All published articles of this journal are available on ScienceDirect.

Shallow and Wide RC Beams, Definition, Capacity and Structural Behavior – Gap Study

Abstract

Wide beam, shallow beam, and banded beam are almost equivalent terms for beams with limited depth and large width. They are often embedded in ribbed slabs to facilitate the formwork. The contribution of web reinforcement in the shear capacity of this type of beam is still a gray area, and all design codes neglected this contribution. The aim of this research is to introduce a general overview of this topic and detect the unstudied gaps in this topic. Nine design codes and about forty previous researches were collected, summarized, analyzed, classified, and mapped with respect to the considered parameters, utilized methodologies, recorded observations, and concluded outcomes to detect further research opportunities. The results indicated that design codes have no unified definition for the shallow or wide beams; most of them neglected the contribution of the shear reinforcement. On the other hand, the analysis of the collected research considering 32 points of the study showed that only 19 points are well studied; it also indicated an extreme shortage in both theoretical studies (using “Finite Element Method” FEM) and predictive models (mathematically using “Artificial Intelligence” AI) for the shear capacity besides the effect of creep and cyclic loading, especially for beams with web openings.

1. INTRODUCTION

Architectural advancements in design and creativity were always the main challenge that pushed structural designers to find new solutions and systems to accommodate these challenges. Clear heights and open lines of sight were always preferable basics to architectural engineers. Reinforced concrete shallow wide beams were not, for a long time ago, a new solution like many others. As the usage of the wide beam increases, concerns regarding their ductility, mode of failure, and load capacity also arise.

Shallow/wide beams may be defined as beams whose width is more than twice its depth (width/depth < 2) [1]. As it was later researched, the shear resistance of a wide beam is different from that of the conventional ordinary dropped (or projected) beam.

2. OBJECTIVES AND METHODOLOGY

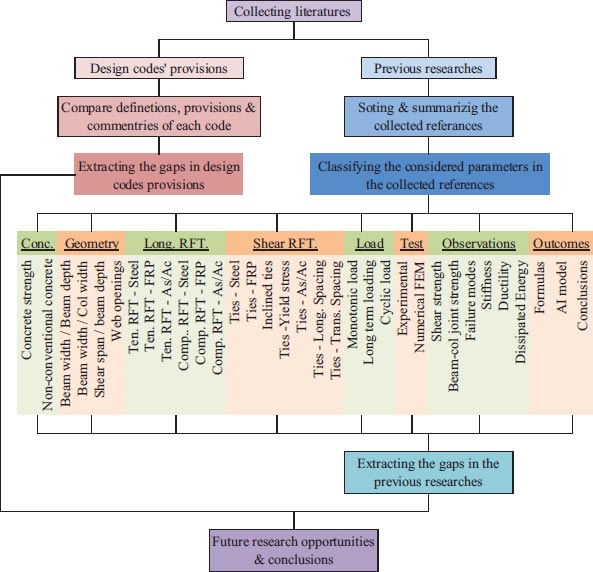

The main objective of this research is to gather all available pieces of information regarding the shear capacity of wide beams and arrange them in a global frame to detect the research gaps in this topic. The considered methodology started with collecting available data, including design codes and previously published research, sorting, analyzing and classifying the collected data, and finally mapping these data with respect to the considered parameters, utilizing methodologies, observed results and concluded outcomes. The generated map illustrates the unstudied and over-studied items regarding this topic. Fig. (1) presents the framework of this study, including the considered parameters.

3. CODES OF PRACTICE

Several codes of practice had approached reinforcing wide beams to resist shear through different notes, while some did not discuss this issue at all. The American Code of Practice ACI 314-2019 states that when the beam depth is less than or equal to 10 in (25.4 cm), to be considered as a shallow depth. At this depth, it’s not required to satisfy the minimum shear reinforcement for the shallow wide beams [2]. In the commentary, it was stated that for some types of wide beams, like what Adam Lubell [3] researched, for instance, shear reinforcement design is advised. However, Euro Code EN 1992-1-1:2004 did not explicitly omit shear reinforcement in wide shallow beams. But it only indicated the insignificance of its presence in solid slabs, flat slabs, and hollow block slabs. It indicated that the minimum reinforcement should be provided by the ordinary equations of the shear reinforcements of beams [4]. Shallow wide beams were not mentioned in Standard Specifications for concrete structures “Design” (the Japanese code of practice). But it was stated that even if the member did not require shear reinforcement, it was necessary to put the minimum reinforcement for shear according to the code [5]. The Canadian Code of Practice CSA A23.3-04 is exceptionally like the American Code of Practice ACI 314-2019, but the minimum depth required for minimum reinforcement is 75 cm which is more forgiving than any other code of practice [6]. The Chinese code of practice GB 50010-2010 considered that a member with a depth of less than 15 cm is not required to place stirrups or minimum stirrups [7]. The Saudi code of practice “SBC304c” referred to different research about how the spacing between stirrups had affected the behavior of the shallow wide beams without giving a minimum requirement for stirrups or a definition of a wide beam for this matter [8]. The Egyptian code of practice “ECP 203-2017” had stated one statement regarding shallow wide beams, which considers any member with a depth less than 25 cm had no shear reinforcement requirement [9].

4. CALCIFICATION OF CONSIDERED PARAMETERS

The guidelines obtained from the previously noted different codes of practice are a bit insufficient, as the shear resistance of a beam is critical for its design for several reasons. Its ductility, mode of failure, and safety as a priority are some of the different reasons.

Researchers felt obligated to investigate this crucial matter of shear resistance of wide beams considering different parameters. These parameters could be classified as follows:

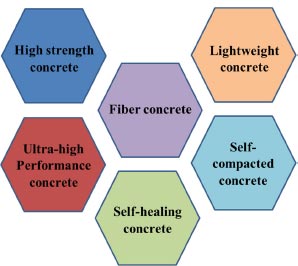

• Parameters related to the used concrete as shown in Fig. (2):

o Concrete strength, usually 28 days cube or cylinder compressive strength.

o Special concrete type, Ultra-high performance, Self-compacted, Lightweight, etc.

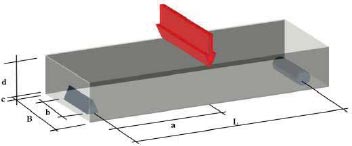

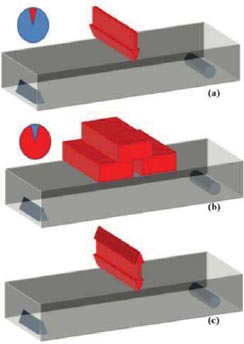

• Parameters related to beam geometry as shown in Fig. (3):

o Beam width / Beam depth.

o Beam width / Support width.

o Shear span/beam depth.

o Web openings.

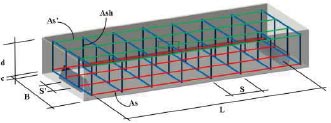

• Parameters related to the longitudinal reinforcement as shown in Fig. (4):

o Tension reinforcement material, steel or “Fiber Reinforced Polymer” FRP.

o Tension reinforcement ratio As/Ac.

o Compression reinforcement material, steel or FRP.

o Compression reinforcement ratio As’/Ac.

• Parameters related to the shear reinforcement as shown in Fig. (4):

o Shear reinforcement material, steel or FRP.

o Shear reinforcement ratio Ash/Ac.

o Shear reinforcement direction, vertically inclined.

o Shear reinforcement spacing in both longitudinal and transverse directions.

o The yield stress of shear reinforcement.

• Parameters related to loading type as shown in Fig. (5):

o Short-term monotonic load.

o long term monotonic load.

o Cyclic load.

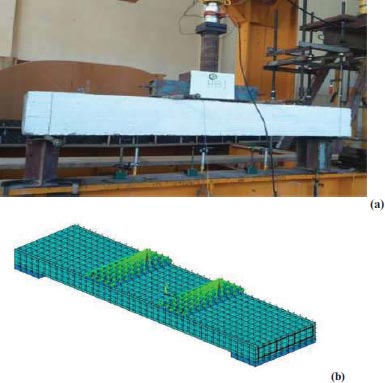

• Parameters related to testing type as shown in Fig. (6):

o An experimental test in the lab.

o Numerical test, using FEM models.

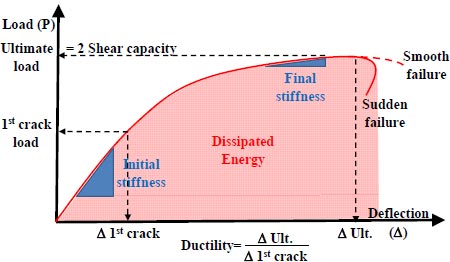

• Parameters related to test observations as shown in Fig. (7):

o Shear strength (half the ultimate load).

o Beam-coal joint strength.

o Failure modes.

o Stiffnesses (initial & final).

o Ductility.

o Dissipated Energy.

Where the ultimate load is the test load at failure, it could be determined experimentally as the peak point of the load-deflection curve. The initial stiffness (un-cracked stiffness) and final stiffness (cracked stiffness) could be determined experimentally from the load-deflection curve as the slope of the first straight zone (un-cracked zone) and the secant slope at failure (cracked zone) as shown in Fig. (7).

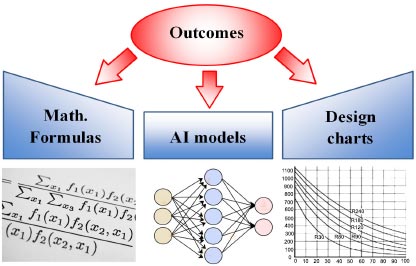

• Parameters related to test outcomes as shown in Fig. (8):

o Quantitative outcomes, Formulas or AI models.

o Qualitative outcomes, just conclusions.

5. PREVIOUS RESEARCHES

A study has been conducted on six specimens with “Glass Fiber Reinforced Polymer” GFRP plates as shear reinforce- ment. All six specimens had dimensions of 800 mm width, 300 mm depth, and 3100 mm length. Deformed steel bars were used as longitudinal reinforcement for the six specimens. GFRP plates with openings were used for all specimens having the same number of openings, legs, and spacing between legs. All parameters were the same except for the transverse spacing between the GFRP plates. Six specimens were tested under a four-point load test. It was found that the shear performance of the wide beams increases as the transverse spacing between the GFRP plates decreases until the spacing is 1.16 of the effective depth [10].

In 2013, nine reinforced concrete wide beam specimens were tested in shear. The nine specimens had dimensions of 700 mm wide, 250 mm thick, and 1750 length. No shear reinforcement was used in the first specimen, while the remaining eight specimens had different shear reinforcement configurations considering the diameter of the steel rebar and the longitudinal spacing between the stirrups. It was found that the shear capacity of the tested reinforced concrete wide beams increased by 132% at maximum shear reinforcement and minimum longitudinal spacing. Moreover, an increase in the ductility of the reinforced concrete wide beams was detected [11].

“Strain Hardening Cementations Composition” (SHCC) jackets were used to enhance the shear behavior of reinforced concrete wide beams. Eleven specimens were tested after categorizing them into three groups. Each group had different reinforcement and jacketing techniques. It was concluded that the different shear reinforcement configurations, in addition to the SHCC, had increased not only the shear behavior but also enhanced the ultimate load [12].

Nine specimens of wide shallow beams were tested while using transverse shear reinforcement and changing the thickness of the beams. The thickness of 250 mm and above had the most effective usage of the stirrups; less than 250 mm had also improved but not as much as above 250 mm [13].

Sixteen wide beam specimens were tested on steel plates with holes instead of stirrups to examine their effect on the overall capacity of the beams. The usage of holed stirrups had only a 5% difference from the conventional stirrups [14].

Several wide beam specimens were investigated by Al-Azab, and different stirrup configurations and concrete mixes were used. The transverse spacing of stirrups had a minor enhancement factor on the shear behavior [15], while the number of branches increased the shear behavior [16]. A finite element model was used to validate several experimental programs; it was mostly accurate to the guidelines of the Egyptian code of practice (ECP-203) [17].

Several wide beams were placed, cast and tested on the supports that are part of the specimens. The shear stresses in the form of cracks are varied depending on the dimensions of the supports, the narrower the supports in relation to the width of the beam, the less shear and flexural capacity the beam endures [18].

An intensive experimental program on full-scale reinforced concrete wide beams was conducted to compare the results and enhance both Euro code 2 and ACI-318. The overall behavior of the specimens was clearly enhanced by the different configurations of stirrups, and they proposed a formula for the enhanced shear capacity. Moreover, it was concluded that the ACI-318 is more conservative than the Euro code 2 [19].

El Ansary had a different approach to test reinforced concrete wide beams in shear. Nine reinforced concrete wide beams were tested using different stirrup configurations (diameter and spacing); spiral reinforcement was used. Results were compared regarding different codes of practice. The spiral reinforcement for concrete wide beams had a noticeable impact, increasing the ductility of the beams, but the cracks had increased compared to standard shear reinforcement [20].

Taha and Abbas tested four reinforced concrete wide beam specimens with dimensions of 400 x 200 x 1600 mm. Spacing between stirrups were the considered variables (0.75 d, 0.8 d, and 1 d). It was concluded that as the spacing between stirrups increased, the shear capacity decreased and deflection increased [21].

Fourteen specimens of RC-wide beams with polypropylene fiber reinforcement were tested by Conforti in 2015. The research goal was to find the optimum shear behavior of the wide beams considering the width-to-depth ratio and stirrups used, if any. Upon using width-to-depth ratios ranging from 2 to 3, an enhancement of shear capacity and behavior was recorded, ranging from 30% - 40%. Moreover, the polypropylene fibers had high tensile strength, changing the mode of failure from shear to flexure, which enhanced the ductility of the shallow beam. Moreover, using a volume fraction of 1.45% of the fibers can occur of the minimum stirrups for shear reinforcement for the whole wide beam [22].

Moubarak and his co-authors tested thirteen wide concrete beams and used external and internal fasteners as shear reinforcement. The fasteners used were external and internal, vertical, and inclined.

The fasteners were very effective at enhancing the shear capacity of wide shallow concrete beams and changing their mode of failure from shear to flexure. External and internal fasteners increased the capacity of the beams ranging from 32% to 72%. Steel plates at the shear span had an edge over using steel angles, which reduced the shear cracks and made the beams more ductile. Inclined fasteners had no significant difference from using vertical fasteners [23].

Five full-scale shallow reinforced concrete beams were strengthened by carbon fiber plates. They were tested to observe the immediate and long-term deflection and crack opening. Three of these full-scale shallow beams were tested with long-term loads, presented as concrete blocks uniformly distributed on the shallow beam to emulate the distributed actual load on the beam. These three previously mentioned beams had concrete blocks for 600 days; immediate and long-term deflection and crack width were measured.

Two of the five full-scale shallow beams were tested under an ordinary four-point load test. It was found that the carbon fiber plates had reduced the immediate deflection and crack openings but had no noticeable effect on the long-term deflection and crack openings [24].

A comparison between conventional T beams and hidden shallow beams embedded in slabs was conducted to figure out how effective shallow beams can be considered as a solution for maintaining clear heights and architectural demands. Fourteen concrete beam specimens were cast. Seven were conventional T beams, and the other seven were hidden wide beams. The specimens were tested under a four-point load test. It was stated that as the depth of the wide beam increases, the more its behavior changes into ordinary beams [25].

In 2020, Alluqmani tested two specimens of reinforced concrete with shallow wide beams. One specimen was designed according to the euro code EC2, and the other was designed according to the Saudi code of practice SBC 304. The author was aiming to find which one would be safer from failure as reinforced concrete with shallow wide beams. It was concluded that SBC 304 was safer than EC2. The author also assured that the stirrup location is most effective at 0.56 d. Moreover, 0.6 d is the most effective longitudinal spacing between the stirrups [26].

Carbon fiber reinforced polymers were used for strengthening the reinforced concrete shallow beams as a technique to enhance the beam to endure more loads. A sudden debonding of these CFRP plates may occur at failure after an intermediate crack.

Thirteen specimens were designed with different dimensions of the “Carbon Fiber Reinforced Polymer” CFRP plate, steel reinforcement, thickness, and width of the beam to examine and study this type of failure. All previous parameters had no effect on the sudden debonding that occurs at the intermediate crack. Only an increased compressive strength delayed debonding failure, but it occurred eventually [27].

In 2021, researchers investigated seven specimens of wide reinforced shallow beam behavior under eccentric loading. The longitudinal reinforcement ratio, eccentricity, and spacing between stirrups had changed throughout the seven specimens. It was concluded that increasing the eccentricity decreases the load capacity of the beam. Decreasing the longitudinal spacing between the stirrups had a huge effect on crack control [28].

Kim and his research team investigated eighteen specimens of reinforced concrete shallow beams to improve the shear capacity equation. Steel plates with openings were used instead of stirrups to enhance the behavior of the beam in shear. It was found that at transverse spacing of the plates more than 1.1 times the depth, it had no impact on the shear behavior or crack control [29].

Five specimens of reinforced concrete shallow wide beams with different percentages of short glass fiber polymers were tested to study the effect of the polymers on the shear behavior and failure of the beams. Using shear reinforcement had an impact on the shear capacity of the beams. Moreover, the preferred percentage for the short glass in the mix is 1%. Moreover, the short glass has enhanced the ductility of the beam [30].

Conforti had tested fifteen specimens of reinforced concrete shallow beams with and without transverse steel reinforcement to resist shear. Shear reinforcement had no significant impact on the first shear crack, but not like the specimens with no transverse stirrups, it had significant resistance to shear by 20 – 25% after the first shear crack. The width and the effective depth had an impact on the mode of failure for the beams [31].

Research and testing of wide beams in torsion are a bit lacking. Nine specimens of high-strength reinforced concrete wide beams were tested under bending and torsion conditions. The torque to bending moment ratio was the main variable. The flexural capacity of the wide beams decreased as the torque to bending moment ratio increased. Moreover, increasing the torque to bending moment ratio has increased the presence of inclined cracks along the span of the beams [32].

A comparison between two specimens of reinforced concrete beam-column joints was made. Wide beams and conventional beams were the difference between the two specimens. The two specimens were tested under quasi-static cyclic loading to examine the performance of the beam-column joints. The specimens had almost the same deformation capacity, but the conventional beam specimen was superior to the wide beam specimen when compared to the initial crack density and approaching the designed capacity of the beams [33].

Al-Harmani and his co-authors tested eight specimens of basalt fiber-reinforced concrete slabs to study their effect on the overall shear capacity of the slabs. The percentage of the basalt fiber-reinforced polymers was changed from 0.792% to 1.27%. Moreover, there was a change from plain concrete itself to basalt macro fiber concrete. The eight specimens were tested under a four-point loading test until failure. The basalt macro fiber concrete had no effect on the flexural behavior of the slabs nor on the compressive strength of the concrete, but it increased the shear capacity of the slabs by about 16.7% [34].

Sixteen FRP concrete specimens of one-way slabs with dimensions of 4000 mm x 1000 mm x 200 mm were tested to study the mechanisms of shear resistance for such specimens. Two types of fibers (glass and carbon) were considered with several cross-sections. The desired ductile failure of the specimens occurred when glass fiber polymers were used. The brittle failure occurred while using carbon fibers [35].

The usage of engineered cementitious composites to replace the stirrups in reinforced concrete beams were tested in 2020 by Wang and his co-authors. 20 mm and 40 mm thickness of the engineered cementitious composite were sprayed on four of the six specimens, which were tested to emulate and compare between these composites and the stirrups.

It was concluded that the optimum thickness of engineered cementitious composites that enhances the maximum shear resistance of the reinforced concrete beams is 20 mm. Moreover, 40 mm had a good impact on the specimens but was not as effective as the 20 mm thickness [36].

New concrete mixtures have the possibility of enhancing the mechanical and physical properties of concrete elements. Reactive powder concrete is a tremendous solution for small spacing between reinforcing steel bars as it eliminates coarse aggregates. In 2020, a group of Iraqi researchers manufactured and tested eighteen specimens of reactive powder concrete beams without stirrups and tested them for shear resistance. Ten mixes of reactive powder concrete were used, producing several compressive strengths for the concrete. Increasing the volume fraction of the reactive powder concrete had an enormous impact on the shear capacity of the beams, increasing it up to 132% depending on the volume fraction [37].

Ebid and Deifalla collected an experimental test results database with 553 records for shear failure in concrete beams longitudinally reinforced with FRP bars, with and without FRP web reinforcement. The database included a wide range of (width/depth) ratios between 0.33 and 5.0; hence it included both wide and projected beams. They applied the well-known “Genetic Programming” technique to develop a unified equation for the shear capacity of such beams considering (width/depth) ratio, (shear span/depth) ratio, modular ratio and both longitudinal and shear reinforcement ratios. The developed equation showed better accuracy than all international design codes and previous related research [38].

Openings in reinforced concrete beams are used for mechanical and electrical purposes, five reinforced concrete shallow beams were cast with different openings along their span to examine their cracking and flexural behavior. The stiffness, shear capacity, deformation, and flexural capacity of the beams decreased as the opening lengths increased [39].

In 1992, beam-column specimens were tested under cyclic load. Encouraged by the common use of narrow, wide beams and the lack of code guidelines at the time, it was found obligatory to research the issue. The proposed detailing by the research team under this specific type of loading has increased the capacity of the specimens for resisting seismic loads [40].

In 2013, test data for one-way slabs under shear conditions were scarce. Ten specimens of one-way slabs were tested to fail in shear with several variables (a/d, concrete compressive strength, reinforcement, and position of loading). Increasing the transverse reinforcement did not have a significant impact on the overall load capacity, but a noted difference was observed on the crack patterns and mode of failure [41].

Utilizing the usage of reinforced concrete wide beams is increasing in many types of buildings due to several reasons (cost of formwork, straight reinforcement, and story height reduction); an Iraqi team reviewed some points about the increasingly popular members. It summed the impact of geometrical, material, reinforcement, and monotonic loading parameters on the shear capacity, failure modes, stiffness, and ductility of wide beams [42].

Column-wide beam joint specimens were tested under simple gravity load while changing the wide beam width and reinforcement distribution. The concentrated reinforcement at the joint area had increased its shear capacity closely to 24%. Since the column width is always smaller than the beam’s, further investigation is needed while increasing the column width, hence controlling the diagonal cracks at the connection area [43].

Shear failures of RC one-way slabs are often omitted by several design codes. However, a comparative study was made using the most utilized codes worldwide to examine the issue. Experimental results by several research had very close results to the French national annex guidelines, while Euro code 2 and ACI 318-14 were very underestimating the phenomena [44].

A collected dataset of 279 records was used to develop two predictive models for the shear capacity of wide beams without web reinforcement. The first model was a mathematical model using nonlinear regression, and the second one was the ANN model. Although both models showed better accuracy than the design codes, the ANN model archived higher accuracy than the regression model [45].

Shear reinforcements for wide beams were ignored by all international design codes; thus, research was conducted to investigate this issue. Ten specimens of reinforced concrete wide beams were tested while considering the shear reinforcement ratio, shear span-to-depth ratio, and spacing between stirrups. The results indicated that the tested specimens were more ductile, had more shear and flexural capacity, and enhanced the crack control as the web reinforcement increased and got closer [46].

Several investigations regarding the shear strength of reinforced concrete wide beams and one-way slabs were conducted by Lantsoght and her team. Testing eight specimens of reinforced concrete slabs while several parameters were being changed, like reinforcement, width of the slab, position of loading, and type of supports, was done to study how these specimens will behave under shear conditions. Compressive strength of concrete had no significant effect on the shear capacity while decreasing the distance of the load to the supports increases the shear capacity of the specimens [47]. Also, eight specimens of slabs were tested under different load combinations and compared to the Euro code (EN 1991-2:2003) guidelines. It was found that the minimum effective shear width is about four times the depth, and a new reduction factor for concentrated loads near the supports was proposed [48]. Recently, they collected a database of 170 shear test results for wide beams without web reinforcement under several loading conditions. They used the database to evaluate the current design code provisions and previously developed shear models [49].

6. RESULTS AND DISCUSSIONS

In the previous sections, nine design codes and forty research works were addressed to collect the puzzle pieces of the shear capacity of wide beams. Now it is time to arrange these pieces together in one unified image and detect the remaining gaps. Table 1 summarizes the wide beam shear capacity provisions in the considered design codes and found gaps in these provisions. One of the most common gaps in most design codes is the lack of accurate and unified definitions for wide (or shallow) beams. Besides that, all design codes neglected the contribution of web reinforcement in the wide beam shear capacity, and even if some codes recommend using a minimum amount of web reinforcement in wide beams, it is mainly to satisfy other requirements than the shear capacity like fire resistance and ductility.

These gaps caused troubles for structural designers regarding the shallow beams definition, shear reinforcement and structural behavior. For example, some codes define a shallow beam as a beam thinner than 250mm; hence the contribution of the shear reinforcement is considered in the design for a 250mm thick beam and neglected for a 220mm thick beam. That doesn’t make sense, even if the efficiency of the shear reinforcement may be reduced in the shallow beams but not with that sudden change. Moreover, most design codes allowed for using shear reinforcement to resist punching stresses (two-way shear) in flat slabs and prohibit using shear reinforcement to resist the one-way shear stress in a shallow beam with the same thickness.

Regarding ductility, both amount and arrangement of shear reinforcement are significantly effective, especially for rotation ductility [50] and rotational capacity [51].

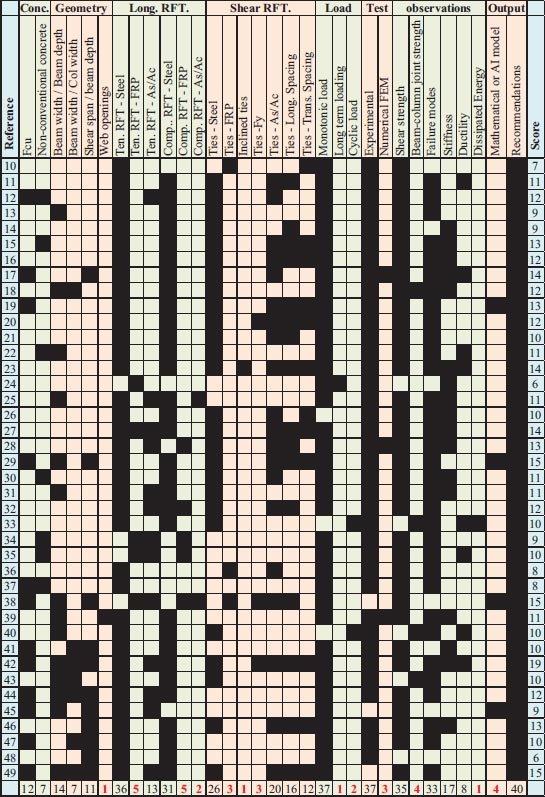

On the other hand, the collected previous research was analyzed, sorted, and classified with respect to their considered parameters, methodologies, observations, and outcomes, as shown in Fig. (9). The score in the last column gives a quick evaluation of the scope of the research regardless its contribution, while the bottom row presents the addressing frequency of each item (or scope).

The average score of the forty considered research was 11/32, with a maximum value of 19 and a minimum of 6. It means that most papers covered about 33% of the items on this topic, which is fair enough. On the other hand, the values in the lower row showed a wide range of variability between the items, starting with items that were only addressed once to items addressed in every research with an average value of 14 addressing times. This row clearly presents the gaps in the image. As shown, the items which addressed less than seven times (half the average) are marked in red; these are the proposed gaps that need further study.

The items of using FRP in longitudinal and web reinforcement and beam-column joint strength were addressed in only four researches, while only four researchers presented the prediction models (two mathematical formulas and two AI models). Other items, such as the impact of web opening, compression reinforcement, inclined ties, long-term loading, and cyclic loading, dissipated energy as damage measurement, were dressed in only one or two researches. And finally, the surprising result is that most researchers depended on only experimental research programs, and only three researchers added FEM models to the experimental work.

| Refs. | - | Design Code | Provision | Gaps |

|---|---|---|---|---|

| [2] |  |

ACI 314-2019 | It’s not required to satisfy the minimum shear reinforcement for members shallower than 25cm; however, using shear reinforcement is advised | - There is no unified definition for the shallow (or wide) beams - The contribution of the shear reinforcement is neglected - Using the minimum shear reinforcement is not required in most codes, however it is required in some codes not to resist the shearing force but to satisfy the fire resistance |

| [4] |  |

EN 1992-1-1:2004 | The impact of the shear reinforcement is insignificant; however, the minimum shear reinforcement must be used. | |

| [5] |  |

SPCS-2007 | Shallow beams aren’t defined; however, the minimum shear reinforcement must be 21used. | |

| [6] |  |

CSA A23.3-04 | It’s not required to satisfy the minimum shear reinforcement for members shallower than 75cm; however, using shear reinforcement is advised. | |

| [7] |  |

GB 50010-2010 | It’s not required to satisfy the minimum shear reinforcement for members shallower than 15 cm. | |

| [8] |  |

SBC304c | It has no definition or minimum shear reinforcement for shallow beams | |

| [9] |  |

ECP 203-2017 | It’s not required to satisfy the minimum shear reinforcement for members shallower than 25cm. |

CONCLUSIONS AND RECOMMENDATIONS

Wide beams are extensively utilized as a cost-effective alternative for structures that require minimizing the overall structural depth. Time-saving is directly related to wide beams as the simplicity of formwork and placement of reinforcement are obtained. Moreover, wide beams eliminate reinforcement congestion and govern cracking and deflection requirements. This research aimed to gather pieces of the global image regarding the shear capacity of wide beams to figure out the gap studies in this topic. Nine design codes and forty previous types of research were addressed, and the outcomes could be concluded in the following points:

1. There is no global or unified definition for wide or shallow beams, distinguish depth is varied between 150mm in the Chinese code to 700mm in ACI-314-2019, and also some codes define the wide beam based on the (width/depth) ratio > 2.

2. Although most research indicated an enhancement in the shear capacity of wide beams due to web reinforcement, all design codes neglected this enhancement.

3. Some design codes included provisions for minimum web reinforcement in wide beams, not to enhance the shear strength but to satisfy fire resistance and ductility.

4. The results mapping indicated some gap studies (research opportunities), such as the shear capacity of wide beams:

a. With FRP longitudinal and web reinforcement,

b. With web opening or inclined ties.

c. Under creep or cyclic loading.

5. There are extreme shortages in FEM models and predictive models (mathematical and AI) for the shear capacity of wide beams.

Based on the previous conclusions, it is recommended to conduct further studies in order to:

1. Develop more accurate and general definitions for wide/shallow beams based on structural behavior instead of beam dimensions (similar to deep beams, which are characterized by their nonlinear distribution of normal stresses under bending moments).

2. Develop more accurate predictive models for the shear capacity of wide beams (or general beams) using mathematical or machine learning techniques (“Genetic programming” (GP) & “Artificial Neural Networks” (ANN) are the most recommended techniques for regression applications). Later, these models may be implemented in the design code.

3. Investigate the shear capacity of wide beams (experimentally & numerically) considering the detected research gaps.

LIST OF ABBREVIATIONS

| FEM | = Finite Element Method |

| AI | = Artificial Intelligence |

CONSENT FOR PUBLICATION

Not applicable.

AVAILABILITY OF DATA AND MATERIALS

Not applicable.

FUNDING

None.

CONFLICT OF INTEREST

The authors declare no conflict of interest, financial or otherwise.

ACKNOWLEDGEMENTS

Declared none.