All published articles of this journal are available on ScienceDirect.

Risk Management Strategies in Construction Organizations

Abstract

Background:

Construction projects are among the riskiest businesses due to the number of factors involved that are difficult to control; hence, the popularity of risk management as part of the decision-making process in construction organizations is increasing. Despite the advancements, there are various risks involved that lead to project failure.

Aim:

Thus, this study aims to assess the risk management strategies in construction organizations in the Gaza Strip, Palestine.

Methods:

Seventy questionnaires were distributed after subjecting them to pretesting and pilot study that confirmed the validity and reliability of the questions. The target respondents included engineers and consultants from the construction organizations, Ministry of Works and Housing, and international agencies. The questionnaire was retrieved with a 65.71% response rate.

Results:

Results indicated that the most popular method of risk factor determination in the Gaza Strip is the “checklist” (RII=84%). For tools/methods of risk analysis, relying on experience in the direct assessment is the most prominent, with an RII of 78%. For the methods of avoiding risk before the project implementation, dependence on experience in the work for preparing and planning was ranked highest (having RII of 81.6%). Finally, follow-up on the implementation to avoid rework, with an RII of 77.6%, was ranked highest among other factors of avoiding risk during the construction projects implementation.

Conclusion:

This study highlights the key risk management strategies that will be beneficial for the construction industry stakeholders to resolve the unwanted risk failures in the construction industry.

1. INTRODUCTION

Risk management is an important tool and forms part of the decision-making process in the construction industry [1, 2]. Management of the risk of a project is one of the major roles undertaken by a project manager [3, 4]. The purpose of project risk management is to increase the probability and impact of positive events and decrease the probability and impact of negative events, which can be harmful to the project [5, 6]. In the last decades, research on risk management in the construction industry has developed [2, 7] due to the high number of risks involved in construction projects [8]. Furthermore, the inherent high risk is due to the nature of construction projects that involve many parties, such as designers, owners and contractors, and others [9, 10]. Hence construction projects risks can be analyzed from two different sides. That is, the main stakeholder, decision-maker and project owner in construction projects [11, 12] on one hand, and contractors on the other hand [13, 14]. These two sides may have different experiences and responses regarding project risks, which presents different possibilities of transferring the risk to the other party as the best solution to deal with it [15, 16]. Usually, project risk management involves the use of systems that focus on quantitative risk analysis. However, most of these systems cannot find and control the risks and solve the problems. Brainstorming has been reported as the most famous method of risk identification in the construction industry, and that the qualitative methods of risk evaluation are used more often in preference to semi-qualitative and quantitative methods [17, 18]. Acknowledging this situation, a system was developed to select appropriate techniques for risk management in the construction environment [7]. These techniques comprise decomposition, artificial intelligence, sensitivity analysis, probabilistic analysis, decision trees, and others. In the construction projects, risks could lead to constrainment of primary objectives, i.e., cost, time, quality, and scope, which means additional expenses that translate to a lower return to the client and a loss of revenue for the construction parties [19, 20].

Due to the unstable political situation in the Gaza Strip, Palestine, there is an increasing need to assess the risk management strategies, especially in the construction industry, with the view to evaluating their suitability for the ever-changing political terrain. The construction project is one of the most dangerous and risky fields of work, where it is surrounded by many uncertainties that require management due to the presence of many internal and external factors that affect the process. This study provides an understanding of the difficulties and barriers in risk management faced by the construction organizations in the Gaza Strip, and also offers recommendations to improve project implementation by building infrastructures upon which other sectors depend for effective service delivery, keeping in view the importance of construction industry in national development. Moreover, key risk management strategies that are highlighted in this study will be beneficial for the construction industry stakeholders.

2. METHODOLOGY

The determination of the risk management strategies employed by construction organizations in the Gaza Strip is the aim of this study. A study of this nature requires the use of the appropriate tools for data collection, which in most cases is the questionnaire. Both qualitative and quantitative types of data have been analyzed for this study.

The design of the questionnaire was based on information obtained from relevant literature. The relevant questions were obtained from the literature and refined through interviews and pilot survey. The target group of the study included engineers working in construction companies, supervising engineers from international agencies, such as UNDP, UNRWA, Ministry of Public Works and Housing. The purposive sampling technique was chosen for the selection of the sample participants. The purposive sampling is a type of non-probability sampling technique that is most effective when there is a limited number of people that have expertise in the field being researched [21]. Purposive sampling can also be used with quantitative and qualitative research methodology. The inherent bias of the method enhances its efficiency, and the method is strong even when tested against random probability sampling. Choosing the purposive sampling method ensures the quality and reliability of the collected data [21].

2.1. The Questionnaire Format

The questionnaire is composed of six parts, each serving as a source for different information from the respondents as follows:

(i) General information about the response person

(ii) General information about the company

(iii) Risk factors

(iv) Determination of risk factor

(v) Avoiding the risk

(vi) Tools for analyzing the risk

The numerical rating scale (five-point Likert scale) was chosen to format the questions with some common sets of response categories called quantifiers (they reflect the intensity of the particular judgment involved) [22]. Those quantifiers were used to facilitate the understanding of the questions.

2.2. Face Validity of the Questionnaire

Face validity is very important in determining whether the questionnaire appears to be valid or not. It was presented for evaluation by experts in the risk management field or statistics [23]. The questionnaire was presented to 10 experts by hand delivery at different periods for evaluation. Many useful comments were made and taken into consideration for the modification of the questionnaire.

2.3. Semi-Structured Interviews (SSI)

SSI is a verbal or conversational type of interchange where an interviewer tries to elicit information from the interviewee by asking a series of predetermined questions in a normal casual conversation style [24]. The SSI approach was adopted in pretesting of the questionnaires. Pretesting is a very necessary step in a study involving a questionnaire survey. It is an important phase to ensure that all errors related to the survey are reduced or removed completely. It contributes to improving the quality of the data. The pre-testing was carried out in two stages, and each stage was tested with 5 professionals in risk management through the SSI approach. The first stage of the pretesting resulted in modifying some words in the questions, in addition to adding more explanation to some items in order to ensure the understanding of the question. After that, the second phase was implemented, and it was sufficient to ensure the success of the questionnaire, as there were no queries or comments from any professional, and all the questions were clear.

2.4. Pilot Study

Pilot research is a trial run for the questionnaire that includes identifying any vague questions, testing the wording of questions, testing the technique which is used to gather the data, etc [22]. The pilot study carried out involved consulting 15 experts in the field of construction and modifying the questionnaire formatting based on their feedback.

2.5. Data Collection

The data collection involved distributing the questionnaire to 60 respondents randomly selected from the target population. The last stage involved conducting a statistical test on the questionnaire to determine its reliability and validity.

For the statistical validity test of the questionnaire, two tests were performed: internal validity and structural validity tests. The internal validity test was carried out by measuring coefficients of correlation (Pearson test) between each item in one field and the whole field [25]. P-values were found less than 0.05; hence, the correlation coefficients of each field were found to be significant at α= 0.05. Thus, it can be said that the items in each field were consistent and valid.

The structural validity test measures the coefficient of correlation between one field and all of the other fields of the questionnaire that have the same level of scale rating (five-point Likert scale) [25]. It was found out that the values of significance for all fields were less than 0.05. Accordingly, it can be noted that the fields were valid to be measured. Other tests carried out included the Cronbach’s Coefficient Alpha; the results were in the range from 0.700 and 0.967, and the general reliability for all items equaled 0.962. This range is considered high (above 0.7). Thus, the result ensures the reliability of the questionnaire. Also, using the Half-Split method, the significance of all the field values was found less than 0.05, indicating the corrected correlation coefficients to be significant at α=0.05. As a result, it can be said that the studied fields were reliable.

After all the tests were carried out, and the results indicated the suitability of the questionnaire for the intended study, it was then distributed to the target respondents with a cover letter explaining the purpose of the research and assuring them of the security and privacy of the information to encourage them to respond. Analysis of the data was undertaken using SPSS (Statistical Package for the Social Science).

2.6. Respondents’ Profile

The respondents' profile is shown in Table 1. 60 responses (representing a retrieval rate of 65.71%) retrieved from the respondents in the construction industry in the Gaza Strip were evaluated in developing the profile based on six (6) categories of questions.

As can be observed from Table 1 , 70% of the respondents were engineers, 11.7% were directors of the engineering office, 6.7 were project managers, 5% were heads of specialization, 3.3% were assistant heads of specializations, and others accounted for 3.3%. Regarding the respondents’ years of experience in the engineering field, 38.3% of them had less than 5 years of experience while 16.7 had more than 15 years of experience. The educational background information indicated that most of the respondents (73.3%) had a bachelor’s degree, followed by 18.3% with master's, 6.7% with a diploma, and 1.7% had a Ph.D. 35% of the respondents implemented more than 15 projects in the last 5 years, while 26.7% did less than 5. Regarding the years of an engineering office in the field of consultancy, 28.3% had between 5 to less than 10 years of experience, followed by 25% who had from 10 years to less than 15 years of experience. Those having less than 5 and more than 15 years of experience accounted for 23.3%. 31.7% implemented a project worth less than 1$ million. 25% implemented a project worth between 1$ million to less than 5$ million in the last 5 years while those that implemented between 5$ million to less than 10$ million and those more than 10 million accounted for 21.7% each.

| Job Title | Frequency (F) | Percent (%) |

|---|---|---|

| Director of Engineering Office | 7 | 11.7 |

| Projects Manager | 4 | 6.7 |

| Head of specialization | 3 | 5.0 |

| Assistant Head of Specialization | 2 | 3.3 |

| Engineer | 42 | 70.0 |

| Other | 2 | 3.3 |

| Years of experience in the engineering field | - | - |

| Less than 5 | 23 | 38.3 |

| 5 - Less than 10 | 15 | 25.0 |

| 10 - Less than 15 | 12 | 20.0 |

| More than 15 | 10 | 16.7 |

| Educational level | - | - |

| Diploma | 4 | 6.7 |

| Bachelor | 44 | 73.3 |

| Master | 11 | 18.3 |

| Ph.D. | 1 | 1.7 |

| Number of projects implemented during the previous 5 years | - | - |

| Less than 5 projects | 16 | 26.7 |

| 5 - Less than 10 | 13 | 21.7 |

| 10 - Less than 15 | 10 | 16.7 |

| More than 15 | 21 | 35.0 |

| Years of experience of the Engineering Office in the field of consultancy | - | - |

| Less than 5 | 14 | 23.3 |

| 5 - Less than 10 | 17 | 28.3 |

| 10 - Less than 15 | 15 | 25.0 |

| More than 15 | 14 | 23.3 |

| Value of projects implemented in the last 5 years | - | - |

| > $1 million | 19 | 31.7 |

| From $1 to less $5 millions | 15 | 25.0 |

| From $5 to less $10 millions | 13 | 21.7 |

| $10 million and more | 13 | 21.7 |

3. RESULTS AND DISCUSSION

After subjecting the data to rigorous analysis using the SPSS software, the following results regarding the risk management strategies in construction organizations in the Gaza Strip were obtained.

3.1. Identification of Risk Factors Methods

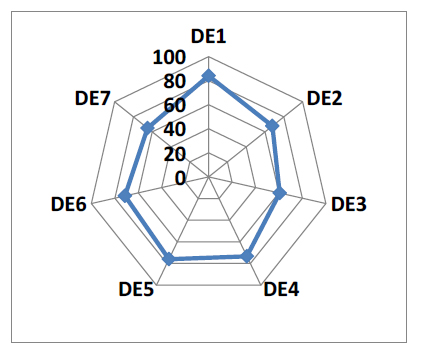

This section reveals the information on the methods used by the construction industries in the Gaza Strip to determine the risk factors. The determination of risk factors is composed of seven methods (DE1 – DE7). The result is presented in Table 2.

| No. | Determination of Risk Factor | Mean | Std. Dev | RII (%) | T Value |

P Value Sig. |

Rank |

|---|---|---|---|---|---|---|---|

| DE1 | Checklists | 4.20 | 0.90 | 84.00 | 10.35 | 0.000 | 1 |

| DE2 | In-house brainstorming | 3.39 | 1.05 | 67.80 | 2.85 | 0.006 | 5 |

| DE3 | Opinion of external subject matter experts | 3.03 | 1.19 | 60.67 | 0.22 | 0.829 | 7 |

| DE4 | Site Analysis | 3.67 | 0.93 | 73.33 | 5.54 | 0.000 | 3 |

| DE5 | Analysis of contract documents | 3.80 | 0.97 | 76.00 | 6.38 | 0.000 | 2 |

| DE6 | Case studies | 3.57 | 1.06 | 71.33 | 4.13 | 0.000 | 4 |

| DE7 | Other | 3.25 | 1.30 | 65.00 | 1.16 | 0.255 | 6 |

The findings indicated that “Checklists” method (DE1) (RII =84.00%; P-value =0.000; T-value= 10.35; SD= 0.90) had the highest rank (Fig. 1). Since P-value here equaled 0.000 which is less than 0.05, and T statistics = 10.35 > T critical (2.00), the statistically significant differences were attributed to the respondents’ opinions at the level of α ≤ 0.05 between the statistical mean (4.20) and hypotheses mean (3). SD equaled 0.90, indicating that the respondents’ results were consistent and not spread out over a wider range of values. So, it can be said that the results were significant.

The use of a checklist ensures that tasks are monitored and kept on track to avoid deviating from the project plan. Doing that helps in identifying potential risks and taking appropriate steps to avoid them, thereby ensuring timely completion of the project and keeping it within the budget. That is the reason why most companies follow that method and commit to following it for evaluation and to identify any risks that may occur. Because of the prevalent use of the checklist in most of the construction projects in the Gaza Strip, it ranksa as the highest among the other types of methods for risk factor determination.

The results also revealed “Analysis of contract documents” determination of risk factors method (DE5) (RII = 76.00%; P-value = 0.000; T-value = 6.38; SD = 0.97) to be in the second position. Since P-value here equaled 0.000 which is less than 0.05, and T statistics = 6.38 > T critical (2.00), the statistical significant difference was attributed to the respondents’ opinions at the level of α ≤ 0.05 between the statistical mean (3.80) and hypotheses mean (3). Thus, it can be said that the results are valid. Contract documents are signed by all parties involved in the project and are governed by the document. Hence, in case of any dispute that may occur between any of the parties, reference documents are reviewed and conformed to. Consequently, it is very important to have a contract between any two parties obliging them to abide by the articles, which is the only reference and legally adopted and customary in the construction issues. For that reason, any terms agreed upon by the parties in the contract documents shall be documented.

“Opinion of external subject matter experts” determination of risk factors method (DE3) (RII = 60.67%; P-value = 0.829; T-value = 0.22; SD = 1.19) was ranked at the last position in this field. Since P-value here equaled 0.829 being greater than 0.05, no statistically significant differences were attributed to the respondents’ opinions at the level of α ≤ 0.05 between the statistical mean (3.03) and hypotheses mean (3). The results were found to be valid. If the solutions to any problem are found internally, in the custom of construction projects, experts from abroad are rarely used, because most of the major engineering companies supervise major projects in the Gaza Strip and have sufficient experience in solving any problem and predicting any risks due to accumulated experience [26-29].

Therefore, it may be noted that the tools mostly used by the construction organizations in the Gaza Strip for the determination of risk factors are the checklist and the contract documents.

3.2. Tools/Methods for Analyzing the Risks

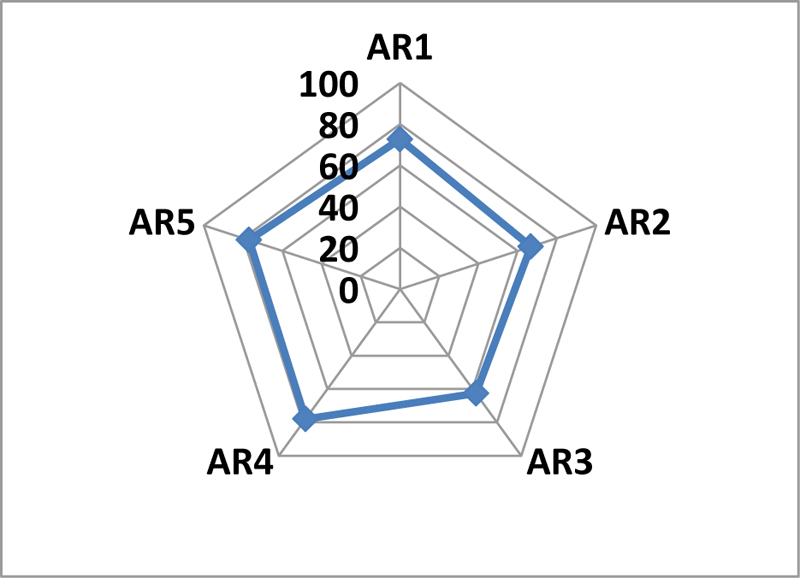

In this section, the tools or methods used by the construction organizations for analyzing the risks are discussed. Five tools are listed in Table 3 together with the results of statistical analysis on the data obtained from the respondents.

The findings demonstrated “Relying on experience in the direct assessment” tool (AR4) (RII =78.00%; P-value =0.000; T-value= 7.33; SD= 0.95) with the highest rank (Fig. 2). Since P-value here equaled 0.000 which was less than 0.05, and T statistics = 7.33 > T critical (2.00), a statistically significant difference was attributed to the respondents’ opinions at the level of α ≤ 0.05 between the statistical mean (3.90) and hypotheses mean (3). The results were found to be valid.

In the case of risks, some companies use experts from abroad to assess and analyze these risks, and most often, internal and external committees are formed to take decisions to overcome any risks. In most projects, there exist arbitration committees or advisory committees to whom any problem is referred, and they are expected to find appropriate solutions and provide a safe environment for completing the project activities. The previous experience of similar projects is very important to detect risks that may occur, and the experts can figure out those risks through observation or technical reports. The use of previous experience in the assessment of risk is very common as many construction organizations in the Gaza Strip employ the services of international companies with vast experience to undertake a risk assessment in order to prevent the occurrence of the risks [30-32].

| No. | Items | Mean | Std. Dev | RII (%) | T Value |

P Value Sig. |

Rank |

|---|---|---|---|---|---|---|---|

| AR1 | Analyzing by using computer applications | 3.63 | 1.16 | 72.67 | 4.22 | 0.000 | 3 |

| AR2 | Probability analyzing by using information history | 3.33 | 1.04 | 66.67 | 2.49 | 0.016 | 4 |

| AR3 | Analyzing by using simulation programs applications | 3.13 | 1.11 | 62.67 | 0.93 | 0.357 | 5 |

| AR4 | Relying on experience in the direct assessment | 3.90 | 0.95 | 78.00 | 7.33 | 0.000 | 1 |

| AR5 | Analyzing by using similar previous projects | 3.85 | 0.92 | 77.00 | 7.18 | 0.000 | 2 |

The results also revealed “Analyzing by using similar previous projects” statement (AR5) (RII = 77.00%; P-value = 0.000; T-value = 7.18; SD = 0.92) to rank at the second position.

Often, the problems and risks are repeated in the projects. Some companies benefit from the solutions to those problems in the previous projects and use them in other projects. This is due to the company's experience in executing the construction works and the size of projects implemented beforehand. That is why, some financiers usually require as a prerequisite the experience of the engineering company in similar construction works.

“Analyzing by using simulation programs applications” statement (AR3) (RII = 62.67%; P-value = 0.357; T-value = 0.93; SD = 1.11) was ranked as the last in this field. Companies are used to employing traditional methods of risk analysis. Therefore, few companies use computer applications to obtain results for risk analysis, although computer analysis is better and faster and gives more accurate results. This could be because the company needs to train the staff on computer analysis which will lead to financial costs that will, in turn, increase the financial burden of the company. Nevertheless, we suggest that the companies consider the importance of this factor in order to obtain more beneficial results.

3.3. Avoiding the Risk

As part of the risk management, construction organizations try to avoid the risk altogether through one or both of the following ways:

(i) Avoiding the risk before the implementation of the project.

(ii) Avoiding the risk during the implementation of the project.

Information retrieved from the respondents on both situations was statistically analyzed and the results are as follows:

3.4. Avoiding the Risk before Implementation

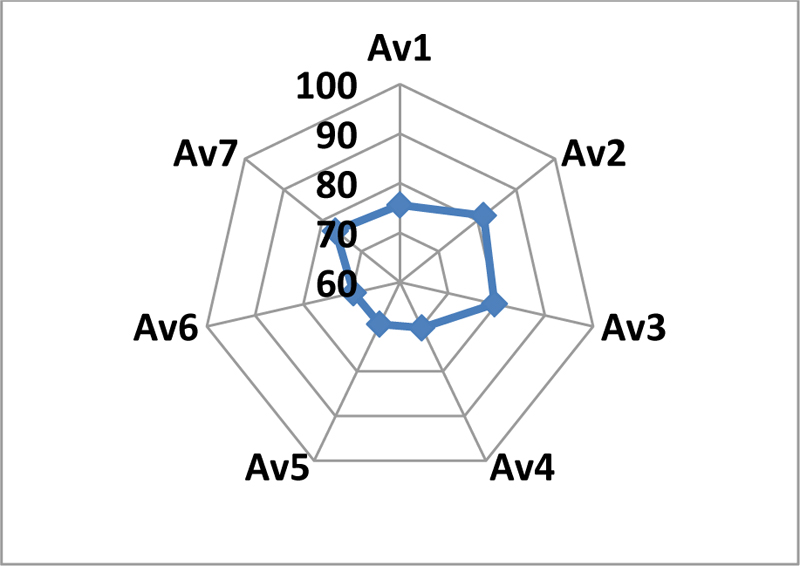

For evaluating this, seven items (Av1 to Av7) are used, as shown in Table 4.

The findings indicated that “Dependence on the experience in work for preparing and planning” statement (Av1) (RII =81.60%; P-value =0.000; T-value= 10.12; SD= 0.83) was ranked as the highest (Fig. 3). Since P-value here equaled 0.000 which was less than 0.05, and T statistics = 10.12 > T critical (2.00), the statistically significant difference was attributed to the respondents’ opinions at the level of α ≤ 0.05 between the statistical mean (4.08) and hypotheses mean (3). SD equaled 0.83, not far from zero, indicating the respondents’ results to be consistent and not spread out over a wider range of values.

Most companies use their expertise to identify any risks that may occur and rely on their expertise and knowledge to provide solutions to any possible problems that may occur. Most companies that apply for tender usually capitalize on their prior experience in handling a similar project, which gives them an edge over their competitors that do not have such experience. Their accumulated experience enables them to identify risks and proactively tackle them without hindering the normal workflow of the project. Hence, selecting an experienced construction company to undertake the project is one of the effective ways to avoid the risk before the implementation of the project.

| No. | Items | Mean | Std. Dev | RII (%) | T Value |

P Value Sig. |

Rank |

|---|---|---|---|---|---|---|---|

| Av1 | Analyzing based on the expectation quantity for the accuracy time | 3.78 | 0.92 | 75.60 | 6.58 | 0.000 | 4 |

| Av2 | Dependence on experience in work for preparing and planning | 4.08 | 0.83 | 81.60 | 10.12 | 0.000 | 1 |

| Av3 | Prepared schedules and plans can be updated at any time | 3.98 | 0.89 | 79.60 | 8.54 | 0.000 | 2 |

| Av4 | Prepare plans at stand by | 3.51 | 1.06 | 70.20 | 3.70 | 0.000 | 5 |

| Av5 | Invest extra time | 3.47 | 0.98 | 69.40 | 3.68 | 0.001 | 7 |

| Av6 | Distributing the risk and transfer to terminals of the project | 3.48 | 0.98 | 69.60 | 3.81 | 0.000 | 6 |

| Av7 | Use similar projects in implementation to obtain accurate project management information | 3.83 | 0.99 | 76.60 | 6.47 | 0.000 | 3 |

The results revealed the “Prepared schedules and plans can be updated at any time” statement (Av3) (RII = 79.60%; P-value = 0.000; T-value = 8.54; SD = 0.89) at the second position. It is very important in the knowledge of construction projects that the plans and engineering tables are subject to any modification and be flexible in the event of any change orders by the owner or consultant so as not to affect the quality of design and operational process. As mentioned earlier, the living conditions in the Gaza strip are unstable, and this is reflected directly in construction projects. Thus, plans of engineering projects must be flexible and be subject to change due to changes in the political and economic conditions. In other words, it is important in construction projects to have a flexible plan and schedules that can be updated, amended or upgraded at any time in the project. Having a rigid plan is risky, especially in areas like the Gaza strip [33]. That is why, this statement has been ranked second.

Ranked at the last position has been “Put the extra time in the time schedules” statement (Av5) (RII = 69.40%; P-value = 0.001; T-value = 3.68; SD = 0.98). There is no doubt that the projects in the Gaza Strip are exposed to risks that affect the supply of materials and equipment to the worksites, and the delay in their supply affects the period for the delivery of the project. Therefore, the construction companies compensate for any potential delay by putting extra time into the plans to avoid any problems in the supply process or any security events that may affect the working days of the construction project. Hence, this may be the reason why this statement has been ranked as the lowest.

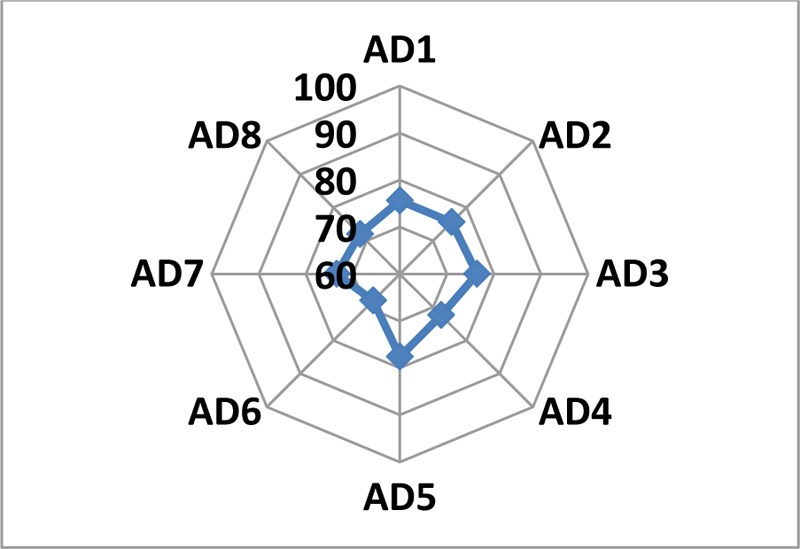

3.5. Avoiding the Risk during Implementation

This factor involeseight statements that determine the avoidance of risk during the time the project is being implemented, as shown in Table 5.

| No. | Items | Mean | Std. Dev | RII (%) | T value |

P value Sig. |

Rank |

|---|---|---|---|---|---|---|---|

| AD1 | Increase manpower and/or equipment | 3.78 | 0.94 | 75.60 | 6.45 | 0.000 | 4 |

| AD2 | Increase the working hours | 3.78 | 0.89 | 75.60 | 6.86 | 0.000 | 3 |

| AD3 | Change the sequence of work by overlapping | 3.82 | 0.91 | 76.40 | 6.94 | 0.000 | 2 |

| AD4 | Coordinate closely with subcontractors | 3.62 | 0.94 | 72.40 | 5.08 | 0.000 | 6 |

| AD5 | Follow up the implementation to avoid rework | 3.88 | 1.08 | 77.60 | 6.36 | 0.000 | 1 |

| AD6 | Change the tools of implementation | 3.40 | 0.96 | 68.00 | 3.23 | 0.002 | 8 |

| AD7 | Obtain insurance | 3.67 | 1.00 | 73.40 | 5.15 | 0.000 | 5 |

| AD8 | Transfer the risk to a subcontractor | 3.60 | 1.03 | 72.00 | 4.52 | 0.000 | 7 |

The findings showed “Follow up the implementation to avoid rework” statement (AD5) (RII =77.60%; P-value =0.000; T-value= 6.36; SD= 1.08) with the highest rank (Fig. 4). Since P-value here equaled 0.000 being less than 0.05 and T statistics = 6.36 > T critical (2.00), the statistically significant difference has been attributed to the respondents’ opinions at the level of α ≤ 0.05 between the statistical mean (3.88) and hypothesis mean (3). SD equaled 1.08, being not far from zero, thereby indicating the respondents’ results to beconsistent and not spread out over a wider range of values.

One of the best ways and means to eliminate any risks or problems is to follow the progress of the work and to comply with the terms of the contract documents and periodically evaluate and address any problems that may occur. This helps directly in identifying risks and predicting them, and finding appropriate solutions for the identified problems. The purpose of following up on the work is to overcome any financial or technical losses that can occur. The major projects stipulate in the contract documents that there should be committees to follow up on the progress of work and supervision. The importance of follow-up during the project implementation through a supervisory engineer is to control and monitor the process of construction project implementation I order to predict possible risks that may occur during the implemen-tation. It is also important to prepare contingency plans that may be used for avoidance of the risks and achievement of the project goals. Continued follow-up of construction projects helps to detect any risks during implementation. Finally, follow-up prevents any problem that may lead to rework, thereby saving effort, time and cost, and preventing any possible dispute between the project parties. Hence, we find this factor as the most important compared to other factors related toavoiding risk during the implementation of the construction project.

The results also revealed that “Change the sequence of work by overlapping” statement (AD3) (RII = 76.40%; P-value = 0.000; T-value = 6.94; SD = 0.91) has been ranked as the second. The executive plan for accomplishing the project activities must be applied to avoid any interference in the activities, which can cause financial risks to the contracting company. This could lead to financial loss in addition to the depletion of human resources, which impacts negatively on the progress of the work and implementation of projects. To get good results and achieve the desired goals, it is best to avoid any overlaps between activities to exclude the possibility of any risks that may occur. Companies often resort to the use of overlaps between activities due to lack of time or change in orders during the implementation phase.

The least ranked statement in this category was the “Change of the tools during implementation” statement (AD6) (RII = 68.00%; P-value = 0.002; T-value = 3.23; SD = 0.96). It is noted that the change of operational tools does not significantly affect the progress (hence the risk) of the project compared to other factors during the implementation. With the existence of a good management team in the workplace and the judicious use of a human resource, any work can be successfully accomplished with the exclusion of risks by appropriate means.

CONCLUSION

Construction projects are one of the high-risk prone undertakings, especially in areas like the Gaza strip. Due to this reason, this study was carried out to determine the risk management strategies employed by the construction industries in the area. Using a well-designed and adequately tested questionnaire, the objective of the study was successfully achieved, and the following conclusions were drawn:

1. It was found out that among the methods used by the construction organizations for the determination of risk factors, the use of a checklist is the most popular because of its ease of use and effectiveness.

2. For the tools/methods employed for risk analysis by the construction industries, relying on experience in the direct assessment is the most preferred method with an RII value of 78%.

3. When trying to avoid the risk before project implementation, the construction organizations mostly opt for “Dependence on experience in work for preparing and planning” in preference to other methods. Similarly, during the implementation of the project, the construction organizations prefer to “Follow up the implementation in order to avoid rework” as a means of avoiding risk in the project.

As a recommendation, companies should develop alternative contingency plans to face any conditions or obstacles that may occur during the implementation process of the project, thereby facilitating the exclusion of any risks. Similarly, good documentation of the progress of the project, follow-up on the progress of work, thorough documentation, and record of any observations or problems and addressing them before they occur will prove to be helpful in risk management.

LIMITATION AND FUTURE DIRECTION

The current study aimed at small samples of construction workers in the Gaza Strip and evaluated the scientific methodologies and techniques used by them to detect the risks in construction projects and their ways of managing those risks . Thus, the study recommends that more researches be conducted on other engineering projects, such as electricity, mechanics, and other infrastructure, involving larger sample sizes so thatseveral indicators that reveal risks in engineering projects along with the ways and means to overcome those risks are explored; this will ensure safe and effective implementation of engineering projects.

CONSENT FOR PUBLICATION

Not applicable.

AVAILABILITY OF DATA AND MATERIALS

The data that support the findings of this study are available on request from the corresponding author [B.A.T], upon reasonable request.

FUNDING

None.

CONFLICT OF INTEREST

Dr. Bassam Tayeh is the Associate Editorial Board Member of The Open Civil Engineering Journal.

ACKNOWLEDGEMENTS

Declared none.