All published articles of this journal are available on ScienceDirect.

Measurement of the Hygric Resistance of Concrete Blocks with Perfect Contact Interface: Influence of the Contact Area

Abstract

Introduction:

Concrete sealing blocks are not only used in Brazil but worldwide. T he knowledge of the material properties in the presence of moisture becomes necessary to study the durability of buildings.

Methods:

An experimental study was carried out in order to analyse the effect of contact area on the capillary absorption coefficient of concrete samples used in sealing blocks, according to several standards: NBR 9779 (2012), EN 1015-18 (2002), ISO 15148 (2002) and ASTM C1794 (2015). Two types of specimens were analysed; monolithic samples and samples with a perfect contact interface. The monolithic samples were also subjected to axial and radial compression in order to enhance the capacity of masonry.

Results:

The experimental results for the samples with perfect contact interface indicate that the water absorption before the interface presents similar behaviour to the monolithic samples. However, it is possible to observe a reduction of the absorption rate when water reaches the interface due to the hygric resistance. In other words, the moisture transport is significantly retarded by the existence of an interface, i.e., the discontinuity of moisture content across the interface indicated that there was a difference in capillary pressure across the interface. Also, the interface contact area does not greatly influence the water-resistance values.

Conclusion:

Finally, the Hygric Resistance values (HR), in multilayer building components, with perfect contact interface are calculated using the “knee point” methodology.

1. INTRODUCTION

There are, currently, a great number of building materials available in the market. These materials have particular characteristics that justify their use for various purposes. In a macro way, two main types of building materials are used in most of the constructions worldwide, namely ceramic materials (bricks or tiles) and concrete.

In the last years, several improvements have been made in the building materials industry related to the production and development of new materials in order to improve the negative sides of some materials, like concrete, contributing to a more sustainable construction [1-5].

Both ceramic and concrete materials have, internally, a complex structure of pores [6]. These pores are able to promote the transport of various substances, liquid and gaseous, present in the environment, as soil, or when subjected to external factors, such as rain.

According to Mendes [7], when it comes to building materials, the main concern is to understand the processes of heat and moisture transfer, i.e., how water molecules are fixed or transported in the material and how these molecules interact with the internal porous structure of the material. The research on moisture transport in building walls is crucial for accurate characterization of the building materials' hygroscopicity. An accurate characterization of the moisture transport phenomena has made it possible to analyse other variables, such as durability, waterproofing, the emergence of pathologies, and thermal performance.

It is well known that a building wall is usually composed of multi-layers, so in studies of moisture transport, this fact should be taken into account considering that the approximation to only one layer leads to a rather simplistic approach that results in many mistakes. In the civil engineering field, several researchers studied multi-layered walls mainly with perfect contact interfaces [8-10]. This assumption implies that the interface will be considered as having no effect on moisture transport [11].

In literature, the studies with imperfect contact are few. Experimental results reported by Derdour et al. [12] showed the influence of thickness and porosity on the drying conditions of several building materials. The authors analysed the interface influence on the drying and wetting processes of ceramic blocks with perfect contact interface, hydraulic contact, and air space interface [13-15].

This work analysed the effect of contact area on the capillary absorption coefficient of concrete samples used in sealing blocks, according to several international standards: NBR 9779 [16], EN 1015-18 [17], ISO 15148 [18], and ASTM C1794 [19]. This innovative analysis on contact area influence was accomplished by comparing the experimental results obtained with different international standards. Furthermore, the influence of interface on the wetting process of concrete blocks with perfect contact interface is also analysed at different heights, i.e., the materials are in contact without interpenetration of the porous structure.

2. MATERIALS AND METHODS

2.1. Materials

In this work, two types of concrete blocks (density of 2116 kg/m3), with different contact areas (5x5 cm2, 7.5x7.5 cm2, and 10x10 cm2) and heights, were analysed; monolithic samples and samples with perfect contact interface (Table 1). The monolithic samples were also subjected to axial and radial compression in order to enhance the capacity of masonry.

For the preparation of test specimens, the concrete mixture used was Portland cement (CPV-ARI), similar to the one used in sealing blocks, the fine aggregate used was coarse sand, based on NBR NM 248 [20] obtained from a traditional supplier of the region and it was sieved through sieve no. 4 (4.8 mm) to remove possible impurities. The coarse aggregate used in this study was gravel #.0, ranging from 4.8 to 9.0 mm in size. This aggregate was used in its dry state without washing. Table 2 exhibits the information of the concrete mix proportion used in the study, and Table 3 presents the granulometric results according to the Brazilian standard NBR NM 248 [20].

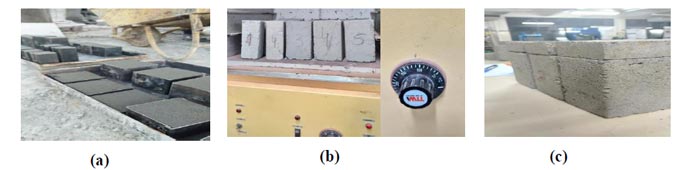

For the preparation of the concrete blocks, the materials were manually mixed (Fig. 1). The laboratory temperature conditions were about 24° C, and the casting of the specimens was made immediately after the kneading. The mixture was thickened into four layers of approximately equal heights, each layer receiving 30 strokes uniform with the normal socket, homogeneously distributed (Fig. 1a). The specimens were demoulded, 24 hours after being cast and were cured for 28 days in a humid chamber (RH>95%); after that, the samples were dried in an oven at a temperature of 105° C (Fig. 1b) until the weight stabilized, according to NBR 9779 [16].

This work evaluated the influence of perfect contact interface on moisture transport, i.e., the moisture flux of these samples was compared, experimentally, with monolithic samples of the same material. For the configurations studied, a monolithic sample of concrete was cut into two smaller pieces, and these pieces were put together in a manner that the two cutting surfaces were placed in a good physical contact (natural contact interface) after a correct surface regularization (Fig. 1c). The samples were kept in “aluminium sheet” in order to guarantee low errors during the experiment, i.e., the “aluminium sheet” could guarantee not only waterproof sideways but also a good connection between layers. Finally, all surfaces of each test specimen were sealed except the top surface, which remained open to the ambient air and the bottom surface was in contact with water to ensure one-dimensional moisture transport.

| Monolithic | |||

| Dimensions (cm) | Samples | ||

| Base | Height | ||

| 5.0x5.0 | 15.0 | 4 | |

| 7.5x7.5 | 15.0 | 4 | |

| 10.0x10.0 | 15.0 | 4 | |

| Perfect Contact Interface | |||

| Base | h1 | h2 | Samples |

| 5.0x5.0 | 12 | 3 | 3 |

| 5.0x5.0 | 9 | 6 | 3 |

| 7.5x7.5 | 12 | 3 | 3 |

| 7.5x7.5 | 9 | 6 | 3 |

| 10.0x10.0 | 12 | 3 | 3 |

| 10.0x10.0 | 9 | 6 | 3 |

| Cement (kg) | FA (kg) | CA (kg) | ||

| Gravel | Sand | |||

| 1 | 5.6 | 1.1 | 4.4 | |

|

Opening of the Sieves (mm) |

Coarse Sand | Medium Sand |

Fine Sand |

Gravel | Weighted Granulometry of Aggregates | |||||

| % Retained | % Retained | % Retained | % Retained | |||||||

| Ind. | Cum. | Ind. | Cum. | Ind. | Cum. | Ind. | Cum. | |||

| # | % | |||||||||

| 12.5 | 0 | 0 | 0 | 0 | 0 | 0 | 4 | 4 | 12.5 | 0.8 |

| 9.5 | 0 | 0 | 0 | 0 | 0.5 | 1 | 16.5 | 21 | 9.5 | 4.5 |

| 6.3 | 0.5 | 1 | 0.1 | 0 | 1 | 2 | 42 | 63 | 6.3 | 13.7 |

| 4.8 | 1 | 2 | 0.15 | 0 | 1 | 3 | 20.5 | 83 | 4.8 | 18.6 |

| 2.4 | 6 | 8 | 0.75 | 1 | 26.5 | 29 | 14.5 | 98 | 2.4 | 42.7 |

| 1.2 | 18 | 26 | 1.8 | 3 | 18 | 47 | 0.5 | 98 | 1.2 | 57.2 |

| 0.6 | 31 | 57 | 16.6 | 19 | 12 | 59 | 0 | 98 | 0.6 | 66.8 |

| 0.3 | 24.5 | 81 | 41.75 | 61 | 14 | 73 | 0 | 98 | 0.3 | 78.0 |

| 0.15 | 12 | 93 | 31.85 | 93 | 20 | 93 | 0.5 | 99 | 0.15 | 94.1 |

| 0.075 | 4 | 97 | 7 | 100 | 4 | 97 | 0 | 99 | 0.075 | 97.3 |

| Bottom | 2 | 99 | 0 | 100 | 1 | 98 | 0 | 99 | 0.075 | 98.1 |

| Total | 98.5 | 98.5 | 100.0 | 100.0 | 98.0 | 98.0 | 98.5 | 98.5 | Total | 98.1 |

2.2. Methods

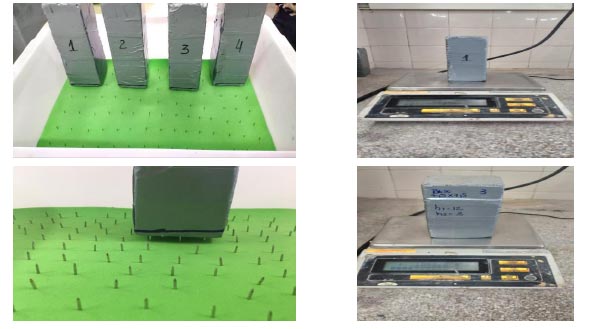

The experiments conducted in this test were guided by the outline of the partial immersion method described by several standards: NBR 9779, EN 1015-18, ISO 15148, and ASTM C1794 [16-19], as described below. All the tested samples were placed in distilled water, with the base submerged only a few millimetres (between 1mm and 3mm) to avoid build-up of hydrostatic pressure. The environmental laboratory conditions were 22° C and 40% RH, and the samples were placed at a constant temperature in a water bath controlled within ±0.5 ºC to avoid changes in water viscosity that might affect the absorption rate. At regular time intervals, the samples were weighed to determine the moisture uptake (Fig. 2).

There are many standards and recommendations, European and international, to evaluate the capillary water absorption coefficient of building materials. For example, the European standard EN 1925 [21] refers to natural stones, EN 1015-18 [17] refers to hardened mortars, EN 13057 [22] refers to hardened concrete, Normal 11/85 standard [23] replaced by UNI 10859 [24] refers to natural and artificial stones, EN 15801 [25] refers to porous inorganic materials, and EN 480-5 [26] refers to concrete, mortars, and grouts.

2.2.1. NBR 9779 (2012)

The Brazilian standard ABNT NBR 9779 [16] establishes the guidelines for the capillary absorption test of concretes and mortars. The standard recommends that, initially, the specimens should be dried at a temperature of 105° C +/- 5° C, after which the building material should be placed at a temperature of 23° C +/- 2° C, in order to determine the material dry mass.

After that, the specimens are placed in a recipient with a constant distilled water level of 5 mm ± 1 mm. It is very important that the tested material does not have direct contact with the bottom of the recipient in order to allow full contact of the bottom face with the water (for this purpose, supports are used).

During the test, the saturated mass of the specimens with standardized time intervals (3h after immersion, then 6 h, 24 h, 48 h, and 72 h, respectively) is determined. Finally, the capillary absorption coefficient, C (in g/cm2), is given by:

|

(1) |

where A is the cross-sectional area (in cm2), msat is the saturated mass of the specimens (in g), and ms is the initial mass of the specimen (in g).

After completing all the steps, the specimens should be ruptured by diametral compression to verify the height of the capillary rise.

2.2.2. EN 1015-18 (2002)

According to the EN 1015-18 [17] standard (for hardened mortar), 3 samples should be prepared with dimensions of 160 mm × 40 mm × 40 mm. After drying each sample at 60±5ºC to constant mass (lesser than 0.2%) in a hot-air oven, dry mass is measured. Each sample is cooled at room temperature and is placed on a tray of distilled water at a depth between 5 mm and 10 mm. The position of the waterfront gradually approaches the opposite side of the sample, and the water intake is governed by capillary and viscous forces. The capillary water absorption coefficient, C, is the gradient of the straight line of representative points, i.e., the mass of the specimen after soaking for 10 min (M1 in kg/m2) and 90 min (M2 in kg/m2) is calculated according to the following equation:

|

(2) |

For renovation mortars, the water absorption coefficient is measured in kg/m2 after 24 h (M3), using the expression:

|

(3) |

Where M0 is the dry mass of the specimen.

2.2.3. ISO 15148 (2002)

In accordance with ISO 15148 [18], the samples should be prepared with a cross-sectional area of at least 50 cm2; however, in the case of materials that include macroscopic particles, such as aggregates, the dimension must be at least ten times the largest particle size. The quantity of the absorbed water is measured at standard time intervals by weighing the specimen. Each weighing should be completed as quickly as possible (typically within the 30s). The capillary water absorption coefficient is the gradient of the straight line obtained by plotting the cumulative mass of water absorbed per unit area against the square root of time t obtained from this first stage (tangent method) according to the following equation:

|

(4) |

Where Aw (kg/m2s1/2) is the water absorption coefficient, A (m2) is the cross sectional area of the specimen and (kg) is the mass of the absorbed water.

2.2.4. ASTM C1794 (2015)

The main purpose of this test procedure is to obtain reliable data on the capillary water uptake of building materials using a simple apparatus. All the procedures must be performed under specified test conditions (temperature between 18º C and 24º C, with a variation during the test of ±2º C). The major face of the specimen should be in contact with the water surface, and after the first 5 minutes, the specimen should be removed and the wet surface pressed against a moist sponge to remove excess water drops. All this should be done within 1 minute to maintain accuracy. Finally, the same procedure should be repeated, and at least two more readings should be taken within the next 24 h. A measurement at 4h is very important. The capillary water absorption coefficient is determined by the tangent method, according to Eq. (4).

3. RESULTS AND DISCUSSION

3.1. Measurement of the Capillary Absorption Coefficient by Different Standards

The Brazilian standard NBR 9779 [16] establishes only the “C” calculation (in g/cm2), called capillarity absorption, presented in Table 4, made for all monolithic specimens. However, NBR 9779 [16] does not establish the calculation methodology for the capillarity absorption coefficient, Aw, which takes into account the root of time according to other standards. However, if it isconsidered that the “C” value is obtained at 24 h, the same value of water capillary absorption coefficient, achieved by ISO 15148 [18] and ASTM C1794-15 [19] standards, is obtained.

| Sample |

Base (cm) |

Height (cm) | NBR 9779 |

ISO 15148 ASTM C1794-15 |

|---|---|---|---|---|

| C (g/cm2) | Aw (kg/m2s0.5) | |||

| Mono-1 | 5.0x5.0 | 15.0 | 2.407 | 0.0691 |

| Mono-2 | 7.5x7.5 | 15.0 | 2.141 | 0.0626 |

| Mono-3 | 10.0x10.0 | 15.0 | 2.677 | 0.0756 |

The standards ISO 15148 [18] and ASTM C1794-15 [19] present a complete approach and provide the necessary guidelines for the determination of the capillary absorption coefficient as described above. ISO 15148 [18] establishes measurements at 20 min, 2 h, 4 h, 8 h, and at least two more measurements at 24 h, whereas ASTM C1794-15 [19] establishes measurements at 5 min, 4 h, and more readings before 24 h. The capillary water absorption coefficient is determined by Eq. (4).

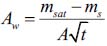

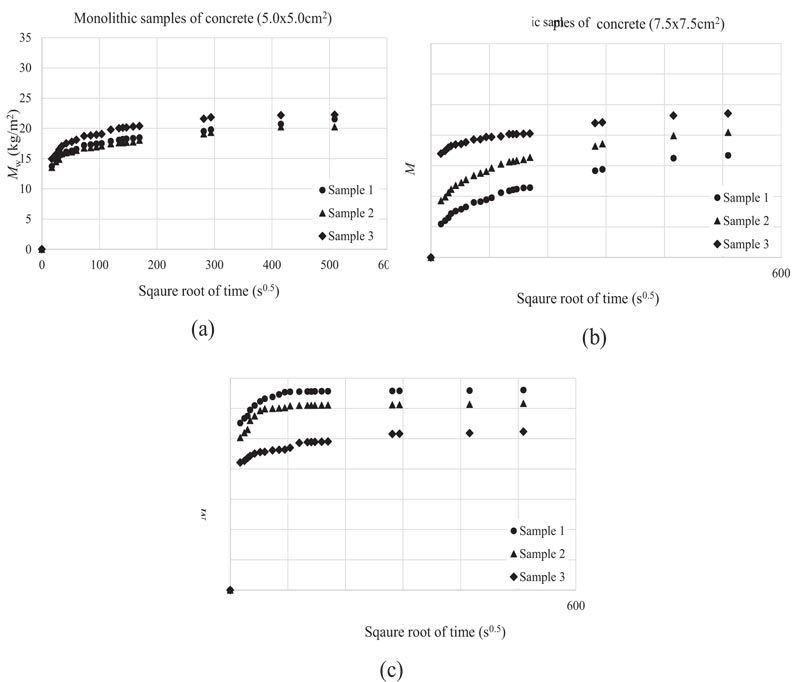

The experimental assessment of the water absorption coefficients showed similar values for different contact areas. The average values obtained are presented in Table 4 and Fig. (3), and the coefficient of variation found for each set of identical samples (same contact area) was approximately 15%. The 3 more representative experimental results for each contact area are represented in Fig. (4).

The results showed that the influence of contact area on the capillary water absorption coefficient is practically negligible since a minimum value of contact area was considered in accordance with the standards.

The experimental results obtained with EN 1015-18 [17] were very different from the other results obtained with the other standards used in this study, which was expected, considering that the studied material was concrete, and this standard is not ideal for analysing this type of material.

3.2. Analysis of the Perfect Contact Interface and Contact Area Influence

This work analysed the moisture transport in multilayer porous materials by a gravimetric method, with discontinuities caused by the existence of an interface (perfect contact interface) between the materials. The existence of an interface (perfect contact) contributes to different ways of moisture transport when compared to a monolithic porous element, as described by several authors [12-15].

As a consequence of these discontinuities, in the porous structure of the building materials, the interface causes a hygric resistance that retards the moisture transport. The Hygric Resistance (HR) is defined by the greater or lesser ease of moisture transfer (expressed in kg/m2s), and is calculated experimentally by the slope of the mass variation curve as a function of time, during a water absorption test, after reaching discontinuity [13-15].

In this work, the Hygric Resistance (HR) was determined by the “knee point” methodology [27]. This methodology is based on the fact that the HR should be measured immediately after the first changing point, so it is important to detect the exact instant time of the “knee point” automatically and with higher precision. An algorithm based on discrete methods, which was intuitive and easy to implement, was developed based on literature methods of knee or jump point detection [28-33].

Fig. (4) and Table 5 show the obtained results in water absorption with perfect contact interface for the tested concrete samples with different contact area interface and heights, in accordance with the standard ISO 15148 [18].

The results presented in Fig. (4) showed that before the interface, the water absorption of the samples with perfect contact interface present similar behavior to the monolithic samples. However, it is possible to observe a hygric resistance when water reaches the interface (at 9 cm or 12 cm in height) by reducing the absorption rate. This result was expectable as the interface between layers retards the moisture (water absorption rate), and for the case of interfaces located in higher positions, the absorption becomes higher (lower values of hygric resistance) as the discontinuity is reached. This result was observed by the authors in previous works [13-15] with ceramic blocks, but only with the same interface contact area.

|

Base (cm2) |

Interface Type |

Hygric Resistance (kg/m2s) |

Standard Deviation | Coefficient Variation (%) | ||||

|---|---|---|---|---|---|---|---|---|

| 5.0x5.0 | Perfect contact (at 12cm) | 1.66x10-5 | 1.60x10-6 | 9.6 | ||||

| Perfect contact (at 9cm) | 1.68x10-5 | 1.59x10-6 | 9.4 | |||||

| 7.5x7.5 | Perfect contact (at 12cm) | 1.65x10-5 | 2.26x10-6 | 13.7 | ||||

| Perfect contact (at 9cm) | 1.41x10-5 | 2.31x10-6 | 16.4 | |||||

| 10.0x10.0 | Perfect contact (at 12cm) | 1.77x10-5 | 2.07x10-6 | 11.7 | ||||

| Perfect contact (at 9cm) | 1.62x10-5 | 2.78x10-6 | 17.2 | |||||

The results also showed that, as for monolithic samples, the influence of contact area on the hygric resistance value is practically negligible.

3.3. Mechanical Properties

The mechanical characteristics of the monolithic concrete blocks were evaluated by individual compressive strength and tensile strength by diametral compression of six cylindrical specimens (3 specimens previously subjected to capillary absorption tests and 3 specimens not subjected to moisture tests), in accordance with Brazilian standards NBR 5739 [34] and NBR 7222 [35], respectively (Fig. 5).

The mechanical properties showed an average value of 3.055±0.450 MPa and 0.297±0.047 MPa for compressive strength and tensile strength by diametral compression, respectively. These values are in accordance with the literature results [36, 37], i.e., a range of the values between 2.0 MPa and 3.1 MPa for compressive strength of concrete blocks commonly used in sealing blocks and tensile strength by diametral compression values in the order of 10% of the compressive strength values, respectively. No significant differences were observed between the specimens subjected to moisture tests and the specimens not subjected to these tests.

CONCLUSION

This work presents an experimental study to analyse the influence of contact area on the water absorption coefficient and the influence of interface on the wetting process of concrete blocks with perfect contact interface at different interface highs.

From the present study, it was possible to conclude that the analysed standards have some divergences and that ISO 15148 (2002) and ASTM C1794-15 are identical and accurate in the study of capillarity absorption than NBR 9779 (2012), and the three standards differ greatly from the mortar absorption test recommended by EN 1015-18.

The hygric resistance values (HR) in multilayer building components with perfect contact interface are calculated using the “knee point” methodology. Finally, the main achievements and conclusions of this work are as follows:

- 1) The samples with perfect contact interface indicate that the water absorption before the interface presents similar behavior to the monolithic samples. However, it is possible to observe a reduction in the absorption rate when water reaches the interface due to the hygric resistance. In other words, the moisture transport is significantly retarded by the existence of an interface

- 2) The interface contact area does not greatly influence the water-resistance values.

| A | Cross-sectional area in cm2 or m2. |

|---|---|

| Aw | Water absorption coefficient in kg/m2s1/2. |

| C | Capillary absorption coefficient in g/cm2 or kg/m2. |

| ms | Initial mass of the specimen in g or kg. |

| msat | Saturated mass of the specimens in g or kg. |

| Mo | Initial mass of the specimen before soaking in kg/m2. |

| M1 | Mass of the specimen after soaking for 10 min in kg/m2. |

| M2 | Mass of the specimen after soaking for 90 min in kg/m2. |

| M3 | Mass of the specimen after soaking for 24 hours in kg/m2. |

| t | Time in s. |

ETHICS APPROVAL AND CONSENT TO PARTICIPATE

Not applicable.

HUMAN AND ANIMAL RIGHTS

All the experimental procedures werecarried out under international guidelines for the care and useof laboratory animals..

CONSENT FOR PUBLICATION

Not applicable.

AVAILABILITY OF DATA AND MATERIALS

The authors confirm that the data supporting the findings of this study are available within the article.

FUNDING

None.

CONFLICT OF INTEREST

The authors declare no conflict of interest, financial or otherwise.

ACKNOWLEDGEMENTS

Declared none.