All published articles of this journal are available on ScienceDirect.

Study of Thermal and Physical Mechanic Properties of CEB-reused PET

Abstract

Introduction

Currently, housing is a necessity in Mexico, considered a national problem that must be addressed through adequate housing proposals. The earth is a material that has worked since ancient times to produce structural elements, presenting advantages mainly in the areas near the site where housing is required due to availability as well as use strategies. On the other hand, it is known that the continuous increase of waste derived from polymers such as PET requires reuse strategies to reduce the environmental impact.

Materials and Methods

This paper, it is presents the analysis of compressed earth bricks with soil from Saltillo, Coahuila, Mexico, which has been produced dosed and undipped with PET shrapnel obtained from reused waste, characterizing its mechanical and thermal properties in addition to electron microscopy and scanning analysis tests.

Results

From the results obtained, it is observed that there is a 5% reduction in the mechanical resistance to compression, but without a significant difference in water absorption. Thermal diffusivity is also greatly improved.

Conclusion

Scanning Electron Microscopy (SEM) analysis results show that high compression can compact PET back to its original shape by removing stress, which can produce micro-cracks, which explains the compressive strength changes.

1. INTRODUCTION

Earth techniques can work as an affordable technique for areas where the social production of housing is required for communities that have a bioavailability of materials and soils in which resistant mixtures can be made.

The production and use of compressed earth blocks (CEB) are sustainable practices with eco-friendly materials that can be manufactured on-site if the construction land is of good quality. The use of organic and inorganic loads can be compatible with the elaboration of CEB; in some cases, it can increase the compressive resistance; the differences in compatibility depend on the type of soil, type of load, particle sizes, stabilizers, and the chemical groups that the materials present.

One of the proposed strategies relates to the addition of Polyethylene terephthalate (PET) fibers with compressed Earth Blocks, which have observed decreases in compressive strength [1] but which may improve other properties. In this case, earth materials are combined with fibbers that come from disposal waste or are produced by PET Bottles. There are several proportions studied [2], although the addition of plastic materials modifies the deformation of the components in which they are used [3]. In all cases, plastic materials change many properties, and a cost-benefit analysis is required, but it is possible to retake plastics for CEB production depending on the geographical situation. In several cases, a decrease in mechanical resistance to compression is recognized when dosing plastics [4]; this can be modified with mixture combinations: it has been observed that the decrease in the size of PET aggregates can work properly with a combination of soil-cement mixtures, increasing the mechanical resistance to compression with ratios of 20% residue and 6% cement [5]. Additionally, their durability can be improved [6]. In this work, we propose a mixture with the best performance and thermal properties, which will be discussed later.

Current studies show improvements in the hygroscopic properties of CEB obtained with mixtures of recycled waste in the form of fibers [7] that can be transferred even to concrete mixtures [8].

Other properties, such as the permeability of Compressed Earth Blocks, can be modified by dosing additives [ 9 ], so the use of recycling materials reduces the environmental impact, and improving them can allow use in different situations.

It is important to note that the construction system based on earth components involves an increase in the thickness of the structural elements [10]. Hence, a greater width compensates for variations in resistance. This can be accompanied by other components that even allow adaptation in seismic locations, making them feasible for their use [11, 12].

This study aims to conduct a comparative analysis of Compressed Earth Blocks (CEBs) made from soil mixtures, both with and without PET (Polyethylene Terephthalate) residue, with the aim of addressing the plastic waste issue. The research is an extension of the CEB project involving PET and commercial stabilizers (FONCYT-funded, project code: COAH-2019-C13 – C101), which commenced in 2020.

The research findings revealed that to produce CEBs with PET, specific soil composition is essential. A compressive strength of 40 kg/cm 2 was achieved using a mixture containing 78% soil, 16% PET, 3% lime, and 3% cement. This composition ensured compatibility with the soil, leading to acceptable results. However, it is recommended that only 10% PET be used in the mixture to optimize cohesion while still allowing the material to pass through an 8-mesh screen. This adjustment is essential for achieving the desired block characteristics.

The CEBs produced in this study underwent comprehensive mechanical evaluation, and microscopic examinations were conducted to observe the surface attributes of the blocks. The research underscores the importance of sustainable practices by recycling PET waste into construction materials, contributing to the reduction of plastic waste, and promoting environmentally friendly building methods.

2. MATERIALS AND METHODS

We worked with a quantitative, exploratory approach, carrying out laboratory work.

2.1. Elaboration of Compressed Earth Blocks

The first is to carry out a soil texture analysis study based on FAO [13] to select the bank that contains the appropriate properties, which is to contain a maximum of 80% sand and between 12 and 20% clay so that there is compatibility with PET. Then we proceed to screen the soil and PET; we proceed to mix them considering a percentage (in weight) of lime of 3%, cement at 3%, PET at 10%, and soil at 84%, with the percentage of moisture needed by the soil determined with the study of the soil, under the ASTM D2216-19 Standard test methods for laboratory determination of water (moisture) content of soil and rock by mass [14], all this introduces into the mixing machine and trying to prevent lumps from becoming lumps. To proceed to manufacture a compressed earth block with Ado-Press 2000 electric hydraulics that produces uniform and raw building blocks of compressed clay earth.

2.2. Compressive Strength Tests

It is an experiment in which the pressure that tends to cause a reduction in the volume of the object to which it is applied is determined; if we assume that the object that perceives this effect is found by planes perpendicular to the pressure exerted, the planes will approach each other.

Compressive strength is calculated using the following equation:

Where R, F, and A are the compressive strength, strength, and cross-sectional area of CEB, respectively.

The process is executed as follows: Using a hydraulic press from the brand ITAL MEXICANA, a consistent quantity of sand is initially positioned. On top of this sand bed is situated the Compressed Earth Block (CEB) chosen for the test. The hydraulic machinery is then employed to apply even pressure to the block until it reaches the point of maximum allowable stress, leading to fracture or failure. The force exerted during this process is indicated on the hydraulic equipment. To calculate the material's resistance, the force applied is correlated with the perpendicular area of the block under evaluation.

2.3. Thermal and Microscopic Tests Performed

2.3.1. Heat Transfer

The procedure, in this case, is based on the theory of the Linear Transient Heat Source, which is useful for studying thermal properties in soils, adobes, and CEB. It consists of the measurement and correlation of the temperature-induced within a material and its transfer through a thermal needle, for which the KD2 Pro Thermal Conductivity Meter was used with the SH-1 Sensor for a time of 30 minutes for the taking of readings in triplicate. (Fig. 1).

2.3.2. Scanning Electron Microscope (SEM) and Analysis

The analyses were performed in two magnitudes. A first with optical microscopy and later another with electron and scanning microscopy, with an acceleration of 200V and 20keV in a half vacuum with FEI equipment. ESEM-QUNTA 200 with 10nm resolution at 500, 1000, and 2000X.

To be able to read the samples in all cases, the blocks were first cut. These blocks were prepared in the laboratory according to the method indicated by Molar-Orozco et al. 2022 [15].

Scanning electron microscopy can reveal the surface morphology of CEB. This includes details such as the roughness, porosity, and any surface coatings. This information is vital for understanding how the surface properties may affect the overall performance of the bricks, especially in terms of durability and resistance to environmental factors. Transmission electron microscopy provides insights into the internal microstructure of CEB. This includes details about grain boundaries, crystallographic features [16-18], and defects within the material. Understanding the microstructure is crucial for assessing the mechanical properties and overall stability of the bricks. Therefore, SEM was selected, although it has some limitations depending on the sample acquisition. For that reason, homogeneity is necessary to observe the boundaries for different sizes of solids added to the mix.

3. RESULTS AND DISCUSSION

3.1. Compressive Strength Results

Laboratory with 10% by weight of PET gave 60 kg/cm2 while an increase in the percentage of PET gave a resistance reduction (around 16% PET gives 40 kg/cm2 approximately). The PET in a percentage of 10 to 16 concerning the weight to the soil, allows reusing the amount of 106 bottles (ground) per CEB, which, when added to the earth, presents a block with a resistance of 40-60 kg/cm2 overcoming the resistance of pressed vibro block.

3.3. Microscopic Analysis Results

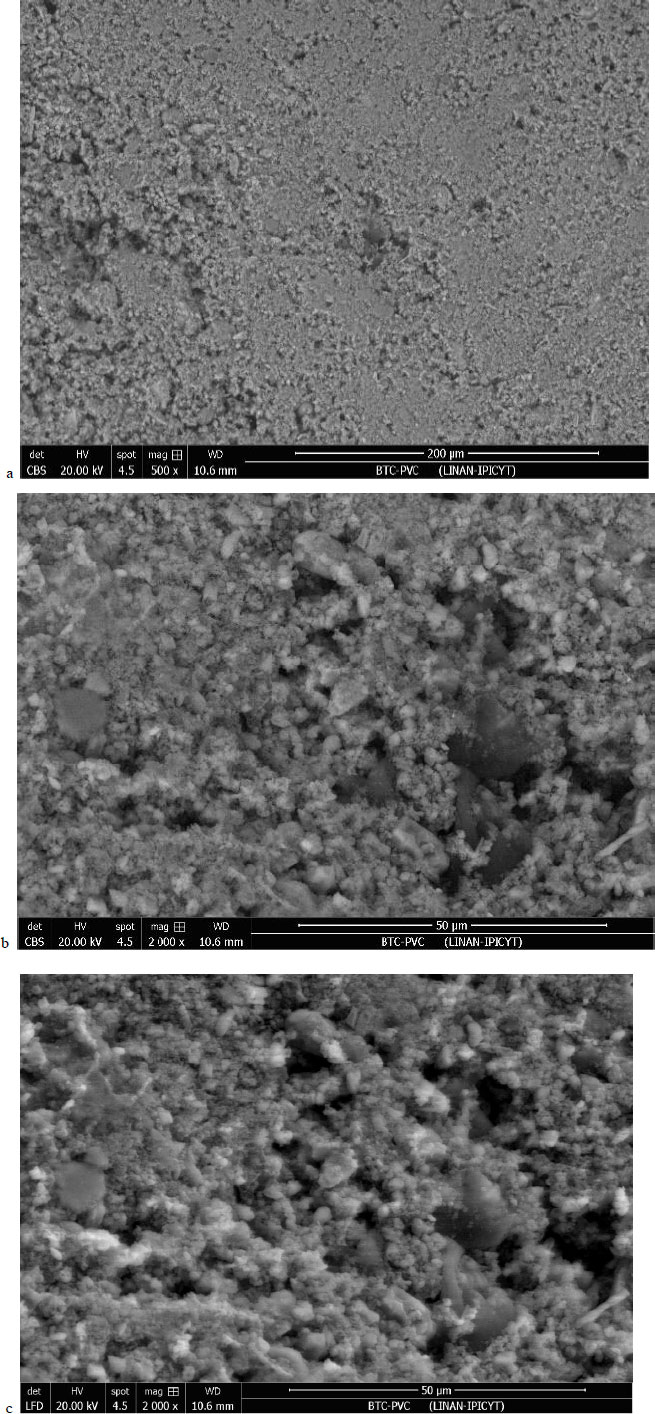

The microscopic analysis results, as illustrated in Figs. (2 and 3), provide detailed insights into the composition and structure of the compressed earth block (CEB) with the incorporation of polymer (PET) and highlight key considerations for optimizing material properties, mainly increasing sustainability.

| - | Material | to | λ | ρ | C | |

|---|---|---|---|---|---|---|

| mm2/s | W/mK | °C.cm/W | MJ/m3K | |||

| 1 | Near the PV | - | 0.099 | 0.131 | 765.5 | 1.314 |

| 2 | Panel CEB | - | 0.151 | 0.220 | 754.0 | 1.461 |

| 3 | CEB only | - | 0.163 | 0.365 | 274.2 | 2.231 |

| - | Error | - | 0.002 | 0.015 | 0.1 | 0.048 |

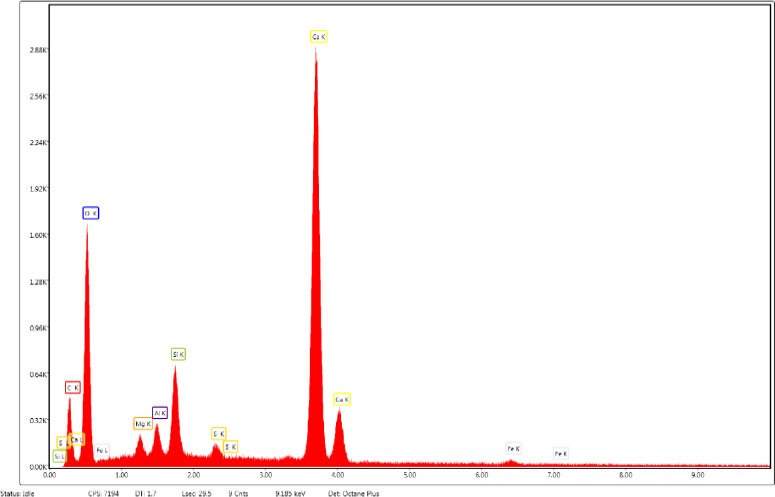

The elemental analysis of the CEB, depicted in Fig. (2), showcases the main components corresponding to silicates and aluminosilicates. This information is crucial for understanding the fundamental composition of the material. Silicates and aluminosilicates are typical components of natural earth materials, and their presence aligns with the expected composition of compressed earth bricks. The elemental analysis provides a baseline understanding of the primary constituents contributing to the structural integrity of the CEB]. Fig. (3) delves into the microscopic details of the CEB, focusing on the area surrounding the PET location. Notably, the presence of stretch marks in the PET is observable, indicating the deformation and accommodation of the material within these marks. However, at the interface areas between the earth material and PET, a pronounced separation is evident. This separation is attributed to the lack of affinity between the two phases.

Fig. (3) shows the field of display of the compressed earth block in the area surrounding the polymer (PET) location.

The observed stretch marks and roughness in the polymer, arising from the housing of the material, underline an important practical consideration. To enhance the overall structural integrity and promote better joints between the earth material and PET, it is advisable to increase the roughness of the polymer. This recommendation stems from the need for improved cohesion at the interface areas, ensuring a more robust integration of the two materials. The microscopic analysis thus guides potential refinements in the manufacturing process, suggesting a strategy to optimize the interaction between the compressed earth and polymer components.

The microscopic analysis results play a pivotal role in understanding the elemental composition and structural intricacies of the CEB with PET. These findings not only provide valuable insights into the material's properties but also offer practical recommendations for enhancing its performance, particularly in terms of interface cohesion and joint integrity.

The fundamental physics governing the process of integrating PET into compressed earth bricks (CEB) and its implications for housing construction involve several principles, i.e., Mechanical Properties, with a reduction in mechanical resistance to compression by 5% attributed to the inclusion of PET. The physics underlying this change involves the interaction between the earth material and the PET component. High compression forces compact the PET back to its original shape, inducing micro-cracks and altering the overall compressive strength. The fundamental physics in Thermal Properties is shown by the improvement in thermal diffusivity of CEB with PET as a result of the thermal characteristics of both materials. PET, known for its insulating properties, enhances the overall thermal behavior of the bricks. The lower heat transfer coefficient (λ) observed in PET-infused CEB compared to traditional materials like concrete or standard bricks is indicative of improved thermal insulation. The assessment of heat transfer characteristics, especially through a 20cm-thick wall constructed with CEB+PET, involves principles of heat conduction and insulation. The PET component contributes to lowering the heat transfer coefficient, demonstrating enhanced thermal efficiency. This has direct implications for the energy efficiency of buildings constructed with these blocks.

Regarding microstructural changes, it was found that scanning electron microscopy (SEM) analysis reveals alterations in porosity on the block's surface due to the deformation of the PET component. The physics here involves the interplay between the compressed earth and PET, impacting the overall structure and porosity of the material. Understanding these microstructural changes is crucial for predicting the long-term performance of the material.

For the ground field, a compact structure with agglomerated crystals is observed throughout the system. When making the enlargements, a smaller porous space is visualized. (Fig. 4).

Detailed microscopic observations provide valuable insights into the characteristics of samples with a significant PET content. These observations reveal a notable lack of uniformity in the peripheral regions of the polymer, often accompanied by the presence of visible cracks, as exemplified in Fig. (3c). The consequence of these observations is a departure from the previously maintained surface uniformity.

This intriguing phenomenon can be primarily attributed to the intricacies of the compaction process. During this phase, the PET component within the mixture may undergo deformation or compaction to a degree that differs from the surrounding soil particles. Consequently, when the compressive force is relieved, the PET tends to revert to its original, larger form, causing it to expand. This expansion has a ripple effect on the adjacent particle spaces, which, in turn, leads to the development of micro-cracks within the overlying soil layer.

3.4. General Implications

The implications of these findings are significant, particularly in the context of material stability and structural integrity. These micro-cracks can potentially undermine the structural strength of the material over time, impacting its overall performance and durability. Therefore, understanding the dynamics of PET interaction within the mixture and its consequences on material behavior is crucial for optimizing its application and addressing any potential challenges that may arise. Further research in this area may provide valuable insights for refining the utilization of PET in such composite materials.

The integration of PET into compressed earth bricks (CEB) in Saltillo, Mexico, represents a significant advancement with multifaceted impacts on the wider public: By incorporating PET into CEB, the research contributes to the development of sustainable and cost-effective building materials, addressing the pressing need for adequate housing in Mexico, providing a tangible solution to the growing issue of plastic waste, utilizing approximately 106 plastic bottles per block. This not only aids in waste reduction but also promotes recycling and environmental responsibility.

The superior thermal behavior of PET-infused CEB enhances energy efficiency in building design. This has direct implications for reducing energy consumption in residential spaces, potentially leading to lower energy bills for homeowners.

Sustainable housing practices, as demonstrated by the PET-infused CEB, can contribute to the overall well-being of communities. Improved living conditions and reduced environmental impact positively affect the health of residents. The development and implementation of PET-infused CEB can create economic opportunities, from local production to the construction industry. It can stimulate job growth and contribute to the local economy.

The research sets a precedent for sustainable construction practices using locally sourced materials, making it potentially relevant and applicable to regions facing similar housing and environmental challenges globally.

Fig. (5) shows the behavior of temporal temperature change according to Saltillo Coahuila climate for May. If we choose the proposed block in this paper, we find that there are no significant changes inside the wall. In this case, the 24 hours of a day is analyzed, finding 3 to 7 °C of difference with the exterior temperature. The results presented correspond to the solution of fundamental equations of transport phenomena [16].

This behavior is interesting because it represents the possibility of microclimates. Hermawan, H. has presented various studies on the impact of materials and spaces on the interior temperature of buildings, as well as the ability of an adaptive design in certain areas to improve comfort [17]. The application of the exposed model makes it possible to foresee that the use of the proposed CEB has thermal properties that would help to improve the comfort of the dwelling, thus reducing energy consumption.

3.5. Sustainable Development Goals (SDGs)

The integration of PET into CEB represents a sustainable construction trend by addressing environmental concerns and promoting eco-friendly building materials. This trend aligns with SDGs 9 (Industry, Innovation, and Infrastructure) and 11 (Sustainable Cities and Communities), emphasizing sustainable practices in the construction industry. The reuse of PET shrapnel in CEB contributes to waste reduction and recycling, and this aligns with SDG 12 (Responsible Consumption and Production) by promoting sustainable consumption patterns and reducing the environmental impact of plastic waste. The improved thermal properties of PET-infused CEB contribute to energy efficiency in buildings, aligning with SDGs 7 (Affordable and Clean Energy) and 13 (Climate Action) by promoting energy-efficient construction practices and reducing greenhouse gas emissions.

It is important to write the Innovation in Building Materials (SDG 9), in developing alternative and innovative building materials (as innovation in the construction sector) and Community Engagement (SDG 17), Ongoing research and feasibility studies in Saltillo reflect community engagement in assessing the viability of PET-infused blocks. Community engagement aligns with SDG 17 (Partnerships for the Goals), emphasizing collaboration and partnerships for sustainable development.

On the other hand, equipment and machines can also be sustainable [19] for engineering development and innovation.

3.6. Engineering Implications

The integration of PET into compressed earth bricks (CEB) presents an opportunity for the development of more sustainable construction materials, reducing reliance on non-renewable resources and promoting eco-friendly construction practices [20, 21].

One of the engineering implications is in Energy Efficiency in Building Design: Demonstrating a lower heat transfer coefficient for CEB blocks with PET has direct implications for energy-efficient building design. Engineers can use these results to develop structures with improved thermal insulation properties.

On the other hand, it is possible to find Innovation in Wall Construction; the comprehensive evaluation of heat transfer characteristics through a 20cm-thick wall constructed with CEB+PET opens opportunities for innovative construction practices. Engineers can consider these thermally enhanced structures in future projects. Thickness can change, too, opening wide opportunities for analysis and uses.

Engineers can explore ways to optimize the production processes of CEB+PET blocks to ensure the economic viability and scalability of this technology. Production efficiency is key to the successful large-scale implementation of this sustainable construction method.

The integration of PET into CEB represents a sustainable practice by addressing the environmental impact of plastic waste. The physics involved include the compatibility of PET with the earth material, ensuring that the structural and thermal properties of the resulting blocks are not compromised while contributing to reduced plastic waste.

It is notable to write that scaling up the production of PET-infused CEB may face logistical and operational challenges; addressing this challenge aligns with SDGs 9 (Industry, Innovation, and Infrastructure) and 12 (Responsible Consumption and Production).

In further work, it will be necessary to evaluate the changes in the behavior of the material with accelerated aging tests. To achieve Material Standardization and Certification (SDG 9), establishing standardized material properties and certifications for PET-infused CEB may be challenging. This is crucial for ensuring the reliability and acceptance of new construction materials. Addressing this challenge aligns with SDG 9 (Industry, Innovation, and Infrastructure).

Finally, Public Perception and Acceptance (SDG 12) are necessary to grow; gaining public trust and acceptance of new construction materials may be a challenge. Overcoming skepticism is crucial for successful adoption and aligns with SDG 12 (Responsible Consumption and Production).

CONCLUSION

The integration of a specific proportion of PET (Polyethylene Terephthalate) into compressed earth blocks is a promising approach that offers numerous benefits. Notably, this inclusion does not compromise the structural integrity of these blocks, maintaining their resistance properties and preserving their thermal behavior. Additionally, it contributes to environmental sustainability by helping to reduce plastic waste, which, in this instance, amounts to approximately 106 plastic bottles. The ongoing research in Saltillo focuses on evaluating the feasibility of producing and implementing these PET-infused blocks in residential construction.

The study at hand delves into the examination of earth bricks that have been augmented with PET, showcasing remarkable characteristics. One notable finding is that these blocks exhibit a lower heat transfer coefficient compared to conventional industrial materials such as concrete or standard bricks. This superior thermal behavior adds value to the material's application in construction.

Furthermore, the research offers comprehensive insights into the structural changes within the material. Scanning Electron Microscopy (SEM) visualization unveils the alterations in porosity on the block's surface, primarily attributed to the deformation of the PET component. Understanding these morphological changes is essential in assessing the material's long-term performance.

The evaluation of heat transfer characteristics underscores the advantageous properties of the PET-infused CEB. These results demonstrate a lower heat transfer coefficient (λ) for the CEB with PET compared to industrial materials like concrete or standard bricks. This superior thermal behavior enhances the suitability of this material for use in construction, promising improved energy efficiency in building design.

A critical aspect of the study involves the assessment of heat transfer characteristics through a 20cm-thick wall constructed using CEB+PET. This comprehensive analysis not only validates the material's thermal efficiency but also opens the door for innovative and sustainable building practices. Ultimately, the findings support the viability of PET-infused compressed earth blocks as an eco-friendly construction solution with superior thermal performance.

The information generated by the study provides a valuable knowledge base for the civil engineering and architecture community. Dissemination of this knowledge contributes to the training of professionals and the widespread adoption of more sustainable practices in the construction industry.

Finally, the physics governing the process involves the mechanical interactions between earth material and PET, the thermal characteristics of both components, and the microstructural changes induced by the incorporation of PET. These insights are essential for understanding the material's behavior, ensuring its structural integrity, and promoting sustainable construction practices in the civil engineering and architecture community. The dissemination of this knowledge contributes to the broader adoption of environmentally friendly and sustainable practices in the construction industry.

LIST OF ABBREVIATIONS

| CEB | = Compressed Earth Block |

| PET | = PolyEthylene Terephthalate |

| SEM | = Scanning electron microscope |

| ASTM | = American Society for Testing and Materials |

CONSENT FOR PUBLICATION

Not applicable.

AVAILABILITY OF DATA AND MATERIALS

The data supporting the findings of the article is available in the Zenodo at [https://zenodo.org/records/10465933], reference number 10465933.

FUNDING

MEMO and LMJ received Funding from agency: CONAHCYT Funder ID 2022. Awards/Grant number: UAC 2022. MEMO and LMJ thanks to project CONACYT UAC 2022.

CONFLICT OF INTEREST

The authors have no conflicts of interest to declare that they are relevant to the content of this article.

ACKNOWLEDGEMENTS

The authors thank the staff who attended the materials characterization and the Nanoscience and Nanotechnology Research National Laboratory (LINAN) at IPICyT for providing access to their facilities. EJSD and JFPS thank to COTACYT 2024 for 2023 announcement. MEMO and LMJ thanks to project CONACYT UAC 2022.