work at the same time, thus effectively reducing idle time between key activities or stages. Furthermore, using this method has enabled the team to start work on the F1 and multi-port flow foundations for all three paved areas at the same time concreting the three primary paved areas was therefore done simultaneously as well. Fig. (3) shows the overall project schedule after compression.

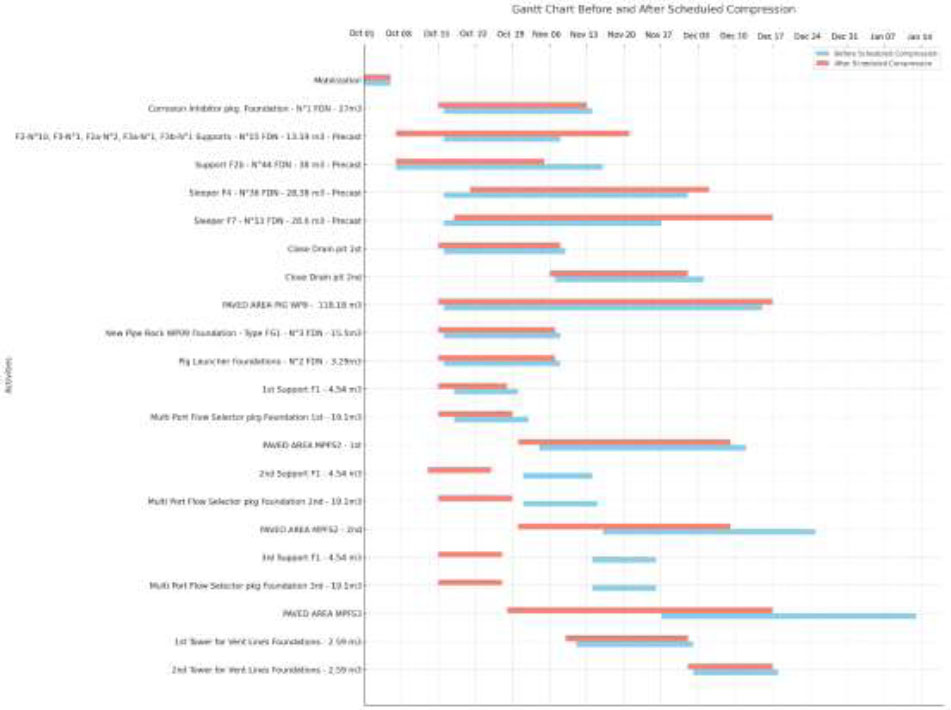

Fig. (4), on the other hand, presents a direct comparison between the original schedule before compression (in light blue) and the compressed schedule (in light red), illustrating exactly where the overlapping occurred.

Nevertheless, carrying out activities overlapping most of the time is accompanied by a chance of work conflicts and team congestion. Therefore, it was imperative for the project management team to carry out rigorous planning to avoid unnecessary delays, and safety risks and provide the appropriate resources. The efficient administration of shared resources, including labour teams, tools, and site access, was essential to the successful execution of activity overlapping. To prevent resource consumption bottlenecks, specialised teams were assigned to each paved area, and task durations were closely monitored. Furthermore, a new method statement and work permit were produced and approved by the relevant HSE authority to reflect the changes in the approach taken to complete these activities.

High-level schedule after compression.

Comparison between schedule before and after compression.

Furthermore, scheduling buffers were intentionally put at key places to account for unanticipated delays, ensuring that vital tasks could still be finished on time even if minor problems emerged in one of the overlapping activities. This flexibility in resource distribution enabled the team to retain momentum despite the complexities of coordinating many tasks at the same time.

4.3.2. Substitution of Construction Methods

A major constraint in the original schedule was the proximity of certain supports and sleepers’ foundations to the paved areas. The planned in-situ casting of these foundations can certainly create conflicts, as space was limited, and the teams working on adjacent paved areas had to wait for these foundations to be completed.

The project manager decided to replace the in-situ casting with pre-cast components. By shifting the manufacturing of these foundations to an off-site workshop, the project team freed up space at the well pad, allowing the paving activities to proceed without obstruction. Pre-casting not only reduced on-site labour requirements but also allowed for improved quality control because the foundations could be manufactured in a controlled environment.

While pre-casting normally speeds up the construction process, transporting and installing the pre-cast components presented logistical obstacles. Accordingly, the project team was required to wisely plan the transportation process of the pre-casting items to the site to make sure they arrived in the specified time to avoid unanticipated delays or conflicts with other activities being constructed on site. Nonetheless, despite these challenges, the substitution of the construction method to pre-casting has played a significant role in shortening the overall project schedule and ensured that critical activities, such as those of the paving areas, can proceed as planned. However, a new method statement and work permit were produced and approved by the relevant HSE authority to reflect the changes in the approach taken to complete these activities, especially since transportation and installation have been introduced.

4.3.3. Resource Reallocation

A significant driver of the schedule compression was effective resource reallocation. The project team was able to ensure that critical items, like concreting activities for the paved areas, received sufficient labour and equipment by optimising the workforce allocation. Those crews that were originally intended to do the support and sleeper foundations were moved onto the paved areas as a result of changing the construction method of these foundations to pre-casting. This approach not only helped keep the project moving but also allowed higher productivity when it came to the paved areas, and the work became quicker than waiting for support and sleeper foundations to be built on-site.

4.4. Risk Mitigation

The project team compressed the schedule while respecting the elevated risks associated with concurrency and on-site congestion. Activity overlap, in particular, can be a major safety hazard, not only because multiple teams are often working near one another but also because they are often using much heavier equipment. Therefore, with the above awareness in mind, the project team was required to put a number of safety mechanisms in place to ensure the construction work was risk-free after implementing these schedule compression techniques. These mechanisms are illustrated below:

4.4.1. Site Segmentation

The construction area was broken down into several sections and relevant teams were assigned to their respective work area in those sections. Accordingly, the team was able to establish clear work zones that contained only the necessary number of workers and equipment so that overcrowding would be prevented in the working areas, which could pose a risk of potential accidents. This mechanism has helped to reduce the chance of activities interfering with each other despite the fact that multiple activities are being carried out at the same time.

4.4.2. Pre-cast Installation Strategy

The substitution of the support and sleeper foundations construction method from cast-in-situ to pre-casting has helped minimise the number of labourers and equipment onsite. This execution plan not only sped up the construction process but also helped reduce on-site congestion, thereby minimising the risk of incidents. Furthermore, the installation process of the pre-cast items was planned meticulously, allowing the use of professional cranes and a minimal number of personnel to carry out the installation process. This mechanism has enabled the project team to work on the paved areas uninterrupted as the precast items are being installed in their designated locations once their locations become available.

4.4.3. Safety Monitoring

The team working on the project ensured safety measures during construction by including additional safety officers to supervise multiple tasks occurring at the same time. Safety officers held safety meetings regularly to ensure all workers understood the dangers associated with multiple tasks occurring in close proximity and the use of heavy machinery. This pre-emptive safety strategy was vital in keeping a safe working environment despite the risks associated with the schedule compression techniques.

Through implementing these risk reduction tactics, the project team was able to shorten the timeline without jeopardising safety or elevating the chances of accidents. These actions guaranteed the completion of the project within the expedited schedule while upholding safety and quality standards.

The implementation of these schedule compression techniques has enabled the project team to effectively reduce project duration from 15 to 11 weeks. The fast-tracking of the paved areas’ activities, along with the substitution of construction methods, has enabled smoother and faster workflows and minimal teams’ congestion and zero-risk incidents. Accordingly, the client’s revised timeline was met, enabling operations to commence in early January 2023, as required.

S-curve of planned values of project after compression.

4.5. Financial Impact of Schedule Compression

The process of schedule compression had a considerable financial impact on the project. The contract value before compression was $841,796 USD of total project cost before profit. This original total project cost is a combination of $84,179 USD as an indirect cost, representing $5,611 USD daily and $757,616 USD as a direct cost.

However, once the schedule compression process was completed, a number of financial changes occurred to the project. This included the total project cost increasing to $881,329 USD, representing an increase of $39,533 USD as compared to the original contract value, as shown in Fig. (5). Below are further details about the changes to the direct and indirect costs of the project.

4.5.1. Breakdown of Financial Changes

4.5.1.1. Indirect Costs

Total indirect cost had risen from $84,179 USD to $88,132 USD, making the daily indirect cost after compression $8,012 USD an increase from $5,611 USD before schedule compression. This increase in the indirect costs of the project was driven by:

- The need for the project manager to hire additional HSE officers to supervise the activities being carried out at the same time in order to ensure a safe working environment as discussed above.

- The need for the project manager to hire additional machinery and equipment to support the overlapping activities and the installation of pre-cast foundations, including cranes and trailers.

- The shift from on-site casting to off-site pre-casting for the support and sleeper foundations has made the project require additional logistical costs for transportation and extra oversight for the installation process.

4.5.1.2. Direct Costs

On the other hand, the direct costs had risen from $757,616 USD to $793,196 USD, reflecting an increase of $35,580 USD. The reasons behind this increase are:

- The need to hire extra labourers to execute the parallel activities in the paved areas work package, which included more workers for rebar bending, rebar fixing, and concrete pouring.

- The manufacturing and transportation of the pre-casted items, namely the support and sleeper foundations.

- The acceleration of procurement processes. This is because compressing the schedule requires the project manager to make available all the necessary resources for concurrent activities at the same time to ensure smooth workflow. This has resulted in higher material costs due to expedited deliveries.

4.5.2. Profit and Compensation

In order to incentivise the contractor to carry out the necessary schedule compression, the client agreed to have an open discussion with the contractor about the financial impact and the additional costs that will be incurred due to the compression process. The client-contractor discussion mainly focused on the increase in the direct and indirect costs required to deal with a compressed schedule.

As illustrated above, the total extra cost required to compress the original schedule had been $39,533 USD. These additional expenses were a result of the need to hire extra safety officers and additional equipment, and implement alternative construction methods to accommodate the changes in the new compressed schedule. The positive matter in this contractual arrangement is that the client agreed to cover these expenses to assure that the contractor can retain project profit and, at the same time, ensure a smooth execution of the compressed schedule.

4.5.3. Overall Financial Impact

The compression led to a total cost rise of $39,533, the costs inclusive of indirect and direct costs in order to accomplish the 11-week schedule. The client paid the extra costs incurred by the contractor which made the contractor not to incur any loss. This open style of working ensured this project was completed as necessary to the advantage of the client through the early completion of this project.

5. DISCUSSION

The results from this case study reveal how several schedule compression practices influenced the extent of project compliance with the schedules in the construction context for the oil industry in Basrah, Iraq. This section will explain how the framework of overlapping and method substitution aligns with prior research and which difficulties and results relate to these approaches.

5.1. Impact of Activity Overlapping

Among the most outstanding techniques applied when compressing the schedule to minimise the time taken to construct the project scope was overlapping of activities, which involved constructing multiple paved areas at once. This approach corresponds with the literature on fast-tracking, which is a form of activity integration where activities that are usually done in a serial manner can be done in parallel [7]. Thus, by starting construction of all three paved areas at once, the project team was able to directly reduce idle time and remove one of the fundamental obstacles in the original schedule, which was the unnecessary time buffer contained in the initial plan.

The practical implementation of activity overlapping in this project was, however, impacted in some ways by the subject matter of the oil field. Unlike conventional construction environments, oil field projects are bound by safety and security regulations, environmental laws, and transportation constraints. This made some level of planning necessary to ensure work is compliant with applicable regulations as well as to avoid interference with any ongoing work such as pipeline installations. Further, space restriction was another challenge that limited access to work areas, especially where sensitive work was being conducted, thereby requiring a lot of planning and control to ensure that the project team got access to the restricted areas safely without causing system interferences. These constraints introduced other levels of complication that are not normally found in green zone construction and thus have made the application of overlapping work more challenging.

This is in line with the literature that emphasises the effectiveness of this technique in shortening project time, especially if delays between activities are problematic [3]. However, the overlap of activities increases the chances of resource conflicts and possible rework, which has been managed comprehensively in this project through proper resource control and deployment of special resources to pre-divided zones. As has been established, a few studies [7, 17] identified that while overlapping tends to come with extra challenges, effective management of available resources and effective placement of buffers can help in avoiding such issues that accompany the use of this compression technique.

This case study indicates that the normal use of activity overlapping cannot be directly transferred to high-risk contexts such as oil fields without major adaptation. Due to safety, logistical, and resource constraints, the project team had to adapt traditional overlapping procedures in ways that were not generally addressed in the literature. The case study project provides a valuable contribution to the existing research on employing schedule compression techniques when dealing with complex and risky environments. This paper underscores the importance of context-based solutions and provides fresh insights into the use of concurrent activities in sectors that require absolute safety and accuracy.

5.2. Substitution of Construction Methods

The change from in-situ casting to the use of pre-cast components proved to be essential in overcoming the spatial limitations to enable working on all paved areas at the same time. The project team's decision to move the production of the support and sleeper foundations to an off-site workshop resulted in gaining not only more workspace at the well pad but also enhanced quality control, advantages which are already evident in the literature [3, 13, 25].

This method substitution is especially applicable to construction projects which are affected by space limitations or where a high degree of accuracy is necessary since it helps provide a better-controlled construction environment and eliminate site congestion. However, the transportation and installation of pre-cast components come with their unique difficulties, as pointed out in this case study reflecting prior studies that recognise that while method substitution may increase work efficiency, it could be accompanied by other difficulties [17], such as in this case transport or installation challenges. Nevertheless, these challenges were addressed by effective planning and thus, the method substitution eventually helped achieve the schedule compression aim. This supports the literature findings on the effectiveness of using alternative methods of construction as the team plans to compress their schedule [8, 9, 13].

With logistical considerations in a constrained working environment, particularly in industries such as oil fields, this case study brings new perspectives to the previously known benefits of method substitution. As previously stated in the literature, pre-casting is beneficial for both quality assurance and reducing the amount of work required on site (Ballesteros-Pérez et al., 2019; Mubarak, 2019); however, the Basrah project highlighted the importance of transport and installation schedule coordination. The nature of the well pad, combined with the limited access roads, posed issues in the pre-cast schedule, as time-linked scheduling was required to reduce time wastage. This factor, given minimal attention in conventional construction operations, shows the importance of undertaking logistical planning along with method substitution alternatives in industrial work. Solving the aforementioned challenges aided the project team in maintaining the normalcy of the work processes, reinforcing the premise that method substitution, when paired with adequate planning, can contribute to schedule compression even in the most difficult scenarios [14].

From a computational viewpoint, managing the compressed project with its overlapping deadlines and method substitutions necessitated the employment of sophisticated scheduling tools. The team used Primavera P6 to manage the difficulties of fast-tracking many activities at the same time, guaranteeing efficient resource allocation and handling of conflicts. While the software made it easier to evaluate various timetable reduction choices, allowing for faster judgments, there were still issues. As with any major project, recalibrating overlapping activities and altering resources in real-time proved difficult, particularly when dealing with logistical challenges and the potential of rework. This example demonstrates how useful advanced project management systems can be in managing the computational needs of real-world schedule compression [8, 9].

5.3. Financial Implications of Schedule Compression

The schedule compression process conducted on this project was complex, financially impacting both direct and indirect costs. However, despite that schedule compression normally led to an increase in project costs, nevertheless, the financial agreement between the contractor and the client ensured the contractor did not suffer any financial losses, as discussed above. This arrangement reflects an open book contracting that is often recommended for managing high-risk and time-sensitive projects [18].

This increase in project cost is in alignment with prior studies that asserted that schedule compression techniques such as fast-tracking and method substitution often lead to increased project cost as a result of the requirement for extra resources and logistical support [1, 3, 8, 9]. However, the financial openness between the client and the contractor has maintained contactor profit, motivating him to carry out the project within the compressed timeline and thus realise client goals – win-win for both parties.

Another financial aspect underlined by this case study is the benefits of risk-sharing strategies when it comes to containing the further consequences of schedule acceleration. Even though most works recognise that fast-track delivery and method substitution, in particular, lead to a direct increase in project costs, this case shows that the effective management of project finances and risk allocation between the project's main stakeholders is crucial. That is why the open book contracting implemented in the frame of this project not only provided for proper protection of the contractor’s profit but also created a proper problem-solving context for the client and the contractor. This level of financial transparency, along with mutual accountability fostered organisational flexibility in decision-making in order to tackle the additional, unprecedented logistical and resource issues raised by the schedule compression. Consequently, this finding implies the importance of advancing risk sharing and monetary transparency during the contract development stage of future projects in order to maximise the applicability and effectiveness of schedule compression in a risker construction environment similar to oil fields (Wilson, 2019; Gerk & Qassim, 2008).

5.4. Risk Mitigation in Overlapping Activities

Despite that, activities overlapping, a form of fast-tracking technique of schedule compression, is effective in shortening project duration, yet it is also prone to introducing significant risks to the project, including safety risks in construction projects. The case study in question has shown how important it is to plan and execute effective risk mitigation strategies in order to address the risks associated with fast-tracking activities. Among these strategies is the segmentation of construction sites into specific zones and allocating separate teams as an approach to minimise the risk of accidents and congestion. This is in line with previous studies recommending effective plans to address risks accompanying fast-tracking and concurrent construction activities [1, 3, 5, 7, 12, 14, 16, 19].

Another effective strategy used in this case study was the decision to switch between cast-in-situ and pre-casting the relevant foundations off-site. This approach has helped in mitigating the risks by effectively reducing labour, personnel and related machinery requirements on site. This is also in line with the literature, which asserts that method substitution can help reduce or even eliminate risks associated with some of the schedule compression techniques [11, 19].

Furthermore, the pre-planned gradual allocation of resources into zones and increasing safety monitoring and controlling via additional safety officers were very efficient strategies in reducing the chances of incidents or accidents occurrence. These risk management strategies are in line with construction project management best practices recommending effective planning to address any potential risks associated with the use of schedule compression techniques [7, 8, 9, 14, 17, 19].

In addition, in terms of applicability to real problems, the identified risk management measures can be used to prevent similar situations in other high-risk conditions that are typical for various industries, such as the oil and gas industry, where site density and activity interconnection are frequent. The three risk mitigation measures adopted in this study, namely zone-based segregation, method substitution, and increased safety monitoring, can be implemented in similar construction projects with complex layouts, and spatial, and logistical issues. Through these measures, project managers can handle the issue of schedule compression, ensuring that the achievement of optimal project schedules does not jeopardize worker safety. As a result, this study has highlighted the general relevance of the risk mitigation techniques identified and discussed in this study to construction projects other than the Basrah oil field project, as well as making a useful contribution to the field of construction project management across different environments.

The findings obtained from this case study highlight the effectiveness of schedule compression techniques, not just in shortening project duration but also in maintaining project safety and quality. Activity overlapping, method substitution and effective resource allocation have enabled the project team to compress the duration of the schedule from 15 to 11 weeks, satisfying client requirements. Moreover, the case study findings have enhanced the body of knowledge of the effective use of schedule compression techniques, showing how it was applied when managing a real construction project done in an oil field that was characterised by spatial limitations and safety considerations.

5.5. Theoretical and Practical Implications

Theoretical Implications: this paper serves to add to the existing knowledge on schedule compression in construction projects, especially in the context of a complex work environment such as the oil fields. The study offers evidential implications to the theories involving fast tracking, method substitution, and resource reallocation in construction, supporting existing literature. Furthermore, the study supports the theory that explores the relationship between schedule compression and project cost to argue how contractors can keep profit whilst delivering within a shorter timeframe. In addition, few studies in the literature show the impact of applying schedule compression techniques on real-world projects. Thus, this study attempts to enrich the existing literature with practical experience in the application of schedule compression techniques.

Practical Implications: Finally, from the practical perspective, the case study provides an understanding of how construction managers can integrate schedule compression methods. Therefore, the activity overlapping and method substitution used in this case proved that even large projects can be accelerated effectively without endangering the safety and quality of work. Moreover, in regard to the client-contractor financial relationship, it is evident that there is a professional relationship between the two that requires discretion in the overall costs that are likely to be incurred in the course of the project. These best practices are of great importance for all construction professionals who work in complex environments where timelines are of critical importance and where delays can have significant financial and operational consequences.

6. RECOMMENDATIONS

Based on the findings from the WP Foundation Work project, several recommendations can be made to enhance the success of future construction projects involving schedule compression:

6.1. Early Identification of Critical Paths

Project teams should identify the activities on the critical paths in the early stages of the planning phase. So that they can be better prepared once schedule compression becomes a necessity, so as to speed up the compression process.

6.2. Consideration of Multiple Compression Techniques

Readily, schedule compression techniques like activity overlapping and construction methods substitution can offer the necessary flexibility for compressing tight schedules without affecting project quality and safety.

6.3. Resource Allocation and Management

The effective management of a compressed schedule requires the project team to dynamically reallocate resources to key activities, ensuring they get sufficient manpower and equipment. Furthermore, effective monitoring and control of resources during the project implementation is very effective in preventing bottlenecks during the execution of compressed schedules.

6.4. Risk Mitigation Planning

Fast-tracking activities can pose inherent hazards to safety. As a result, effective and efficient countermeasures should be implemented, including site segmentation, phased resource distribution, and improved safety surveillance to ensure that the workplace remains safe.

6.5. Open Communication with Clients

Having an open discussion with the client about any additional costs that are likely to be incurred as a result of schedule compression is very important to ensure smoother financial planning and better relationships, leading to both parties benefiting from schedule acceleration.

Implementing the aforementioned practices can help achieve shorter schedules for construction projects while maintaining safety, quality, and financial stability.

7. LIMITATIONS

Despite that, this research paper focuses on one construction project in the oil and gas sector of Basrah, yet the findings obtained from this case presented a significant understanding of schedule compression techniques and can be applied to similar projects. Although the financial arrangement for this case is unique to this project and is not a common practice in all sectors, however, it emphasises an effective method that can benefit projects with similar importance and sensitivity to time. In addition, activity overlapping and method substitution are powerful techniques for schedule compression; however, their effective application depends on a number of variables, including resource availability, logistical capabilities, and contractor expertise, which may be different among projects.

CONCLUSION

This case study demonstrates that schedule compression techniques are useful and relevant in construction, especially in critical contexts such as oil fields. Intrinsically, through activity overlapping, method substitution, and appropriate resource relocation, the project team was able to significantly decrease project duration from fifteen weeks down to eleven weeks, thus catering to the client’s operational requirements. This was accomplished without sacrificing safety and quality and while also ending up on the positive side in terms of any monetary profit-making, stressing the effectiveness of these techniques if used correctly.

This study underpins support for the extant literature on the effects of activity overlapping and method substitution on project duration. However, it also underlines the need to effectively address the risks associated with them and adopt proper financial and resource management techniques so as not to aggravate costs, risks, or schedule issues. Returning to the discussion on schedule compression, the case study project was financially successful, and this success is attributed to the open financial discussion with the client, which was initiated as a result of the client's requirement to compress the schedule for their own operation benefit.

Succinctly, this work has practical and theoretical significance to construction project management. This paper gives insight into how theoretical knowledge can be applied in real-life situations and hints that, if well implemented, schedule compression can be effectively useful in meeting short deadlines without compromising on quality and safety issues. Despite the potential generalisability of the findings presented in this study, considerations regarding the context in which this study was conducted and the resulting limitations when applying them to other construction environments are warranted.

In general, this work makes substantial contributions to our understanding of how to appropriately employ schedule compression strategies in building projects, notably in the oil fields. The findings provide not only theoretical confirmation of past research but also practical recommendations for dealing with project restrictions in similar situations. This research could help future publications examine durations, costs, and safety objectives, as well as assist industry practitioners in meeting expectations, budgets, and safety criteria when completing their projects.

In addition, schedule compression's implications on quality, stakeholder satisfaction, and post-project performance metrics could all be the subject of future study. The adaptation of these methods to a different area or under various circumstances, such as the congested urban construction scene, with differing accessibility for client-contractor interaction, may also be the subject of future studies.

AUTHOR’S CONTRIBUTION

The author confirms sole responsibility for the following: study conception and design, data collection, analysis and interpretation of results, and manuscript preparation.

ETHICS APPROVAL AND CONSENT TO PARTICIPATE

The study was approved by the Basrah University Research Ethics Committee.

Research Ethics Committee Reference Number: FM/24/225

HUMAN AND ANIMAL RIGHTS

All human research procedures followed were in accordance with the ethical standards of the committee responsible for human experimentation (institutional and national), and with the Helsinki Declaration of 1975, as revised in 2013.