REVIEW ARTICLE

Technical Conditions Survey of Simple-Support Bridges in a Severe Cold Region in Northeast China

Jinquan Zhang, Pengfei Li*, Yan Mao, Zhenhua Dong, Zhenyu Jiang

Article Information

Identifiers and Pagination:

Year: 2018Volume: 12

First Page: 122

Last Page: 133

Publisher ID: TOCIEJ-12-122

DOI: 10.2174/1874149501812010122

Article History:

Received Date: 26/3/2018Revision Received Date: 17/4/2018

Acceptance Date: 8/5/2018

Electronic publication date: 14/6/2018

Collection year: 2018

open-access license: This is an open access article distributed under the terms of the Creative Commons Attribution 4.0 International Public License (CC-BY 4.0), a copy of which is available at: (https://creativecommons.org/licenses/by/4.0/legalcode). This license permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Abstract

Background:

Based on the routine inspection of 637 simple-support bridges in a severe cold region in northeast China, the technical condition data were collected and analyzed according to China’s bridge condition evaluation code.

Results and Discussion:

The results indicate that the appraisal rating of the bridges decreases with service time gradually. For bridges with a service life of 3-5years, 7 years and more than 15 years, the proportion of rating of “poor condition” is 14%, 22% and 43%, respectively. Besides, the inspection results show that cracking, concrete scaling, and corrosion of reinforcement are the major damage types of the bridges, and the freeze-thaw and salt induced corrosion are the main deterioration causes. It is recommended based on the inspection results that timely drainage of water is very important in reducing bridge damages in severe cold regions. Meanwhile, protective measures of durability should be specially considered in the design and construction stages.

1. INTRODUCTION

There are a total of 614,387 bridges in the U.S. in 2016, of which approximately 9.1% were structurally deficient. According to the American Society of Civil Engineers’ 2017 Report Card for America’s Infrastructure, America’s backlog of bridge rehabilitation needs is $123 billion [1]. Similarly, China also has a large numbers of bridges. By 2017, there were 832,500 highway bridges in China [2], most of which were simple-support bridges [3]. However, the damage type, level and characteristics of these bridges and the actual condition of bridge structural components are not clear, which results in shortage of knowledge for effective bridge management. Moreover, insufficient condition evaluation of bridges directly leads to improper maintenance measures and unnecessary or premature rehabilitation or replacement of the structures or their components.

The evaluation or rating of the existing bridges is a continual activity to ensure the safety of the bridges, providing necessary information for decisions on bridge maintenance and management. In China, quantitative data is difficult to obtain. This makes many decisions remain in a qualitative perspective, and maintenance funds can not be well utilized. At the same time, the distribution of maintenance funds can not only stay on the technical condition of bridges or components, it should be further considered for the universality of the diseases distribution, the service time of the bridges and the types of the bridges. The acquisition of typical diseases and their causes will provide important help for the rational distribution of maintenance funds.

Therefore, with the aim to provide a fundamental information for bridge evaluation, this study focuses on investigating the technical condition of simple-support bridges in a severe cold region in northeast China. Based on the routine inspection reports performed by the Research Institute of Highway, Ministry of Transport of China, the technical condition information of 637 simple-support bridges were collected and analyzed [4]. The distribution rule of bridge's technical condition was statistically analyzed. Meanwhile, the influence of service time, design load and bridge span on the technical condition was analyzed. According to the inspection condition, the typical diseases and the proportions of simply supported bridges were given in northeast China. Finally, combined with on-site inspection and engineer experience, the causes of typical diseases were analyzed. The results can be used to identify critical components for inspection and repairing, and to assist in developing rational maintenance strategies for simple-support bridges in severe cold regions.

2. CONDITION EVALUATION METHOD

The Chinese code (JTG H11-2004) describes the condition evaluation method for highway bridges [4]. In this method, bridge elements are rated according to three indicators, namely defect degree, influence degree on structural function by the defects, and tendency of the development or change of the defects. A score is assigned to each indicator to evaluate the condition of the bridge elements, as shown in Table 1. Note that 0 refers to a good condition or the type that is not available, while 5 refers to a dangerous condition.

| Defect Condition and Scale | Composite Scale | |||||||

|---|---|---|---|---|---|---|---|---|

| Defect degree | Degree | small→large | ||||||

| less→more | ||||||||

| slight→serious | ||||||||

| Scale | 0 | 1 | 2 | |||||

| Influence degree on structural function | Non | 0 | 0 | 1 | 2 | |||

| Small | +1 | 1 | 2 | 3 | ||||

| Large | +2 | 2 | 3 | 4 | ||||

| Composite scale of the two above-mentioned indicators | 0 | 1 | 2 | 3 | 4 | |||

| Development or change of the defect | Non | -1 | 0 | 1 | 2 | 3 | ||

| Slow | 0 | 1 | 2 | 3 | 4 | |||

| Rapid | +1 | 1 | 2 | 3 | 4 | 5 | ||

| Deficit condition of the bridge element(Ri) | 0 | 1 | 2 | 3 | 4 | 5 | ||

| level 1 | level 2 | level 3 | level 4 | level 5 | ||||

According to the scores of the bridge elements, the condition score of the whole bridge (Dr) can be calculated by Eq (1).

|

(1) |

where Ri is the condition score of bridge element i (from 0 to 5), and is the weight of element i that is defined in Table 2.

| i | Element | Weights (Wi) |

|---|---|---|

| 1 | Wing wall | 1 |

| 2 | Conical slope | 1 |

| 3 | Abutment | 23 |

| 4 | Pier | 24 |

| 5 | Foundation | 8 |

| 6 | Bearing | 3 |

| 7 | Major load-bearing elements (e.g., beam, girder) | 20 |

| 8 | Minor load-bearing elements (e.g., hinge joint, diaphragm, wet joint) | 5 |

| 9 | Bridge deck pavement | 1 |

| 10 | Transition slab at bridge head | 3 |

| 11 | Expansion joints | 3 |

| 12 | Sidewalk | 1 |

| 13 | Guardrail | 1 |

| 14 | Highway signs | 1 |

| 15 | Drainage | 1 |

| 16 | Regulating structure | 3 |

| 17 | Others | 1 |

According to the calculated results of Dr, the appraisal rating of bridges can be determined, as shown in Table 3.

| Dr | Appraisal Rating | Technical Condition |

|---|---|---|

| Dr≥88 | Level I | Good condition(no problems or some minor problems) |

| 88> Dr≥60 | Level II | Satisfactory condition (structural elements show some minor deterioration) |

| 60> Dr ≥40 | Level III | Poor condition (advanced section loss, deterioration or scour) |

| 40> Dr | Level IV | Serious condition (deterioration has seriously affected primary structural components) |

| 40> Dr * | Level V | “Imminent” failure condition (bridge closed) |

To better explain the above assessment methods, an example was given. The evaluation object is a two-span simple-support bridge Through field inspection, it is found that there are a lot of circumferential cracks in the pier, and the cracks are no longer developing. There are no diseases in other bridge elements. The deficit condition evaluation for pier is show in Table 4. The calculation of Dr is show in Table 5. The appraisal rating of the bridge is Level II.

|

3. OVERVIEW OF THE INVESTIGATED BRIDGE

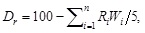

The 637 simple-support highway bridges investigated include 19 reinforced concrete (RC) T-beams, 269 RC hollow-core slabs, 42 RC solid beams, 10 RC cast-in-place slabs, 49 prestressed concrete (PC) T-beams, 81 PC adjacent box beams, and 167 PC box girders. The longest span of the bridges is 50 m, and the shortest is 5.0 m. The distribution of the bridge by length is presented in Fig. (1). The age of the bridges ranges from 3 to 19 years; about 27.63% are over 15 years or older, and the ages of most bridges are either 5 (22.30%) or 7 (43.01%) years.

| i | Element | Weights (Wi) | Deficit Condition of the Bridge Element(Ri) | Dr. |

|---|---|---|---|---|

| 1 | Wing wall | 1 | 0 |

Dr=85.6 Appraisal rating of the bridge: Level II |

| 2 | Conical slope | 1 | 0 | |

| 3 | Abutment | 23 | 0 | |

| 4 | Pier | 24 | 3 | |

| 5 | Foundation | 8 | 0 | |

| 6 | Bearing | 3 | 0 | |

| 7 | Major load-bearing elements | 20 | 0 | |

| 8 | Minor load-bearing elements diaphragm, wet joint) | 5 | 0 | |

| 9 | Bridge deck pavement | 1 | 0 | |

| 10 | Transition slab at bridge head | 3 | 0 | |

| 11 | Expansion joints | 3 | 0 | |

| 12 | Sidewalk | 1 | 0 | |

| 13 | Guardrail | 1 | 0 | |

| 14 | Highway signs | 1 | 0 | |

| 15 | Drainage | 1 | 0 | |

| 16 | Regulating structure | 3 | 0 | |

| 17 | Others | 1 | 0 |

|

Fig. (1). Bridge distribution by length and age. |

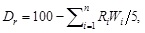

Four types of loads were designed for these bridges. The layout of the design loads is shown in Fig. (2). The relevant quantity of bridges designed for different loads is expressed in the round brackets.

|

Fig. (2). Design loads and the relevant quantity of bridge. |

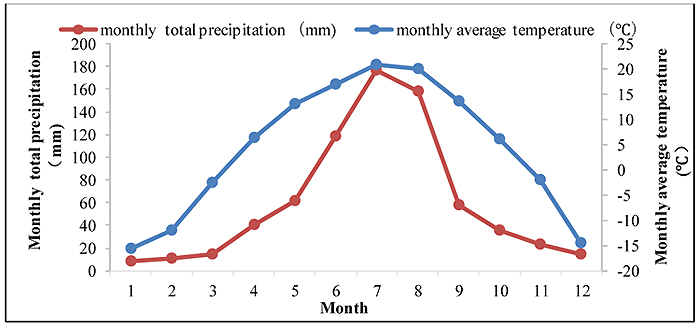

The monthly average temperature and total precipitation in the region is presented in Fig. (3) [5]. In addition, the annual numbers of freezing-thawing cycles are 119 in this region [6].

|

Fig. (3). Monthly average temperature and monthly total precipitation. |

4. APPRAISAL RATING OF BRIDGES

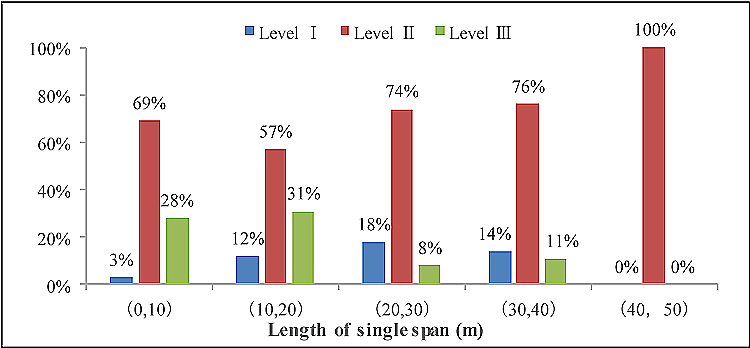

Based on the condition evaluation method described above and the routine inspection reports of the 637 simple-support bridges, the appraisal ratings were determined. The 637 simple-support bridges were all in the categories of LevelIto Level III. The proportions of rating in each span group is shown in Fig. (4); Level II is a dominant rating for all the span groups. No obvious correlation between the appraisal ratings and the span lengths was observed.

|

Fig. (4). Appraisal ratings vs length of single span. |

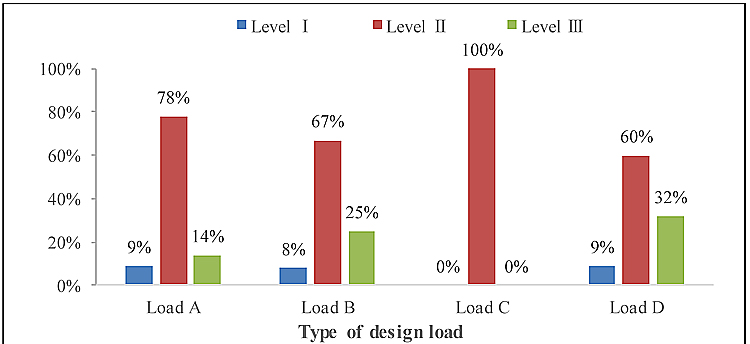

Fig. (5) gives the rating proportion for each design load. In general, the appraisal ratings of bridges decrease with the increase of the design load level. As mentioned earlier, only 5 bridges were designed with load C, which were all rated as LevelII. Other groups demonstrated better statistical significance. For the 12 bridges designed with load B, 8% of which were rated as LevelI, 67% were LevelII,and the remaining were Level III. For the 199 bridges designed with load A and 421 bridges designed with load D, similar distribution was observed.

|

Fig. (5). Appraisal ratings vs type of design loads. |

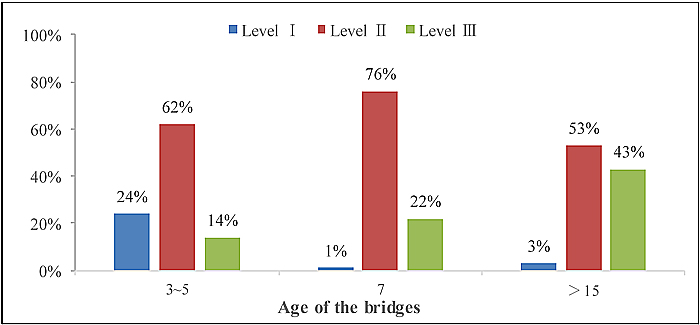

The relationship between appraisal ratings and age of the bridges is shown in Fig. (6). It has been observed that the appraisal ratings of the bridges decrease with the passage of time. For bridges with a service life of 3-5 years, 7 years and more than 15 years, the proportion of rating of “poor condition” are 14%, 22% and 43%, respectively. These bridges are generally designed for 50 years or 100 years, thus, the rapid deterioration of the bridges is a great challenge to the bridge owners.

|

Fig. (6). Appraisal ratings vs age of the bridges. |

5. TYPICAL DAMAGES OF THE BRIDGES

The damage types of the bridge elements and their proportions are shown in Table 4. Pictures of some of the typical damages are shown in (Figs. 7-11).

|

Fig. (7). Concrete scaling and reinforcement exposing of pier. |

|

Fig. (8). Longitudinal crack of deck pavement. |

| Element | Typical Damages | Proportion | Corresponding Picture |

|---|---|---|---|

| Wing wall | Concrete scaling and reinforcement exposing | 4% | |

| Conical slope | Breakage | 44% | |

| Abutment | Concrete scaling | 62% | |

| Vertical crack | 45% | ||

| Concrete scaling and reinforcement exposing | 42% | ||

| Water stains | 34% | ||

| Pier | Concrete scaling and reinforcement exposing | 17% | Fig. (7) |

| Concrete scaling | 14% | ||

| Vertical crack | 5% | ||

| Bearing | Part separation | 14% | |

| Breakage | 13% | ||

| Shear deformation | 7% | ||

| Bridge deck pavement | Transverse crack | 41% | |

| Breakage | 16% | ||

| Longitudinal crack | 10% | Fig. (8) | |

| Slant crack | 9% | ||

| Crocodile crack | 8% | ||

| Transition slab at bridge head | Vehicle bump at bridge head | 8% | |

| Expansion joints | Breakage of anchorage zone | 50% | |

| Blockage | 36% | ||

| Breakage of sealing strips | 29% | Fig. (9) | |

| Guardrail | Concrete scaling | 45% | Fig. (10) |

| Concrete scaling and reinforcement exposing | 23% | ||

| Crack | 14% | ||

| Drainage | Impeded | 16% | Fig. (11) |

| Major load-bearing elements (RC-T) | Longitudinal crack | 63% | |

| Slant crack | 63% | ||

| Concrete scaling and reinforcement exposing | 37% | ||

| Water stains | 26% | ||

| Pitting surface | 26% | ||

| Corrosion of reinforcement | 16% | ||

| Concrete scaling | 11% | ||

| transverse crack | 5% | ||

| Minor load-bearing elements (wet joint) | Crack and water stains | 31% | |

| Concrete scaling and reinforcement exposing | 9% | ||

| Pitting surface | 6% | ||

| Minor load-bearing elements (diaphragm) | Crack | 15% | |

| Water stains | 11% | ||

| Concrete scaling and reinforcement exposing | 11% | ||

| Pitting surface | 5% | ||

| Major load-bearing elements (RC hollow-core slabs) | Longitudinal crack | 42% | |

| Corrosion of reinforcement | 41% | Fig. (11) | |

| Transverse crack | 41% | ||

| Water stains | 41% | ||

| Concrete scaling and reinforcement exposing | 23% | ||

| Concrete scaling | 7% | ||

| Hinge joint | Crack and water stains | 42% | |

| Major load-bearing elements (RC solid slabs) | Corrosion of reinforcement | 74% | |

| Concrete scaling | 33% | ||

| Concrete scaling and reinforcement exposing | 29% | ||

| Transverse crack | 12% | ||

| Water stains | 10% | ||

| Longitudinal crack | 7% | ||

| Major load-bearing elements (RC cast-in-place slabs) | Water stains | 40% | |

| Concrete scaling and reinforcement exposing | 30% | ||

| Longitudinal crack | 10% | ||

| Transverse crack | 10% | ||

| Corrosion of reinforcement | 10% | ||

| Concrete scaling | 10% | ||

| Major load-bearing elements (PC-T) | Water stains | 63% | |

| Concrete scaling and reinforcement exposing | 57% | ||

| Longitudinal crack | 55% | ||

| Corrosion of reinforcement | 27% | ||

| Concrete scaling | 12% | ||

| Transverse crack | 10% | ||

| Major load-bearing elements (PC adjacent box beams) | Longitudinal crack | 67% | |

| Corrosion of reinforcement | 25% | ||

| Water stains | 22% | ||

| Transverse crack | 21% | ||

| Concrete scaling and reinforcement exposing | 16% | ||

| Major load-bearing elements (PC box girders) | Longitudinal crack | 65% | |

| Water stains | 40% | ||

| Concrete scaling and reinforcement exposing | 37% | ||

| Corrosion of reinforcement | 14% | ||

| Transverse crack | 11% | ||

| Slant crack | 10% |

|

Fig. (9). Breakage of deck joint sealing strip. |

|

Fig. (10). Concrete scaling of guardrail. |

|

Fig. (11). Short drainage pipes fail and reinforcement corrosion of the side RC hollow-core slabs. |

As shown in Table 4 and Figs. (7-11), concrete scaling and corrosion of reinforcement are the major damages of bridges in the severe cold region. The main reasons of these damages can be attributed to the following four aspects.

5.1. Freeze-Thaw Cycles and Salt Induced Corrosion

The meteorological data indicates that the yearly numbers of freeze-thaw cycles are 119 in this region [6]. Meanwhile, the deicing salt is widely used for melting ice and snow in the winter season. It is widely acknowledged that the freezing and thawing durability of concrete is of utmost importance in regions having subzero temperature conditions [7]. Besides, the use of deicing salt has caused great damages to bridges and roads [8]. Previous researches indicated that the durability of concrete is often lower under the combined influence of frost and deicing salts than under frost influence or salt induced corrosion alone [9]. In other words, it is easier to cause damages to concrete exposed to a coupled frost and deicing salt environment, and the corresponding damages are more severe [10].

5.2. Maintenance

The extensive use of deicing salt is a great challenge for the bridge owners. However, currently it is impractical to stop using deicing salt or replace it with other alternative materials. Therefore, to reduce the bridge damage caused by the use of deicing salt, timely drainage of water out of bridges is very important and helpful. In case of slow or damaged drainage facility, significant damages of bridges were inevitable. Two examples are given below.

First, the effect of deck joint sealing strips is significant. The breakage of sealing strips allows water flowing from the deck to abutments and piers, providing convenience for causing the freeze-thaw cycles and salt induced corrosion conditions. Fig. (9) shows a typical condition of the breakage of deck joint sealing strips.

Second, a good drainage can bring water out of bridges, inversely, water will flow to deck and beams and be kept there, which creates the cracking of deck pavement and hinge joints. Under the combined action of water, freeze-thaw cycles and salt induced corrosion, the hinge joints and deck deteriorate quickly, and the lateral load transfer becomes disproportional due to joint cracks. Typical joint cracks are shown in Fig. (8). In general, side slopes take water to the side beams; the effect of freeze-thaw cycles or salt induced corrosion on the side beams will be intensified if the water is not drained out timely. Fig. (11) presents typical damages on the side beams. The drainage pipes in Fig. (11) are too short to take water out of the bridge.

Timely and proactive maintenance can help mitigate the damage. For example, cracks can occur and propagate rapidly if they are not repaired in time. Moreover, maintenance intervals have a significant influence on bridge safety. Premature interventions may cause a high economic burden, but retarded interventions may cause a quick growth of damages.

5.3. Construction

It is observed that improper maintanence of concrete is the dominant reason that causes longitudinal shrinkage cracks in cold regions. Meanwhile, premature bearing load may further exacerbate the propagation of cracks. Therefore, in the construction stage, it is very important to choose proper construction materials (such as low shrinkage concrete) and perform a reasonable curing scheme to ensure the safety of bridges.

5.4. Design

The design stage has a crucial influence on the performance of bridges. Research indicated that the possibility of the effect of design on the eventual performance of bridges is about 30%, and the construction and maintenance stages only account for about 20% and 15% respectively [11]. Unfortunately, the traditional bridge design method often focuses on strength than to durability measures [12]. Some designs do not consider on preventive measures, which can increase the risk of failure and corresponding costs [13]. The preventive measures include increasing the cover thickness of the RC members [14], using corrosion inhibitors, and adding a waterproof concrete layer. Corrosion prevention measures should be used in guardrails and side beams, otherwise, the rapid deterioration of the guardrails and side beams will seriously affect the safety of bridges. Typical picture of guardrails is shown in Fig. (10).

CONCLUSION

This paper focuses on Technical conditions of simple-support bridges in a severe cold region in northeast China. The technical condition information of 637 simple-support bridges were collected and analyzed. From the conducted analysis and comparison, the following conclusions can be drawn:

- There is no obvious relationship between the length of bridges and the appraisal rating. The appraisal ratings of bridges decrease with the increasing of the levels of design loading and age of the bridges. For bridges aged 3-5years, 7 years, and more than 15 years, the proportion of “poor condition” rating are 14%, 22% and 43%, respectively.

- Cracking, concrete scaling and corrosion of reinforcement are the major defects of bridges in the severe cold region. Freeze-thaw cycles and salt induced corrosion are the major causes of the damages.

- The drainage of water is very important in reducing bridge damages in cold regions. Good drainage facilities can significantly improve bridge Technical conditions. Meanwhile, protective measures for improving the durability of bridges should be considered in the design and construction stages to mitigate hazards created in the cold weather operations.

CONSENT FOR PUBLICATION

Not applicable.

CONFLICT OF INTEREST

The authors declare no conflict of interest, financial or otherwise.

ACKNOWLEDGEMENTS

Declared none.