All published articles of this journal are available on ScienceDirect.

Investigating the Properties of Drainage Concrete Pavement through the Pore Creation Method: A Study

Abstract

Background:

Over the past decade, the pervious concrete pavement has become a popular innovation due to its highly porous spaces that allow for easy air and water flow from the surface to the underlying layers. However, the increased void content could potentially make the concrete weaker and less durable, which creates a need for alternative methods to maintain its strength while improving its drainage capabilities.

Objective:

This study aims to analyze the characteristics of drainage concrete pavement using a novel method for creating pore structures.

Methods:

To address the challenges of conventional concrete pavement, various pore patterns and diameters were examined, including a 2x2, 3x3, and 4x4 row arrangement with pore diameters of 2, 3, and 4 mm. The concrete mixture was formulated to comply with the standards established by the Department of Highways in Thailand. The study analyzed both the fresh concrete properties, such as slump test and setting time, and the hardened properties, such as compressive strength, flexural strength, and water absorption. The draining capability was evaluated through water permeability performance and the clogging effect was measured by very fine sand particles.

Results:

The test results showed that the slump value of concrete complied with the design specifications, and the initial setting time was recorded to be 230 minutes. The compressive strength and flexural strength tended to decrease while water absorption tended to increase as the pore pattern arrangement and pore diameter increased. However, the compressive strength of all mixtures exceeded 85% when compared to the control. Additionally, the water permeability coefficient ranged between 2.69-18.52 mm/s, and the permeability coefficient tended to decrease when the clogging effect occurred in the range of 18.18-37.27%.

Conclusion:

The findings of this study contributed to our understanding of the properties and behavior of concrete with pore creation. By refining our knowledge of the intricate correlation between porosity and compressive strength, it has become evident that reducing porosity is necessary to enhance the mechanical properties of concrete and ensure its long-term durability. Furthermore, sustainable infrastructure applications can improve the relationship between permeability and effective porosity through construction techniques.

1. INTRODUCTION

According to the Global Report on Road Safety by the World Health Organization, road-related injuries and deaths are on the rise, with low- and middle-income countries experiencing a disproportionate share of the burden. The number of road fatalities increased from 1.25 million per year in 2009 to 1.35 million per year in 2018 [1]. Environmental factors are a significant contributor to road accidents, with slippery roads during heavy rainfall being a major cause [2]. When water accumulates on the road surface, it can lead to the loss of tire traction, resulting in steering and braking difficulties. Hydroplaning, which occurs when tires spin above the water level, further increases the risk of accidents, especially when driving at high speeds, splashing through water, or running over puddles [3]. To minimize hydroplaning, drivers should reduce their speed, ensure proper tire maintenance, and avoid sudden movements while driving. In addition, road maintenance and design can play a critical role in preventing hydroplaning by ensuring proper drainage and upkeep of road surfaces.

The proliferation of impervious surfaces such as buildings, concrete pavements, sidewalks, and parking lots in cities, as a result of urbanization and population growth, has given rise to several problems during and after rainfall. The accumulation of rainwater on impermeable surfaces leads to flooding and increases the amount of runoff, which can overwhelm drainage systems and result in flash flooding. In China, for instance, urbanization since the 1980s has exacerbated the problem of urban flooding, which has been difficult to address with conventional drainage systems. Additionally, impervious surfaces contribute to temperature and humidity imbalances, which can result in greenhouse and hot land effects. During rainy days, the splashing of water on the road can also pose safety hazards [4-7]. To mitigate these problems, several solutions have been proposed. One approach is to reduce the number of impermeable surfaces or to use non-absorbent materials to cover the ground. However, this is often impractical. Alternatively, permeable concrete has been widely recognized as a sustainable urban drainage solution capable of effectively reducing stormwater runoff and alleviating localized urban flooding. This solution is not only cost-effective but also environmentally friendly, making it an ideal solution for cities grappling with water scarcity and pollution issues [8-10].

Permeable concrete, often known as pervious concrete, is a form of concrete that includes little or no fine aggregate. Instead, it consists of coarse aggregate particles with relatively large voids between them, resulting in highly porous spaces that allow air and water to easily pass from the surface to the bottom layers [11-13]. Pervious concrete primarily serves to reduce stormwater runoff by allowing water to percolate into the ground rather than flowing off into a storm drain. This innovative material has gained rapid recognition in sustainable construction due to its potential to facilitate groundwater recharge and enhance rainwater quality by acting as a filter [14, 15]. The application of pervious concrete in situations that require high permeability is particularly attractive, while there is a growing interest in its use in low-traffic areas including driveways, walkways, and low-traffic roadways to minimize the risk of flash flooding runoff. Pervious concrete can also contribute to sustainable construction by enhancing insulation performance, reducing noise, and improving the quality of water [15-20].

Pervious concrete and permeable pavements were first developed in Europe around 45 years ago. These pavements were initially designed to facilitate water infiltration rather than runoff and took various forms, including open aggregate and grass pavements. Over time, they were reinforced with cell structures made from concrete or plastic materials to enhance their load-carrying capacity [21]. In India, a study found that the infiltration rate of pervious concrete pavements remained stable even one year after construction [22]. The quantity of cementitious materials and water used to make a paste that forms a thick covering around aggregate particles is carefully controlled in the pervious concrete. The thickness of the paste determines the void space, with a larger paste thickness resulting in a smaller void space [23]. Pervious concrete typically has a low sand content, resulting in a considerable volume of voids. By carefully adjusting the amount of paste and flow to bind the aggregate particles together and ensuring adequate compaction, a network of highly permeable and interconnected voids can be created. This facilitates rapid drainage [24, 25]. A modified approach to designing the pervious concrete involves measuring the layer of cement paste coating the gravel and assuming that the paste only acts as a coating, rather than filling the voids between the gravel grains [5]. The volume of paste relative to the inter-particle void ratio has a significant impact on the strength, density, porosity, and permeability of pervious concrete [16]. Research has shown that using coarser aggregate fractions improves the hydraulic and mechanical properties of pervious concrete. Alterations to the aggregate sizes result in changes to the pore structure, which plays a critical role in the structural and functional effectiveness of the pervious concrete [26-28].

In the realm of concrete pavement, pervious concrete differs fundamentally from conventional concrete due to its significant, interconnected void spaces. However, the increased void content can compromise the material's load transfer capacity, thereby resulting in decreased strength, elasticity, and durability of the mixture [29]. While the addition of silica fume and superplasticizer to pervious concrete can considerably increase its strength, the high cost of their application limits their use [30]. Moreover, the collection of sediments within the interior pores of pervious concrete, known as clogging, remains a major obstacle to its widespread application [8, 14, 19, 31]. To overcome these limitations, Li et al. [32] developed a new method for constructing a porous concrete pavement with physical, interconnected pores based on reactive powder mortar. The new method was designed to achieve high permeability and good mechanical properties, while also meeting or exceeding the standards for conventional concrete pavements. However, the question remains of how this concept will impact the pore-making process and properties of concrete in mixes with high amounts of coarse aggregates. To address this question, this paper proposes a novel method for creating pores on conventional concrete pavement by varying pore arrangements and diameters to examine the mechanical properties and draining capability of concrete. The paper further explores the clogging test to measure the reduction in the water permeability of the concrete. The goal of the proposed method is to develop a sustainable and long-lasting pavement system with easy construction techniques and maintenance that overcomes the limitations of previous approaches.

2. MATERIALS AND METHODS

2.1. Materials

2.1.1. Cement

The ASTM C150 [33] type 1 Portland cement (OPC) used in the experiment comprised 71.83% calcium oxide (CaO) as the major constituent, and the other chemical compositions are indicated in Table 1. The specific gravity and surface area of the OPC were 3.14 and 3,640 cm2/g, respectively, in terms of its physical properties, respectively.

2.1.2. Aggregate

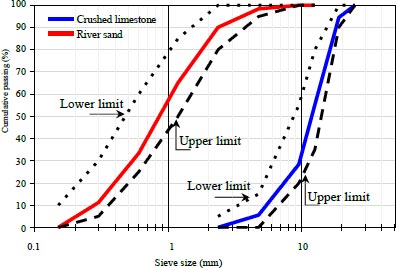

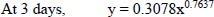

River sand with a maximum size of 4.5 mm and retention on a No. 100 sieve (opening size 0.15 mm) was used as fine aggregate. Crushed limestone was ground into coarse aggregate with a maximum size of 20 mm and a size retained on a No. 4 sieve (opening size: 4.75 mm). As demonstrated in Fig. (1), the results of particle size distribution are represented by grading curves. Conforming to the ASTM C33 [34] standards for aggregate grading limits, both the fine and coarse aggregates were determined to have a grading that was quite fine. The test results for the physical properties of the aggregates are shown in Table 2.

2.1.3. Water

All concrete mixes and curing of specimens in this experiment used regular household tap water.

2.1.4. Admixture

According to ASTM C494 [34], commercially available superplasticizers were utilized as chemical admixtures in concrete. Reducing the proportion of water to cement enhances the mechanical characteristics and workability of concrete.

2.2. Proportions of Concrete Mix

Before conducting tests, the mixture design and mixture trials must be performed, with the amount and proportion of the mixture conforming to the Department of Highways, Thailand standard no. DH-S 309 [35]. The ratio between the total aggregate and cement must not exceed 7:1. The cement used in the concrete mixture must weigh no less than 350 kg/m3. The ratio between water and cement must not exceed 0.55 by weight. The design strength of concrete must not be less than 32 MPa, including the modulus of rupture of no less than 4.2 MPa after 28 days of curing, and the fresh concrete slump must be between 30 and 70 mm. The proportion of the concrete pavement mixture utilized in this investigation is provided in Table 3.

| Constituent | SiO2 | Al2O3 | CaO | Fe2O3 | K2O | MgO | P2O5 | SO3 | TiO2 |

|---|---|---|---|---|---|---|---|---|---|

| Cement (%) | 15.49 | 3.30 | 71.83 | 3.57 | 0.4 | 1.38 | 0.06 | 3.15 | 0.28 |

| Properties | River Sand | Crushed Limestone |

|---|---|---|

| Bulk density (kg/m3) | 1,643 | 1,542 |

| Water absorption (%) | 0.85 | 0.55 |

| Fineness modulus | 3.02 | 7.39 |

| Specific gravity | 2.65 | 2.72 |

| Los Angeles value (%) | - | 23.00 |

| Constituent | This Study | DH-S 309 [35] |

|---|---|---|

| Portland cement (kg/m3) | 400 | >350 |

| River sand (kg/m3) | 790 | - |

| Crushed limestone (kg/m3) | 1093 | - |

| Superplasticizer (%) | 3.4 | - |

| Water/cement ratio | 0.30 | <0.55 |

| Aggregate/cement ratio | 5:1 | <7:1 |

| Model Design | Diameter (mm) | Arrangement | Designation |

|---|---|---|---|

| Control | 0 | - | D0 |

| Series I | 2 | 2x2, 3x3 and 4x4 | D22, D23 and D24 |

| Series II | 3 | 2x2, 3x3 and 4x4 | D32, D33 and D34 |

| Series III | 4 | 2x2, 3x3 and 4x4 | D42, D43 and D44 |

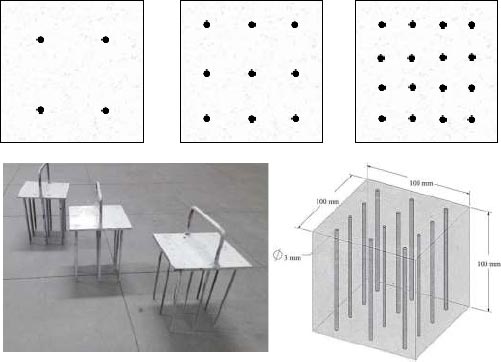

2.3. Sample Preparation and Pore Creation

The drainage concrete mixture was prepared in the laboratory in accordance with the design requirements. A rotating-drum mixer was used to mix the ingredients until a cohesive, homogenous, and free of segregation was obtained. The mixture was then cast into a mold for compaction before being smoothed with a vibrating table. The mechanical and drainage properties of the concrete mixture were evaluated using the pore creation model design based on the research carried out by Li et al. [32] as depicted in Table 4. This evaluation involved creating pores with diameters of 2, 3, and 4 mm in three different arrangements (2 x 2, 3 x 3, and 4 x 4) using the apparatus shown in Fig. (2). The pore creation process was carried out by inserting a cylindrical rod into the center of the sample and tapping it gently to form the pores. This process was repeated until the desired number of pores was achieved. The drainage concrete was cured by covering the specimens and mold with a plastic sheet and keeping them at room temperature for one day. After removing the mold, the samples were stored in a curing pond until the day of testing.

2.4. Test Methods

To evaluate the properties of freshly mixed concrete, a variety of tests are conducted. The consistency of the concrete is determined through the slump test, which assesses its workability in accordance with ASTM C143 [34] standards. The initial and final setting times of the concrete are also measured in accordance with ASTM C403 [34] standards. Compressive strength testing of 10 x 10 x 10 cm specimens, in compliance with British Standard BS 1881 [36], is used to evaluate the mechanical properties of the concrete. Similarly, flexural strength tests of 10 x 10 x 50 cm concrete beam specimens are conducted using the third-point loading weight placement method, following ASTM C78 [34] guidelines. Before testing, both compressive and flexural strength specimens are cured in water for 3, 7, and 28 days. Finally, water absorption tests of 10 x 10 x 10 cm concrete specimens are conducted after 28 days, as per ASTM C642 [34] standards.

The draining capability of the concrete is evaluated through two methods, which are based on the water permeability rate of 10 x 10 x 10 cm concrete specimens with designated pores. The water permeability rate is determined by placing water on top of a plastic box and measuring the time it takes for the water level to change. This testing method was proposed by Yang and Jiang [30]. Clogging testing is performed to evaluate the concrete's ability to permeate water in clogged conditions, which can occur due to extended use and result in problems with water permeability. For this test, clogging sand of varying sizes (0.0–1.0 mm) is employed to simulate clogging conditions and measure the water permeability rate compared to normal conditions, based on the study conducted by Huang et al. [32].

3. RESULTS AND ANALYSIS

3.1. Fresh Concrete Properties

3.1.1. Slump Test

As per the ASTM C143 standard [34], the slump test was used to evaluate the workability of fresh concrete. The concrete sample was divided into three equal parts by volume and placed in an Abrams cone. Each layer was compacted by 25 tamping strokes with a tamping rod. The cone was lifted vertically, and the slump value was determined. The test was carried out within 150 seconds as per the standard protocol, and the concrete was found to have a slump value of 60 mm, as shown in Fig. (3). The obtained value is consistent with the design specifications of the concrete mix, classifying it as having medium workability (50-100 mm). However, the results differ from previous concrete mixtures, which exhibited very low or zero slumps and a stiffer consistency compared to conventional mixes [5, 12, 24]. The amount of water in the mix was identified as a crucial factor affecting the slump value of concrete. Decreasing the water content reduces the slump value while adding water-reducing admixtures enhances the workability of the concrete [12].

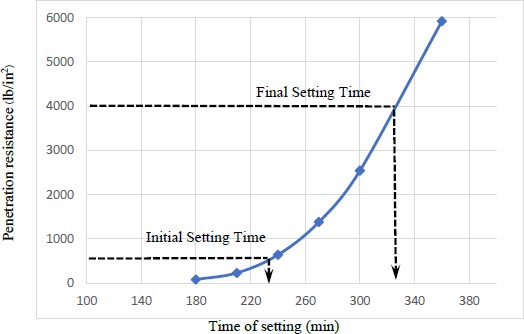

3.1.2. Time of Setting

Concrete setting time is determined by measuring two important stages: the initial and final setting times. The initial setting time denotes the point at which the mortar begins to offer resistance to penetration, characterized by a resistance of 500 lb/in2, whereas the final setting time refers to when the mortar reaches a resistance of 4,000 lb/in2. The experimental results indicated that the concrete sample under investigation had a 230-minute initial setting time and a 325-minute final setting time, as illustrated in Fig. (4). The initial setting time is a crucial parameter that defines the available time for the mixing and placement of concrete in position, thereby making it a significant factor in determining the pore creation time in this study, as reported in a prior research [32]. Pervious concrete often has a shorter setting time than normal concrete. This is because pervious concrete is typically designed to have a lower water-cement ratio and a higher cement content, which promotes faster hydration and setting of the cementitious materials. In addition, the open structure of pervious concrete allows for more rapid diffusion of water and air, which further accelerates the setting process. As the pervious concrete sets rapidly and, thus, must be constructed as expeditiously as possible [24, 29, 31].

| Designation | Compressive Strength (MPa) | Flexural Strength (MPa) | Water Absorption (%) | ||||

|---|---|---|---|---|---|---|---|

| - | 3d | 7d | 28d | 3d | 7d | 28d | |

| D0 | 24.9 | 28.9 | 37.8 | 3.55 | 3.95 | 4.62 | 4.04 |

| D2(2x2) | 23.9 | 28.2 | 37.4 | 3.47 | 3.89 | 4.56 | 4.38 |

| D2(3x3) | 23.1 | 27.6 | 36.7 | 3.4 | 3.81 | 4.51 | 4.89 |

| D2(4x4) | 22.2 | 26.4 | 35.7 | 3.28 | 3.63 | 4.32 | 5.46 |

| D3(2x2) | 22.7 | 27.0 | 36.3 | 3.36 | 3.72 | 4.42 | 5.06 |

| D3(3x3) | 20.9 | 25.0 | 34.7 | 3.16 | 3.52 | 4.18 | 6.19 |

| D3(4x4) | 20.0 | 24.1 | 33.9 | 3.06 | 3.42 | 4.06 | 7.28 |

| D4(2x2) | 21.7 | 25.7 | 35.2 | 3.23 | 3.58 | 4.27 | 5.64 |

| D4(3x3) | 19.6 | 23.5 | 33.4 | 2.99 | 3.35 | 3.99 | 7.36 |

| D4(4x4) | 18.9 | 22.7 | 32.4 | 2.86 | 3.23 | 3.81 | 8.47 |

3.2. Hardened Properties

The results of the hardness testing on the prepared concrete specimens are shown in Table 5. Destructive testing employing compression tests on 10 cm cubes till failure was used to measure the compressive strength. In order to calculate the flexural strength, the tensile strength was evaluated using third-point bending tests on prismatic specimens, and the water absorption was evaluated by calculating the increase in weight of the sample before and after drying. The average value of three different specimens was used to calculate the final results.

3.2.1. Compressive Strength

According to the data presented in Table 4, the compress- ive strength tests conducted on concrete specimens suggest that longer curing times result in higher compressive strength. This is due to the continual hydration interaction between water and cement, which increases compressive strength. At 3, 7, and 28 days after placement, the control concrete (D0) showed compressive strengths of 24.9 MPa, 28.9 MPa, and 37.8 MPa, respectively. Additionally, the compressive strength of concrete tends to decrease as the pore diameter increases. Stated differently, there exists an inverse relationship between pore volume and pore diameter, and the compressive strength of concrete. The compressive strength of concrete with a 2 x 2 pore arrangement was studied, and specimens with a 2 mm pore diameter had 28 days compressive strengths was 98.9% when compared to the control, 97.1% with a 3 mm pore diameter sample and 94.4% with a 4 mm pore diameter, respectively. The compressive strength of concrete with a 3 x 3 pore arrangement was studied, and specimens with a 2 mm pore diameter had 28 days compressive strengths was 96.0% when compared to the control, 91.8% with a 3mm pore diameter sample and 89.7% with a 4mm pore diameter, respectively. The compressive strength of concrete with a 4x4 pore arrangement was studied, and specimens with a 2mm pore diameter had 28 days compressive strengths was 93.1% when compared to the control, 88.4% with a 3 mm pore diameter sample and 85.7% with a 4 mm pore diameter, respectively. The findings of the test indicate that the compressive strength of all mixtures exceeded 85% when compared to the control. This study compared the compressive strength of conventional concrete specimens with pore-making to that of porous concrete. It was discovered that the compressive strength of concrete may be increased by adding fine material, specifically sand [5, 23]. On the other hand, between 2.8 to 28 MPa is typically the range for the compressive strength of porous concrete. This is due to the higher porosity and lower density of pervious concrete, which are the result of voids between aggregate particles [5, 8, 9, 12, 15, 18, 22, 24, 27]. However, with proper design and placement, the pervious concrete can still be sufficient compressive strength for many applications [26].

3.2.2. Flexural Strength

It is difficult to determine the tensile strength of concrete directly, thus, it is more appropriate to evaluate it through testing concrete beams under bending forces. This technique is used to determine the modulus of rupture, a measure of the highest tensile strength situated near the bottom of the beam. The flexural strength test findings are significant in ensuring the quality of concrete works, such as road and airport slabs, as concrete must possess sufficient flexural strength to bear weight [10, 24]. At 3, 7, and 28 days of age, the flexural strength test results for the control concrete (D0) revealed a modulus of rupture of 3.55, 3.95, and 4.62 MPa, respectively. The flexural strength of concrete with a 2 x 2 pore arrangement was studied, and specimens with a 2 mm pore diameter had 28 days flexural strengths was 98.7% when compared to the control, 97.6% with a 3 mm pore diameter sample and 93.5% with a 4 mm pore diameter, respectively. The flexural strength of concrete with a 3 x 3 pore arrangement was studied, and specimens with a 2 mm pore diameter had 28 days flexural strength was 95.7% when compared to the control, 90.5% with a 3mm pore diameter sample and 87.9% with a 4 mm pore diameter, respectively. The flexural strength of concrete with a 4x4 pore arrangement was studied, and specimens with a 2 mm pore diameter had 28 days flexural strength was 92.4% when compared to the control, 86.4% with a 3mm pore diameter sample and 82.5% with a 4 mm pore diameter, respectively. The test findings demonstrate that the modulus of rupture tends to increase as the curing time increases, which is in accordance with the findings of the compressive strength test. Pervious concrete typically has a flexural strength between 2.0 and 3.0 MPa, which is lower than that of normal concrete [21]. This is because pervious concrete typically has a higher porosity and lower density, which reduces its load-bearing capacity and ability to resist bending stresses. The open structure of pervious concrete also allows for more significant deformation under load, which can further reduce its flexural strength [10, 17, 18, 26]. Moreover, a variety of parameters affect flexural strength, including compaction level and aggregate/cement ratio [24].

3.2.3. Water Absorption

The concrete water absorption test is a methodology utilized to gauge the speed of water infiltration via the pores or empty spaces within concrete. To perform the test, the concrete samples were cured for 28 days and subsequently desiccated in an oven at 105°C for 48 hours until a consistent mass was attained. Following this, the specimens were immersed in water for 24 hours, and the weight gain was measured as the water infiltrated through the surface of the sample. Subsequently, the percentage of water absorption was computed, and the findings of the water absorption test are presented in Table 4 as an average. The results show that the control concrete (D0) had a water absorption rate of 4.04%, which was lower compared to the concrete specimens with different pore arrangements. The water absorption rate of concrete with a 2 x 2 pore arrangement was higher compared to the control, ranging from 8.4% to 35.1% for a pore diameter of 2-4 mm. In the 3 x 3 pore arrangement, the water absorption rate was higher than the control, ranging from 25.2% to 80.2% for a pore diameter of 2-4 mm. Meanwhile, the water absorption rate for the 4 x 4 pore arrangement was higher compared to the control, ranging from 39.6% to 109.7% for a pore diameter of 2-4 mm. The findings of the water absorption experiment demonstrate a strong correlation between the patterns of pore arrangement, pore diameter, and the amount of absorbed water. The water absorption capacity of concrete is significantly influenced by both its surface condition and porosity. As the pores become more organized and larger, the concrete's water absorption rate increases, leading to a greater amount of water being absorbed by the concrete sample. Porosity refers to the amount of void space within the concrete, and it can be affected by factors such as the mix design and curing conditions. The more porous the concrete, the more water it will absorb. In general, reducing the porosity of concrete can help to reduce its water absorption rate. This can be achieved through proper mix design, compaction, and curing. Additionally, maintaining a smooth surface on the concrete can help to reduce its water absorption rate by minimizing the amount of surface area available for water to adhere to [20, 37, 38].

3.3. Drainage Properties

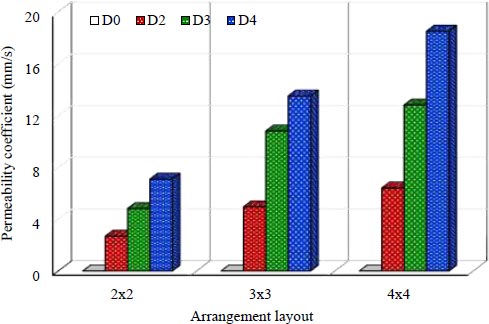

3.3.1. Water Permeability

Previous concrete is ideal for a range of applications due to its key property of water permeability [4, 9, 14]. The average values of the concrete sample water permeability test results are displayed in Fig. (5). The control concrete (D0) was assumed to have no water permeability coefficient due to the solid nature of the concrete specimens without any pore creation. The findings reveal that the concrete with a 2 x 2 pore arrangement has a permeability coefficient in the range of 2.69-7.09 mm/s for a pore diameter of 2-4 mm. For the 3 x 3 pore arrangement, the permeability coefficient was in the range of 4.95-13.51 mm/s for a pore diameter of 2-4 mm. Meanwhile, the permeability coefficient for the 4 x 4 pore arrangement was in the range of 6.41-18.52 mm/s for a pore diameter of 2-4 mm. Observation reveals that the water permeability coefficient increases with the arrangement pattern. In addition, the increase in pore volume from 2 x 2 (4 no. of pores) to 3 x 3 (9 no. of pores) or to 4 x 4 (16 no. of pores) can be observed that the permeability coefficient of water was increased. According to the test results, the water permeability coefficients increased due to the arrangement pattern and the increased volume of drilling pore. It has been proved that the permeability of pore-making is affected by pore size, pore size distribution, and pore continuity [4]. The permeability coefficient of water was in the range of 2.69-18.52 mm/s, which is higher than the permeability coefficient of porous concrete, which is between 2-6 mm/s [9, 18, 26]. According to a recent study, it has been found that the permeability of pore-making concrete is three times greater than that of porous concrete. The distribution of pores in pervious concrete is random and includes three types: connected, semi-connected, and closed pores. Among these, only connected pores play a role in determining water permeability, which is a critical aspect affected by effectively connected porosity. This finding is supported by several studies [18, 28, 32, 37] and highlights the importance of controlling effectively connected porosity in pore-making concrete to ensure optimal water permeability.

3.3.2. Clogging

The concept of pervious concrete clogging pertains to the buildup of particles, sediment, or other substances in the spaces between the aggregate particles, which may impede the material's capacity to effectively drain water. This can result in reduced permeability, potential flooding, or other problems in stormwater management systems [8-10]. The clogging effect on water permeability was investigated, as illustrated in Fig. (6). The 2x2 arrangement with 2 mm diameter pores had a decrease in permeability coefficient of 37.27%, the 3 mm diameter drilled pores had a decrease of 30.83% and the 4 mm diameter drilled pores had a decrease of 26.56%.

Similarly, the 3x3 arrangement with 2 mm diameter pores had a decrease of 30.82%, the 3 mm diameter drilled pores had a decrease of 25.10%, and the 4 mm diameter drilled pores had a decrease of 21.28%. The 4x4 arrangement with 2 mm diameter pores had a decrease of 23.92%, the 3 mm diameter drilled pores had a decrease of 20.00%, and the 4 mm diameter drilled pores had a decrease of 18.18%. The study findings reveal that an increase in pore diameter from 2 mm to 4 mm leads to a decreased reduction of the permeability coefficient. Moreover, an increase in pore volume also significantly decreases the reduction of the permeability coefficient. The outcomes suggest that the pore network exhibits a lower reduction in permeability coefficient than pervious concrete. The pore channels in pervious concrete are responsible for this because of their tremendous complexity and heterogeneity, which are tortuous, have varying cross-sections, and have random interconnectivity. As such, the increased tortuosity of the pore channels in pervious concrete elevates the potential for clogging [8-10, 12, 14, 15, 18, 19].

4. DISCUSSION

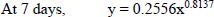

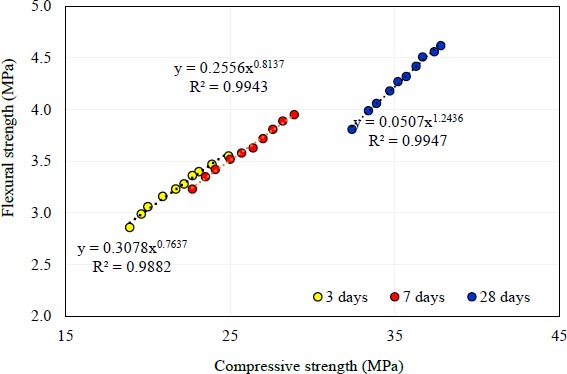

4.1. Correlation between Compressive Strength and Flexural Strength

Pervious concrete is a type of concrete that allows water to pass through it, rather than accumulating on the surface. It is considered an effective approach for low-impact development in pavements due to its economic, structural, and user benefits [9, 12, 39, 40]. The mechanical properties of pervious concrete are essential in controlling the design thickness of the pavement layer and its durability characteristics. The two crucial properties for designing pavements to meet their structural and functional requirements are compressive strength and flexural strength [12, 24, 39]. Compressive strength refers to the ability of concrete to withstand crushing forces, while flexural strength refers to its ability to resist bending or breaking under a load. Both of these properties are essential for the structural integrity of pervious concrete [39]. There is generally a relationship between compressive strength and flexural strength in concrete, where an increase in compressive strength usually corresponds to an increase in flexural strength [10, 26, 41]. The correlation between the compressive strength of a concrete specimen and its flexural strength is depicted in Fig. (7), which separates the results by different test ages. It is evident that the flexural strength of the concrete sample grows proportionally to its compressive strength, following a power relationship as indicated by Eq. 1 to 3, where x represents compressive strength and y represents flexural strength.

|

(1) |

|

(2) |

|

(3) |

The R-square value is a statistical measure used in regression modeling to quantify the proportion of variance in the dependent variable that can be accounted for by the independent variable. In simpler terms, it shows how well the data fit the regression model. The results indicate that the R-square value of the strength of the concrete, depending on each test age, was highly consistent with the regression model. Specifically, the R- square values for the 3-day, 7-day, and 28-day tests were 98.82%, 99.43%, and 99.47%, respectively. However, the relationship between these two properties is not always linear and can vary depending on several factors, such as the mix design, curing conditions, and testing methods [27, 32, 41].

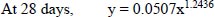

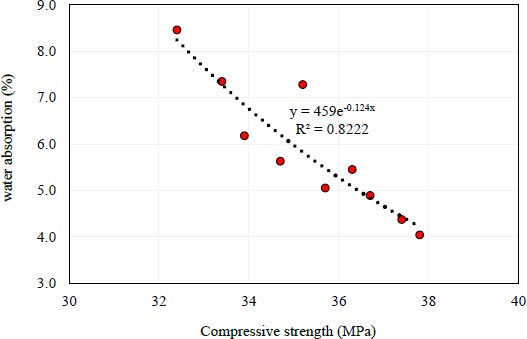

4.2. Correlation between Compressive Strength and Water Absorption

The quality and durability of pervious concrete are often evaluated based on its compressive strength and water absorption properties [38]. Water absorption refers to the amount of water that can be absorbed by the concrete when it is exposed to moisture or submerged in water. In general, there is an inverse relationship between compressive strength and water absorption in pervious concrete. As the compressive strength of the concrete increases, its ability to resist water absorption also tends to improve. This is because higher compressive strength usually corresponds to a denser and more compact concrete matrix, which can help to reduce the permeability and porosity of the material [20, 38, 42]. Fig. (8) illustrates the inverse relationship between water absorption and the compressive strength of concrete. The presence of voids or pores on the surface of the concrete can weaken the bond between the aggregate and paste, ultimately impacting the concrete's strength. As the compressive strength of the concrete increases, its water absorption decreases, as shown in Eq. 4.

|

(4) |

where x represents the compressive strength and y represents the water absorption. The strong exponential relationship between the two variables is supported by the high R-squared value of 82.22%. If the water absorption of concrete is higher than the control, it may indicate that the concrete is porous and prone to deterioration over time due to the effects of freeze-thaw cycles, chemical attacks, or other environmental factors [5, 8, 12, 40]. Therefore, careful control of the mix design and curing conditions of pervious concrete is important to achieve a balance between compressive strength and water absorption [4, 38, 41]. By optimizing these properties, it is possible to produce pervious concrete that is both strong and durable while maintaining its ability to allow water to pass through it [20].

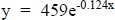

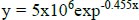

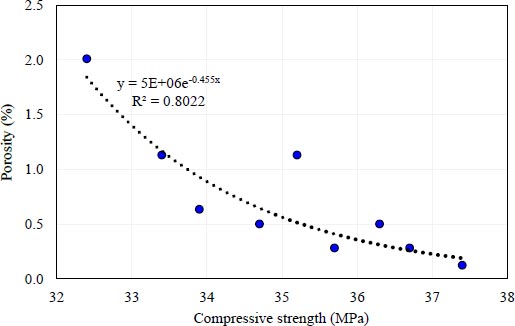

4.3. Correlation between Compressive Strength and Porosity

The properties of pervious concrete, namely compressive strength, and porosity, are interrelated and crucial to its strength, durability, and permeability [18]. Porosity is the measure of the empty spaces or voids within the concrete material, which can affect its mechanical properties. In general, there is an inverse relationship between compressive strength and porosity in pervious concrete [12, 13, 18, 29, 42]. As porosity decreases, the compressive strength increases, indicating that a denser and more compact concrete matrix can resist deformation and failure under compressive loads. Conversely, high porosity can make pervious concrete weak and susceptible to damage under compressive loads, as well as increasing water absorption and permeability, which reduces the material's strength and durability [39, 40]. The correlation between porosity and compressive strength in concrete with created pores is an essential research area since porosity can impact the mechanical characteristics of concrete. Studies have shown that the porosity of the pore-creation concrete has an inverse correlation with compressive strength, implying that increased porosity decreases strength properties. The relationship between porosity and compressive strength in all arrangement patterns of concrete specimens is depicted in Fig. (9), and it follows an exponential model represented by Eq. 5.

|

(5) |

where x and y represent compressive strength and porosity, respectively. The R-square value of the correlation between concrete porosity and compressive strength at 28 days is 80.22%. Several factors can influence the correlation between porosity and compressive strength, such as cement type, aggregate qualities, water/cement ratio, and curing conditions [4, 8, 12, 13, 16, 18, 23, 29, 37]. Despite these complexities, reducing porosity is still considered one of the most effective ways to increase compressive strength. Using high-quality aggregates, proper mixing and curing techniques, and the use of admixtures and other additives that can reduce the amount of water needed for hydration are some methods to achieve this [15, 21, 24].

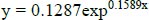

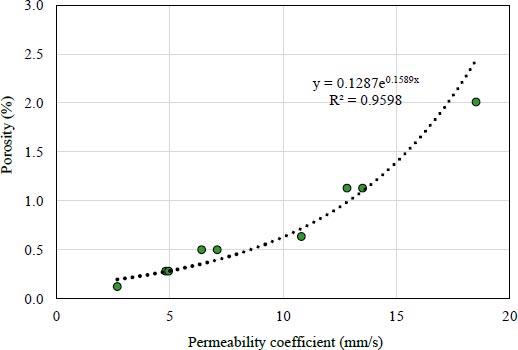

4.4. Correlation between Water Permeability and Porosity

The porosity and water permeability of permeable concrete are closely related to each other [4]. Water permeability refers to the speed at which water passes through the concrete material, while porosity refers to the amount of voids or empty spaces within the material that can hold water. Generally, there is a direct relationship between water permeability and porosity in permeable concrete [12, 29]. As the porosity of the concrete increases, its water permeability also tends to increase [39]. This is because a more porous concrete material can provide more channels and spaces for water to flow through, allowing it to pass through the material more quickly [18, 41]. An accurate understanding of the relationship between permeability and effective porosity is essential for the successful mix design of pervious concrete. Several studies have investigated this relationship, including identifying the factors that affect the permeability of the pervious concrete and developing models and testing methodologies to precisely measure the material's porosity and permeability [4, 8, 12, 14-16, 18, 23, 29, 37]. Fig. (10) demonstrates the correlation between the porosity and the permeability coefficient of concrete specimens arranged in various patterns. The results indicate a direct relationship between the porosity of pore-creating concrete and the permeability coefficient of water. The permeability coefficient tends to increase following an exponential relationship, as shown in Eq. 6, as the percentage of porosity increases.

|

(6) |

where x represents the permeability coefficient and y represents the porosity of the concrete. The relationship between porosity and permeability coefficient has an R-square value of 95.98%. Water permeability is a crucial feature of concrete that can significantly impact its durability and ability to withstand different types of damage, such as chemical attacks, freeze-thaw cycles, and reinforcement corrosion. Therefore, managing water permeability and controlling porosity are essential factors in ensuring the durability of concrete structures. A reduction in porosity has been recognized as an effective approach to decreasing the water permeability of concrete [5, 8, 12, 15, 26, 38, 40].

To sum up, the findings of these studies contributed to our understanding of the properties and behavior of pore-creating concrete. The complexity of the correlation between porosity and compressive strength in concrete necessitates continued refinement of our knowledge. One clear area of focus for improving the mechanical properties and long-term durability of concrete is reducing porosity. Additionally, improvements in the construction technique and performance of this critical material can enhance the relationship between permeability and effective porosity, which is vital for the development of sustainable infrastructure applications.

4.5. Challenges and Perspectives

The manufacturing process of conventional and previous concrete involves the use of coarse aggregates, particularly in previous concrete [42], where they help form interconnected macropores that allow for rapid water infiltration [31, 40]. However, construction methods are critical for permeable concrete, and their impact on long-term durability is not well understood [8]. Compaction during placement is necessary, and the coarse aggregate on the surface should be properly seated to prevent surface ravelling [13]. For this pore creation method, plate-pressing pores can be obstructed by coarse aggregates, resulting in jamming, making it essential to consider the coarse aggregate size and volume fraction reduction to facilitate pore punching. Test results have shown a high coefficient of permeability through water, causing water to flow under the concrete pavement and drain the aggregate material out through the pavement cracks or joints. This phenomenon, known as “pumping action,” may cause the subbase layer to expand into a cavity, leading to structural cracks in the concrete slab. Therefore, the use of permeable concrete is limited and most appropriate for low-traffic pavement concrete, such as low-volume roads or car parks. Synthetic fibers (geotextiles) and appropriate subbase layer patterns may help control aggregate outflow due to water flow. Additionally, the use of pore creation concrete can be seen in precast concrete pavement, and uncomplicated construction techniques are needed to address the problem of permeable concrete [21, 30]. Understanding the mixture constituents, proportioning, and placement is necessary for successful implementation [4, 40].

CONCLUSION

The following conclusions can be drawn from the experimental findingsThe designed mixtures met the criteria for slump value. Moreover, the formation of pores in concrete is greatly influenced by the initial setting time, which was measured to be 230 minutes.The pore creation concrete had compressive strengths at 28 days ranging from 32.4-37.4 MPa, while the flexural strength ranged from 3.81-4.56 MPa. The strength of concrete is negatively correlated with its pore volume and diameter. As the porosity of the concrete increases, its strength tends to decrease. However, all mixtures had a compressive strength of over 85% compared to the control.

- The water absorption of pore-creation concrete ranged from 4.38-8.47%, which was higher than the control concrete. The capacity of concrete to absorb water is directly linked to both the volume and diameter of its pores. As the porosity of the concrete increases, its water absorption tendency also increases.

- The water permeability coefficient, calculated using the pore creation technique, ranged between 2.69-18.52 mm/s. It is noteworthy that the arrangement pattern enhances the water permeability coefficient. Increasing the pore volume from 2 x 2 (4 no. of pores) to 3 x 3 (9 no. of pores) or 4 x 4 (16 no. of pores) showed an increase in the permeability coefficient of water.

To assess the effects of clogging fine sand on permeability coefficients, the study examines the impact of clogging on these coefficients post-clogging. Our findings indicate that the permeability coefficient declines when clogging occurs within the 18.18-37.27% range.

- The study's findings significantly contribute to improving the mechanical properties and draining capacity behavior of concrete through sustainable construction techniques for infrastructure applications.

- The limitations of this study include the possibility of plate-pressing pores becoming obstructed by coarse aggregates, leading to jamming. To address this limitation, future research could focus on optimizing the concrete mixture to consider the size and volume fraction reduction of coarse aggregates to facilitate pore punching.

LIST OF ABBREVIATIONS

| CaO | = Calcium Oxide |

| ASTM | = American Society for Testing and Materials |

| D0 | = Control Concrete |

CONSENT FOR PUBLICATION

Not applicable.

AVAILABILITY OF DATA AND MATERIALS

All the data and supportive information are provided within the article.

FUNDING

The Rajamangala University of Technology Phra Nakhon (RMUTP) was a contributor to the funding of this research.

CONFLICT OF INTEREST

Dr. Gritsada Sua-iam is the Editorial Advisory Board of The Open Civil Engineering Journal.

ACKNOWLEDGEMENTS

Declared none.