RESEARCH ARTICLE

Analysis of the Vibration Isolation Effect of the Railway Rigid Sandwich Wall

Sun Chenglong1, 2, *, Gao Liang1

Article Information

Identifiers and Pagination:

Year: 2017Volume: 11

First Page: 121

Last Page: 130

Publisher ID: TOCIEJ-11-121

DOI: 10.2174/1874149501711010121

Article History:

Received Date: 05/8/2016Revision Received Date: 04/11/2016

Acceptance Date: 13/11/2016

Electronic publication date: 24/02/2017

Collection year: 2017

open-access license: This is an open access article distributed under the terms of the Creative Commons Attribution 4.0 International Public License (CC-BY 4.0), a copy of which is available at: https://creativecommons.org/licenses/by/4.0/legalcode. This license permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Abstract

The vibration isolation effect of the rigid sandwich wall was measured and the characteristics of time and frequency domain at low frequency was analyzed on the basis of the environmental isolation engineering of the railway in the Beijing suburb in this paper. The results indicated that environmental vibration significantly decreased after building the rigid sandwich walls. The vibration isolation efficiency of the rigid sandwich wall is respectively 0.32 and 0.46 at a distance of 35 meters and 40 meters away from railway center. It is obvious that a distance of 5 meters behind the vibration isolation barrier shows a more obvious vibration isolation effect than 10 meters. The vibration isolation barrier has an obvious effect in middle-high frequency (10~80 Hz) of the vibration, especially formed by sleeper spacing action rate (22.7 Hz). In addition, the effect is not obvious with a frequency below 10 Hz, such as the low frequency vibration formed by the moving axle load (7 Hz). In this paper, a vibration model of the earth-rigid sandwich wall was established. It also studied the effect of width, depth and position of the barrier on the vibration isolation, and provided the application condition and the setting requirement of key parameters for the rigid sandwich wall. These results provided the technical support for controlling projects of environmental vibration with rigid sandwich walls.

1. INTRODUCTION

In recent years, with the further development of high speed and heavy load railway, the negative impact of environmental vibration has become prominent increasingly. The complaints about environmental vibration of the railway have increased especially in the existing main railway lines. At present, there are three ways of railway vibration reduction at home and abroad, respectively at vibration sources, at the route of transmission path and using the protected body. Then, the vibration isolation at the source is one of the most common and effective methods that generally improve the track structure and the railway vehicle bogie to reduce the contact force between wheel and track. The abovementioned method is mainly used in the new, reconstruction and expansion projects of the railway. When the vibration attenuation measures still can’t meet the requirements, or environmental vibration exceeds the standard on the existing railway without reconstruction and expansion, setting the vibration isolation barrier on the vibration propagation path is one of the effective measures.

The railway vibration isolation barrier mainly includes the continuous vibration isolation barrier (isolation ditch, wall) and the non-continuous vibration isolation barrier (pile). Railway rigid sandwich wall is a kind of filling ditch which uses the larger impedance between different medium to reduce the vibration transmission. At present, the domestic and foreign scholars mainly study the railway vibration isolation ditch (wall) in theory. Foreign scholars, such as Yang. B and Hung. H [1], L. Andersen and S. R. K. Nielsen [2], Michele Buonsanti [3], Takemiya. H [4], and Domestic scholars, such as Liu [5], Zhai [6], Luo and Lei [7], established the numerical model by using the finite element method and the boundary element method to study the effect and rules of the vibration isolation barrier. The research results show that the good vibration isolation effect can be achieved when the vibration isolation barrier has a certain depth. In Switzerland, Germany and Japan, the vibration isolation trench test shows [8] when the depth of trench is 3~5m, the vibration isolation effect reaches 5dB in low frequency (6Hz~8Hz) in some of the test points around the railway.

The vibration isolation effect of rigid sandwich wall under typical conditions was measured through the field test of the ring railway in the Beijing eastern suburb. Moreover, the earth-isolation barrier vibration simulation model was established to analyze influence of the width, depth and location of isolation barrier theoretically and put forward the application condition and the key parameters’ requirements of rigid sandwich wall. The research results provide the technical support for the engineering of railway environmental vibration with rigid sandwich wall.

2. VIBRATION ISOLATION TEST OF THE RIGID SANDWICH WALL

Combining the rigid sandwich wall isolation engineering of the ring railway in the Beijing eastern suburb implemented by the China railway academy of sciences, the field vibration isolation test of rigid sandwich wall is carried out. The vibration response of the ground and the vibration isolation effect of the rigid sandwich wall are analyzed.

2.1. Test Condition

The vibration reduction effect of the rigid sandwich wall was tested on the direct method on the ring railway in the Beijing eastern suburb.

There are some parameters of the rigid sandwich wall. The depth is 8 m and the width is 4 m. The wall is made of C15 plain concrete, and the sandwich material is made of 0.6-metre-thick foam styrene. The concrete cover plate which is 0.2 m thick is set at the top of the foamed styrene, pouring into a whole with both sides of the concrete wall. The train with harmonious locomotive and four marshaling moves at speed of 50 km/h.

2.2. Arrangement of Measuring Points

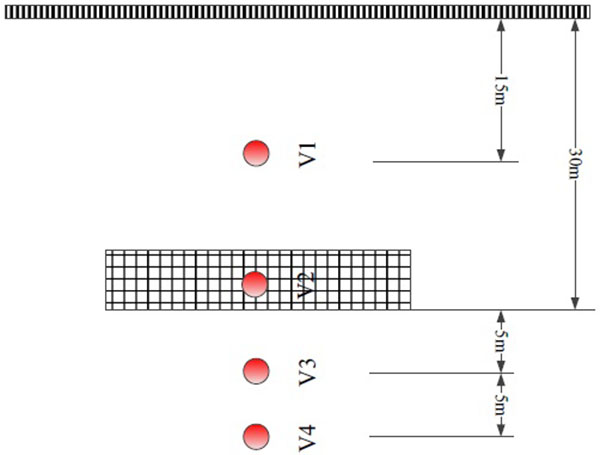

Four measuring points are arranged in the vertical direction of the railway. One of them is 15 m away from the railway as well as in front of the vibration isolation barrier and two points are apart from the railway 35 m behind the vibration isolation barrier, and last point is set on the vibration isolation barrier to test the change of vibration response after setting the vibration isolation barrier. The arrangement of measuring points is shown in Fig. (1). The field sampling frequency is 512 Hz. There are some field test facilities including the vibration pickup, the signal amplifier, the data acquisition instrument and the computer storage and analysis software. Table 1 shows key technical indexes of the vibration pickup and Fig. (2) shows field test facilities.

|

Fig. (1). Schematic diagram of measuring point layout of environmental vibration. |

|

Fig. (2). Pictures of field test facilities. |

| Gear technical indexes |

1 | 2 | 3 | 4 | |

|---|---|---|---|---|---|

| Acceleration | Low speed | Intermediate speed | High speed | ||

| Sensitivity | 0.3 | 23 | 2.4 | 0.8 | |

| Meter Full Scale | Acceleration (m/s2,0-p) | 20 | -- | -- | -- |

| velocity (m/s,0-p) | -- | 0.125 | 0.3 | 0.6 | |

| Displacement (mm,0-p) |

-- | 20 | 200 | 500 | |

2.3. Analysis Index

According to the Urban Regional Environmental Vibration Standards (GB10070-88) [9] and Urban Regional Environmental Vibration Measurement Method (GB10071-88) [10], the vertical Z vibration level VLzmax is used to evaluate the environmental vibration caused by rail transit and the acceleration amplitude attenuation coefficient is used to evaluate the vibration isolation efficiency of the vibration isolation barrier. is expressed as, where is the vertical acceleration amplitude of the observation point in the shield area after setting the vibration isolation barrier and is the vertical acceleration amplitude of the observation point before setting the vibration isolation barrier.

|

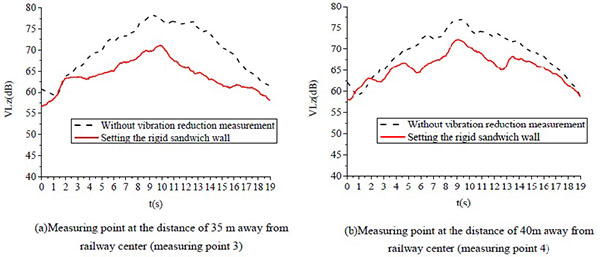

Fig. (3). Z vibration level time history diagram before and after setting rigid sandwich. |

2.4. Analysis of Vibration Isolation Effect

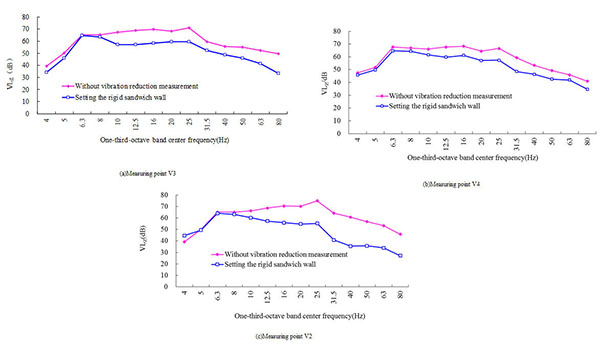

2.4.1. Analysis of Vertical Z Vibration Level

The vibration reduction effect of the rigid sandwich wall at the measuring point V3 and V4 is shown in Fig. (3) when the train passes. The Fig. (3) shows that the vibration level of the isolated area obviously decreased after setting the rigid sandwich wall. The vibration attenuation of Z vibration level is 6.0~12.0 dB and the average attenuation amount is 9.0 dB at a distance of 35 m away from the railway center. The vibration attenuation of Z vibration level is 3.7~8.2 dB and the average attenuation amount is 5.7 dB at a distance of 40 m away from the railway center. Obviously, the vibration isolation effect of 5 m away from the barrier is better than that of 10 m.

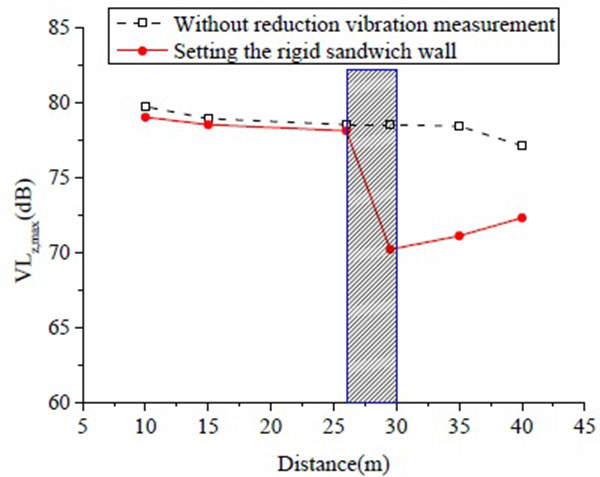

The maximum value VLzmax of the vertical Z vibration level is shown in Fig. (4) before and after setting the rigid sandwich wall. The Fig. (4) shows that the maximum value of the vertical Z behind the barrier decreased rapidly after setting the rigid sandwich wall. The maximum value of the vertical Z vibration level can be reduced to 7.3 dB at a distance of 35 m away from the railway center and to 4.8 dB at a distance of 40 m away from railway center. Due to the limitation of the depth and length of the isolation barrier, the vibration wave with longer wavelength is transmitted to the rear of the vibration isolation barrier by diffraction. There is an obvious shielding area behind the vibration isolation barrier. The closer the distance barrier, the stronger the effect of shielding vibration wave. Therefore, to ensure that the barrier has the appropriate length and width so as to reduce the diffraction of the ground vibration wave.

|

Fig. (4). Comparison of the vibration level before and after the rigid sandwich wall. |

2.4.2. Analysis of Vibration Isolation Efficiency

According to the test results, the effective values of the acceleration at 35 m and 40 m before and after setting the vibration isolation barrier are shown in Table 2. As shown in the table, the acceleration amplitude attenuation coefficient at the point of 35 m was 0.32 and is 0.46 at the point of 40 m. The vibration isolation effect of 40 m is lower than that of 35 m.

| Vibration isolation types | Measuring points | Without vibration isolation | With vibration isolation | ARF | |||

|---|---|---|---|---|---|---|---|

| Maximum | Average | Maximum | Average | Range | Average | ||

| Rigid sandwich wall | Measuring point at the distance of 35m away from railway center | 0.0188 | 0.0160 | 0.0062 | 0.0050 | 0.26~0.37 | 0.32 |

| Measuring point at the distance of 40m away from railway center | 0.0134 | 0.0111 | 0.0063 | 0.0051 | 0.35~0.55 | 0.46 | |

2.5.1/3. Frequency Doubling Analysis of Vibration Isolation Effect

In order to study the vibration isolation effect of the rigid sandwich wall at different frequencies, the acceleration response of 29 m, 35 m and 40 m apart from the railway is analyzed by 1/3 double frequency, 1/3 frequency doubling spectrum is shown in Fig. (5). As shown in the figure, when the frequency is less than 8 Hz, the vibration level curve of the vibration isolation barrier is almost coincident. That is, there is no vibration isolation effect. When the frequency is in the range of 8~80 Hz, the vibration isolation effect of the sandwich wall begins to appear and shows a trend of increasing with the increase of frequency. The results show that the vibration isolation effect of the rigid sandwich wall is not obvious in the low frequency band, but it has good vibration isolation effect in the middle and high frequency segments.

|

Fig. (5). 1/3 double frequency spectra of rigid sandwich wall. |

Before the rigid wall is set up, the energy of the ambient vibration is mainly distributed in the frequency range of 8~31.5 Hz, which reaches the peak at the frequency of 25 Hz. After the rigid wall is set up, the vibration of over 8 Hz is rapidly attenuated (attenuation is 4.0~10.8 dB at 35 m, and is 6.9~16.2 dB at 40 m).

3. PARAMETER OPTIMIZATION DESIGN OF THE RIGID SANDWICH WALL

Due to the limitations of the test conditions, the influence of the depth, width and the position of the vibration isolation barrier on the vibration response of the ground observation point is simulated through establishment of Earth-rigid sandwich wall finite element model in ANSYS finite element software. Then the vibration isolation effect under different conditions is analyzed to obtain the optimal combination of design parameters.

3.1. Finite Element Model of Rigid Sandwich Wall

Main geological parameters of railway environment are shown in Table 3.

| Layer number | Types | Thickness m |

Shear wave velocity m/s |

Compression wave velocity/ m/s |

Dynamic elastic modulus MN/m2 |

Dynamic Poisson's ratio | Density kg/m3 |

Damping ratio |

|---|---|---|---|---|---|---|---|---|

| 1 | Mixed backfill soil | 0~3 | 173 | 356 | 139 | 0.35 | 1650 | 0.02 |

| 2 | Silt Clay | 3~18 | 235 | 473 | 308 | 0.33 | 2010 | 0.02 |

| 3 | Pebble and Round gravel | 18~100 | 332 | 620 | 670 | 0.29 | 2050 | 0.02 |

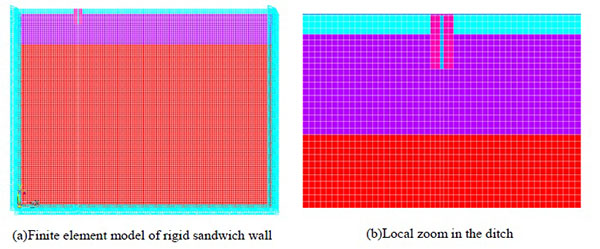

The rigid sandwich wall is continuous barrier, which can be calculated according to the plane model whose length is 120 m and width is 100 m. The finite element model adopts plane 42 element and meshing grid length is 1 m. The right boundary, the bottom boundary and the left boundary of the model are all made of viscoelastic artificial boundary so as to simulate infinite foundation. The coupled dynamic analysis model of the earth-rigid sandwich wall is shown in Fig. (6).

|

Fig. (6). The model of rigid sandwich wall. |

3.2. The Model Verification

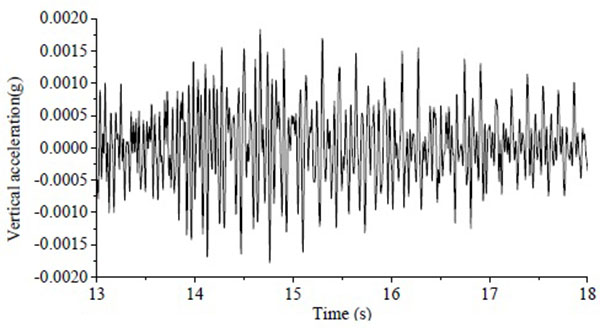

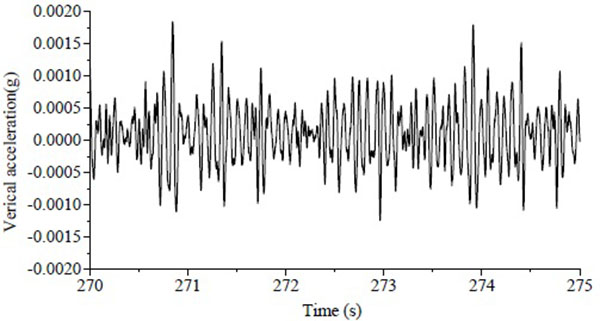

The speed of train is 13.6 km/h based on the actual measurement. The vertical acceleration of earth at a distance of 28 m from the center line of railway is selected to demonstrate the validity of the software. Figs. (7 and 8) show earth vertical acceleration time history curve according to the numerical simulation and the actual measurement respectively. The results show the magnitude of the simulation data is the accordant with the test data and the maximal amplitude is about 0.0015 g. Table 4 shows the maximum value VLzmax of the vertical Z vibration level in the condition of different distance away from the railway. The comparison result shows the maximum Z vibration level measured is in good agreement with the simulation data.

|

Fig. (7). The simulation data of earth vertical acceleration time history at a distance of 28.8 m from the center line of railway. |

|

Fig. (8). The test data of earth vertical acceleration time history at a distance of 28.8 m from the center line of railway. |

| Maximum value VLzmax | Distance from the center line of railway/m | |||

|---|---|---|---|---|

| 28.8 | 30.75 | 32.7 | 42.52 | |

| Test value/dB | 75.20 | 74.1 | 73.23 | 71.23 |

| Calculated value/dB | 75.03 | 73.12 | 72.71 | 72.17 |

Above all, according to the comparison of the acceleration time history based on the simulation data and test data which the barrier is separately located in the 28.8 m from the center line of railway and other distance, the model is effective. The model is used to simulate the effect of the vibration attenuation in different conditions.

3.3. Analysis of Key Parameters

3.3.1. The Influence of the Depth of Rigid Sandwich Wall

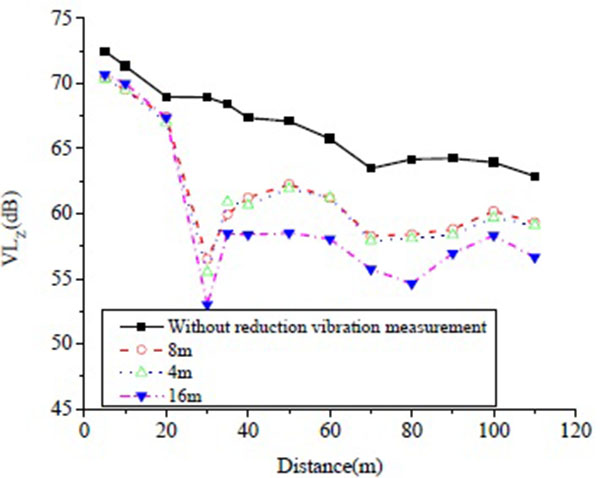

The width of the sandwich wall is 4 m and the thickness of the sandwich layer is 0.6 m, which is set at 26 m away from the railway. Considering three kinds of working conditions, the depth of the core wall is respectively 4 m, 8 m and 16 m. Comparison of vibration level of the sandwich wall with different depth is shown in Fig. (9). As shown in the figure, the vibration isolation effect of the sandwich wall whose depth is 8m is almost the same with that the depth is 4 m. It is shown that the depth of the sandwich wall only increases in a certain range and the effect of the vibration reduction is obvious. Moreover, selecting the depth of the rigid sandwich wall should consider the factors such as the cost and construction.

|

Fig. (9). Comparison of vibration level of sandwich wall with different depth. |

3.3.2. The Influence of the Width of the Rigid Sandwich Wall

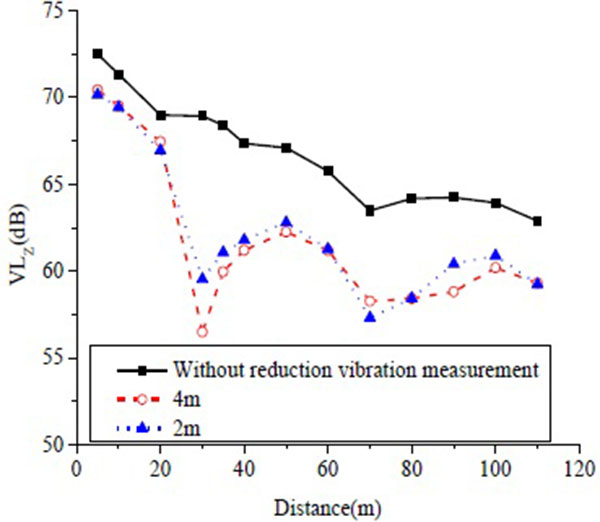

The depth of the sandwich wall is 8 m and the thickness of the sandwich layer is 0.6 m, which is set at 26 m away from the railway. Considering two kinds of working conditions, the width of the core wall is respectively 4 m and 2 m. Comparison of vibration level of sandwich wall with different width is shown in Fig. (10). As shown in the figure, the difference of the vibration reduction is small. Therefore, the increase of vibration reduction effect is not obvious with the increase of the width of the sandwich wall. And the cost of the project would increase exponentially and the area would increase with the increases of the width of the rigid sandwich wall. So the width of the rigid sandwich wall should be decided firstly before considering other key factors to achieve the ideal isolation effect of the barrier.

|

Fig. (10). Comparison of vibration level of sandwich wall with different width. |

3.3.3. The Influence of the Position of Rigid Sandwich Wall

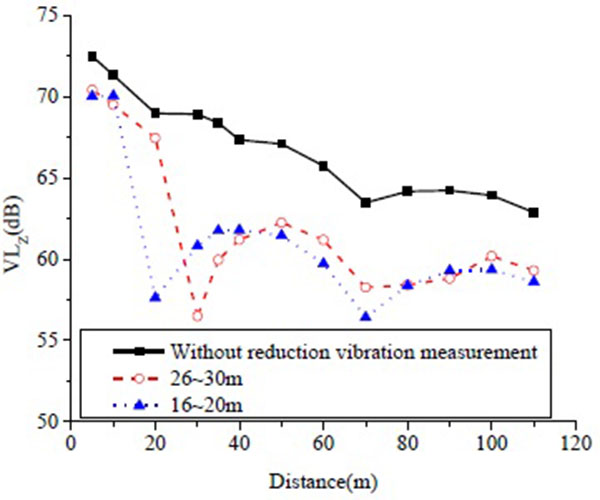

The depth of the sandwich wall is 8 m, the width of the sandwich wall is 4 m and the thickness of the sandwich layer is 0.6 m. Considering two kinds of working conditions, the position of the core wall is separately 16 m and 26 m apart from the railway. Comparison of vibration level of the sandwich wall with different position is shown in Fig. (11). As shown in Fig. (11), the vibration isolation effect which the rigid sandwich wall is located in the 26 m is better than that is located in the 16 m at a distance of 30 m~45 m from the railway; the vibration isolation effect which the rigid sandwich wall is located in the 16 m is better than that is located in the 26 m at a distance of 45 m~80 m from the railway. Obviously, the effect of position of the rigid sandwich wall on the vibration isolation is not stable. The closer the position of the rigid core sandwich wall to the protected body is the better the damping effect.

|

Fig. (11). Comparison of vibration level of sandwich wall with different position. |

CONCLUSION

The vibration isolation effect of the rigid sandwich wall was measured under typical operating conditions and the influence of the parameters of the rigid sandwich wall on the vibration isolation effect was analyzed. The conclusions are drawn as follows:

- The vibration level of the isolated area is obviously decreased after setting the rigid sandwich wall. The vibration attenuation of Z vibration level is 6.0~12.0 dB, the average attenuation amount is 9.0 dB at a distance of 35 m from the railway center. The vibration attenuation of Z vibration level is 3.7~8.2 dB and the average attenuation amount is 5.7 dB at a distance of 40 m from the railway center.

- When the frequency is less than 8 Hz, the vibration level curve of the vibration isolation barrier is almost coincident whether there is the vibration isolation barrier. That is, there is no vibration isolation effect. When the frequency is in the range of 8~80 Hz, the vibration isolation effect of the sandwich wall begins to appear and shows a trend of increasing with the increase of frequency. The results show that the vibration isolation effect of the rigid sandwich wall is not obvious in the low frequency band, but it has good vibration isolation effect in the middle and high frequency segments.

- The depth of the sandwich wall only increases in a certain range and the effect of the vibration reduction is obvious. Moreover, selecting the depth of the rigid sandwich wall should consider the factors such as the cost and construction.

- The increase of vibration reduction effect is not obvious with the increase of the width of the sandwich wall. And the cost of the project will increase exponentially and the area will increase with the increases of the width of the rigid sandwich wall. The width of the rigid sandwich wall should be decided firstly before considering other key factors so as to achieve the ideal isolation effect of the barrier.

- Obviously, the effect of the position of the rigid sandwich wall on the vibration isolation is not stable. The closer the position of the rigid core sandwich wall to the protected body, the better is the damping effect.

CONFLICT OF INTEREST

The authors confirm that this article content has no conflict of interest.

ACKNOWLEDGEMENTS

The authors would like to acknowledge the support provided by the Chinese National Science Foundation (Grant No. 51478004). Meanwhile, the financial support from North China University of Technology is also appreciated.