RESEARCH ARTICLE

Decision Support Model for Contractor Selection

Reem T. Mergawy1, *, Hossam E. Hosny1, Abdelazeem S. Abdelazeem1

Article Information

Identifiers and Pagination:

Year: 2023Volume: 17

E-location ID: e187414952301270

Publisher ID: e187414952301270

DOI: 10.2174/18741495-v17-e230215-2022-51

Article History:

Received Date: 26/09/2022Revision Received Date: 13/01/2023

Acceptance Date: 16/01/2023

Electronic publication date: 29/03/2023

Collection year: 2023

open-access license: This is an open access article distributed under the terms of the Creative Commons Attribution 4.0 International Public License (CC-BY 4.0), a copy of which is available at: https://creativecommons.org/licenses/by/4.0/legalcode. This license permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Abstract

Introduction:

The construction and infrastructure industries in Egypt have recently experienced huge growth, which of course requires methodical planning, full feasibility studies, and wise selections of project executors' teams, including engineering design offices, management agencies, and contracting firms. Consequently, to guarantee achieving the predetermined project designs and objectives, a careful assessment of the incorporating contractor company must be carried out.

Problem Statement:

Improper contractor selection leads to several problems throughout the project delivery phase, including inadequate quality and delays in the expected project time, which results in cost overruns. Rather, it also sometimes results in suspending the project and failing to complete it. Moreover, in most public and governmental projects, in accordance with law 182/2018, the responsible employee is forced to choose the lowest-priced bid regardless of any other considerations, only passing the project's minimum technical score defined by the appropriate authority, and this is illogical and must be reconsidered.

Methodology:

In order to find a solution to these problems, the following steps were taken in this paper: (1) Forty-eight factors affecting contractor selection were identified through surveying; (2) the seven most important factors were selected based on the fuzzy Delphi technique (FDT); and (3) competitive contractors were prioritised at the pre-bidding stage for the construction project by utilising the analytic hierarchy process (AHP) combined with the analytic network process (ANP).

Results:

Seven of the forty-eight factors were selected using the fuzzy Delphi technique, and to calculate their relative weights, AHP and ANP were combined to obtain the most important variables affecting contractor selection. Next, a model user interface for picking contractors was developed to make it easier for project owners and managers to apply. To fully understand how the model functions, a realistic case study involving four bidders competing for the contract has been included.

Conclusion:

Since government agencies oblige decision-makers to select the lowest-priced bidder, this model can be used during the tendering process's prequalification stage to ensure that all potential contractors are qualified while including the most influential criteria from the Egyptian construction market's perspective.

1. INTRODUCTION

The process of contractor selection is the most complicated decision that the owners must make. Decision-making can be described as a mental process derived from the most appropriate contractor selection based on vagueness factors [1], which are arbitrarily chosen by the decision-maker [2]. Because government procurement employees in Egypt are held accountable for their decisions, it is nearly impossible to select a specific contractor rather than the one offering the lowest price [3, 4].

As a real-world experiment, a scenario has been formulated based on the previous analysis in which the lowest-priced contractor will win the contract. This analysis included the contractor's responsiveness to claims, rework that may arise during the project due to insufficient experience, or any other negative spots that could result in additional costs above the original price. These additional expenses could include (1) rework due to poor quality; (2) delays due to disability; (3) short life periods due to poor quality of materials; (4) excessive and maintenance problems due to insufficient experience; and (5) numerous claims due to poor management [5, 6]. As contractors quote low prices by decreasing the quality of work and hope to be reimbursed by submitting claims, this directly leads to cost overruns, financial issues, delays, and failure to meet the required specifications [7]. As a result, the researchers have begun looking for the most acceptable approach to selecting a contractor to protect the project from the abovementioned risks. Fong and Choi [8] stated that it is super clear that the lowest bid is not always the most cost-effective choice in the long run. Therefore, Bamberger and Stark [9] distinguished the best-value method from the lowest-tender strategy that is based only on cost; they concluded that the best-value tender is the selection procedure where the total construction cost as well as other non-cost aspects are included in the evaluation and awarding of the contractor. Therefore, determining the best value is more difficult than simply choosing the lowest tender [6]. It can be described as a multicriteria choice driven by uncertainty, which varies by project type. As a result, several contractor selection approaches based on financial and technical criteria have been made. Therefore, unquestionably, technical needs and bid cost, among other things, should be considered while selecting a contractor [10].

Due to the facts highlighted above, hundreds of research studies on judging technical factors have been conducted, including those in our African region, such as the Ghana study [11-25]. A sample of 26 peer-reviewed publications was chosen for the study, and their content was analysed to find the essential contractor pre-qualification requirements, broadening practitioners' and researchers' perspectives. The only limitation of this research was the small number of examination papers that were chosen for examination based on the Scopus search engine. Also, in Nigeria, the major contractors' prequalification standards were discovered through data collected from 60 surveys given to industry professionals and ranked via Excel's AHP interface [26-41].

The same issue was found in the Arabic study region, where almost 60% of construction projects in the Kingdom of Saudi Arabia were delayed in the last ten years. As a result, an extensive literature review, market analysis, and information gathering were conducted in collaboration with industry-academia specialists who developed a forty-criteria-based selection framework with their proportional weight developed in comparison to values produced using smart techniques and validated by using the Multi-Attribute Utility Theory score (MAUT) [42].

In Egypt, two studies have been conducted. Coincidentally, a total of 105 completed questionnaires have been received back from specialists and workers in the field of construction engineering. The data have been evaluated using programs, like SPSS, Microsoft Excel, and others. And contractor selection software has been developed to accelerate the evaluation of the contractor's technical and financial proposal for the person in charge of awarding the contract [43, 44]. Each of these study-resulting factors is summarised later in our literature review.

In this study, as a matter of continuous development, the base of participants in the questionnaire was expanded to two hundred, and an attempt was made to involve all relevant parties, not just decision-makers, to cover all aspects that have an effect on the construction site. Additionally, three collaborative methodologies, FDT to identify the most influencing criteria and AHP/ANP to determine their weights, were merged to create a simple and direct computer model that can be applied by any institute to almost any construction project.

2. MATERIALS AND METHODS

2.1. Methods of Contractor Selection

There are six ways to select a contractor, supplier, or vendor. (1) Least cost: this is the most basic method, using which most contractors and vendors are selected. Therefore, using price as the sole selection factor should be limited in certain situations when the work is reasonably well specified and understood by the contractors. Otherwise, it is very risky with the high possibility of extra work (and money) that might be required. (2) Qualification only: it is the polar opposite, in which the contractor is chosen solely on the basis of his qualifications with no regard for cost. After the contractor is selected based on his qualifications, he is requested to submit a price. This method is limited to small projects or small parts of larger projects that do not have an impact on the project budget. Therefore, it is used when the qualifications are significantly more important than the price. (3) Quality- and cost-based: this method is used when the price is on par (at the same level of importance) as the other qualification-based factors in the same submission. (4) Sole source: in this method, there is only one contractor who is asked to do the job, and he is selected without any competition from others. With this selection method, there are no qualifications evaluated, and the technical proposal may or may not be required. Therefore, if the scope and price are acceptable, the contractor is asked to proceed. (5) Fixed budget: this method depends on the price specified by the owner, and then the contractor is asked to specify and adjust the scope of work to suit it. This is implemented in rare cases when the owner wants to perform whatever work is possible within his budget. (6) Quality-based system: in this method, the quality is more important than the price, but the price is considered important too. Therefore, contractors are asked to submit two separate bids: a technical bid and a price bid. The technical one is reviewed and evaluated first to get a technical score to avoid price bias, and then the price bids are opened and factored into the technical score to get the final score [11].

This approach is the most modern and most suitable for all projects in different circumstances, but it requires a well-organized process for calculating the technical score and financial score, which is called the tendering process. As indicated in Egyptian research, one-stage tendering is employed for small projects within a 1 million LE project budget. Furthermore, two-stage tendering is employed for the evaluation and selection of contractors for medium-sized, large, and mega projects. The first stage, known as prequalification, selects companies that are thought to be appropriately qualified and competent to handle the project. In the second stage, the bidding stage, each response bid is carefully evaluated (bid evaluation) to award the contract to the best bid [45].

2.2. Factors Affecting Contractor Selection

Jennings and Holt [12] conducted research to find the most essential factors in the process of contractor selection, and they concluded that the most significant variables to consider while prequalifying contractors are company reputation, company financial standing, and company experience with similar construction. Moreover, Abdelrahman et al. [3] found factors affecting contractor selection and classified them into four main groups as follows:

1. Primary project requirements: This group measured the essential concerns of owners, which included the planned contractor’s bid price, the scheduled timeline, and the percentage of risk sharing between the owner and the contractor.

2. Financial capability: This group evaluated contractors' financial stability, including their capacity to meet current liabilities, long-term financial responsibilities, and existing commitments while working on the project.

3. Past performance: This group typically evaluated the contractor's reputation from four aspects: the percentage of previous projects finished on time, the contractor's previous relationship with the owner, the contractor's response to claims, and his health and safety statistics.

4. Experience: This group investigated resource availability, equipment shortages, and low productivity that cause delays. In addition, the contractor crew's level of expertise and if the contractor has previously handled tasks of similar scope and complexity have been considered.

Qualification-based selection (QBS) system has been recently used as a selection approach, in which, besides the price, non-price criteria, such as the contractor’s past performance, financial ability, technical skills, and management skills, are adopted [13].

Moreover, according to Huang [14], many factors should be examined as follows: (1) Financial standing, including financial stability, turnover, profit, obligations, due dates, and monetary funds owned; (2) Technical aptitude, including experience, plant and equipment, and employees; (3) Management capacity, including prior performance and quality, quality control policies, quality management systems, project management systems, technical personnel expertise, and management knowledge; (4) Quality, safety, and senior management, including experience, employment with the company, and responsibility division; (5) Current projects and backlog, including number, size, and location of projects; percentage of capacity used; status and expected completion; past failures in finished projects; the number of years in construction; and previous failures in completed projects.

In a late African study, it was stated that owners, when bidding for a construction project, should investigate the underlying factors behind contractor selection using five factors: managerial capabilities, quality standards, resource availability, duration, project cost, and location. Through this reclassification of selection factors, professionals would find it easier to make well-informed decisions in contractor selection [15] and in the Acheamfour paper [25], which was conducted in Ghana and discussed six major classification categories, including technical management, financial reputation, general experience, health, safety, and environmental considerations. Also, in Nigeria, a study found that a contractor's past performance is the most significant existing requirement for pre-qualification in the study area, while the contractor's resources play the largest determining role in the selection of these criteria [41].

In the Middle East region, a forty-criterion-based selection framework was developed in Saudi Arabia. Project value, financial capability, reputation, management structure, technical capability and performance, organisational culture, safety, and environmental health were defined as the primary categories of the selection criteria. Quality assurance and control were shown to be the most crucial factors, while current or past joint ventures were the least significant [42].

In order to gather actual data about Egypt's crucial selection criteria for contractors, Atia et al. employed an investigational approach that indicated a total of 15 main criteria and 67 sub-criteria. Experience, working schedule, bid specifics, general information, registration details, and management and organisation of the contractor were the most crucial factors [43].

Also, in a later Egyptian paper, for the project scale of 5 million LE, financial soundness had been found to have a great effect on the technical success of the contractor, as it accounts for 47% of the overall technical evaluation. In this paper, the most important technical criteria for contractor selection were discovered to be previous contract failure, availability of qualified supervisors, management expertise, safety management responsibility, technical staff experience, and liquidity [44].

2.3. Contractor Selection Approach

According to previous literature reviews, contractor selection is a multicriteria problem and needs different multicriteria techniques as a solution [10]. Multiple criterion decision-making (MCDM) is a sophisticated decision-making tool that incorporates both quantitative and qualitative criteria, and it has been used in recent years to choose the best feasible options. Therefore, it is applied in the construction business to pick project procurement systems, contractors, and vendors, as well as to resolve disputes [16].

Multi-utility theory, AHP, and ANP are simple weighting techniques and models used for making informed decisions that consider the specific needs of a project. One of the most common approaches to ranking and prioritising contractor selection factors is AHP, which uses a pairwise comparison scale to analyse multicriteria situations. AHP is composed of both qualitative and quantitative elements. It qualitatively breaks down the decision problems from the top goal to a set of manageable categories, sub-categories, and so on, down to the final level, including the alternatives. Quantitatively, it assigns weights to variables at the category and subcategory levels using pairwise comparisons, and then calculates global weights for the final assessment [17]. This technique, according to Fong and Choi [8], achieves satisfying outcomes in the final contractor selection process that are not solely dependent on the lowest bid. One of the key advantages of this tool is that it may be combined with other decision-making aids, such as fuzzy logic and ANP.

The ANP is a supplement to the AHP that allows interdependency between criteria when choosing contractors [18]. Moreover, it has the power to deal with complex decisions and complex relationships between criteria, in which AHP fails due to its limitations as it is applied only in simple hierarchical structures [5]. This combination of tools is not the first of its kind; similar studies have been conducted, such as the study by Abdelrahman et al. [3], which suggested the concept of best value modelling by coupling AHP with the weighted average technique to assign the weights for the criteria used to pick the contractor. The primary goal of this study was the selection of the contractor with the greatest value, and not to determine if the contractor with the best value would be successful.

Moreover, Kwong et al. [19] and Bevilacqua and Petroni [20] employed the scoring system with fuzzy theory to determine the best value bids. These decision support tools have aided in selecting the best contractor; however, there is no confirmation that they will lead to successful outcomes [21]. Similar technique combinations have been used in the Middle East region, specifically in Saudi Arabia, where the fuzzy AHP approach has been employed for determining the criteria weights and the fuzzy TOPSIS method has been used to find out the performance of contractors. As a result, a suggested approach to selecting the best contractor or splitting the projects among equally strong contractors has come into play [24]. As demonstrated in this study, the Fuzzy Analytic Hierarchy Process (FAHP) is preferable as an extended AHP decision-making tool to overcome the uncertainty involved in rating a contractor. The selection criteria were identified and grouped into eight major criteria, while the importance weight of the selection criteria was calculated based on the experts' ratings and ranked based on an AHP pair-wise comparison matrix, which was the basic part to form the decision-making model [46].

Our study is an extension of the previous research, which determined the most important aspects of the Egyptian fair using fuzzy Delphi technology to make it more realistic and avoid the uncertainty and ambiguity inherent in construction works, and then their relative weights were determined using AHP combined with ANP, which offers a more capable decision-making tool than AHP in determining not only the hierarchical order of each criterion but also the interdependence of each criterion [18, 47]. Following that, a model was used to rate each contractor while also emphasizing the price and combining it with technical factors to determine the final score.

2.4. Research Methodology

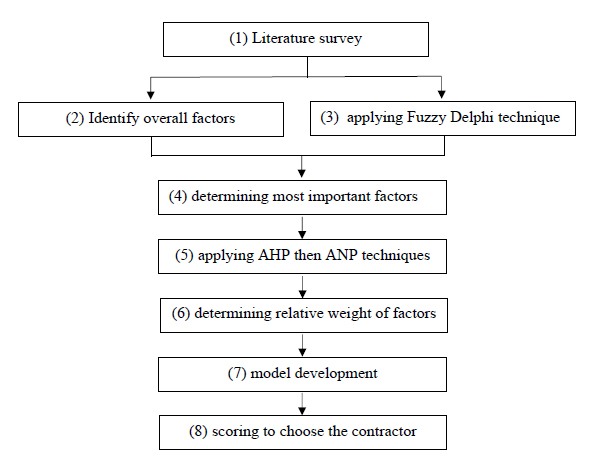

This paper describes three main approaches in detail, as illustrated in Fig. (1).

|

Fig. (1).

Research methodology. Cheng, Eddie WL, and Heng Li. "Contractor selection using the analytic network process." Construction management and Economics 22, no. 10 (2004): 1021-1032. [18] |

1- Forecasting and screening factors are required to evaluate a contractor's capacity to fulfill the project according to the owner's needs, based on the FDT.

2- The appropriate weights for the criteria identified in the previous steps needs to be determined. Therefore, AHP combined with ANP is used to assign factor weights.

3-Through the use of those tools, a Microsoft Excel sheet-based decision model for contractor selection can be developed. This computer model will consider the incomplete and imprecise information on which the experts’ opinions are formed, and the validity of this model will be tested using a real case.

2.4.1. First: Identifying and Screening Overall Factors Based on the FDT

This research identified the main factors that affect the contractor selection process. These effective factors are selected based on experts’ opinions from previous literature, and then a fuzzy decision model for contractor selection is developed that makes the selection process more systematic and realistic. Forty-eight qualitative criteria involved in contractor selection were aggregated from the literature review of several research studies and grouped into groups and sub-factors to conduct a questionnaire that will be used as an instrument to identify the most important factors, as represented in Table 1.

| Factors and Sub-factors | References |

| A. Past Performance | - |

| 1- Compliance with specifications and quality standards | Fong and Choi [8], |

| 2- Cost and schedule overruns in the past projects | Singh and Tiong [22], |

| 3- Attitude towards correcting faulty or incomplete works | Nieto-Morote and |

| 4- Attitude towards claims and counterclaims | Ruz-Vila [23], |

| 5- Relationship with past clients and subcontractors and suppliers | Taylan et al. [24], |

| 6- Past failure (failure to have a contract completed) | and Acheamfour et al. [25] |

| B. Past Experience | - |

| 1- Types of project completed | Fong and Choi [8], |

| 2- The scale of projects completed | Nieto-Morote and Ruz-Vila [23], |

| 3- Experience in the local area | Acheamfour et al. [25], |

| 4- Past experience with the client | Arazi et al. [26], |

| 5- Experience of the contractor in constructing similar structures | Marzouk and Khalifa [27], and Ha and Lee [28] |

| C. Performance Potential | - |

| 1- Size of structure | Acheamfour et al. [25] |

| 2- Project specific criteria | Singh and Tiong [22] |

| 3- Contract conditions | and Egemen and Mohamed [29] |

| 4- Construction program | - |

| 5- Current workload | - |

| 6- Ownership of construction machinery (plant and equipment) | - |

| D. Financial Capabilities | - |

| 1- Financial stability and risk prevention skills | Fong and Choi [8], |

| 2- Financial statement (credit rating) | Plebankiewicz [10] |

| 3- Banking arrangement and bonding | Taylan et al. [24], |

| 4- Budget and finances management for the project | Acheamfour et al. [25], |

| 5- Financial guarantees | Marzouk and Khalifa [27] |

| 6- Taxation details | Ha and Lee [28] |

| 7- Profit during the last three years | and Rashvand and Ghavamirad [30] |

| 8- Turnover history | - |

| 9- Reliable financing contractor sources | - |

| 10- Innovative methods of financing | - |

| E. Management Capability | - |

| 1- Availability of qualified managerial staff | Nieto-Morote and Ruz-Vila [23] |

| 2- Ability to timely complete projects with a workload | Taylan et al. [24] |

| 3- Certified management systems (quality system, safety policy) | Acheamfour et al. [25] |

| 4- Manpower qualification | Doloi [31] and Patil et al. [32] |

| F. Health and Safety | - |

| 1- Safety plan and safety recording system | Nieto-Morote and Ruz-Vila [23] |

| 2- Experience modification rating | Taylan et al. [24] |

| 3- Management safety accountability | Acheamfour et al. [25] |

| 4- OSHA incident rate | Rashvand and Ghavamirad [30] |

| 5- Propose an adequate plan to control safety and environmental sanitation | Patil et al. [32] and Puri and Tiwari [33] |

| G. Technical Competencies and Methodology | - |

| 1- ISO quality certification6- Effective project controlling | Arazi et al. [26] |

| 2- Propose a plan to manage quality and stay on schedule and within budget | Ha and Lee [28] |

| 3- Relation with other partners in the project | ndRashvand and Ghavamirad [30] |

| 4- Propose a logical approach to the tasks and issues of the project | - |

| 5- Capacity to understand and meet the requirements of the owner | - |

| H. Contractor Reputation | - |

| 1- Quality assurance plan | Taylan et al. [24] |

| 2- Quality management program | Acheamfour et al. [25] |

| 3- Quality and durability of the contractor’s work | Marzouk and Khalifa [27], |

| 4- The reputation of the contractor and team member | Rashvand and Ghavamirad [30] |

| Doloi [31] | |

| I. Tender Characteristics | - |

| 1- Time for the preparation of the bid | Marzouk and Khalifa [27] |

| 2- Criteria of bid selection | - |

A questionnaire has been distributed to around 200 respondents, including 21 site engineers with different experience periods ranging between 10 and 15 years, 30 project managers with more than 5 years’ experience working for both public and private sectors, 23 contractors with different rankings ranging from the forth to the second degree, 27 tender and pricing engineers working in both private and public institutes, 17 senior planning engineers working for large private companies, 35 private construction consulting offices with more than 10 years’ experience in Egyptian fair, and of course, the greatest focus was on the owners and financiers of construction projects, including 19 governmental agencies specialized in public service buildings and road construction and 25 private sectors constructing different types of projects for more than ten years.

Respondents were asked to determine the strength of the following factors influencing the selection of the contractor using a five-point Likert scale, where 1 is very weak, 2 is weak, 3 is medium, 4 is strong, and 5 is very strong.

Verbal expressions have limitations in their ability to fully reflect the respondent ‘s perspective. For example, the phrase “good” for respondent A is not the same as “good” for respondent B. At the same time, if a crisp number is used to quantify both individuals' views, the results would have been skewed. Therefore, to resolve this issue and create a value that accurately reflects the various language expressions, fuzzy sets have been used, which are more consistent with human linguistic and sometimes confusing descriptions [34].

Zadeh (1965) was the first to establish the fuzzy set approach, which essentially converts ill-defined linguistic variables into traditional quantitative ones [35]. Respondents can express their opinion of contractors' performance on decision criteria in verbal terms rather than as crisp values using this technique. The five phases of a fuzzy decision-making framework are as follows:

1. Identifying and clarifying the types of fuzzy numbers to be employed by decision-makers, as well as their membership functions.

2. Creating the scale of preference structure that decision-makers will apply.

3. Giving fuzzy values to attributes based on how well they perform on the judgement criteria.

4. Aggregating fuzzy numbers across decision-makers.

5. Performing defuzzification.

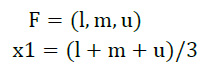

Triangular fuzzy number (TFN), according to Habibi et al.'s research, is a fuzzy number represented by three real numbers (l, m, u). The greatest value of the fuzzy number is marked by u, where the lowest value of the fuzzy number is represented by l, and m is the most likely value. Fig. (2) depicts the triangular fuzzy spectrum of the value of criteria for a five-point Likert scale, and Table 2 depicts it.

|

Fig. (2).

Triangular fuzzy number. Singh, D. A., and Robert LK Tiong. "A fuzzy decision framework for contractor selection." Journal of construction engineering and management 131, no. 1 (2005): 62-70. [22] |

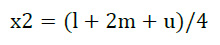

The values should be defuzzified after a fuzzy aggregate of expert opinions using the triangular fuzzy approach and converted into a crisp and intelligible number. A crisp value is the best average that sums up the aggregation of triangular or trapezoidal values. The defuzzification can be accomplished using the following equations: (1-3).

|

(1) |

|

(2) |

|

(3) |

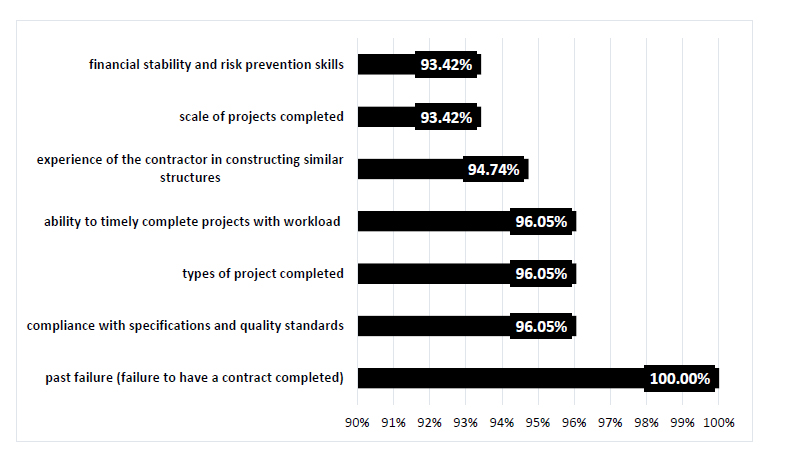

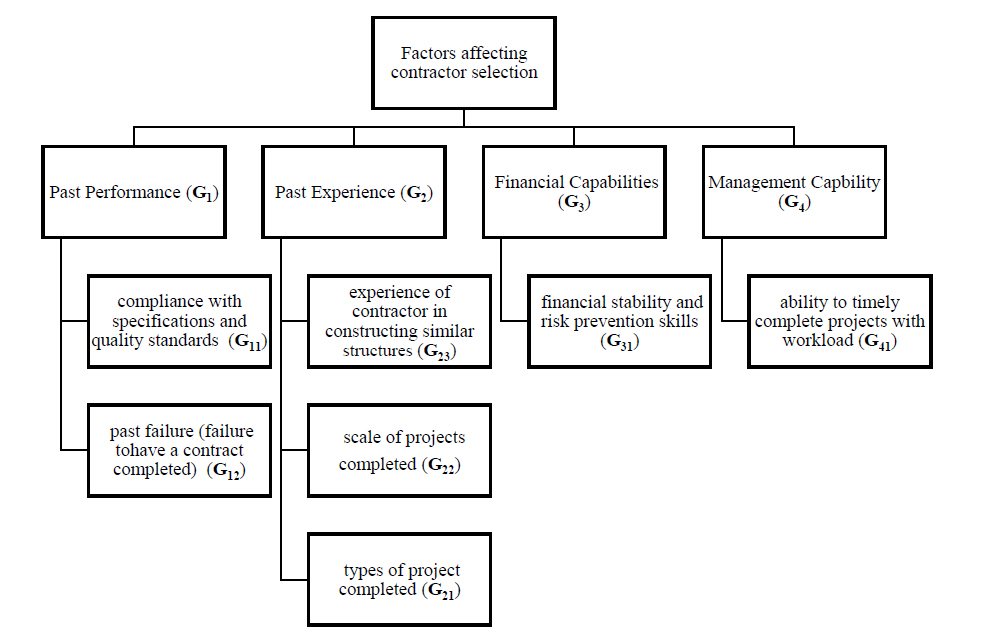

The crisp number (threshold) equals the maximum of x1, x2, and x3. In most studies, the threshold is 0.7, but it varies depending on the researcher's opinion. If the crisp value is greater than the threshold, the criterion is confirmed; if it is less than the threshold, it is removed. As a result of the four main influencing factors underlying seven sub-factors, the following (Fig. 3) was created as an initial graph showing the importance of the factors in relation to each other based on the crisp number.

2.4.2. Second: Determining Relative Weights for Previously Identified Factors

In this section, the overall objective is “selecting the most capable contractor,” so the next step is a prioritisation procedure to define the priority (or weight) of each factor using AHP combined with ANP after the factors and subfactors are identified. The traditional hierarchical structure of the AHP technique is constructed, as shown in Fig. (4). The next step is to systematically assess the alternatives by making pair-wise comparisons for each of the chosen criteria [36].

To address the uncertainty and interdependence among criteria, AHP and ANP techniques were used. AHP converts empirical comparisons into numerical values, which are then evaluated and compared. Starting at the top of the hierarchy and working down, the elements at each level are compared pairwise in terms of their importance to an element at a higher level. According to a study conducted earlier [37], the advantage of utilising a pairwise technique is that it allows the decision-maker to concentrate on comparing two things while keeping the observation free of outside influences.

A pairwise comparison questionnaire was made using Saaty’s 9-point scale, as indicated in Table 3, and distributed to more than a hundred experts in the fields of construction engineering and contract management, from whom a total of forty responses were obtained.

Pairwise comparison is explained as the element in the left-hand column is always compared with the element in the top row, and the value is provided to the element in the column as it is compared with the element in the row, and it takes a matrix form [8]. The first comparison is conducted between factors, and the results are represented in Table 4.

| Very weak | Weak | Medium | Strong | Very strong |

|---|---|---|---|---|

| (0,0,0.25) | (0,0.25,0.5) | (0.25,0.5,0.75) | (0.5,0.75,1) | (0.75,1,1) |

|

Fig. (3).

Factors and their relative importance based on the crisp value. Fong, Patrick Sik-Wah, and Sonia Kit-Yung Choi. "Final contractor selection using the analytical hierarchy process." Construction management and economics 18, no. 5 (2000): 547-557. [8] |

|

Fig. (4).

Traditional hierarchical structure of factors affecting contractor selection. El Agroudy, Mohamed, Emad Elbeltagi, and M. El Razek. "A fuzzy logic approach for contractor selection." In Fifth International Conference on Construction in the 21st Century on Collaboration and Integration in Engineering, Management and Technology, Istanbul, Turkey, May, pp. 20-22. 2009. [4] |

| Intensity of Importance | Definition |

|---|---|

| 1 | Equal importance |

| 3 | Moderately more importance |

| 5 | Strongly more importance |

| 7 | Very strongly more importance |

| 9 | Extreme more importance |

| - | G1 | G2 | G3 | G4 | Criteria Weight |

|---|---|---|---|---|---|

| G1 | 1.00 | 2.95 | 2.38 | 3.10 | 0.44 |

| G2 | 0.34 | 1.00 | 3.28 | 2.66 | 0.28 |

| G3 | 0.42 | 0.30 | 1.00 | 3.31 | 0.18 |

| G4 | 0.32 | 0.38 | 0.30 | 1.00 | 0.09 |

Based on Weber-Psychophysical Fechner's law, the core AHP absolute number scale employs the absolute numbers 1, 2, 3.. 9 or their verbal equivalents. However, theoretically, there is no reason to be limited to these numbers. There have been a few other numerical scales proposed to retain the consistency ratio (CR) of 10% and keep the weight matrix consistent. There are about eleven AHP scales to be used; one of them is the Root Square scale [38] with some restrictions, while the maximum range of entry values in the decision matrix is reduced to lower values than nine [39]. Therefore, the new values are calculated using Equation 4 as follows:

|

(4) |

Where,

x: the value on the integer judging scale for pairwise comparisons from 1 to 9

C: the ratio used as entry into the decision matrix; the maximum value of c is 9

Therefore, we get the new matrix with a consistency ratio of CR=3.67%, as presented in Table 5.

Next, our methodology continues to complete pairwise comparisons for each factor as sub-factors are compared against each other. Therefore, a pair-wise comparison is conducted to compare the importance of past performance factors affecting contractor selection, as represented in (Table 6, and the importance of experience factors affecting contractor selection, as represented in Table 7.

The overall priority scores of the contractor selection factors are aggregated and calculated, as represented in Table 8.

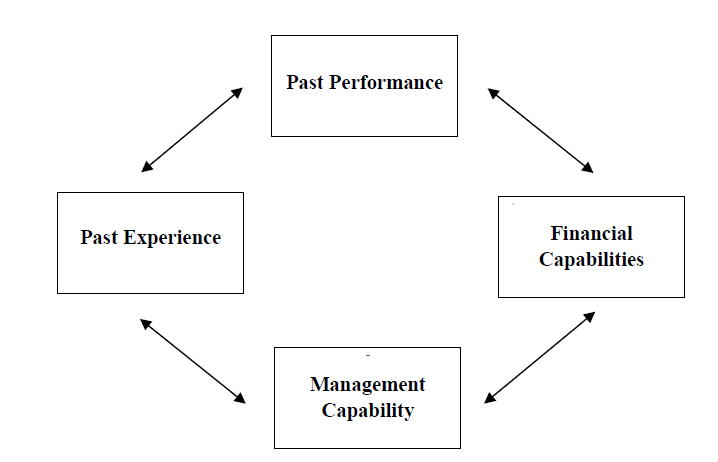

In this section, the inner dependence among the contractor selection factors is extracted by considering the impact of each factor on each of the other factors using comparison matrices using ANP, which extends the function of AHP as a viable method for multicriteria decision problems that involve interdependent relationships. Interdependency interactions among influential criteria can produce cause-and-effect dynamics; such connections can have a significant impact on choosing the best contractor [39].

The inner dependences among the contractor selection factors established are shown schematically in Fig. (5).

| - | G1 | G2 | G3 | G4 | Criteria Weight |

|---|---|---|---|---|---|

| G1 | 1.00 | 1.72 | 1.54 | 1.76 | 0.35 |

| G2 | 0.58 | 1.00 | 1.81 | 1.63 | 0.27 |

| G3 | 0.65 | 0.55 | 1.00 | 1.82 | 0.22 |

| G4 | 0.57 | 0.62 | 0.55 | 1.00 | 0.16 |

| - | G11 | G12 | Criteria Weight |

|---|---|---|---|

| G11 | 1.00 | 2.78 | 0.74 |

| G12 | 0.36 | 1.00 | 0.26 |

| - | G2.1 | G2.2 | G2.3 | Criteria Weight |

|---|---|---|---|---|

| G2.1 | 1.00 | 3.20 | 1.58 | 0.52 |

| G2.2 | 0.31 | 1.00 | 1.57 | 0.25 |

| G2.3 | 0.63 | 0.64 | 1.00 | 0.23 |

| - | Group priority |

Factors Affecting Contractor Selection | Factor Priority within the Group via AHP | Overall Priority of Factor |

|---|---|---|---|---|

| G1 | 0.35 | G11 | 0.74 | 0.259 |

| G12 | 0.26 | 0.091 | ||

| G2 | 0.27 | G21 | 0.52 | 0.140 |

| G22 | 0.25 | 0.068 | ||

| G23 | 0.23 | 0.062 | ||

| G3 | 0.22 | G31 | 1.00 | 0.220 |

| G4 | 0.16 | G41 | 1.00 | 0.160 |

Almeida, Michael. "A Selection Method In Construction Project Management Using Analytic Network Process (ANP) As A Tool In Decision." In DLSU Research Congress, pp. 1-14. 2017.

|

Fig. (5).

Inner dependence among the contractor selection factors. Görener, Ali. "Comparing AHP and ANP: an application of strategic decisions making in a manufacturing company." International Journal of Business and Social Science 3, no. 11 (2012): 194-208 [39] |

| - | Past Experience | Financial Capabilities | Criteria Weight |

| Past experience | 1.00 | 2.96 | 0.75 |

| Financial capabilities | 0.34 | 1.00 | 0.25 |

| - | Past Performance | Management Capability | Criteria Weight |

|---|---|---|---|

| Past performance | 1.00 | 2.18 | 0.69 |

| Management capability | 0.46 | 1.00 | 0.31 |

| - | Past Experience | Financial Capabilities | Criteria Weight |

|---|---|---|---|

| Past experience | 1.00 | 2.88 | 0.74 |

| Financial capabilities | 0.35 | 1.00 | 0.26 |

| - | Past Performance | Management Capability | Criteria Weight |

|---|---|---|---|

| Past performance | 1.00 | 2.89 | 0.74 |

| Management capability | 0.35 | 1.00 | 0.26 |

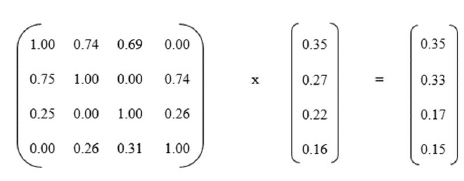

The inner dependence matrix of contractor selection factors, considering the calculated relative importance, is generated as each factor of the contractor selection is affected by two other factors, so the past performance factor is affected by experience and financial capability factors, the financial capability factor is affected by past performance and management capability factors, the management capability factor is affected by experience and financial capability factors, and the experience factor is affected by past performance and management capability factors. These results are presented in the next four Tables 9-12 to get the final ANP matrix, as represented in (Table 13).

| - | Past Performance | Past Experience | Financial Capabilities | Management Capability |

|---|---|---|---|---|

| Past performance | 1.00 | 0.74 | 0.69 | 0.00 |

| Past experience | 0.75 | 1.00 | 0.00 | 0.74 |

| Financial capabilities | 0.25 | 0.00 | 1.00 | 0.26 |

| Management capability | 0.00 | 0.26 | 0.31 | 1.00 |

| Factors | RW of Factors | Sub-factors | RW of Subfactors |

||

|---|---|---|---|---|---|

| G1 | 0.35 | - | - | ||

| - | - | G11 | 0.74 | ||

| G12 | 0.26 | ||||

| G2 | 0.33 | - | - | ||

| - | - | G21 | 0.52 | ||

| G22 | 0.25 | ||||

| G23 | 0.23 | ||||

| G3 | 0.17 | - | - | ||

| - | - | G31 | 1.00 | ||

| G4 | 0.15 | - | - | ||

| - | - | G41 | 1.00 | ||

|

Fig. (6).

Contractor selection group priority via ANP. Görener, Ali. "Comparing AHP and ANP: an application of strategic decisions making in a manufacturing company." International Journal of Business and Social Science 3, no. 11 (2012): 194-208 [39] |

After completing the inner dependence matrix using the ANP technique, it will be multiplied by contractor selection group priority via the AHP technique, so the priority of each factor changes as follows: past performance is still the same at 0.35, experience is increased from 0.27 to 0.33, financial capability is reduced from 0.22 to 0.17, and management capability is reduced from 0.16 to 0.15 to get the new matrix, as shown in Fig. (6).

2.4.3. Third: Microsoft Excel Sheet Decision Model for Contractor Selection

To take advantage of the results obtained, a simple model will be made that includes all values and relationships resulting from the different comparisons, a model through which users can evaluate contractors applying for any construction project.

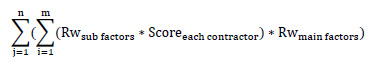

Group priority weights of factors via ANP and relative weights of sub-factors via AHP calculated from previous steps are abbreviated in (Table 14) and ready to be used. Therefore, the next step is to score contractors to get the one named by technical score using equation 5.

|

(5) |

Where, n = number of factors, m= number of sub-factors.

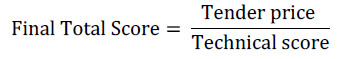

The contractor with the highest score is the most suitable contractor in terms of technicality, and it can be considered relatively guaranteed to implement the project within the specified cost and delivery time. Tender price is illogically ignored because it is not included as one of the factors influencing other factors. Therefore, it must be added as the main independent factor used to calculate the final total score, or in other words, ‘the best tender value’ for each contractor using equation 6.

|

(6) |

Here, in this equation, the contractor with the lowest score is the contractor who has achieved the balance between the financial and technical aspects.

As a result of these two equations, the model is run by allowing a competent employee to insert contractors' company alternatives with their tender price and then assigning a score to each competitor based on the submitted bid in each criterion.

2.5. Case Study Model Validation

Our case study is a paving project on the road from Ammar Bridge in the direction of Faqous, Al-Sharika, Egypt. Four contractors, lets name them A, B, C, and D, were interested in bidding for this project. What happened is that contractor C, with the lowest bid, was chosen without considering any other qualifications. This led to a delay in the delivery of the project of around five months, which certainly led to additional costs borne by the owner. In careful research, it was found that the reason for that delay was his lack of experience in organising project implementation in addition to his financial failure, which means that a different method to select a suitable contractor is needed. Therefore, our developed model can be applied.

As the four bids, A, B, C, and D, have been re-evaluated by asking the parties in charge to assign each contractor a score on a unified scale of 1 to 5 for each factor by studying his technical envelope and awarding him a suitable degree, the next step is to absolutely insert the tender bid financial value for each contractor, which was excluded during the study of affecting factors, as represented in (Table 15).

As the model is applied, it can be noticed that contractor A obtained the highest technical score with a score of 3.7, which equals around 74% of the ultimate target, while pre-selected contractor C, with the lowest tender price, obtained a 2.27 score with a difference of 28.6% compared to contractor A.

According to our model, as each contractor’s tender price is divided by his technical score, the most reliable contractor is the one with the lowest final score. Therefore, the best tender value in our case is contractor D, with a 3.64 score that equals around 72.8% of the ultimate target and a 27.4% increase in the technical score and a 12% increase in the tender price over the failed pre-selected contractor C. So, contractor D scored the best tender value (final total score) that achieved the balance between them, as it is shaded in grey in (Table 15).

3. RESULTS AND DISCUSSION

Appropriate contractor selection leads to fewer disputes throughout the project delivery and less delay in the expected project duration, which ultimately results in cost underruns. A total of 49 factors affecting contractor selection have been identified, including tender price. 7 of the 48 factors were selected based on the fuzzy Delphi technique. To avoid any unfair comparison, the tender price was excluded earlier from the questionnaire stage. On the other hand, the financial capability was included among the factors, and it was already selected from the most influential ones. This is what we are seeking to establish, as there is no value in a price that the contractor cannot achieve. Instead, the ability of the contractor to manage his finances and resources is much more significant than the price he established to get the job. Additionally, this study shows how Egyptian project managers are aware of the significance of quality factors.

To determine the value of the overall priority vector or the weights of the criteria and alternatives, the results from ANP and AHP are compared for the main four categories as ANP allows interdependent influences. Therefore, the relative weights had been slightly modified, as they are still approximately the same, except for past experience, whose relative weight increased from 0.27 to 0.33, which makes sense according to our research.

So the outcome, including relative weights of group and sub-factors, in brief was as follows: (1) Past performance weighted 35% with two sub-categories: compliance with specifications and quality standards (74%) and past failure (failure to have a contract completed) (26%); (2) Experience weighted 33% with three sub-categories: types of projects completed (52%), scale of projects completed (25%), and experience of a contractor in constructing similar structures (23%); (3) Financial capabilities weighted 17% with sub-category: financial stability and risk prevention skills; (4) Management capability weighted 15% with sub-category: the ability to timely complete projects with workload.

The collaboration between AHP and ANP achieves three key objectives: (1) making decisions in situations of uncertainty, which is the main objective; (2) including inter-dependencies between factors; and (3) handling selection, including a large variety of alternatives.

These results have been used to formulate a simple interface model that can be used for prequalification and final bid evaluation stages for an open number of competitors, where it incorporates basic factors aligned with Egypt's construction industry's community vision.

| - | - | A | B | C | D |

|---|---|---|---|---|---|

|

Price Factors |

Tender Price | 3,234,000 | 3,190,500 | 2,660,000 | 3,030,000 |

| - | Scoring Each Factor | ||||

| Non-price factors | Compliance with specifications and quality standards G11 | 5 | 5 | 2 | 4 |

| Past failure (failure to have a contract completed) G12 | 3 | 2 | 2 | 5 | |

| Types of projects completed G21 | 4 | 4 | 1 | 5 | |

| Scale of projects completed G22 | 4 | 3 | 3 | 1 | |

| Experience of the contractor in constructing similar structures G23 | 4 | 4 | 2 | 1 | |

| Financial stability and risk prevention skills G31 | 3 | 2 | 5 | 4 | |

| Ability to timely complete projects with workload G41 | 2 | 1 | 1 | 3 | |

| Technical score | 3.70 | 3.20 | 2.27 | 3.64 | |

| Best tender value (final total score) | 874527 | 995631 | 1171342 | 833013 | |

CONCLUSION

In Egypt, the final contractor selection process might be very strict and not flexible, especially in government institutions, which may expose the responsible person to accountability or punishment in case he did not choose the lowest-priced bidder. In this situation, it is at least recommended to apply the model in the prequalification phase of the tendering process to ensure that all proposed contractors are competent and possess the minimum technical capabilities. As the factors chosen are responsive to different types of projects, locations, and respondent characteristics, the model can be used in almost any project delivery system. Additionally, despite being conducted in Egypt, the study is helpful to professionals planning to work on building projects throughout the Middle East's developing region due to the shared patterns in contemporary practices.

Moreover, it is advised that employers and consulting firms test, enhance, and use this straightforward interface model for different types of projects. The difficulties, however, lie in obtaining credible information, as the Egyptian construction industry requires a reliable database system that can give decision-makers the accurate information they need for the contractor selection process.

LIST OF ABBREVIATIONS

| FDT | = Fuzzy Delphi Technique |

| AHP | = Analytical Hierarchy Process |

| ANP | = Analytical Network Process |

| MCDM | = Multiple Criterion Decision Making |

| QBS | = Qualification-Based Selection |

| TFN | = Triangular Fuzzy Number |

LIST OF SYMBOLS

| u | = The greatest value of the fuzzy number |

| l | = The lowest value of the fuzzy number |

| m | = The most likely value of the fuzzy number |

| x1 | = First average of the fuzzy number |

| x2 | = Second average of the fuzzy number |

| x3 | = Third average of the fuzzy number |

| CR | = Consistency Ratio |

| x | = The value on the integer judging scale for pairwise comparisons from 1 to 9 |

| C | = The ratio used as an entry into the decision matrix; the maximum value of c is 9 |

| Rw | = Relative weight |

CONSENT FOR PUBLICATION

Not applicable.

AVAILABILITY OF DATA AND MATERIALS

The data supporting the findings of the article is available in the Zenodo at https://doi.org/10.5281/zenodo.7620867 reference number: 10.5281/zenodo.7620867.

FUNDING

None.

CONFLICT OF INTEREST

The authors declare no conflict of interest, financial or otherwise.

ACKNOWLEDGEMENTS

Declared none.