All published articles of this journal are available on ScienceDirect.

Experimental Investigation of the Elastic Moduli of Existing Minangkabau Wooden Buildings using Non-Destructive Testing

Abstract

Introduction

The existing Minangkabau traditional wooden buildings that are more than 100 years old are commonly found in Tanah Datar Regency, West Sumatra Province, Indonesia. However, it is necessary to assess the residual strength of the wood to evaluate the main structural members, such as beams and main columns, which may have experienced a decrease in strength. The aim of this research is to carry out non-destructive testing to obtain the dynamic elastic moduli of the existing buildings.

Methods

Non-destructive testing was conducted using ultrasound technology specifically designed for wood. The members studied were the main columns and beams of the existing buildings. This study focused on the two existing Minangkabau wooden buildings located in Tanah Datar Regency.

Results

The test results for the first building yielded a dynamic elastic modulus (MoEd) of 14,600.8 MPa, with a standard deviation of 1,803.1 MPa and a coefficient of variation of 12.35% (0.1235). In comparison, the second building showed a dynamic elastic modulus of 11,108.52 MPa, with a standard deviation of 1,720.14 MPa and a coefficient of variation of 15.48% (0.1548). Additionally, the elastic modulus for the first building was 10,282.25 MPa, while the second building had an elastic modulus of 7,822.90 MPa.

Discussion

The results from this study indicated that the elastic modulus of the first existing building showed a trend of no significant decrease in strength. These results matched with visual observation that the tested columns and beams did not experience damage. In contrast, the test results for the second building indicated that the tested main beams experienced a decrease in strength due to damage, which ranged from 28.23% to 35.18%.

Conclusion

The non-destructive testing of existing timber buildings offers benefits, including providing recommendations for repairs and assessing structural members that need to be replaced due to strength degradation using the same quality or the same species of timber. This study suggests a non-destructive testing method for evaluating existing timber buildings.

1. INTRODUCTION

Wooden buildings that are built without special protection will generally experience a decrease in strength due to damage or weather influences. Traditional Minangkabau houses, which are numerous in West Sumatra Province, for example, in Tanah Datar Regency, include buildings built without special protection. After construction, the wood is typically painted but lacks additional protective treatment. Wood is susceptible to weather effects, so it is crucial to protect it from moisture. One of the protection methods is applying a layer of protective varnish to the exterior parts and structural members to create a barrier against the members. To preserve the natural appearance of the wood, it may be necessary to apply periodic treatments, such as transparent varnishes. These treatments protect the structural members from stains and fading.

The existing Indonesian traditional wooden buildings named Minangkabau that are more than 100 years old are commonly found in Tanah Datar Regency, West Sumatra Province, Indonesia. These buildings continue to function as residences. From a structural perspective, there is no significant damage even though there have been several earthquakes hitting the area. However, it is still necessary to check the remaining strength of the wood to evaluate main structural members, such as beams and columns, that may have experienced a decrease in strength due to the influence of weather, age, or other pest attacks. One of the assessment methods for investigating the residual strength of wood in existing buildings is the non-destructive method [1, 2] because this method does not cause damage to the existing structural members of buildings. This method was previously widely used to study the remaining strength of living trees to avoid the possibility of trees falling due to heavy rain or earthquakes [3, 4]. Non-destructive testing in the engineering field is not only used in building structures made from wood, but also in other materials [5-7].

This research aimed to carry out non-destructive testing to obtain the dynamic elastic moduli of the existing buildings.

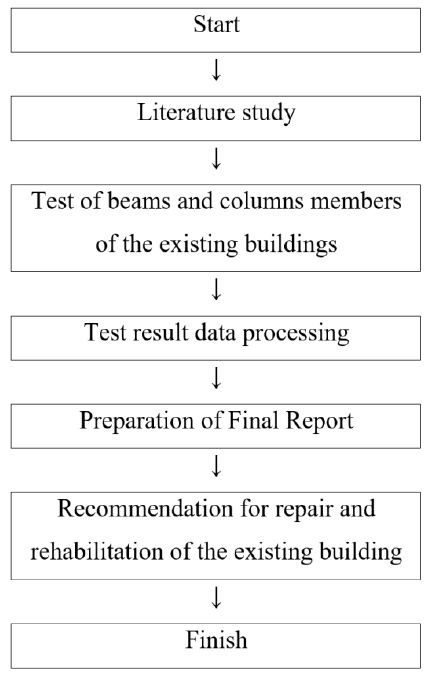

This research focused on traditional Indonesian wooden buildings, namely Minangkabau, located in Tanah Datar Regency, West Sumatra Province, Indonesia. Two existing buildings were studied, both classified as historic structures. The first building, Rumah Gadang Datuak Bandaro Kuniang (coordinates: -0.4617653266, 100.571 3323962), is shown in Fig. (1). The second building, Rumah Tuo Kampai nan Panjang Balimbiang (coordinates: -0.5224518903, 100.5699440901), is shown in Fig. (2). Non-destructive testing was conducted using ultrasound technology for wood quality assessment by employing the Sylvatest 4 [8] test equipment. The buildings members studied were the main columns and beams. To obtain consistent velocity data, the column and beam elements selected for testing had a dry moisture content ranging from 10% to 18% [2]. The temperature conditions in the area where the buildings are located are above 0°C, so the velocity test data do not require correction with an adjustment factor [2].

2. LITERATURE STUDY

2.1. Previous Research

Since the elastic modulus is an important parameter for designing compression members, tension members, flexural members, and connections in timber buildings, accurate prediction of its value is essential for building calculations and design. Research and development of testing equipment using non-destructive methods was initiated by Sandoz [9], who developed an instrument for grading construction timber using the ultrasound method.

The past research on wood testing using acousto-ultrasonics was carried out by Sandoz et al. [10]. This research highlighted several acousto-ultrasonic parameters for the non-destructive evaluation of timber strength. Technological developments and calibrations are expected to facilitate its industrial application in timber transformation, like defect detection and grading of timber. Acousto-ultrasonics has been used for the inspection and accurate grading of wooden pole networks in asset management [11]. Another previous study used non-destructive technology to evaluate the mechanical properties of timber in existing wooden historical monuments [12]. Research on the use of instruments with ultrasound wave-based methods is also complemented by the development of empirical equations to determine the ratio of dynamic elastic moduli to elastic moduli, as seen in the studies by Fabiana et al. [13] and Francesco et al. [14].

The first existing building, namely Rumah Gadang Datuak Bandaro Kuniang.

The second existing building, namely Rumah Tuo Kampai Nan Panjang, Balimbiang.

Ultrasound-based prediction of bending properties for several softwood species grown in Turkey was also conducted [15], with the results providing predictions of dynamic elastic moduli for these timber species. Additionally, research on the use of non-destructive techniques for the determination of the mechanical properties of wood from urban trees in Spain was also carried out [16].

2.2. The Ultrasonic Measurement and an Acousto-Ultrasonic Measuring Device

The ultrasonic method was first introduced in t 1985. This method, used for measuring the mechanical properties of timber (specifically elastic moduli), was validated for wood as a structural material. In 1989, technology transfer was achieved with the development of a non-destructive testing device named Sylvatest [8]. This device measures the speed of wave propagation in the main longitudinal direction of the wood.

The speed of propagation is correlated to the elastic moduli, while the energy is correlated to the knots, grain direction, degradation area, etc. Sylvatest is an acousto-ultrasonic measuring device that provides a diagnosis of the timber log, structural member of a building (for example, column and beam), or bridge element (for example, timber truss bridge), based on the speed of the transmitted ultrasonic wave.

There are two methods of registering the wave propagated by the material in non-destructive testing in terms of ultrasonic waves, which are indirect and direct methods. In the direct method, the time of transmitting a signal between the receiver and the transducer is measured. The instruments are placed on the opposite plane to the sample tested. In the indirect method, both the instrument heads are placed on the wooden surface (on the same plane) of the sample and register the reflected signal [17].

Some potential limitations of ultrasonic non-destructive testing methods, for example, potential measurement errors due to internal defects that cannot be detected by ultrasound, can be overcome by selecting a defect-free surface so that the wave propagation speed data transmitted by the transducer can be recorded accurately by the receiver. The influence of moisture content on the accuracy of test results is a major concern in this study. Therefore, the wood tested was wood with a dry moisture content in the range of 10% to 18% so that the velocity data results remained accurate [2].

2.3. The Dynamic Elastic Moduli

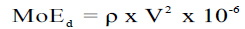

With the two parameters, which are the timber log's direct velocities (V) and the timber density (ρ), the dynamic elastic moduli can be calculated [17] using Equation 1, and the dynamic elastic moduli have a ratio to the static elastic moduli of 1.42 when the velocity is measured with ultrasound [14]. The static elastic moduli can be calculated using Equation 2:

|

(1) |

|

(2) |

Where: MoEd is the dynamic elastic moduli of the timber, ρ is the specific gravity or the timber density (kg/m3) at 12% of moisture content, V is the timber log’s direct velocities (m/s), and MoE is the elastic moduli of the timber.

2.4. Physical and Mechanical Properties of Johar Wood (Cassia Siamea Lamk)

Johar wood is a subfamily of Caesalpiniaceae that thrives in India, Indonesia, Malaysia, Philipines, Vietnam, Laos, and Thailand. In Indonesia, Johar wood is widely distributed in the areas of Java, West Nusa Tenggara, North Sumatra, and West Sumatra. Based on the literature, the specific gravity (average) of Johar wood is 0.805 (805 kg/m3) [18]. Meanwhile, previous research conducted by Nanjar [19] provided parameters for the physical properties of Johar wood (Senna siamea), including a specific gravity (G) of 0.69, equivalent to 690 kg/m3.

The elastic modulus of Johar wood is 116500 kg/cm2 or 11875.64 MPa, according to the International Tropical Timber Organization [20]. The previous research by Mulyani and Prawiroharmojo [21] indicated that the elastic modulus of Johar wood is 118400 kg/cm2 (12069.32 MPa). However, according to the Wood Database [22], the elastic modulus of Johar wood is 10900 MPa, and the average specific gravity is 0.71 (710 kg/m3). Meanwhile, according to Manthani and Fauzan [23], the elastic modulus of Johar wood is 11000 MPa, and the specific gravity is 800 kg/m3. A summary of previous research on the physical and mechanical properties of Johar wood is presented in Table 1.

2.5. Repair Method for Timber Building

In previous research, Jose outlined the principles for the restoration of existing wooden buildings [24]. The study demonstrated that it is possible to preserve difficult and demanding architectural construction while adhering to modern construction methodologies. This approach involves restoring structures using non-mechanical beam-to-column connections, as well as column and beam members made from wood of the same quality or species as the original.

Splice repairs [25] involve the simple substitution of defective elements in a timber structure with new members of the same species or quality, which are fitted to the old structures that have lost strength due to damage. When repairs are required for timber elements in an existing building, the repair process must be guided by the results of thorough diagnostic investigations, ensuring that the wooden elements in need of replacement are accurately identified.

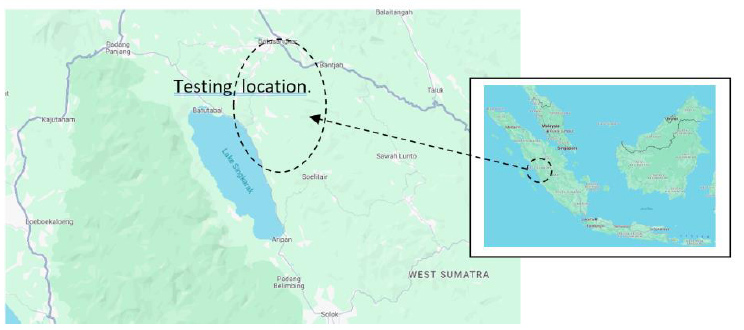

3. METHODS

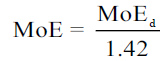

This study used a non-destructive testing method, with the test object being the column and beam components of the existing building. The purpose of the test was to obtain empirical data and facts on the wave propagation velocity, which were then converted into dynamic elastic moduli parameters. After the dynamic elastic moduli (MoEd) parameters were obtained, the next stage was to compare the dynamic elastic moduli of existing wood with the secondary data reference of the elastic moduli (MoE) of Johar wood (Cassia siamea Lam).

The results of the study provide information on whether the elastic moduli of the existing buildings remain within the range of undamaged wood or if they have experienced a decrease in strength. This information is very important to provide recommendations on whether to replace wooden components in existing buildings if there has been a decrease in strength or damage. The flowchart of the research is shown in Fig. (3).

Specimens for the non-destructive tests were the existing main columns and beams of the buildings, the first building, namely Rumah Gadang Datuak Bandaro Kuniang, and the second building, namely Rumah Tuo Kampai nan Panjang Balimbiang, where the sample points for placing the transducer and receiver were visually sorted to obtain defect-free parts. The location of non-destruction testing in Tanah Datar Regency, West Sumatra Province, Indonesia, is presented in Fig. (4).

Flowchart and method of research.

Location of non-destruction testing in tanah datar regency, West Sumatra province, Indonesia.

4. RESULTS AND DISCUSSION

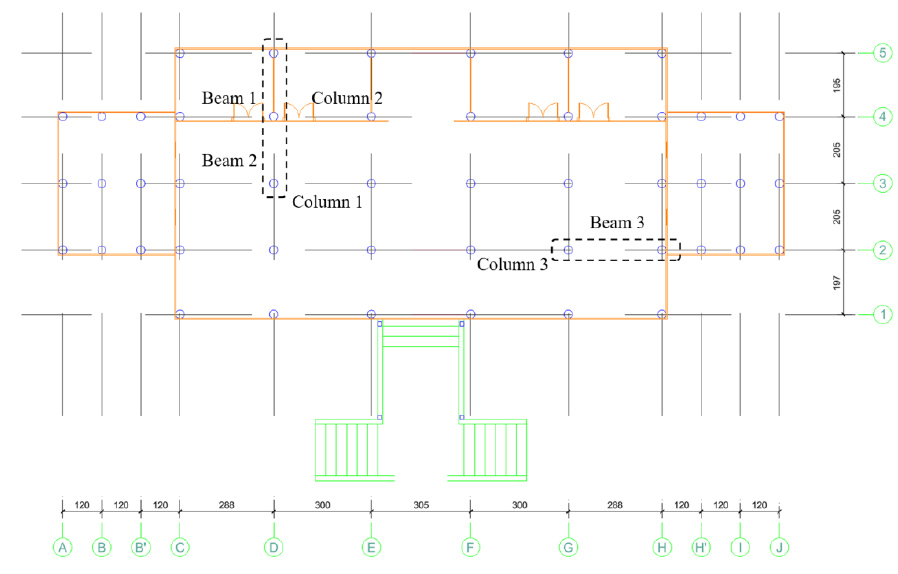

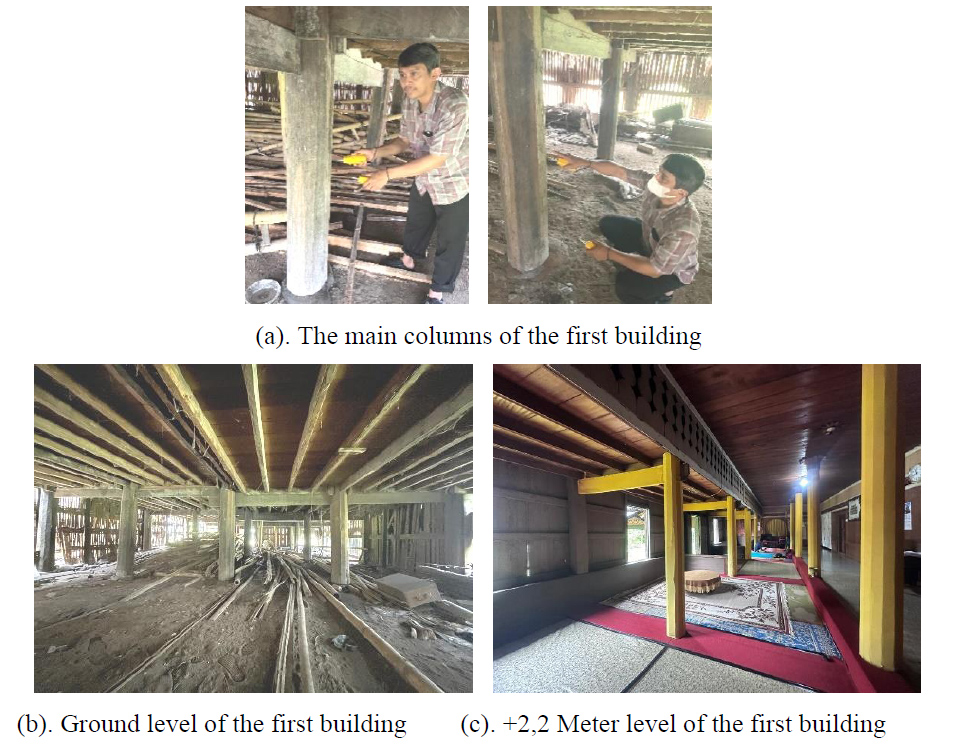

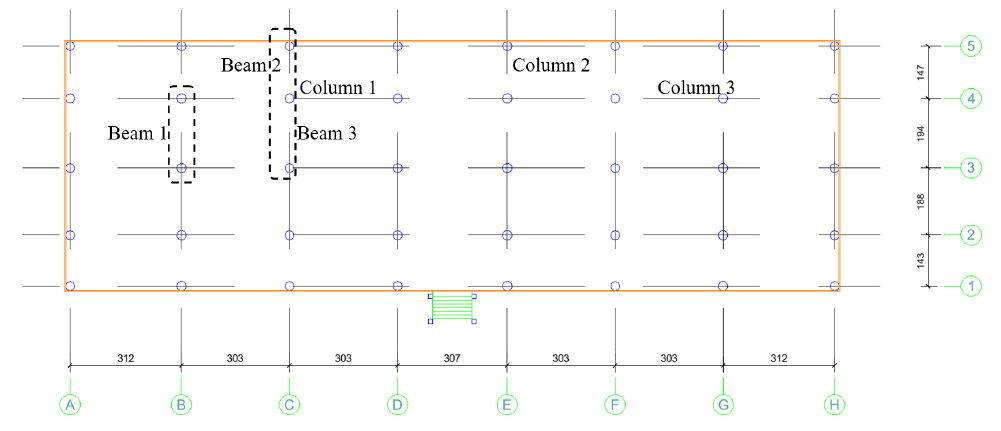

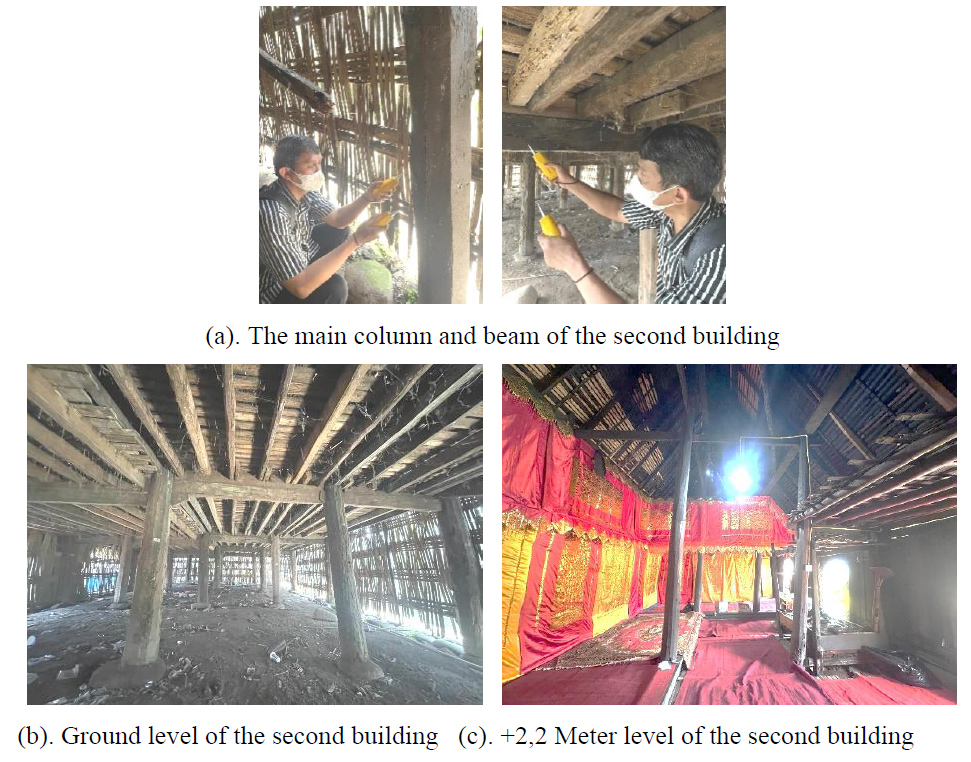

Two wooden buildings were studied. The first building had a floor plan, as shown in Fig. (5). Fig. (6) shows the testing process for the first building. The floor plan of the second building is shown in Figs. (7, and 8) depicts the testing process for the second building.

The floor plan of the first building. The main columns and main beams were tested.

The first existing building, rumah gadang datuak bandaro kuniang.

The floor plan of the second building. The main columns and main beams were tested.

The second existing building, rumah tuo kampai nan panjang balimbiang.

For both the first and the second buildings, the column members reviewed were 3 main columns, while for beam members, three main column members and three main beam members were reviewed. Each structural member was subjected to non-destructive testing at 9 test points. In total, there were 54 test points (each house). The main floor beams (both the first and the second buildings) were at a height of +2.2 meters above ground level. None of the main beams or column members were given a protective layer to facilitate easy testing. The indirect method was used for the test.

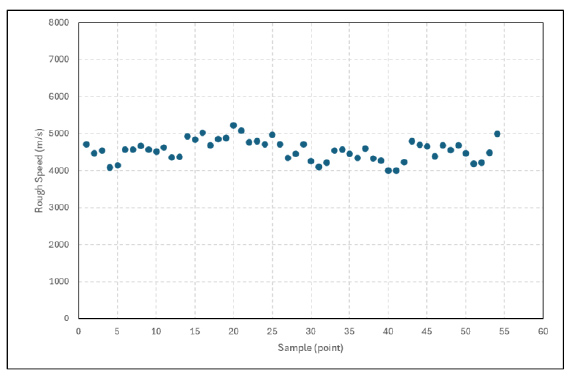

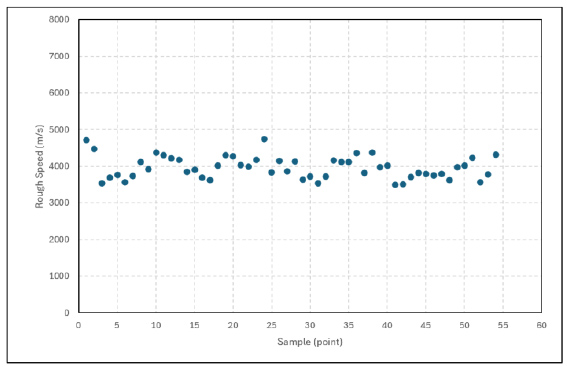

Both the transducer and receiver were not blocked by the surface layer of wood. The complete test results for the two buildings are shown in Fig. (9) (first existing building) and Fig. (10) (second existing building), representing the direct velocities (V) of the timber logs.

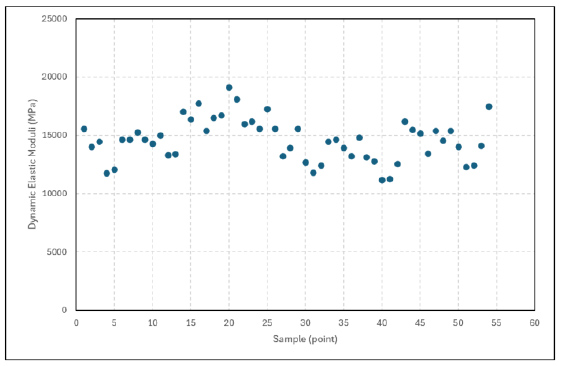

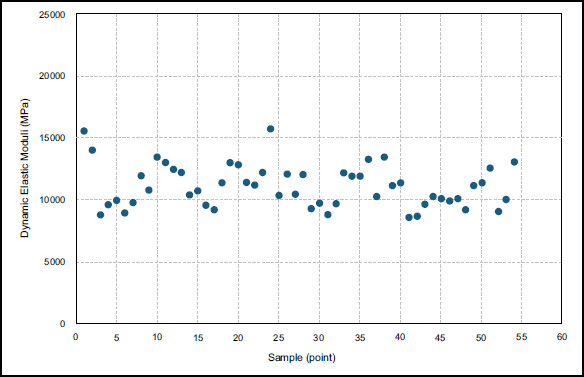

The test results generally indicated that the velocity (V) obtained ranged from 4000 m/s to 5226 m/s with a mean value of 4558.54 m/s, a standard deviation of 281.95 m/s, and a coefficient of variation of 6.19% for the first building, while for the second building, a velocity ranging from 3497 m/s to 4747 m/s was obtained with a mean of 3972.26 m/s, a standard deviation of 303.6 m/s, and a coefficient of variation of 7.64%. These results were then further processed into dynamic elastic modulus parameters using Equation 1. The complete calculation results are shown in Fig. (11) for the first building and Fig. (12) for the second building.

The first building and the second building are both made from Johar (Cassia siamea Lam.) timber, with the wood quality class being in the class I-II range based on the Indonesian Wood Atlas [26]. The test results generally indicated that the dynamic elastic modulus obtained was in the range from 11200 MPa to 19117.75 MPa with a mean of 14600.8 MPa, a standard deviation of 1803.1 MPa, and a coefficient of variation of 12.35% (0.1235) for the first building, while for the second building, a dynamic elastic modulus ranging from 8560.31 MPa to 15773.81 MPa was obtained with a mean of 11108.52, a standard deviation of 1720.14 MPa, and a coefficient of variation of 15.48% (0.1548). This coefficient of variation value was lower than the allowable limit of 25% (0.25) in accordance with the NDS timber code [27] and the SNI timber code [28], indicating accurate test results.

These dynamic elastic moduli (MoEd) values were then converted into elastic moduli (MoE) using Equation 2 [7]. The dynamic elastic modulus has a ratio of 1.42 to the static elastic modulus when the velocity is measured using ultrasound. The complete calculation results are presented in Table 2, indicating that the elastic modulus of the first existing building (Rumah Gadang Datuak Bandaro Kuniang) has a trend similar to the one observed in several studies [15-18]. These results matched with visual observation that the tested columns and beams did not experience damage.

However, the test results for the second building (Rumah Tuo Kampai nan Panjang) demonstrated a lower elastic modulus, indicating that the beams and columns selected for testing had experienced a decrease in strength with a relative difference of 28.23% to 35.18% lower than the reference [17, 16]. Based on visual observations during testing of the second building, there was indeed a decrease in strength because the main beams began to be damaged due to the influence of the weather.

Results of the velocities (rough speeds) obtained from non-destructive testing of the first existing building.

Results of the velocities (rough speeds) obtained from non-destructive testing of the second existing building.

| Existing Building | The Dynamic Elastic Moduli (MPa) | The Elastic Moduli (MPa) |

|---|---|---|

| Rumah Gadang Datuak Bandaro Kuniang | 14600.80 | 10282.25 |

| Rumah Tuo Kampai nan Panjang | 11108.52 | 7822.90 |

Results of the dynamic elastic modulus of the first existing building.

Results of the dynamic elastic modulus for the second existing building.

CONCLUSION

In this study, the first existing building (Rumah Gadang Datuak Bandaro Kuniang) had a dynamic elastic modulus of 14600.8 MPa with a standard deviation of 1803.1 MPa and a coefficient of variation of 12.35% (0.1235), while the second existing building (Rumah Tuo Kampai nan Panjang) had a dynamic elastic modulus of 11108.52 MPa with a standard deviation of 1720.14 MPa and a coefficient of variation of 15.48% (0.1548). This coefficient of variation value was found to be lower than the allowable limit of 25% (0.25), indicating accurate test results.

The first building had an elastic modulus of 10282.25 Mpa, while the second building had an elastic modulus of 7822.90 MPa. The results indicated that the elastic modulus of the first existing building demonstrated a trend similar to the reference, and there was no decrease in strength. These results matched with visual observation that the tested columns and beams did not experience damage. In contrast, the test results for the second building indicated that the tested main beams experienced a decrease in strength (ranging from 28.23% to 35.18%) due to damage.

This study employs a non-destructive testing method for evaluating existing buildings. This method was previously widely used to assess the remaining strength of living trees to prevent the risk of trees falling due to heavy rain or earthquakes. It offers several benefits, including recommendations for assessing building components that need to be replaced due to a decrease in strength using new wood of equivalent quality.

AUTHORS’ CONTRIBUTIONS

The authors confirm their contribution to the paper as follows: data collection: IN; data analysis or interpretation: OP; methodology: AS; draft manuscript: YP. All authors reviewed the results and approved the final version of the manuscript.

LIST OF ABBREVIATIONS

| V | = Timber log's direct velocities |

| G | = Specific gravity |

| ρ | = Timber density |

AVAILABILITY OF DATA AND MATERIALS

The data supporting the findings of the article is available in the [Zenodo Repository] at [https://zenodo.org/records/15493414/files/0418097801_NDTM.pdf?download=1], reference number [version v1].

FUNDING

This study was funded by Ministry of Education, Culture, Research, and Technology Funder ID: Regular Fundamental Research National Competitive Research (Awards/Grant number: 106/E5/PG.02.00.PL/2024).

ACKNOWLEDGEMENTS

Declared none.