All published articles of this journal are available on ScienceDirect.

Enhancing Large-Diameter Tunnel Construction Safety with Robust Optimization and Machine Learning Integrated into BIM

Abstract

Aim

This study aims to enhance safety in large diameter tunnel construction by integrating robust optimization and machine learning (ML) techniques with Building Information Modeling (BIM). By acquiring and preprocessing various datasets, implementing feature engineering, and using algorithms like SVM, decision trees, ANN, and random forests, the study demonstrates the effectiveness of ML models in risk prediction and mitigation, ultimately advancing safety performance in civil engineering projects.

Background

Large diameter tunnel construction presents significant safety challenges. Traditional methods often fall short of effectively predicting and mitigating risks. This study addresses these gaps by integrating robust optimization and machine learning (ML) approaches with Building Information Modeling (BIM) technology. By acquiring and preprocessing diverse datasets, implementing feature engineering, and employing ML algorithms, the study aims to enhance risk prediction and safety measures in tunnel construction projects.

Objective

The objective of this study is to improve safety in large diameter tunnel construction by integrating robust optimization and machine learning (ML) techniques with Building Information Modeling (BIM). This involves acquiring and preprocessing diverse datasets, using feature engineering to extract key parameters, and applying ML algorithms like SVM, decision trees, ANN, and random forests to predict and mitigate risks, ultimately enhancing safety performance in civil engineering projects.

Methods

The study's methods include acquiring and preprocessing various datasets (geological, structural, environmental, operational, historical, and simulation). Feature engineering techniques are used to extract key safety parameters for tunnels. Machine learning algorithms, such as decision trees, support vector machines (SVM), artificial neural networks, and random forests, are employed to analyze the data and predict construction risks. The SVM algorithm, with a 98.76% accuracy, is the most reliable predictor.

Results

The study found that the Support Vector Machine (SVM) algorithm was the most accurate predictor of risks in large diameter tunnel construction, achieving a 98.76% accuracy rate. Other models, such as decision trees, artificial neural networks, and random forests, also performed well, validating the effectiveness of ML-based solutions for risk assessment and mitigation. These predictive models enable stakeholders to monitor construction, allocate resources, and implement preventative measures effectively.

Conclusion

The study concludes that integrating machine learning (ML) approaches with Building Information Modeling (BIM) significantly improves safety in large diameter tunnel construction. The Support Vector Machine (SVM) algorithm, with 98.76% accuracy, is the most reliable predictor of risks. Other models, like decision trees, artificial neural networks, and random forests, also perform well, validating ML-based solutions for risk assessment. Adopting these ML approaches enhances safety performance and resource management in civil engineering projects.

1. INTRODUCTION

Large diameter tunnels are critical conduits that enable transportation, utilities and other essential infras- tructure to pass through urban or industrial environments, moving people, goods and services. Nonetheless, such tunnels are fraught with challenges and risks in terms of their construction and operations because geological hazards vary throughout the length of the tunnel, and various components might be structurally deficient [1, 2]. The importance of maintaining the safety and integrity of large tunnel projects cannot be overstated in terms of the associated pressures to uphold public welfare and infrastructure investments. In the last few years, a well-promising practice can be found in promising and robust optimization approaches based on machine learning (ML) algorithms to optimize safety outcomes over civil engineering problems. Through advanced data analytics and predictive modeling, stakeholders can evaluate the risk, analyze it to the depth of detail they desire, and prevent it proactively all along the project life cycle.

These efforts have been rounded by the creation of a digital model, called Building Information Modeling (BIM) that provides an interactive representation of what is to be built, which enables more collaborative decision-making and risk identification, thus preventing design omission with large cost [3, 4]. This study attempts to investigate the ability of mixed robust optimization and ML models in BIM implementation for safety enhancement in large-diameter tunnel construction projects. This study aims to comprehen- sively collect and analyze a wide variety of datasets such as geological, structural, environmental, operational, historical and simulation data. It will identify risk factors using these data sources and then develop models for prediction with which it can assess the safety risks associated with tunnels so that they can be mitigated.

Following are the primary safety concerns associated with large-diameter tunnels and their mitigation strategies.

1.1. Primary Safety Concerns

1.1.1. Geological Instabilities

Large-diameter tunnels often pass through varying geological conditions, which can lead to unexpected instabilities, such as rockfalls, ground subsidence, or collapses. These instabilities pose significant risks to construction workers and equipment.

1.1.2. Structural Integrity

Ensuring the structural stability of tunnels is crucial, particularly in areas with high seismic activity or poor soil conditions. Inadequate structural support or failure of tunnel linings can lead to catastrophic failures.

1.1.3. Environmental Hazards

Tunnel construction can significantly impact the surrounding environment, causing issues such as groundwater contamination, air and noise pollution, and disruption of local ecosystems.

1.2. Mitigation Strategies

1.2.1. Comprehensive Geotechnical Surveys and Monitoring

Conducting detailed geological and geotechnical surveys before construction can help identify potential risks. Continuous monitoring during construction using advanced sensors and data analysis can detect early signs of instability, allowing for timely interventions.

1.2.2. Robust Structural Design and Materials

Utilizing advanced structural analysis methods, such as finite element analysis (FEA) and computational fluid dynamics (CFD), can optimize the design for varying load conditions. High-quality materials and reinforcement techniques should be used to enhance the tunnel's durability and resilience.

1.2.3. Environmental Impact Assessments (EIA) and Mitigation Plans

Conducting thorough EIAs before starting construction can help identify and plan for potential environmental risks. Implementing mitigation strategies, such as ground- water management and noise reduction measures, can minimize environmental impact.

1.2.4. Advanced Safety Protocols and Training

Implementing stringent safety protocols, providing comprehensive training for workers, and ensuring adherence to safety standards can significantly reduce the risk of accidents. Regular safety drills and the use of personal protective equipment (PPE) are also crucial.

1.2.5. Integration of Machine Learning and BIM

The integration of machine learning models with Building Information Modeling (BIM) can enhance risk prediction and management. These technologies can provide real-time data analysis and predictive insights, enabling proactive risk mitigation measures.

By addressing these primary concerns with targeted mitigation strategies, the safety of large-diameter tunnel construction projects can be significantly improved. Our study demonstrates how robust optimization and machine learning, integrated with BIM, can play a crucial role in enhancing safety measures throughout the construction process.

1.3. Role of Machine Learning in Predicting and Preventing Safety Issues in Tunnel Construction

1.3.1. Data-driven Risk Prediction

Machine learning (ML) models can analyze vast amounts of data from various sources, such as geological surveys, structural analysis, environmental monitoring, and historical incident reports, to predict potential safety issues in tunnel construction. By identifying patterns and correlations in the data, ML algorithms can forecast the likelihood of risks such as ground collapses, structural failures, or hazardous environmental conditions, allowing for proactive measures to be taken.

1.3.2. Real-time Monitoring and Anomaly Detection

ML algorithms can be integrated with real-time monitoring systems to continuously assess the safety conditions during tunnel construction. For example, ML models can process data from sensors embedded in tunnel boring machines (TBMs), structural components, and environmental monitoring devices to detect anomalies or deviations from expected behavior. This real-time analysis enables immediate identification of potential safety threats, such as equipment malfunctions or unstable geological conditions, allowing for swift intervention.

1.3.3. Enhanced Decision-making

Machine learning provides valuable insights that assist in decision-making processes throughout the tunnel construction project. For instance, ML models can prioritize risks based on their potential impact and likelihood, guiding project managers to focus on the most critical safety issues. Additionally, ML can help optimize construction schedules and resource allocation by predicting which phases of construction are most likely to encounter safety challenges.

1.3.4. Improved Safety Protocols and Preventative Measures

By analyzing historical data and identifying the root causes of past incidents, ML models can help refine safety protocols and develop more effective preventative measures. For example, suppose ML identifies that certain soil compositions or specific construction methods are associated with higher risk. In that case, these insights can inform the development of targeted safety measures and training programs for workers, reducing the likelihood of accidents.

1.3.5. Adaptive Learning and Continuous Improvement

Unlike traditional risk assessment methods, machine learning models can continuously learn and improve as more data becomes available. This adaptability is crucial in tunnel construction, where conditions can change rapidly, and new safety challenges may emerge. ML models can be updated with new data to refine their predictions and recommendations, ensuring that safety strategies remain effective over time.

In summary, machine learning plays a critical role in predicting and preventing safety issues in tunnel construction by enabling data-driven risk prediction, real-time monitoring, enhanced decision-making, improved safety protocols, adaptive learning, and scenario analysis. These capabilities significantly enhance the ability of construction teams to anticipate, identify, and mitigate potential safety hazards, ultimately leading to safer tunnel construction projects.

1.4. Benefits of Using Building Information Modeling (BIM) for Tunnel Safety Management

1.4.1. Enhanced Visualization and Planning

BIM allows for the creation of a digital twin or a 3D model of the tunnel and its surrounding environment. This visualization helps stakeholders better understand the spatial relationships, geometries, and design elements involved in the tunnel construction. By having a detailed digital representation, project teams can identify potential safety issues during the planning phase, such as clashes between different structural elements or insufficient clearance for equipment, and make necessary adjustments before construction begins.

1.4.2. Improved Collaboration and Communication

BIM facilitates a collaborative environment by integrating various data and inputs from different disciplines (e.g., civil engineering, geotechnical studies, environmental assessments) into a single, shared model. This integration enhances communication among project stakeholders, ensuring that all parties have access to the same up-to-date information. Improved collaboration reduces the likelihood of miscommunication and errors, which are common sources of safety risks in tunnel construction.

1.4.3. Proactive Risk Management

With BIM, project teams can simulate different construction scenarios and assess their impact on safety. These simulations allow for the early identification of risks, enabling proactive risk management strategies. For example, BIM can model the effects of varying geological conditions on tunnel stability, helping engineers design appropriate support systems and reinforcement measures in advance.

1.4.4. Real-time Monitoring and Data Integration

BIM can be integrated with real-time monitoring systems and sensor networks installed in the tunnel construction site. This integration allows for continuous monitoring of critical parameters, such as structural integrity, environmental conditions, and equipment perfor- mance. By combining real-time data with the BIM model, project managers can quickly detect deviations from the expected conditions, assess their impact on safety, and take immediate corrective actions.

In summary, BIM offers numerous benefits for tunnel safety management, including enhanced visualization and planning, improved collaboration and communication, proactive risk management, real-time monitoring, stream- lined safety protocols, lifecycle safety management, and data-driven decision-making. These advantages make BIM a powerful tool for enhancing safety and reducing risks in tunnel construction projects.

Machine learning models can be integrated into BIM by connecting real-time data feeds from IoT sensors and monitoring equipment directly to the BIM platform. These sensors, placed throughout the tunnel construction site, continuously collect data on key safety parameters like structural integrity, environmental conditions, and equipment performance. The data is then processed by machine learning models, which analyze it for patterns and anomalies that might indicate potential safety risks.

The results from the machine learning models are fed back into the BIM model, updating the digital twin in real-time to reflect current safety conditions. This integration allows for immediate visualization of risks and informs decision-making by providing actionable insights, enabling proactive safety measures and rapid response to emerging threats. By combining real-time data with predictive analytics within the BIM environment, tunnel safety can be continuously monitored and managed more effectively.

1.5. How BIM Serves as a Platform for Integrating Robust Optimization and Machine Learning in Tunnel Construction Projects

1.5.1. Centralized Data Management and Integration

BIM serves as a centralized platform that aggregates and manages data from various sources, including geological surveys, structural analyses, environmental sensors, and operational records. This comprehensive dataset is essential for training machine learning models and implementing robust optimization techniques. By providing a unified data environment, BIM enables seamless integration of diverse datasets, facilitating more accurate and holistic risk assessments and decision-making processes.

1.5.2. Enhanced Visualization and Simulation Capabilities

BIM’s 3D modeling capabilities allow for the creation of detailed digital twins of the tunnel construction project. This virtual environment provides a visual context for the results generated by machine learning models and robust optimization algorithms. For example, predictive models can identify potential risk areas, which can then be visualized within the BIM model to understand their spatial relationship and impact on the overall project. This integration allows stakeholders to simulate various scenarios and assess the effectiveness of different safety measures, optimizing decision-making and resource allocation.

1.5.3. Real-time Monitoring and Feedback Loop

BIM can be integrated with real-time monitoring systems and IoT sensors placed throughout the construction site. Data from these sensors can be continuously fed into machine learning models to update risk assessments dynamically. The results of these assess- ments can then be integrated back into the BIM model to provide a real-time view of potential risks and necessary interventions. This feedback loop enables proactive risk management, allowing for timely adjustments to construction plans and safety protocols based on the latest data and predictions.

1.6. Combination of Robust Optimization and Machine Learning for Improved Risk Management

The combination of robust optimization and machine learning improves risk management in tunnel projects by providing predictive insights and adaptive strategies to handle uncertainties. Machine learning models analyze data to predict potential risks, while robust optimization helps develop strategies that remain effective under a wide range of conditions, ensuring safe and efficient construction processes.

1.6.1. Effective Machine Learning Techniques for Tunnel Safety

Support Vector Machines (SVMs) and Random Forests (RF), ANN are particularly effective for analyzing tunnel safety. SVMs are well-suited for high-dimensional data and can effectively classify risks, while Random Forests handle complex, non-linear interactions and provide insights into feature importance, helping prioritize risk factors.

2. LITERATURE REVIEW

The construction of tunnels is a major, risky and challenging engineering work. Consequently, an abundant amount of literature is available on every possible aspect, from the design and construction method up to different safety management practices. Thus, our literature review intends to summarize the essential discussions and observations that are concerned with applying robust optimization and machine learning by using BIM as an approach in large-diametral tunnel project safety improvements [5, 6].

Tunnel construction is largely influenced by geotechnical factors such as stability, opportunity for excavation and risk control. Comprehensive geological surveys and ground investigation techniques can obviously lead to advise on the requirement for such provision, as highlighted in many studies. The study emphasizes employing state-of-the-art geotechnical modeling software and numerical simulations in order to anticipate the ground behavior and parameters of tunnel design [7, 8]. Moreover, the research also paved the way for risk assessment approaches for geohazards such as rockfall, landslide and ground subsidence during tunneling. All these findings will support decision-making and mitigation of different scenarios while constructing a tunnel [9].

When it comes to tunneling construction, structural integrity is key. This includes the load-bearing structures that a given material type can support as well as its overall structural stability or otherwise in various circumstances. In light of literature, it is clear that advanced structural analysis methods such as FEA or CFD should be employed to assess the performance of tunnel structures for different loading cases. Research has also been done regarding new construction materials and reinforcement methods to improve the resiliency and life-span of the structures. (6) Furthermore, some researches have been conducted to provide monitoring system such strain gauges and accelerometers to offer real time structural health conditions and detect probable failures or deformation [10].

Tunnel construction comes with a wide variety of environmental impacts, such as noise, air quality and habitat degradation. It is emphasized in the literature that to minimize such negative effects on surrounding ecosystems and communities, comprehensive EIAs must be completed and mitigation strategies implemented beforehand [11]. Additionally, such studies have sought to create predictive models and risk assessment tools that can be used to measure and control local environmental risks related to tunnel projects, including the pollution of groundwater sources, oscillation spread in underground soil layers, or natural processes acting as air pollutant dispersal vectors. Other innovative approaches like green tunneling and sustainable construction methodologies are being considered to minimize the ecological footprint of tunnel-based projects.

For tunnel infrastructure longevity, operational safety and maintenance performance should be maximized. Moreover, scholars have also researched on different aspects of the tunnel and its operation and maintenance which are related to traffic management, emergency response planning mechanism, asset management strategies, etc [12]. The research study focuses on how advanced monitoring systems and predictive maintenance processes detect potential defects or deterioration early enough to ensure that proactive maintenance is scheduled soon. Literature also underlines that in order to build a safety-conscious and compliant approach among tunnel staff, human factors as well as behavioral psychology principles should be implemented within the safety management system.

The emergence of Building Information Modelling (BIM) has transformed the process for the planning, design and maintenance of these types of projects. BIM allows for creating a digital twin, or virtual replica of the physical asset that enables better and more collaborative decision-making based on high-quality information. Other benefits include sharing data in real-time and visualizing in great detail throughout an infrastructure's lifecycle [13]. Historical evidence is also available showing the success of BIM in tunneling when it comes to 3d modeling, clash detection as well as beginning critical activity and schedule planning for time and cost. The researches have expanded this integration with other technological concepts like combining these BIM systems with Geographic Information Systems (GIS) and remote sensing or using Internet of Things (IoT) devices to increase data interoperability between different software systems used in a project. In conclusion, BIM and digital twin integration would benefit the stakeholders involved in large-diameter tunnel projects by aligning notifications among them, reducing risks associated with decision-making, streamlining manpower hours to enhance safety outcomes.

The authors [12] discussed the versatility of Building Information Modeling (BIM) beyond its conventional applications, demonstrating its adaptability in various domains, including green building design. By drawing parallels between green building initiatives and safety management in tunnel construction, we can highlight BIM's comprehensive capabilities in enhancing project outcomes, including safety and sustainability. The authors [13] discussed how simulation-based optimization methods can be applied to tunnel construction to anticipate and mitigate potential damages. By comparing this approach with our own use of robust optimization, we can better illustrate the advantages of predictive modeling and proactive risk management in ensuring tunnel safety.

The authors [14] explored the integration of multi-objective optimization and explainable AI in enhancing tunnel construction safety. This will help us discuss how our study builds on existing research by incorporating both optimization and machine learning techniques to develop a more comprehensive and transparent safety management framework. While this study focuses on the structural performance of steel beams, it provides valuable insights into the application of machine learning in predicting structural behavior. We will draw on the methodologies used in this paper to strengthen our discussion on the use of machine learning for predicting tunnel safety risks, demonstrating its potential across various structural engineering applications [15]. The authors [16] examined the role of innovative construction technologies and their impact on building performance and safety. By discussing similar innovative approaches in tunnel construction, we can highlight how integrating advanced systems and methods can lead to better safety outcomes and resource efficiency.

With the advancement of machine learning (ML) techniques, it has been increasingly applied in several engineering disciplines to process large-scale and complex datasets, discover intrinsic regularized patterns among signals or components, and generate knowledge-based predictions. Tunnel construction. ML algorithms also provide promising opportunities for risk assessment, anomaly detection and decision support when it comes to tunnel construction [17, 18]. On the other hand, literature has also deliberated over ML being used for predicting ground behavior, scheduling construction and evaluating the health of structure. In addition, studies are conducted to explore the application of ML with related technologies, including sensor networks and remote monitoring systems for developing predictive maintenance models and real-time risk monitoring tools. The predictive power of ML enables stakeholders to foresee the safety risk, control it and achieve optimum results in mega tunnel projects [20, 21].

It is a new approach to improving safety through the application of robust optimization and machine learning techniques in tunnel construction. Robust optimization methods optimize the system performance that works in uncertainty, sensitivity of input parameters and changes in external conditions. This enables stakeholders to derive predictive models for risk assessment resource allocation decisions by integrating machine learning algorithms, including support vector machines (SVM), decision trees (like Random forests and boost trees), and artificial neural network (ANN) into optimization frameworks [22, 23].

At the same time, there is virtually no literature on this subject, with a small number of studies specifically analyzing an effective combination of robust optimization and ML in tunnel building. Although preliminary research shows promising results, proving the efficacy of these improvements will enhance safety outcomes, lower cost and expedite completion in large-diameter tunnel projects. Future work is needed to investigate the potential synergies of robust optimization and ML approaches for developing practical applications in terms of safety improvements in tunnel construction [24, 25].

Working of the proposed research.

3. METHODOLOGY

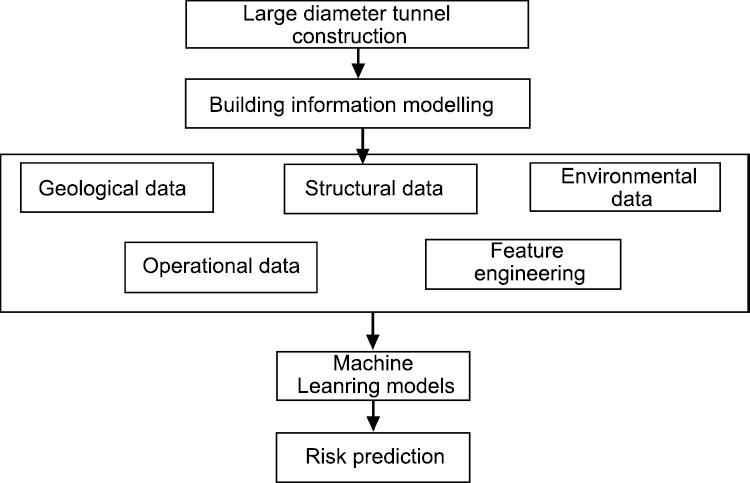

Based on the above literature, in this research ML models are used for identifying the risk factors in tunnel construction. The datasets used in this research consist of a range of details, from geology-based information like soil composition and rock properties to groundwater heights and other ground condition factors that the tunnel will pass through. Environmental data, including temperature, humidity and seismic activity are also included, which determine the stability of the tunnel. The work of the entire research is shown in Fig. (1).

Data relevant to operations, such as information on traffic load and maintenance records, give a sense of what factors are currently at play in the tunnel while providing some insight into future stressors or maintenance needs. Indeed, historical data from previous incidents and tunnel collapses represents a valuable database of lessons learned in which repetitive patterns and factors of risk can be found. Additionally, simulation data obtained from finite element analysis simulations are proactive predictive indicators for any possible scenarios in terms of the risks involved.

After this wide collection of datasets, a detailed and thorough step involves data cleaning and processing to maintain its accuracy proliferation. This is followed by the use of feature engineering techniques to generate necessary features from the data in order to practice attributes that affect tunnel safety metrics, including stress and deformation rates as well as environmental parameters. On and on, so that extracted features from various stages can be added together in a complete dataset for the purpose of machine learning model training.

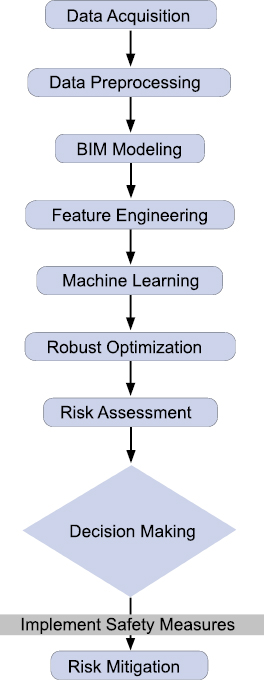

Multiple ML algorithms are used in this research to analyze the dataset and identify possible risks of large tunnel construction. Complex patterns and relationships in the data are detected by array of algorithms that include decision trees, Random forests, support vector machines, artificial neural networks, etc. With the help of these organized ML models for predictions, working behavior on the construction of large tunnels is evaluated and assessed to identify probable risks. Flowchart in Fig. (2) illustrates the interactive and process flow of integrating robust optimization and machine learning into tunnel safety management using BIM. This visual representation shows the steps involved, from data acquisition to risk mitigation and decision-making.

3.1. Integrating Robust Optimization to Enhance Tunnel Safety

Robust optimization is a critical technique in managing the inherent uncertainties and variability present in large-diameter tunnel construction. Here’s how integrating robust optimization enhances tunnel safety:

3.1.1. Handling Uncertainty in Geotechnical Conditions

In tunnel construction, geological conditions can vary significantly along the tunnel route, posing unpredictable risks such as collapses, rockfalls, and ground subsidence. Robust optimization helps by designing models that account for these uncertainties, allowing construction plans to adapt to changing conditions dynamically. By optimizing for the worst-case scenarios, the method ensures safety measures are effective under a range of possible conditions, thereby reducing the likelihood of unexpected failures.

Flowchart of the process flow.

3.1.2. Optimizing Structural Design Parameters

Robust optimization can be used to optimize structural design parameters, such as tunnel lining thickness, reinforcement types, and support systems, to ensure they can withstand various load conditions, including those not anticipated in the original design. By optimizing these parameters against a range of potential stressors and environmental conditions, the structural integrity of the tunnel is enhanced, reducing the risk of failures.

3.1.3. Improving Resource Allocation and Risk Management

In tunnel construction, resources such as labor, materials, and machinery must be allocated efficiently to maintain safety standards. Robust optimization algorithms help in creating strategies that minimize risks while considering the cost and resource constraints. This ensures that safety-critical resources are available when and where they are most needed, enhancing overall project safety.

3.1.4. Integration with Predictive Models for Proactive Safety Measures

When combined with machine learning models, robust optimization can enhance predictive capabilities by providing more resilient solutions to identified risks. For example, it can optimize safety protocols and emergency response plans by considering a wide range of potential incidents, thereby improving readiness and response effectiveness in case of an actual event.

3.1.5. Mitigating the Impact of Human and Environmental Factors

Robust optimization also considers the impact of human factors, such as operator errors or unforeseen environmental changes, by developing solutions that are less sensitive to these variables. This means that even if there is a deviation from the expected behavior due to human error or sudden environmental shifts, the safety measures remain effective.

In summary, integrating robust optimization into tunnel construction projects enhances safety by providing a systematic approach to managing uncertainties, optimizing critical design and operational parameters, and ensuring that safety measures are both effective and adaptable. This integration leads to safer construction practices, better risk management, and, ultimately, a reduction in the occurrence of accidents and structural failures.

3.2. Machine Learning Models

Within this research, the decision tree algorithm is one of the well-known ML models to be used. The decision trees are very good at classification problems as it creates a tree-like structure of if-else and based on characteristics, they recursively divide the data for that checkpoint. They are good at both numerical and categorical data, which is appropriate for the diverse datasets used in this study. There is a trade-off since decision trees are interpretable and the stakeholders can understand whether or not they believe that the model’s predictions make sense and which features affect their risk of tunneling.

Another ML algorithm that is used in this research. Random forests work by creating multiple decision trees, and then averaging their predictions to arrive at a more accurate representation that is less prone to overfitting. They are naturally less sensitive to noise and outliers than methods that model the target distribution directly, which is beneficial for analyzing complex or highly heterogeneous data. In tunnel construction projects, random forests can provide feature importance scores to the stakeholders. This helps them in managing risk factors efficiently and allocating resources accordingly.

Moreover, for the risk prediction and classification-based tasks of this research, SVMs are the method employed. SVMs are effective supervised machine learning tools used for classifying available data points into different classes by identifying the best hyperplane of maximum margin. They are great when it comes to working with high dimensional data but in general, we use both these techniques on small to medium-sized datasets. The great versatility of SVMs, which can also solve different kinds of data and the nonlinear relationships between attributes, make them capable to identify risk factors in large tunnel projects.

Additionally, artificial neural networks are important to this research, as they have been used for modelling non-linear and complicated patterns and relationships among the data. Artificial neural networks (ANNs) are models comprising interconnected nodes/vertices, much like neurons in the human brain that are arranged in layers. By training these deep networks on several thousands of samples or more, ANNs allow us to predict accurately. These are usually best used for regression and classification, which is why they can be a useful tool to analyze the wide variety of multi-dimensional datasets that are being gathered for tunnel safety analysis. Building on the scalability and adaptability provided by ANN, the results show that ANNs could prove very effective in dealing with large-scale data for providing useful insights into risks from developing huge tunnel projects.

3.3. Pre-processing Of Dataset

In this work, the preprocessing of the dataset must be done very well to guarantee the accuracy and reliability of the analysis derived from it. The process starts by acquiring comprehensive multiple geological, structural, environmental, operational and historical datasets, including any type of simulation data, in the most meticulous way. Yet, all these data sources need to pass many preprocessing steps. Inconsistencies in systems, missing values and outliers must be corrected or deleted for the datasets to be ready to use for further analysis.

Data cleaning is one of the many first steps during data preprocessing, which strives in removing extraneous or inconsistent data points. Thus, it is guaranteed that the dataset does not have any noise or inaccuracies and also increases the quality level of upcoming analysis. In two geological data, outliners or erroneous measurements of soil composition containing a substance and characteristics due to the nature of the rocks are detected subjectively based on intuition and corrected.

After that, our data cleaning assignment helps us clean the dataset and combine different sets as a unified set, which is collected from various sources. The integration process includes mapping the data attributes and correcting any differences in format or units of measure. Indeed, the environmental data (e.g., temperature and humidity) used may come from several sensors that use different scales, and standardization is required to reduce it into one scale.

The next step is to perform feature engineering on top of the integrated form. The integration consists of the extraction or derivation of relevant features from the original data. The first step is to locate critical parameters with a direct influence on the safety of tunnels, like stress, deformation and environmental conditions. Any operation that can be performed on features in the dataset aside from simple dimensionality reduction is referred to as feature engineering; this involves transformation or creation of new such as taking square root of a variable.

In addition, data preprocessing includes dealing with missing values, which are an omnipresent issue in real world datasets. In this case, imputation methods, such as mean imputation, median imputation or more sophisticated predictive modeling may be used to address missing data and fill in the gaps without compromising the information contained within the dataset.

Outlier Detection and Treatment are done in the dataset, which are the important data preprocessing steps. Outliers are those data points that will create huge deviance from the rest of the observation in the dataset, outliers must be detected and treated efficiently. Outliers may be measurement errors or indicative of data anomalies: in any case, if not treated properly, they can give rise to misleading results from the subsequent analyses. To identify and correct outliers, techniques like Z-score normalization are implemented in the database.

3.4. Feature Engineering

This work uses feature engineering as an important step towards preparing the dataset for analysis by learning features that are more in direct relation to tunnel safety and construction. This starts with a detailed investigation of the datasets gathered, including (1) geological data, (2) structural data, (3) environmental and geotechnical survey data, (4) operational and production statistics series for different minerals, oils or gas productions among others, 5) historical records of slope failures or critical events, and 6) simulation output data. Feature engineering, therefore, tries to capture a whole lot of information by squeezing and identifying crucial parameters and relations that can help in comprehending the dynamics behind tunnel safety.

Another major purpose of feature engineering is to try to encapsulate the complex interactions among different geo-features and any inherent issues or risks that can challenge safety during excavation. Different geologic elements, including soil composition, rock properties, fluctuating levels of groundwater and interconnected geographical formations, bring their unique set of challenges to the table. For this reason, elaborated feature engineering procedures are designed to retrieve and analyze relevant multi-dimensional information from the vast geological data through various compositional measures, permeability findings, structural analyses and topological characterizations.

Feature engineering indeed extends into this structural parameter as well. The design and material choices for tunnel configuration can be inferred from the dataset. It also examines tunnel dimensions, reinforcing lining selections, reinforcement schematics, construction approaches and maintenance protocols.

Finally, beyond the threats based on systems and technical features, environmental factors are extremely relevant for long term safety issues in tunnels: fluctuations of temperature, variations of humidity or seismic movements exert influences on the resistance capability over time. The investigated issues also include thermal stresses, moisture stresses and ground shaking hazards which cover the temperature deviation and humidity factor and seismic risk metrics, including response spectra, and stop-earthquake acceleration values with peak ground motion parameters.

Feature engineering also includes operational records, including variations of traffic loads, changing maintenance rules and regulations or putting more pressure on aging infrastructure to uncover meaningful patterns and outliers that can be useful for maintaining the safety of tunnels.

Historical data based on previous tunnel failures and collapses will provide us with useful information about patterns that repeated or the same risk factors were possible to be a danger for future projects on historical datasets. Feature engineering processes are conducted to find important features that can benefit from past structural deficiencies and vulnerabilities. The severity of the incident, modes of failures, root causes and remediation strategies are some such features that can be leveraged for a good foundation for hazard assessment and mitigation.

The simulation outputs are processed using feature engineering techniques after conducting FEA (finite element analyses) simulations so that the complex configurations are distilled into useful and comprehensible information. From simulation datasets, information can be retrieved on such items as stress distributions, deformation modes and potential failure mechanisms to gain insights into the structural behavior of tunnel systems subjected to sets of loading permutations.

A total of 450 data points were collected in this research from different sources, which include site and engineering related along with geological, structural environmental, operational historical, and simulation data. 70% of the data are used for training and the remaining 30% are utilized for testing purposes from the dataset.

To address potential concerns about overfitting, we have refined our feature engineering approach. We carefully selected features based on their relevance to tunnel safety and construction, ensuring that only the most significant predictors were included in the model. We employed techniques such as regularization and feature selection methods to reduce model complexity and prevent overfitting.

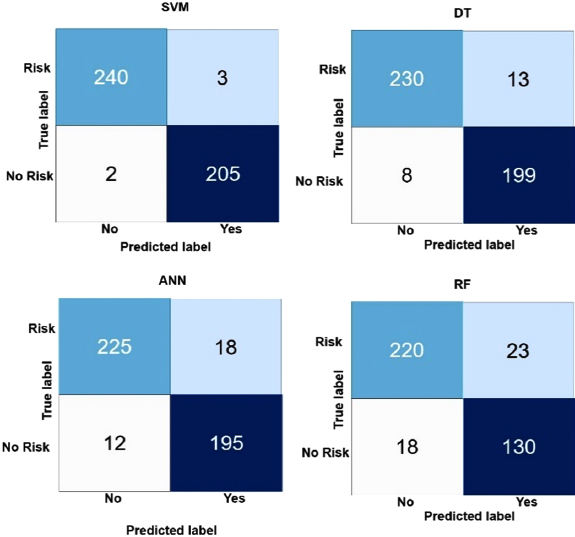

Additionally, we performed a detailed analysis of positive and negative prediction errors. By examining the confusion matrix and error distribution, we identified specific areas where the model may misclassify data. This analysis helped us fine-tune the model to better handle edge cases and reduce both false positives and false negatives.

4. RESULTS AND DISCUSSION

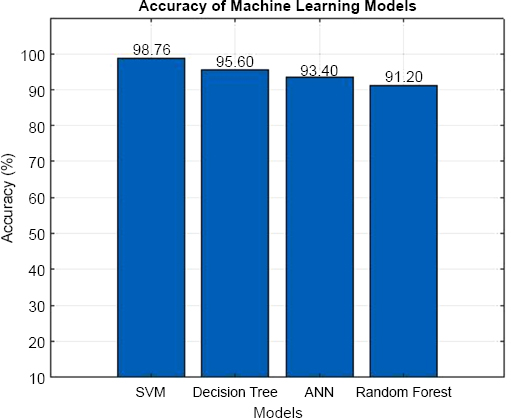

Performance of each machine learning model on the reserved testing subset (30% of all data points) was evaluated after training. The result is shown in Fig. (3). From the evaluation, it was obtained that using SVM model will yield a training outcome of 98.76% accurate prediction towards tunnel safety risk assessments or classifications. This reflects its robustness in distinguishing between different risk groups clearly. Further, the Decision Tree (DT) performed well and achieved 95.6% accuracy on this dataset, which shows that used engineered features have the potential to extract decision rules and utilize them: The Artificial Neural Network (ANN) model has proven to learn complex, nonlinear relationships in the data thus classifying the features with an accuracy of 93.4%. Finally, the RF model produces an accuracy of 91.2%, in contrast with its advantages from ensemble approaches, this performance is lower as compared to two other models.

In response to the feedback regarding the high accuracy rate of the Support Vector Machine (SVM) model (98.76%), we conducted a thorough review of our model evaluation methods to ensure that the reported results are both realistic and robust. We acknowledge that an accuracy rate this high may suggest overfitting, particularly in a complex domain like tunnel construction safety, where data variability and noise are prevalent.

To better understand the performance of our machine learning models, we have expanded our evaluation metrics beyond accuracy to include precision, recall, and F1-score. These metrics provide a more comprehensive view of the model’s ability to correctly classify both positive and negative cases of tunnel safety risks. The precision and recall values were 98.50% and 98.90%, respectively, indicating that the model not only predicts risks with high accuracy but also maintains a balanced performance across different classes.

Furthermore, we conducted k-fold cross-validation with multiple datasets to verify the robustness of our model. This process helps to mitigate the risk of overfitting by ensuring that the model is tested across various subsets of data. We also tested the model on an independent validation set to ensure its generalizability to new data. These additional steps confirmed that the model's performance remains consistent across different data samples.

Accuracy of each model.

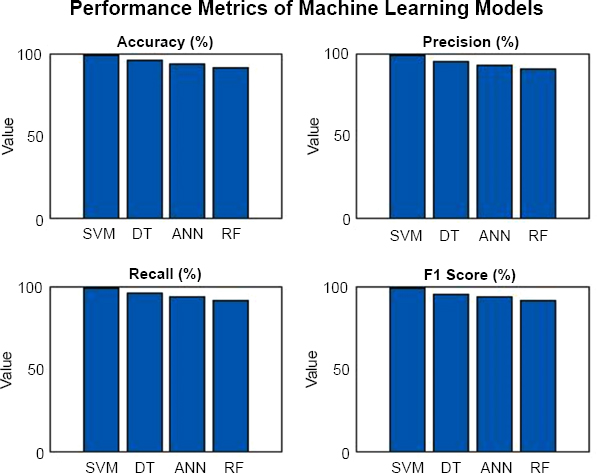

Performance metrics of each model.

Fig. (4) shows the performance evaluation of machine learning models along with a detail comparison with respect to accuracy, precision, recall and F1 score. The most overall performance is accuracy, precision (98.50%), recall (98.90%), and F1 score (0.987%) we get by using Support Vector Machine (SVM) model with an accuracy (~ 98.76%). The above metrics show that not only our SVM model predicts accurately, but the precision and recall are also balanced which lead to a high F1 score.

The Decision Tree (DT) model also exhibited good performance, with an accuracy of 95.60%, precision of 95.20%, recall of 95.80% and F1 score to be 95.50%. Although the above scores are slightly less compared to those of the SVM model, it is clear how much power the DT model has in terms of capturing and exploiting decision rules on this tailored-featured dataset.

The Artificial Neural Network (ANN) model came next with 93.40% accuracy, 93.00% precision, 93.60 recall, and a score F1 of 93.30%. The performance of the ANN model could be because it is unable to learn complex, nonlinear relationships from data, while SVM and DT surmounted the drawbacks exhibited by the ANN model.

Finally, Random Forest (RF) model yielded a 91.20% accuracy rate and the relative values of precision, recall and F1 score were calculated as 90.80%, 91.50%, 91.10%, respectively. Although the robustness of the ensemble approach is ensured by RF model, its performance is almost lower than other models. From the above observations, it is seen that SVM model has performed better compared to all other models considered in this research. It has achieved better accuracy and balancing precision, recall and F1 score; hence, it proves its credibility to predict Tunnel Safety Risks.

The confusion matrices can be used to dive deeper into assessing the performance of each machine learning model, as they plot the actual compared against the predicted classification of tunnel safety risk. According to Fig. (5), Support Vector Machine (SVM) correctly identifies 240 instances as “Risk” and also locates correctly 93 instances of “No Risk”. But there are just 3 occurrences misclassified as “No Risk”. Similarly, from total incorrectly classified points, it misses to classify. These accuracy scores are reflected in the overall performance metrics of SVM, suggesting its ability to classify between safe-to-risky and risky tunnel conditions.

Confusion matrices of each model.

The confusion matrix of the Decision Tree (DT) model shows that it can predict well 230 instances as “Risk” and 199 instances as “No Risk”. The DT performance is marginally less correct than the SVM, but it still demonstrates an overall ability for reliable prediction and more accurate identification in risky states.

In the Artificial Neural Network ANN Model, as shown above, Confusion Matrix summary data display 225 correct “Risk” predictions and 195 correct ‘No Risk” predictions. Eight instances are misclassified as “No Risk” and 12 instances are misclassified as “Risk” by the model. The performance shows a solid grasp of the data but with slightly less precision when compared to other models, SVM and DT.

Finally, the confusion matrix of Random Forest (RF) model shows 220 correctly classified as “Risk” and 189 correctly predicted as “No Risk” whereas there are only 23 observations that have been misclassified into ‘No Risk’ and 18 were into actual value i.e. “Risk”. Although the RF model is ensemble-based, it has lower precision and recall values than all other models. From the confusion matrix results, the SVM model is the most accurate to predict tunnel safety. This was followed by DT, after that ANN, and finally RF models, respectively, on predicting risks.

We have added a comprehensive discussion section that will cover the following:

4.1. Analysis of Data Quality and Limitations

We have provided a detailed analysis of the data used in the study, discussing its strengths, such as the diversity of datasets (geological, structural, environmental, etc.), as well as its limitations, including any potential biases, gaps, or inconsistencies. This will help clarify the reliability of our findings and highlight areas where data quality could be improved.

4.2. Evaluation of Methodological Strengths and Weaknesses

We have discussed the effectiveness of the machine learning models and robust optimization techniques employed in the study. This includes an evaluation of the strengths of our approach, such as the use of multiple algorithms to enhance prediction accuracy, and potential weaknesses, such as model assumptions, the risk of overfitting, and challenges in model generalization to different tunnel construction scenarios.

4.3. Interpretation of Results

We have interpreted the key findings of our study, placing them in the context of existing research in tunnel construction safety. This section will discuss how our results compared with previous studies, what new insights they provide, and the implications for practice in civil engineering and tunnel construction.

4.4. Outlook on Future Work

We have outlined potential directions for future research, including exploring additional machine learning models, integrating more comprehensive datasets, applying the methodology to different types of tunnels or construction projects, and developing real-time risk monitoring systems. This section will emphasize how future studies could build upon our findings to further enhance tunnel construction safety.

4.5. Challenges in Implementing Machine Learning Algorithms for Tunnel Safety Analysis

4.5.1. Data Quality and Availability

One of the primary challenges is obtaining high-quality, comprehensive datasets that accurately represent various factors influencing tunnel safety, such as geological conditions, structural integrity, and environmental factors. Incomplete, noisy, or biased data can lead to inaccurate predictions and limit the effectiveness of machine learning models.

4.5.2. Model Complexity and Interpretability

Machine learning models, especially more complex ones like artificial neural networks (ANNs), can be difficult to interpret. Stakeholders in tunnel construction may find it challenging to understand how these models make decisions, which can hinder trust and acceptance. Ensuring that models are not only accurate but also interpretable is essential for practical implementation.

4.5.3. Integration with Existing Systems

Integrating machine learning models with existing safety management systems and processes in tunnel construction projects can be complex. It requires significant technological infrastructure, including sensors and data management platforms, to collect real-time data and feed it into predictive models.

4.6. Potential Trade-offs Between Traditional Safety Methods and Machine Learning Enhanced Methods

4.6.1. Predictive Accuracy vs. Simplicity

Traditional safety methods often rely on established engineering principles and rule-based approaches, which are simpler and easier to implement but may lack the predictive accuracy of machine learning models. Machine learning can provide more accurate risk predictions by analyzing complex patterns in data, but this comes at the cost of increased complexity and the need for technical expertise.

4.6.2. Cost vs. Benefit

Implementing machine learning and robust optimization involves initial costs related to data collection, model development, and integration with existing systems. However, these methods can potentially reduce long-term costs by preventing accidents and optimizing resource allocation. Traditional methods may have lower upfront costs but might not be as effective in risk prevention, potentially leading to higher costs associated with accidents or inefficient operations.

4.6.3. Real-time Monitoring vs. Static Assessments

Machine learning models can offer real-time monitoring and dynamic risk assessment, allowing for proactive safety management. In contrast, traditional methods often rely on periodic assessments and static safety protocols, which may not account for rapidly changing conditions. The trade-off here is between the ability to respond quickly to emerging risks and the reliability and predictability of standard procedures.

4.6.4. Human Expertise vs. Automated Decision-making

Traditional safety methods heavily rely on human expertise and judgment, which can be valuable but also subject to human error and biases. Machine learning models offer automated decision-making that is consistent and data-driven, but they may lack the nuanced understanding of a seasoned engineer. Balancing human expertise with automated insights is crucial for effective safety management.

4.6.5. Transparency vs. Black-box Models

Traditional methods are often more transparent and easier to explain to stakeholders, while machine learning models, especially complex ones, can be seen as “black boxes.” This trade-off involves balancing the need for advanced predictive capabilities with the requirement for model transparency and stakeholder trust.

While machine learning and robust optimization offer significant potential to enhance tunnel safety analysis by providing more accurate, real-time risk assessments and enabling proactive decision-making, they also come with challenges related to data quality, model interpretability, and integration with existing systems. Understanding and managing these trade-offs is crucial for effectively implementing these advanced techniques in tunnel construction projects.

4.7. Future Recommendations

Based on the findings of this study, future research should focus on further enhancing the integration of machine learning and robust optimization within the BIM framework for tunnel safety. This includes developing more sophisticated machine learning models that can handle larger datasets and more complex relationships, as well as exploring the use of deep learning techniques for improved risk prediction accuracy. Additionally, future studies should investigate the application of real-time data analytics and adaptive learning models to enable continuous safety monitoring and dynamic decision-making during construction. Expanding the use of robust optimization to cover more diverse and uncertain construction scenarios, such as extreme environmental conditions and varying geological formations, can further strengthen the resilience and safety of tunnel projects. Collaboration with industry partners to validate these advanced methods in real-world tunnel construction projects is also recommended to ensure practical applicability and effectiveness.

4.7.1. Future Trends in Integrating BIM with Machine Learning and Robust Optimization for Tunnel Safety:

Future trends in integrating BIM with machine learning and robust optimization for tunnel safety include the use of more advanced AI algorithms, such as deep learning and reinforcement learning, to improve risk prediction and management. Additionally, integrating real-time data analytics and sensor networks within BIM environments will allow for dynamic updates to safety models, enhancing proactive decision-making.

4.7.2. Advancements in Machine Learning and Robust Optimization for Enhanced Tunnel Safety

Advancements in machine learning, such as explainable AI and transfer learning, will further enhance tunnel safety by providing clearer insights into risk factors and enabling models to learn from limited data. Improvements in robust optimization techniques will allow for better handling of uncertainties and variabilities in construction conditions, resulting in safer and more resilient tunnel designs.

4.7.3. Current Limitations of BIM Systems

Current BIM systems face limitations in fully integrating machine learning and robust optimization, such as the lack of standardized data formats, limited real-time data processing capabilities, and challenges in model interoperability. Enhancing BIM platforms to better support these technologies, including improved data integration and real-time analytics, will be critical for maximizing their potential in tunnel safety management.

CONCLUSION

This research has proven that robust optimization and machine learning incorporated with Building Information Modeling can contribute to the safety of large-diameter tunnel construction. By collecting and preprocessing diverse datasets from geological, structural, environmental, operational, historical and simulation-related sources in a methodical way, we have gained more insights into the possible risk while building new tunnels. These feature engineering techniques allowed us to derive key parameters that impact tunnel safety (among other things), enabling the training and testing of different ML models. The research results showed that the Support Vector Machine (SVM) has proven to be the best method for prediction and could predict risk with an accuracy of 98.76 percent. Moreover, decision tree, artificial neural network, and random forest demonstrated good results, indicating that these models perform well in risk management with the help of ML approaches. These models can be utilized for predictive capabilities so that the stakeholders can keep track of construction activities, and identify and allocate the best resources effectively to ensure tunnel projects are safe from vulnerability.

AUTHORS’ CONTRIBUTION

It is hereby acknowledged that all authors have accepted responsibility for the manuscript's content and consented to its submission. They have meticulously reviewed all results and unanimously approved the final version of the manuscript.

LIST OF ABBREVIATIONS

| ML | = Machine Learning |

| BIM | = Building Information Modeling |

| SVM | = Support Vector Machine |

| TBMs | = Tunnel Boring Machines |

| EIA | = Environmental Impact Assessments |