All published articles of this journal are available on ScienceDirect.

Sustainable Stabilization of Brown and Green Clays Using Industrial By-products

Abstract

Background

The disposal of industrial by-products and the rising cost of construction materials are critical issues globally, particularly in developing nations such as Jordan. Brown and green clay are considered problematic types of soft clay, as they fail to meet the necessary specifications for use in construction.

Objective

This study aims to assess the efficiency of Cement Kiln Dust (CKD) and Silica Fume (S.F.) as stabilizing agents for brown and green clays. The research explores how CKD and S.F. can be used as cost-efficient and eco-friendly alternatives to enhance the mechanical properties of soft clays, improving their viability for construction.

Methods

An experimental approach was used to investigate the impact of CKD and S.F. on brown and green clay stabilization. The study examines the effect of varying CKD and S.F. concentrations on the clays' plasticity, compaction, unconfined compressive strength, and consolidation properties. CKD was tested at four different levels (0%, 5%, 10%, and 15%), as was S.F. (0%, 5%, 10%, and 15%).

Results

The findings revealed a notable enhancement in the engineering properties and behavior of both brown and green clay, with reductions observed in the plasticity index (P.I.), compression index (Cc), compressive strength (qc), and maximum dry density (γd).

Conclusion

Adding 15% CKD to brown clay resulted in the most significant improvements after a curing period of 7 days based on the unconfined compressive strength test results.

1. INTRODUCTION

Soil is one of the most important and primary construction materials [1]. It is necessary to investigate the behavior of the foundation design and to consider the expansive properties of soft soils [2]. The high excessive settlements of soft clays, low strength, and high instability problems cause severe damage to the structures that are built above [3]. Moreover, the clay soil behavior changes in different seasons as changes in moisture content occur. In wet seasons, the voids are filled with water, while in dry seasons, they shrink as their voids lose water [4]. This extreme change in volume can easily cause huge damage to a home, building, or roadway. Some expansive soils can expand as much as 10% [5].

Soft clay soils cover large expanded areas in Jordan. Almost 40% of Amman city is covered with brown, green, and many other types of expansive clay soils. These deposits can reach a thickness of 6 meters of the ground [6].

The engineering characteristics of clay soil may be improved to make them suitable for many engineering applications. Improvement and stabilization of soil can lead to improvements in the engineering properties of soil by treating the soil with different enhancing products. Stabilization is accomplished by increasing the shear strength and the overall bearing capacity of the soil [7]. Stabilized soil means decreased permeability and reduced shrink/swell potential [8].

Often, soils are chemically treated to enhance the engineering properties of the soil, such as moisture content. Some previous research indicated that soil stabilization is accomplished by using different additives such as cement, lime, cement kiln dust, lime kiln dust, silica fume, fly ash, steel slag, and rice husk [9]. Adding some additive materials to clay soils will make compaction easier and reduce the plasticity index. Easier compaction helps in achieving the maximum dry density [10]. Also, having a reduced value for the plasticity index makes the soil more friable and workable by improving the critical water contents of the soil [11].

Jordan is one of the leaders in cement production in the global market. Today, Jordan has four leading cement production companies that produce double the locally needed cement [12]. A massive amount of cement is produced locally, and more than 4.3 billion tonnes of cement is produced annually all around the world. To supply this high demand for cement, a negative impact is placed on natural resources. Subsequently, the cement industry is one of the major sources of greenhouse gases (GHG) in the world. Therefore, it is necessary to minimize the amount of cement used in engineering applications [13].

In a study conducted by Sreekrishnavilasam et al. [14] in 2007, the effects of two types of fresh cement kiln dust (CKD) and one type of landfilled CKD on soil treatment were investigated. The results indicated that incorporating 10-20% CKD could effectively compact soil beyond its usual compaction limits. Similarly, Ghorab et al. [15] explored the use of CKD along with other industrial by-products for the chemical stabilization of soil, aiming to produce building materials. The durability of the samples was assessed through compressive tests, revealing that CKD could lead to cost-effective housing solutions and additional benefits.

Carlson et al. [16] evaluated the role of CKD in stabilizing two different soil samples, testing various proportions of CKD at 4%, 10%, 15%, and 20%. The laboratory findings showed enhancements in the unconfined compressive strength and drying rates of the CKD-treated samples. Ebrahimi et al. [17] researched CKD's potential for improving the stiffness of pavement and road surface gravel, testing CKD at concentrations of 0%, 5%, 10%, and 15%. Their results highlighted the positive effects of CKD on expansion and modulus changes during the curing phase.

Ismaiel [18] conducted research to enhance the geotechnical properties and mitigate swelling in expansive high-plasticity soil from Pliocene deposits in the El-Kawther quarter. Chemical stabilization using CKD and a combination of CKD and lime was employed. Soil samples were collected from the area, and both lime and CKD underwent chemical analyses. Scanning electron microscopy (SEM) was utilized to assess microstructural alterations before and after treatment. Various geo- technical properties, including plasticity, compaction parameters, unconfined compressive strength (qu), ultrasonic velocities, and free swelling, were measured. The optimal CKD content determined was 16%, which led to increased unconfined compressive strength after seven days of curing.

Imoh [19] showed that CKD can effectively reduce the reliance on cement for soil stabilization while improving soil strength, often yielding better results than traditional cement applications. This strength enhancement is attributed to the chemical reactions between CKD and clay soil particles. The effectiveness of CKD stabilization is influenced by its composition, particularly the presence of CaO, SiO2, alkali, and sulfate, as well as its particle size distribution.

Another environmentally and economically significant material in soil stabilization is silica fume, a highly pozzolanic by-product generated during the production of ferrosilicon alloys and silica metals. Recent studies have focused on the effects of silica fume as an additive in clayey soils to improve their geotechnical properties. Al-Zairjawi [20] conducted experiments to evaluate the shear strength and compaction properties of clayey soil with varying percentages of cement and silica fume, specifically at ratios of 2%, 4%, and 6%. The findings indicated a marked increase in unconfined compressive strength and optimum water content, rising from 80 kPa to 190 kPa and from 19% to 23%, respectively, when 6% silica fume was combined with 8% cement paste. This observation aligns with conclusions drawn by Kalantari et al. [21], who also emphasized the economic advantages of using silica fume instead of cement and noted the significance of a 90-day curing period for achieving adequate strength in stabilized soil.

Furthermore, a study by Al-Soudany [22] found that increasing levels of silica fume in the mixture led to reductions in the liquid limit, maximum dry unit weight, and plasticity index of soft clay soil while improving the California bearing ratio, swelling pressure, and unconfined compressive strength as silica fume content increased from 0% to 7%. The novelty of this study can be demonstrated through the number of tested samples and the variety of experimental tests conducted on them. Additionally, the green clay soil material is widely spread in Jordan, and only limited studies have been performed to investigate their soil stabilizing potentials. It is also worth mentioning that using green clay was confined to industrial cosmetics studies. Thus, this research studied the stabilization of green and brown clay despite the noticeable similarity between both soil types.

It should be noted that tire-derived aggregate (TDA) and emulsified asphalt represent promising applications for sustainable stabilization in construction and civil engineering [23-26]. TDA, made from recycled tires, offers enhanced mechanical properties and durability when used as a lightweight aggregate in various construction applications. It reduces waste and improves the performance of concrete and asphalt mixtures. Similarly, emulsified asphalt is an effective binder that can enhance stability and longevity for road surfaces and other structures. Together, these materials contribute to eco-friendly practices in construction by promoting the use of recycled materials and reducing the reliance on traditional aggregates, thus supporting sustainability in the industry. Regarding sustainability, using recycled plastic aggregates to replace natural aggregates in construction has been an eco-friendly potential alternative that may help reduce the ecological impact [27].

2. MATERIALS AND METHODS

This study was conducted over several phases to ensure a thorough and systematic approach to investigating brown and green clay stabilization using cement kiln dust (CKD) and silica fume (S.F.). A comprehensive literature review was performed initially to identify the challenges associated with the disposal of industrial by-products and the rising costs of construction materials in Jordan. Following this, an experimental approach was undertaken to assess the impact of varying concentrations of CKD and S.F. on the mechanical properties of the clays. Concentrations of CKD and S.F. at 0%, 5%, 10%, and 15% were tested to evaluate their effects on plasticity, compaction, unconfined compressive strength, and consolidation properties. This structured methodology effectively addressed the research objectives, culminating in findings demonstrating the potential of CKD and S.F. as cost-efficient and eco-friendly stabilizing agents for improving the viability of soft clays in construction applications.

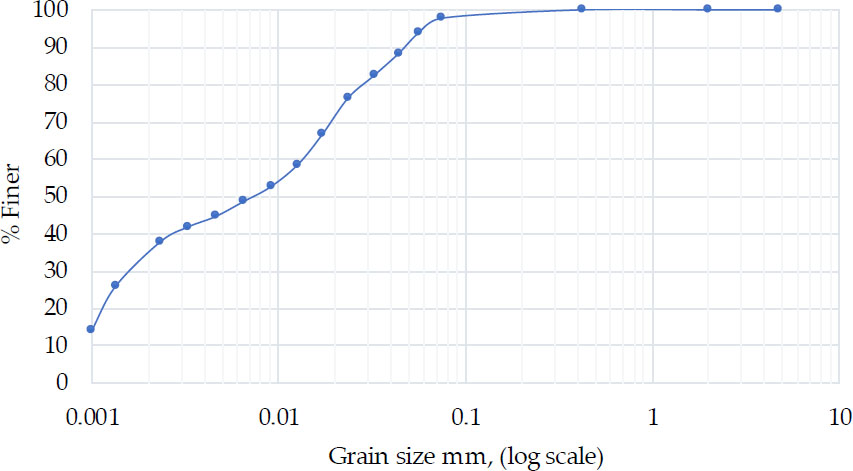

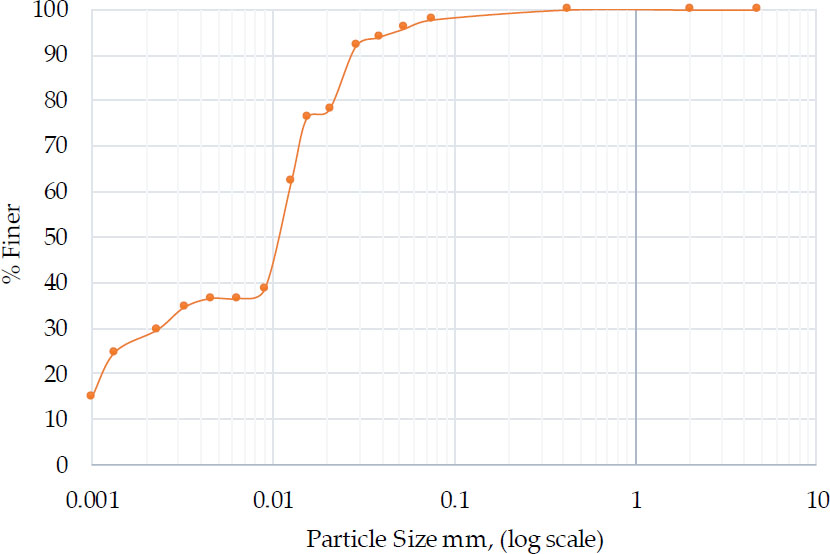

This study examines five materials: brown clay, green clay, silica fume, cement kiln dust, and water. The brown clayey soil was sourced from the Natural Resources Authority in Amman, Jordan, while the green clayey soil was collected from Al-Tafilieh City, Jordan. Standard testing procedures were conducted to assess the physical and chemical characteristics of both soil types, along with the two additives, CKD and silica fume (S.F.). The particle size analysis performed in this study utilized the traditional grain size distribution method. As illustrated in Fig. (1), the brown clay comprises 3.72% sand, 96.28% fines, and 0% gravel. Meanwhile, Fig. (2) presents the grain size distribution for the green clay, which consists of 2.23% sand, 97.77% fines, and 0% gravel.

Values for the specific gravity of the brown and green clay soil solids were determined by ASTM D854-14 [23]. The liquid limit was determined by the Casagrande method ASTM D4318-18 [28]. The plastic limit was also determined according to ASTM D4318-18 [28] specification. The soil was classified by using the Unified Soil Classification System (USCS). Table 1 shows the physical properties of both brown and green clay materials. Table 2 shows the chemical and physical properties of soil and soil stabilizer, which was performed at the Al-Ahliyya Amman University labs.

Grain size distribution for the brown clay material.

Grain size distribution for the green clay material.

| Property | Brown Clay | Green Clay |

|---|---|---|

| Specific Gravity, Gs | 2.69 | 2.7 |

| Gravel (%) | 0 | 0 |

| Sand (%) | 3.72 | 2.23 |

| Fines (%) | 96.28 | 97.77 |

| Liquid Limit (%) | 59.88 | 74.93 |

| Plastic Limit (%) | 29.20 | 33.29 |

| Plasticity Index (%) | 30.68 | 41.64 |

| USCS Classification | CH | CH |

| Activity (ASTM) | 0.81 | 1.41 |

| LOI (%)(ASTM) | 6.54 | 5.8 |

| Maximum Dry Unit Weight (kN/m3) | 13.73 | 14.22 |

| Optimum Moisture Content (%) | 25.15 | 22.54 |

| Maximum Dry Unit Weight (kN/m3) | 13.73 | 14.22 |

| Analyte | % | |||

|---|---|---|---|---|

| Brown Clay | Green Clay | Cement Kiln Dust | Silica Fume | |

| SiO2 | 60.41 | 42.89 | 5.84 | 79.52 |

| Al2O3 | 14.41 | 15.19 | - | - |

| Fe2O3 | 14.26 | 10.36 | 2.69 | 7.54 |

| CaO | 4.8 | 15.76 | 59.44 | 5.19 |

| SO3 | 0.51 | 9.97 | 0.59 | 1.23 |

| K2O | 2.71 | 4.10 | 17.10 | 3.02 |

| MgO | - | - | - | 2.48 |

| TiO2 | 2.33 | 1.35 | 0.29 | 0.16 |

| Cl | - | - | 13.40 | 0.22 |

| Loss on Ignition | 6.54 | 5.80 | 4.41 | 2.61 |

| Specific Gravity | 2.69 | 2.7 | 2.83 | 2.30 |

2.1. Testing Program

Disturbed soil samples were used in this work. First, the soil was oven-dried. The prepared samples were then mixed with the predetermined amount of stabilizer (i.e., CKD and S.F.). Past literature indicates that the typical dosage rates commonly used for CKD ranged between (0, 5, 10, 15, and 20) %, and for S.F., the typical percentage was 2, 4, and 6% by weight replacement. For this reason, the selected percentages of CKD and S.F. were 0, 5, 10, and 15% of the dry weight of the untreated soil. For each of the mentioned percentages, several tests were made to investigate the soil behavior after adding CKD and S.F.

3. RESULTS AND DISCUSSION

3.1. Results of Atterberg Limits test

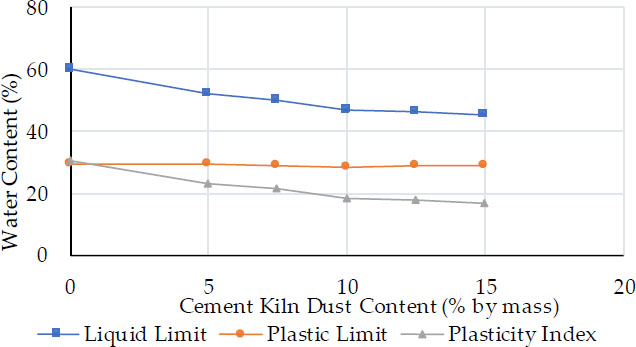

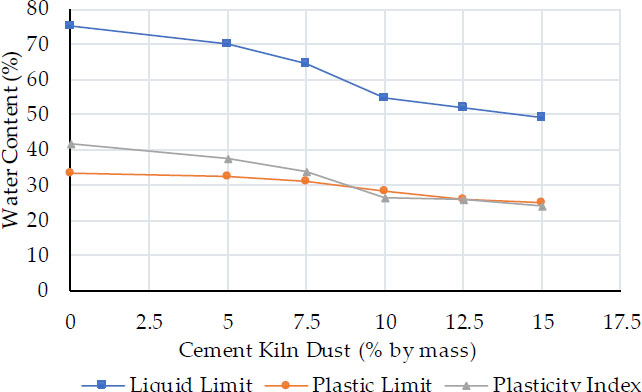

The effect of adding CKD to the soft soil (brown and green clay) on Atterberg limits is shown in Figs. (3 and 4). Three specimens were tested for each sample following the ASTM D4318-17 [29]. The results showed that the liquid limit exhibited a decrease while the plastic limit increased; this, in turn, decreased the plasticity index. The decrease in the plasticity index indicated that the soil exhibited an advantageous loss of plasticity in its characteristics. The measurable decrease in plasticity may be related to the reactions between the soil and CKD and mainly the high percentage of CaO in the soil mixture. The cation ion exchange of Ca+2 reactions in soil/CKD mix helps bond soil particles together and increase the attraction force, leading to the flocculation of particles. This bonding helps give an aggregated structure to the soil, which in turn explains the reduction in the plasticity of the soil [30]. It is also worth mentioning that along with the ion exchange reaction between the soil and the CKD, a crowding of additional ions around the clay particles causes a denser state of the soil to be reached. This denser state of the clay particles is a key factor in reducing the soil’s affinity to water. As the soil’s affinity to water is lessened, its resistance to water absorption and changes to volume due to varying moisture content is increased [31]. Therefore, a decrease in the swell and shrinkage potential is expected after the addition of the CKD to both types of clay. The fact that the plasticity of sampled soil was substantially reduced gives an important indication of CKD's usefulness as a soil stabilizer. The reduction of plasticity can lead to an increase in workability, which is beneficial when working with the sampled type of soil that is very common in Jordan. CKD reactivity is affected by additional factors to the ion exchange reaction. It is affected by its fineness as well as the presence of alkali and sulfate content [32].

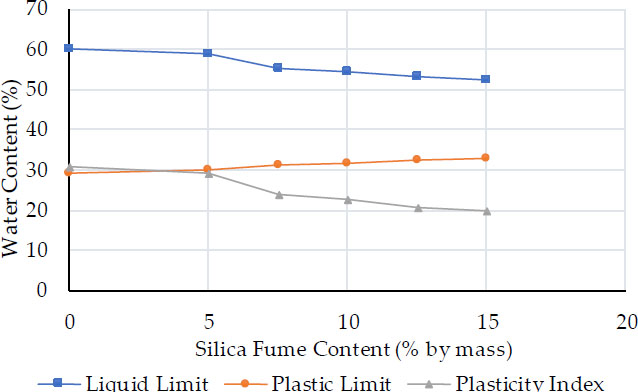

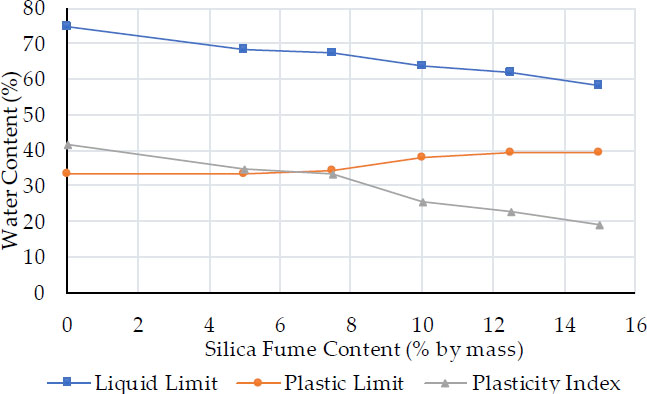

The influence of adding silica fume (S.F.) to soft soils, including brown and green clays, on the liquid limit (L.L.), plastic limit (P.L.), and plasticity index (P.I.) is presented in Figs. (5 and 6). The findings indicate that as the S.F. content increased, the L.L. decreased while the P.L. increased. Consequently, this led to a reduction in the P.I. as the S.F. content was raised.

The decrease in the plasticity index of both brown and green clay can be explained by several factors. One key reason is the replacement of highly plastic, expansive clay particles with non-expansive materials such as S.F. Adding S.F. to soft, expansive clays leads to the aggregation of particles, resulting in a reduction in both the liquid limit and plasticity index. Additionally, the silica fume creates a coating on the clay particles, binding them together. This occurs through a pozzolanic reaction between the S.F. and the aluminous compounds in the clay, further contributing to the reduction in L.L. and P.I. as more S.F. is incorporated.

Variations of Atterberg limits of brown clay with CKD%.

Variations of Atterberg limit of green clay with CKD%.

Variation of atterberg limit of brown clay with SF%.

3.2. Results of the Compaction Test

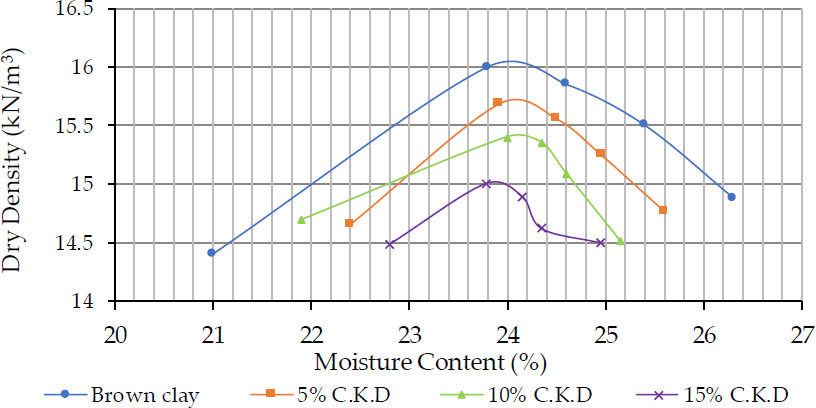

Fig. (7) shows the dry unit weight variation with moisture content for the brown clay and CKD samples. The compaction experiment results for soil-CKD mixtures, following the ASTM D698 [33], indicated that the dry unit weight of brown clay dropped from 16 kN/m3 to 15 kN/m3 when 15% of CKD was added. Meanwhile the moisture content increased from 21% to 26.3%.

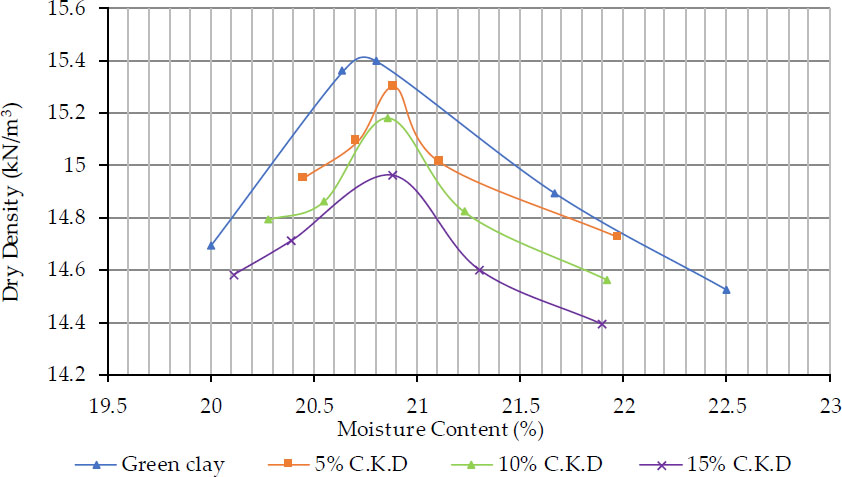

Fig. (8) shows the dry unit weight variation with moisture content for the green clay and CKD samples. According to bell-shaped compaction curves, the dry unit weight of the green clay reduced from 15.4% kN/m3 to 14.96% kN/m3 when 15% of CKD was added, and the moisture content increased from 20 to 22.5%.

The additional finer particles in the soil samples contribute to the increased moisture content value. With the addition of the chemical stabilizer (CKD), the dry density will decrease and the moisture content will increase as the soil particles will become larger, causing the void ratio to increase and the density to decrease [30, 34, 35]. When the soil particles become larger, a textural change will occur because of the soil particles being coated by CKD. This, in turn, will require additional water to coat the surface area and allow the chemical additive to perform the pozzolanic reactions. Also, the reduction in the maximum dry unit is due to the lower specific gravity value for soil mixtures containing CKD compared to natural soil.

Variation of Atterberg limit of green clay with SF%.

Variation of the dry unit weight with moisture content for brown clay with different CKD percentages.

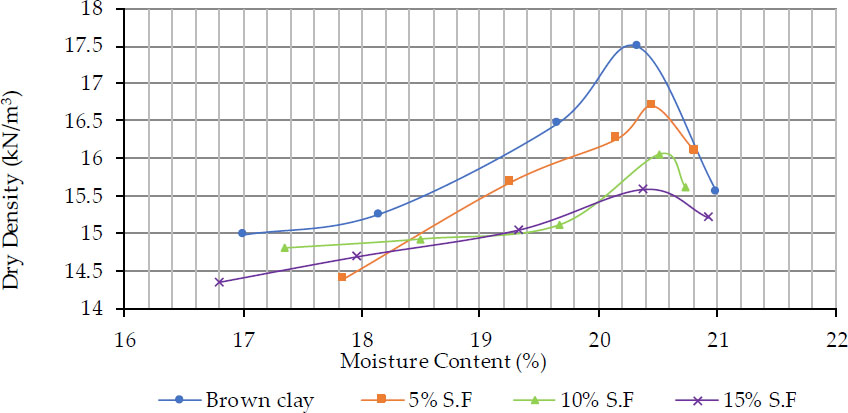

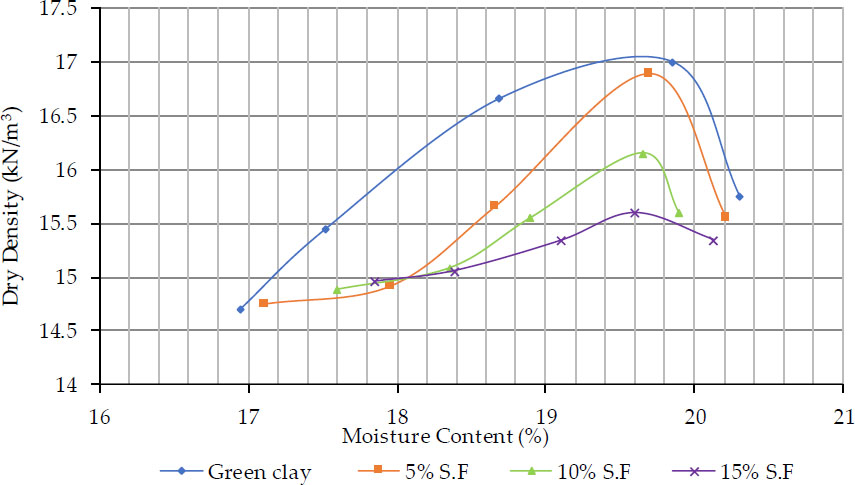

The results from the compaction experiments for the soil-silica fume (S.F.) mixtures revealed that the dry unit weight of the brown clay combined with S.F. decreased from 15.4 kN/m3 to 14.96 kN/m3 when 15% S.F. was incorporated. In contrast, the moisture content increased from 20% to 22.5% (refer to Fig. 9). For the green clay mixed with S.F., as illustrated in Fig. (10), the dry unit weight dropped from 17 kN/m3 to 15.6 kN/m3, while the moisture content rose from 16.8% to 20.3% with the addition of 15% S.F. These findings indicate that the increase in moisture content is a result of changes in the particle size distribution and surface areas of the silica fume-stabilized clay samples. Additionally, incorporating silica fume reduces the free silt clay fraction, leading to the formation of coarser material with a larger surface area, which requires more water for compaction. The decrease in maximum dry unit weight can also be attributed to the lower specific gravity of the soil mixtures containing CKD compared to natural soil. Fig. (11) displays the samples prepared for consolidation.

Variations of the dry unit weight with moisture content for green clay with different CKD percent.

Variations of the dry unit weight with moisture content for brown clay with different S.F. percentages.

3.3. Results of Unconfined Compression Test

3.3.1. Curing Results of the Brown Clay Specimens with Cement Kiln Dust

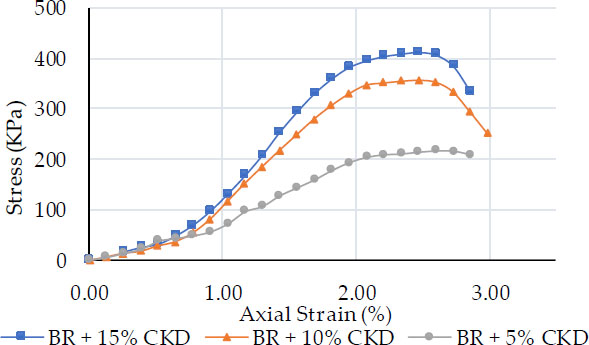

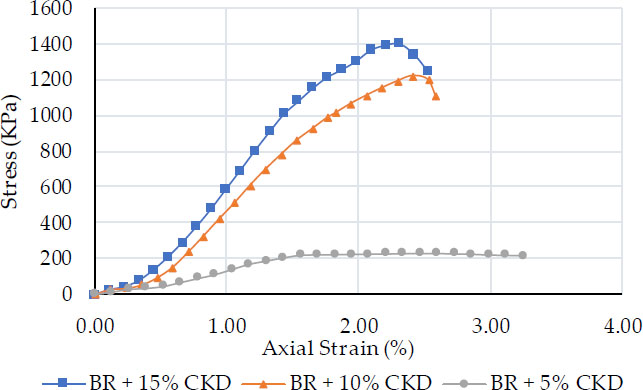

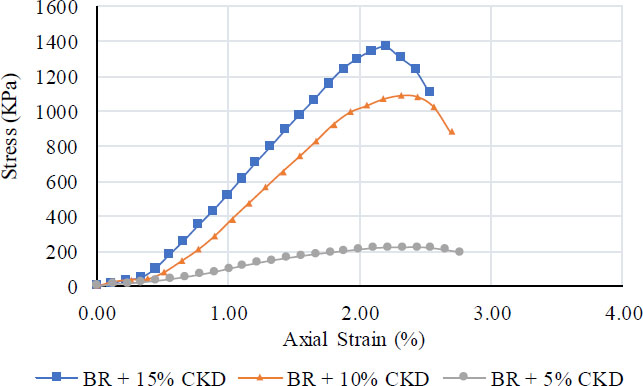

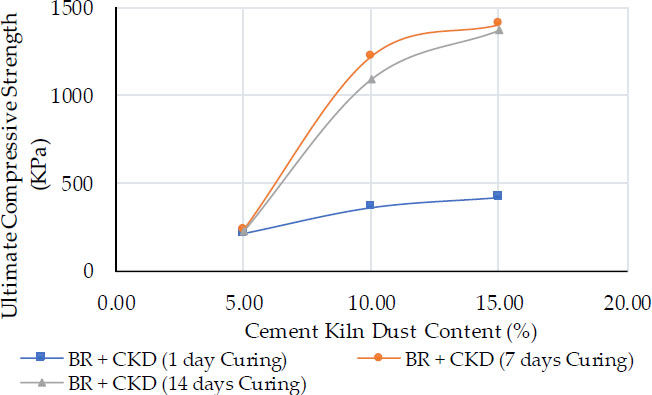

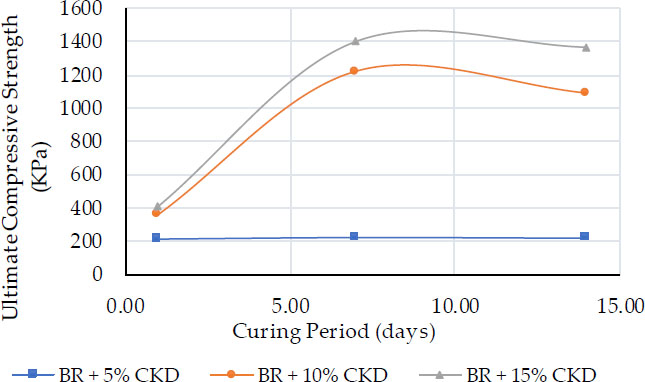

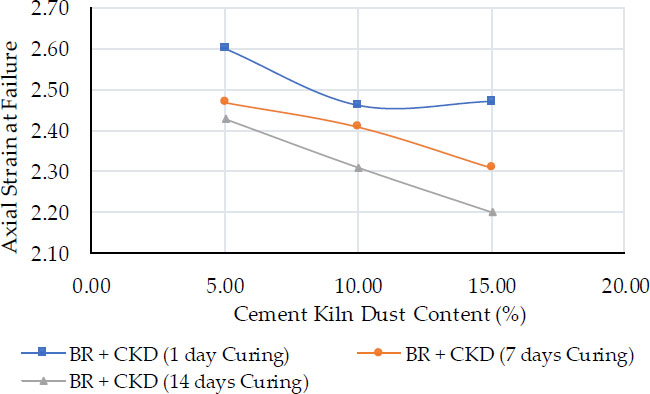

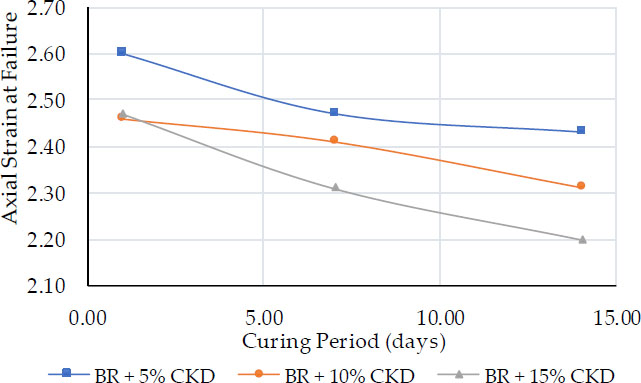

Figs. (12-18) illustrate the effect of cement kiln dust (CKD) on the unconfined compressive strength (UCS), showing the axial strain of brown clay over varying CKD percentages. The UCS results show a significant increase in strength from 410 kPa at one day to a peak of 1400 kPa at 7 days, followed by a slight decline to 1300 kPa at 14 days, suggesting that optimal bonding occurs within the first week. The axial strain at failure decreases as both CKD content and curing time increase, indicating that the soil becomes stiffer and more brittle with stabilization. Overall, these figures confirm that CKD improves the strength and stiffness of brown clay, making it more suitable for engineering applications, though higher CKD content reduces ductility.

Variation of the dry unit weight with moisture content for green clay with different S.F. percentages.

Consolidation samples.

Brown clay with cement kiln dust samples cured for 1 day.

Brown clay with cement kiln dust samples cured for 7 days.

Brown clay with cement kiln dust samples cured for 14 days.

Variation of ultimate compressive strength of brown clay with cement kiln dust content.

Variation of ultimate compressive strength of brown clay with curing periods.

Variation of axial strain at failure with cement kiln dust content.

Variation of axial strain at failure with curing periods.

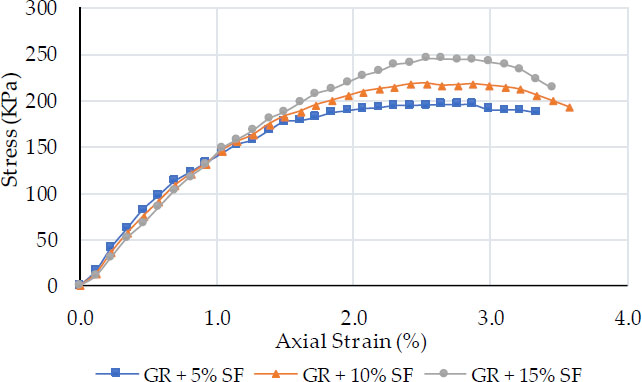

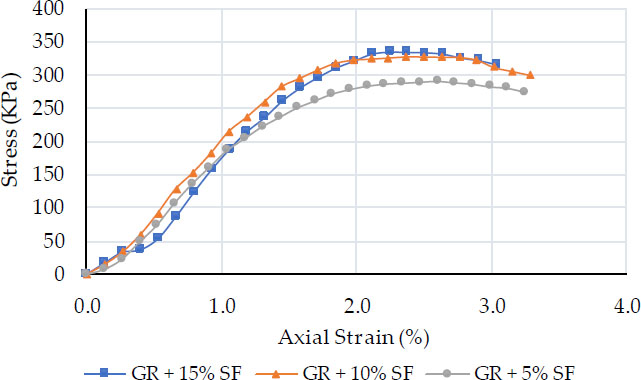

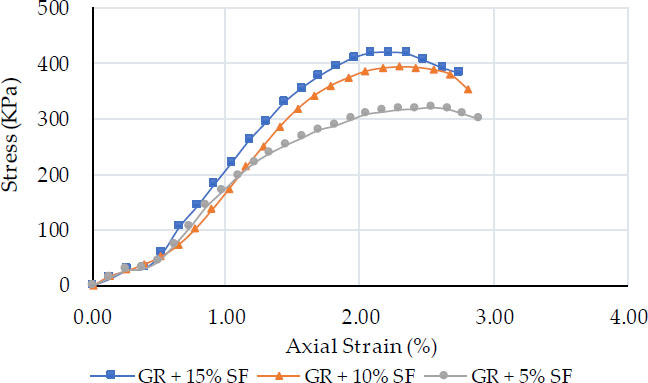

3.3.2. Curing Results of the Brown Clay Specimens with Cement Kiln Dust

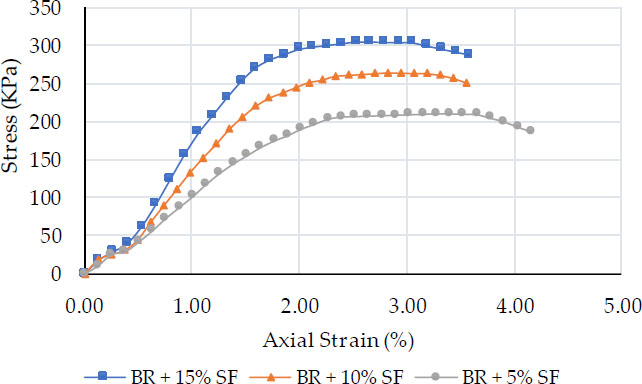

Figs. (19-25) illustrate the curing results of brown clay specimens treated with cement kiln dust (CKD). These figures detail various aspects of the curing process, showcasing the impact of CKD on the physical and mechanical properties of the brown clay over time. Fig. (19) presents the changes in moisture content, indicating how CKD influences water retention during the curing phase. Figs. (20 and 21) display the compressive strength and plasticity index variations, revealing significant improvements in the soil's load-bearing capacity and workability with increasing CKD content. Figs. (22) through Fig. (24) further explore the changes in swelling and shrinkage behavior, demonstrating CKD's effectiveness in mitigating expansive characteristics typical of brown clay. Finally, Fig. (25) summarizes the overall performance metrics, highlighting the enhanced stability and durability of the brown clay specimens treated with CKD, thus supporting its application in geotechnical engineering and construction practices.

Brown clay with silica fume cured for 1 day.

Brown clay with silica fume cured for 7 days.

Brown clay with silica fume cured for 14 days.

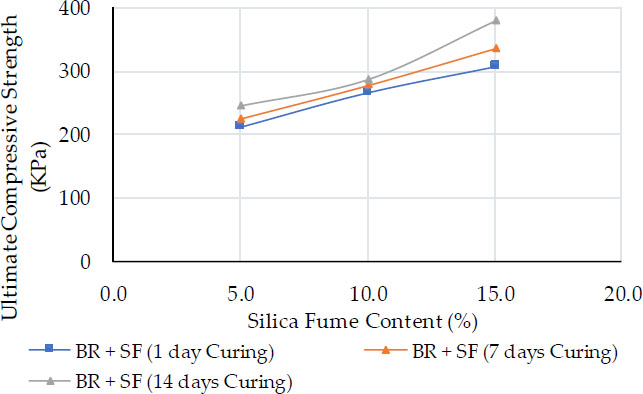

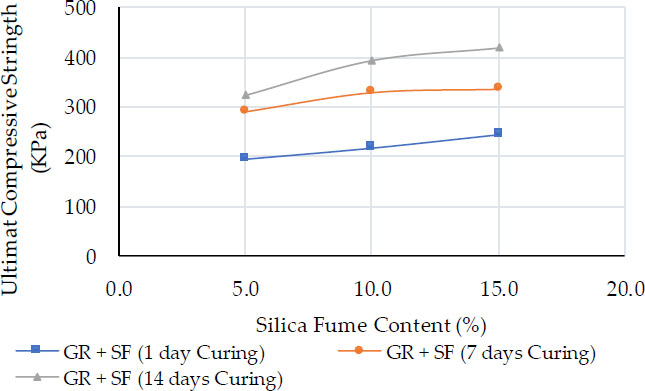

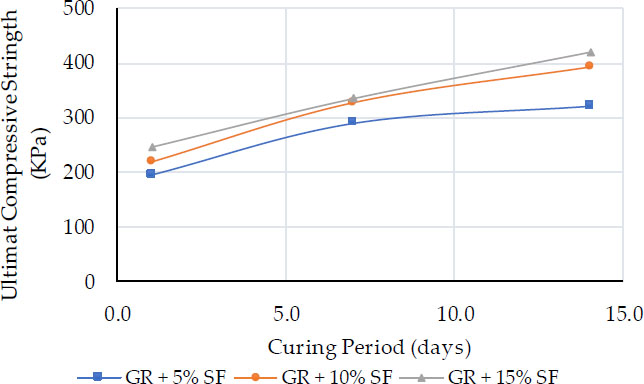

Variation of ultimate compressive strength of brown clay with silica fume content.

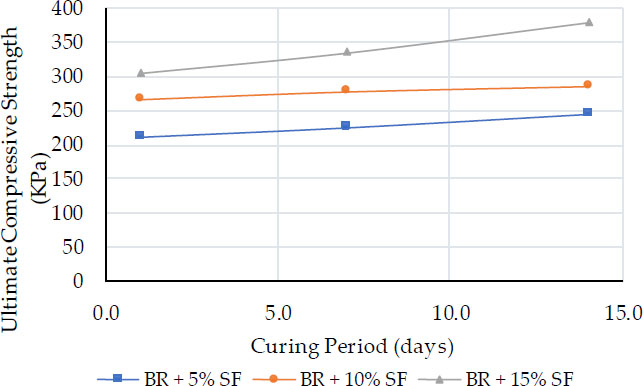

Variation of ultimate compressive strength of brown clay with curing periods.

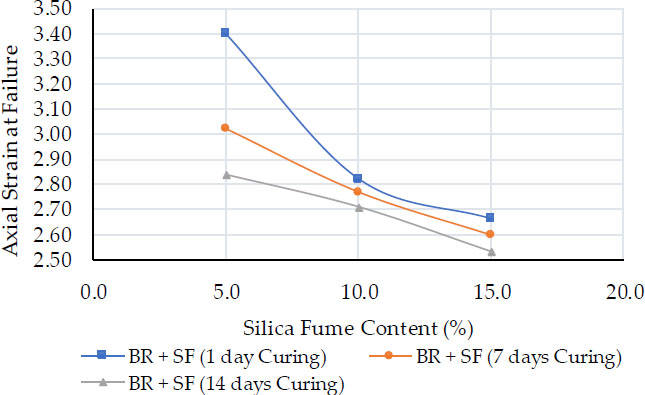

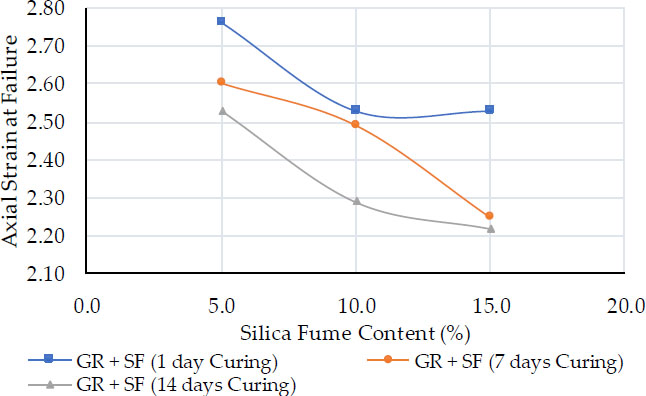

Variation of axial strain at failure with silica fume content.

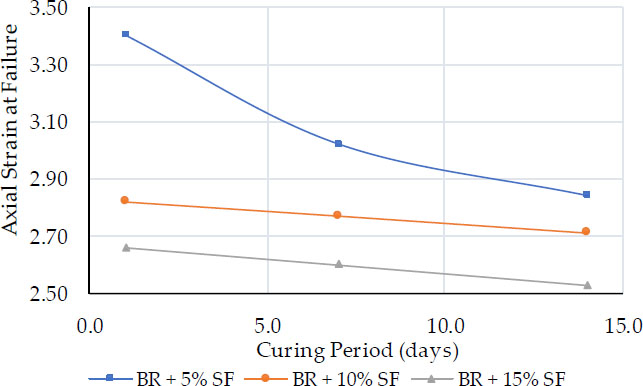

Variation of axial strain at failure with curing periods.

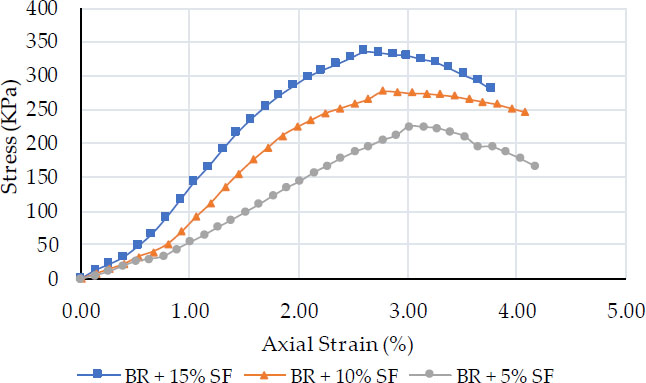

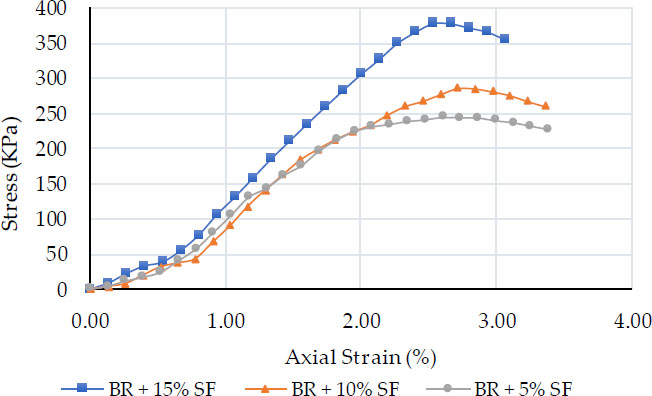

3.3.3. Curing Results of the Green Clay Specimens with Silica Fume

Figs. (26-32) present a comprehensive analysis of the mechanical and geotechnical properties of brown clay specimens treated with varying percentages of cement kiln dust (CKD). Specifically, Fig. (26) illustrates the relationship between CKD content and the unconfined compressive strength (UCS), indicating a notable increase in strength as CKD percentage rises, which underscores its effectiveness in stabilizing the soil. Fig. (27) further examines the effect of CKD on the soil's shear strength parameters, revealing enhanced cohesion and internal friction angles, suggesting improved resistance to shear failure. Figs. (28 and 29) focus on the variations in the Atterberg limits, demonstrating that the addition of CKD reduces the plasticity index and liquid limit, thus enhancing the workability of the brown clay. Figs. (30 and 31) showcase the results of the California Bearing Ratio (CBR) tests, illustrating a significant increase in load-bearing capacity, particularly beneficial for subgrade applications. Finally, Figs. (32-36) encapsulates the overall findings, confirming the positive impact of CKD treatment on the mechanical performance and stability of brown clay, making it a viable option for construction and geotechnical applications.

Green clay with silica fume cured for 1 day.

Green clay with silica fume cured for 7 days.

Green clay with silica fume cured for 14 days.

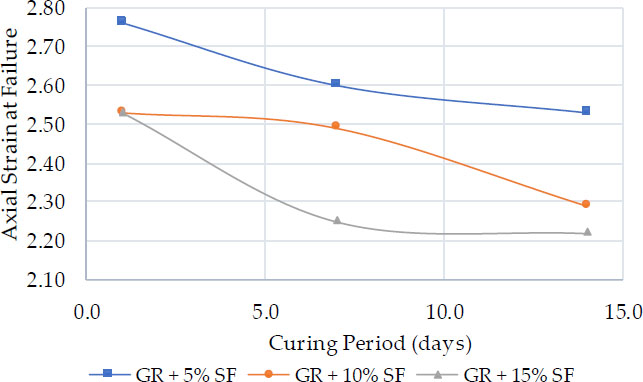

Variation of ultimate compressive strength of green clay with silica fume content.

Variation of ultimate compressive strength of green clay with curing periods.

Variation of axial strain at failure with silica fume content.

The unconfined compressive strength (UCS) is an adapted method to evaluate the strength of the soil. It is also an essential test to determine the amount of additive that should be used. UCS tests were performed on the brown clay/CKD, brown clay/S.F., and green clay/S.F. Green clay/CKD UCS test values were almost the same as obtained from the tests on the brown clay/CKD mixture.

From the figures above, one can notice that the peak stress increases whenever the curing periods are increased for S.F. mixtures. The effect of S.F. content on peak stress was the highest when the curing period was 14 days. Moreover, the effect of the curing period was the highest at the highest S.F. content used in the soil mixture (Brown and green clay). These results can be justified as follows:

When the curing period increases, the cementitious products developed in the soil mixture become stronger, which generates more resistance to the applied stress. The peak stress was the highest for the curing period of 14 days when S.F. was added to both soil mixtures.

However, the UCS test results for brown clay/CKD mixtures show an increase in strength during the curing period (7 days). This result can be explained by the progressive creation of the bonding material.

The peak stress values were 410 kPa, 1400 kPa, and 1300 kPa for the curing periods of 1 day, 7 days, and 14 days for brown clay with CKD, respectively. The values for brown clay with S.F. were 310 kPa, 349 kPa, and 385 kPa for the curing periods of 1 day, 7 days, and 14 days, respectively. The results for green clay with S.F. were 250 kPa, 348 kPa, and 440 kPa for the curing periods of 1 day, 7 days, and 14 days, respectively. All of these values were consistent according to the national standards.

Some of the results observed herein are intended to be discussed in depth by showing the chemical reactions and their effects, which caused a reduction in the OMC values under the presence of CKD and the slightly higher value noticed of the 7-day cured specimens UCS compared to that of the 14-day ones. This chemical reaction interpretation will be the point of investigation discussed in the upcoming paper, with the addition of the microstructural analysis that will be able to justify the above-mentioned test results.

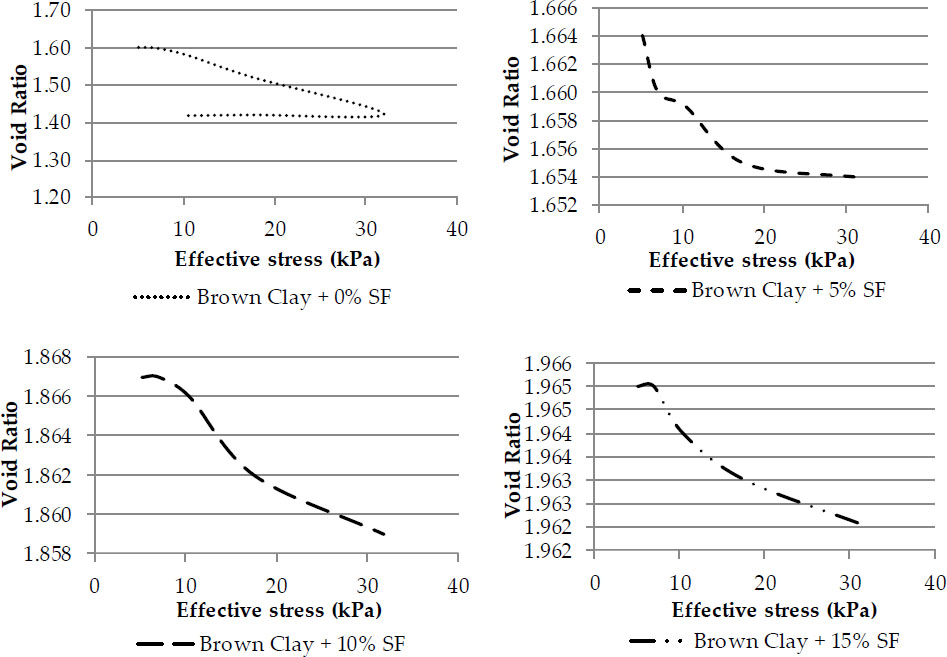

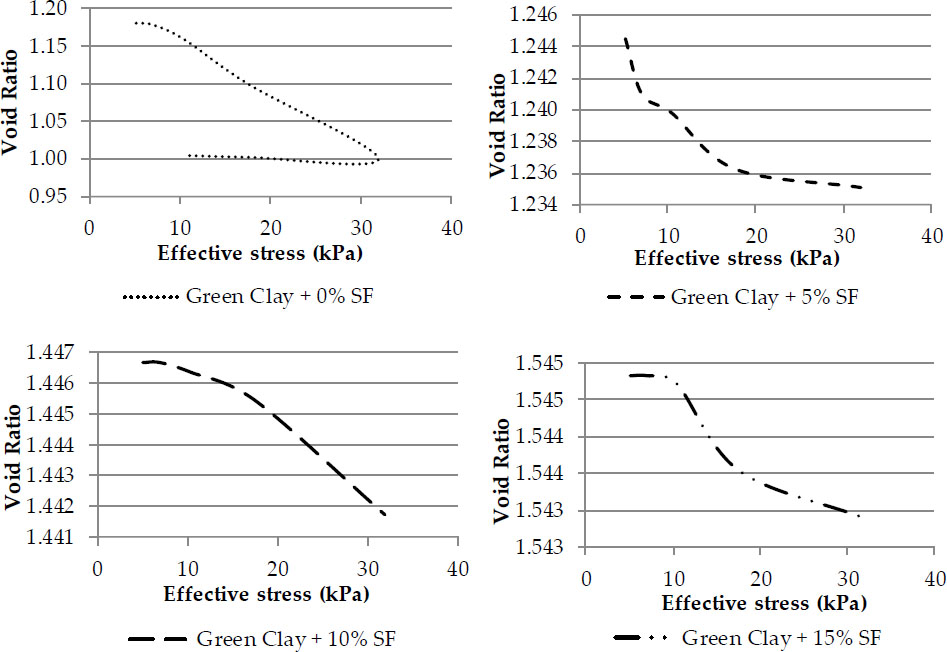

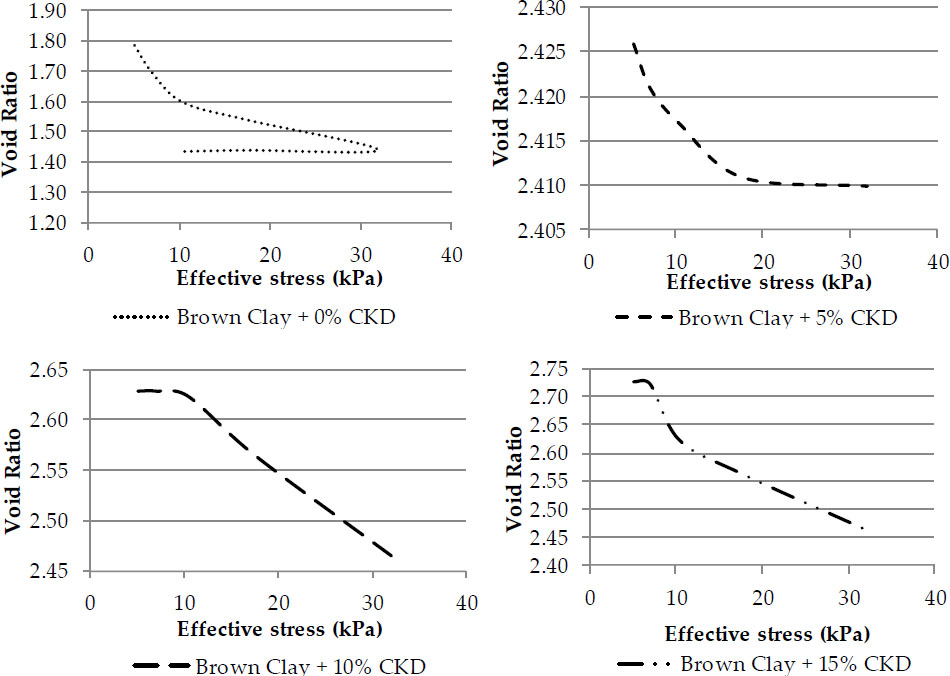

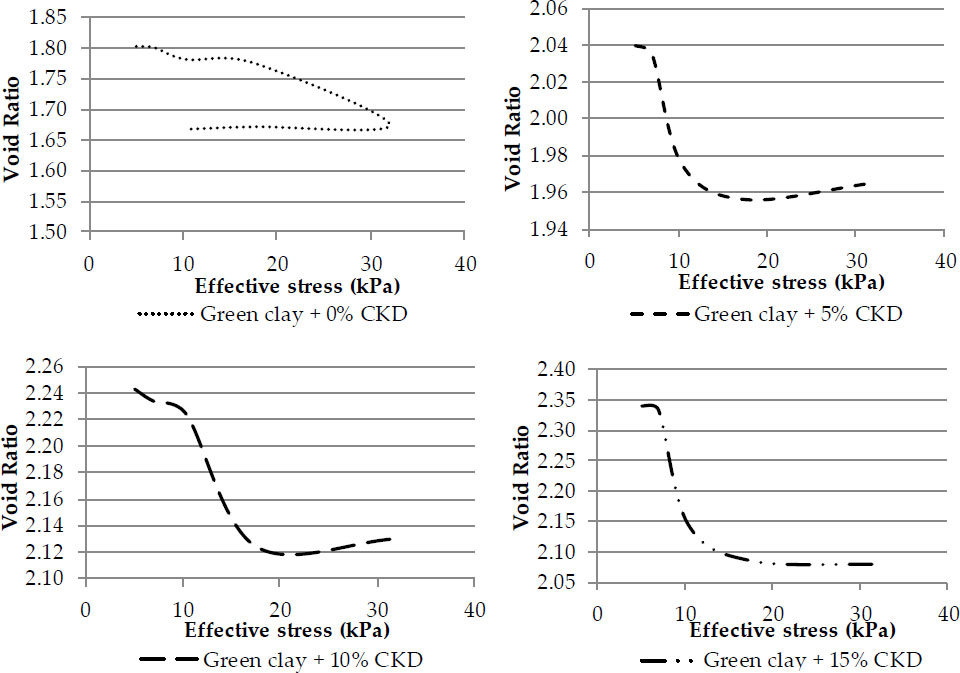

3.3.4. Consolidation Results

Figs. (33-36) present the effective stress versus void ratio for brown clay with S.F., green clay with S.F., brown clay with CKD, and green clay with CKD. Consolidation results show a decrease in the compression index, which indicates the elimination of large settlements experienced by such clayey soil in the field. This reduction in the settlement may be attributed to the pozzolanic reactions that take place between the soil and the S.F and due to S.F filling the voids between the soil particles.

This paper considers that the deformation amount to soil is equal to the volume of water discharged from the soil pores, and theoretically, it deduces the calculation method of soil consolidation degree with water content. The results show that the degree of consolidation calculated by water content is smaller than that calculated by deformation.

Variation of axial strain at failure with curing periods.

Effective stress vs. void ratio for brown clay with S.F.

Effective stress vs. void ratio for green clay with S.F.

Effective stress vs. void ratio for brown clay with CKD.

Effective stress vs. void ratio for green clay with CKD.

CONCLUSION

The experimental study discussed in this paper evaluates the use of brown and green clay materials with the addition of cement kiln dust and silica fume on the soil, stabilizing at different percentages. Based on the results, the following conclusions were drawn:

In this study, CKD and S.F. were able to successfully stabilize the soft clay soil (brown and green clay) used; the admixtures of both additives were able to reduce the liquid limit and the plasticity index of the soil tested in this study. This decrease in plasticity is likely due to the crowding effect of ions around the soil particle and also due to the flocculation and aggregation of the soil particles together, which increases the size of the particles.

The strength of the S.F. soil mixture (brown and green clay) was increased by increasing the additive content and the curing period. Peak stress was 440 kPa for the green clay/S.F. mixture at a curing period of 14 days. This is related to the progressive formation of cementitious materials. Peak stress was 1400 kPa for the brow clay/CKD mixture at a curing period of 7 days. This result can be explained by the progressive creation of bonding material.

The compaction experiment results for soil-CKD mixtures indicated that the maximum dry unit weight of brown clay dropped from 16 kN/m3 to 15 kN/m3, while the moisture content increased from 21% to 26.3% when 15% of CKD was added. According to bell-shaped compaction curves, the maximum dry unit weight of the green clay reduced from 15.4% kN/m3 to 14.96% kN/m3 and the moisture content increased from 20 to 22.5 when 15% of CKD was added.

The compaction experiment results for soil-SF mixtures indicated that the dry unit weight of brown clay + S.F. dropped from 15.4 kN/m3 to 14.96 kN/m3, while the moisture content increased from 20% to 22.5% when 15% of S.F. was added. The dry unit weight of the green clay + S.F. reduced from 17 kN/m3 to 15.6 kN/m3 and the moisture content increased from 16.8 to 20.3 when 15% of S.F. was added.

This reduction in dry density is related to resistance to compaction effort offered by the soil particle after the reactions between the soil and the chemical additives have begun. On the other hand, optimum moisture content slightly increased, which can be related to the nature of CKD and S.F. acting as a drying agent, which in turn requires slightly more water to be added to the mix to get higher density readings.

As a final note, the large quantities of industrial waste expected to be generated will likely pose a serious issue for the environment. Therefore, proper utilization of this combustion product as CKD as a soil stabilizer will likely help elevate any economic and health issues related to the disposal of such material and also aid in improving the quality of construction of many road networks and other engineering works in the country.

Further experimental studies on different materials, for instance, lime kiln dust, are needed to investigate their significance in the field of soil stabilization. Such material is considered an advantageous alternative for the cement kiln dust and silica fume since it works efficiently in fine-grained soil.

AUTHORS' CONTRIBUTION

M.A-J.: Methodology; R.I.: Data Collection; R.Al-S.: Writing the Paper; A.Al-Q.: Data Curation; M.K.: Data Analysis or Interpretation; A.B.: Writing - Reviewing and Editing; B.T.: Writing - Reviewing and Editing.

LIST OF ABBREVIATIONS

| CKD | = Cement Kiln Dust |

| S.F. | = Silica Fume |

| P.I. | = Plasticity Index |

| Cc | = Compression index |

| qc | = Compressive strength |

| SEM | = Scanning Electron Microscopy |

| GHG | = Greenhouse Gases |

| TDA | = Tire-Derived Aggregate |

| USCS | = Unified Soil Classification System |