All published articles of this journal are available on ScienceDirect.

Experimental Investigation on the Static and Impact Behaviors of Basalt Fiber-Reinforced Concrete

Abstract

Experimental studies on basalt fiber have been performed in China and abroad. Specifically, the compressive properties, flexural properties, splitting tensile properties and impact test behavior of chopped basalt fiber-reinforced concrete have been investigated. In addition, the effects of the mixing amount of fibers on the mechanical properties of C30 concrete were scrutinized, and the best mixing amount of fibers was obtained. The results indicate that the static and impact test behaviors of basalt fiber reinforced concrete significantly improved, and strengthening and toughening effects were achieved.

1. INTRODUCTION

As a nonlinear quasi-brittle material [1], the largest drawback of concrete is its low tensile strength, which causes it to easily crack. However, the application of fiber-reinforced technology is an effective method for improving the strength and brittleness. Basalt fiber is a new fiber material that is composed of natural volcanic rock ore subjected to high-temperature melting and wire drawing. It is a typical silicate fiber with natural consistency and superior mechanical properties [2-4]. In addition, basalt fiber is both environmentally protective and inexpensive; thus, its application in concrete has become an active research topic both at home and abroad. J. Lian [5] investigated the influence of basalt fiber volume content and the monofilament length-diameter ratio on the compressive strength, splitting tensile strength, flexural strength and fracture resistance of basalt fiber reinforced concrete and demonstrated that the strength and fracture resistance of concrete significantly improved after the addition of random chopped basalt fiber. Z.C. Deng [6] examined the influence of basalt fiber on the flexural impact behavior of concrete and suggested that basalt fibers can substantially improve the flexural impact behavior of concrete. D. P. Dias [7] and K. Zieliński [8] explored the influence of basalt fiber content on the fracture ductility and strength of basalt fiber-reinforced inorganic polymer cement concrete and compared the results with the results of basalt fiber-reinforced concrete. They concluded that basalt fiber-reinforced inorganic polymer cement concrete has a superior fracture resistance. C.H. Jiang [9] investigated the influence of the volume fraction and length of basalt fiber on the mechanical properties of basalt fiber-reinforced concrete. Compared with ordinary concrete, the compressive, splitting tensile and flexural strength of concrete that has been reinforced with 12 mm basalt fiber increased by 0.18~4.68%, 14.08~24.34% and 6.30~9.58%, respectively. As the basalt fiber length increased to 22 mm, the corresponding strengths separately increased by 0.55~5.72%, 14.96~25.51% and 7.35~10.37%. Z.B. Kan [10] analyzed the current research situation of basalt fiber-reinforced concrete based on previous research results. When concrete is incorporated with basalt fiber, the compressive performance of concrete is instable and the tensile strength changes with the fiber content; however, the durability, bending performance and impact resistance exhibits distinct improvement. Z.C. Girgin and M.T. Yıldırım [11] focused on basalt fiber as an alternative material to glass fiber in fiber-reinforced cement composites. They investigated the variations of the flexural efficiency in plate specimens with basalt fiber at 1, 7, 28-day curing periods and afterwards in harsh environmental conditions. J. Branston [12] evaluated the relative merit of two types of basalt fiber (bundle dispersion fibers and minibars) for enhancing the mechanical behavior of concrete based on flexural and drop-weight impact testing. W.M. Li and J.Y. Xu [13] investigated the impact mechanical properties of basalt fiber-reinforced geopolymeric concrete (BFRGC) of three different matrix strengths using a 100-mm-diameter split Hopkinson pressure bar (SHPB) and investigated the strain rate effect on the dynamic compressive strength, critical strain and specific energy absorption.

The objective of this study was to investigate the compressive, flexural, splitting tensile strength and impact ductility of chopped basalt fiber reinforced concrete. The influence of the addition of basalt fiber on the performance of concrete and the optimum content of basalt fiber are also studied and discussed.

2. MATERIAL AND METHODOLOGY

2.1. Materials of Test

P. O42.5-rated ordinary Portland cement of “Hailuo”, which is an Anhui brand, is employed. The chemical components of the cement are listed in Table 1; for fine aggregate, medium sand with a 2.7 fineness modulus is adopted; coarse aggregate is continuously graded gravel with a particle size that ranges from 5 ~ 10 mm; the indexes of chopped basalt fiber’s main physical and mechanical properties are listed in Table 2. Concrete with the strength grade C30 is employed as the design basis of the experiment, and the adopted mix proportions are listed in Table 3.

| Components | SiO2 (%) | Al2O3 (%) | Fe2O3 (%) | CaO (%) | MgO (%) | SO3 (%) | Na2O (%) | LOI (%) |

|---|---|---|---|---|---|---|---|---|

| Cement | 22.45 | 5.82 | 3.78 | 61.58 | 2.23 | 1.82 | 1.21 | 1.11 |

| Filament diameter/μm | Length/mm | Density/kg·m-3 | Tensile modulus/GPa | Tensile strength/MPa | Elongation at break/% |

|---|---|---|---|---|---|

| 15 | 12 | 2650 | 93~110 | 3800~4800 | 3.2 |

| Cement | Sand | Crushed limestone | Water |

|---|---|---|---|

| 445 | 605 | 1155 | 210 |

2.2. Test Method

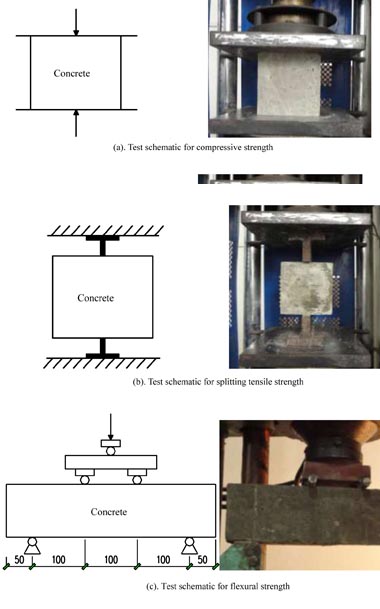

Compressive tests, splitting tensile tests and flexural tests were performed using the Standard of Ordinary Concrete Mechanical Performance Test Method (GB/T50081-2002), as shown in Fig. (1). The basalt fiber dosages in this test are 0, 0.5, 1, 1.5, 2, 2.5 kg/m3, and the corresponding test specimens are labeled H0, H1, H2, H3, H4, and H5, respectively. Cube samples with a side length of 150 mm, with three samples per group, are employed as test specimens in the compressive test and splitting tensile test. The dimensions of the test specimens in the flexural test are 100 mm×100 mm×400 mm; three test specimens are utilized per group. All specimens are released from a casting mold after 24 hours and maintained in a standard curing room for 28 days. Afterward, they are taken from the curing room to dry for three hours prior to the tests.

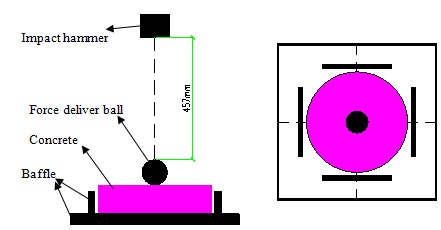

Following the impact test method proposed by the ACI Committee 544 [14], the impact toughness test employs a home-made device of the drop-weight impact test type, as shown in Fig. (2). The test specimens, which are divided six per group, take the shape of a round cake with a diameter of 152 mm and a thickness of 63.5±3 mm. The baffles of the chassis are placed inside a test specimen, and the molding surface is positioned face-up. Then, a steel ball with a diameter of 63.5 mm is placed in the center of each test specimen’s surface, fixed by a hoop frame. After adjusting and fixing the locating frame of the impact hammer to 457 mm, a steel hammer of 4.5 kg freely falls from a height of 457 mm to impact the steel ball, which is employed for power transmission. Each impact is counted as a cycle. When the first visible crack appears on the surface of the test specimen, we record the initial-crack impact cycle number. The impact was performed until the test specimen touches any three of the four baffles, after which it was regarded as a fracture. Then, the fracture impact cycle number was recorded.

The impact resistance of the fiber concrete is represented by the impact energy W and the ductility index λ, which are calculated according to the formula (1) and formula (2), respectively:

|

(1) |

|

(2) |

Nc denotes the initial-crack impact cycle number of a test specimen; Nf denotes the fracture impact cycle number; m represents the impact hammer’s weight; h represents the impact hammer’s impact height; and g denotes the acceleration of gravity, which is 9.8 m/s2.

λ is the ratio of the impact energy absorbed by the fiber concrete from crack to damage to the impact energy absorbed by the early crack of the fiber concrete, which directly reflects the toughness of the fiber-reinforced concrete test specimens after cracking.

3. RESULTS AND ANALYSIS

3.1. Analysis of Basalt Fiber-Reinforced Concrete Static Mechanical Performance Test

Based on the experimental design, the compressive, flexural and splitting tensile strengths of basalt fiber reinforced concrete are separately measured with different fiber dosages of 0, 0.5, 1.0, 1.5, 2.0, 2.5 kg/m3, as shown in Table 4.

| NO. | Basalt fiber dosage (kg/m3) |

Compressive strength ffc,cu /MPa |

Relative increase /% |

Flexural strength ffc,m /MPa |

Relative increase /% |

Splitting tensile strength ffc,spl /MPa |

Relative increase /% |

|---|---|---|---|---|---|---|---|

| H0 | 0 | 42.3 | 0 | 4.3 | 0 | 3.2 | 0 |

| H1 | 0.5 | 43.4 | 2.6 | 4.6 | 7.0 | 3.4 | 6.3 |

| H2 | 1 | 45.2 | 6.9 | 5.3 | 23.3 | 3.8 | 18.8 |

| H3 | 1.5 | 46.5 | 9.9 | 5.8 | 34.9 | 4.1 | 28.1 |

| H4 | 2 | 46.2 | 9.2 | 6.2 | 44.2 | 4.4 | 37.5 |

| H5 | 2.5 | 45.7 | 8.0 | 6.0 | 39.5 | 4.2 | 31.3 |

As shown in Table 4 and Fig. (3), the compressive strength, flexural strength and splitting tensile strengths of concrete follow an “increase first and then decline” rule as the dosage of basalt fiber increases. In addition, the increase in flexural strength and splitting tensile strength exceeds the increase in compressive strength. When the fiber dosage is 1.5 kg/m3, the compressive strength exhibits a peak value of 46.5 MPa, which is an increase of 9.9% relative to ordinary concrete. When the fiber dosage is 2.0 kg/m3, the flexural strength and splitting tensile strength exhibit peak values of 6.2 MPa and 4.4 MPa, respectively, which increase by 44.2% and 37.5%, respectively, relative to the plain concrete. Therefore, when the basalt fiber dosage ranges from 1.5 ~ 2 kg/m3, it has a significant influence on the basic mechanical strength improvement of concrete with a strength grade of C30.

The influence of basalt fiber dosage on the compressive strength, flexural strength and splitting tensile strength of concrete does not monotonically increase with an increase in dosage. When an appropriate interval for the fiber dosage is attained, its extra mixture will destroy the best inner structure that has already formed in concrete. When the total surface area of the fiber increases, it cannot be wrapped by a sufficient amount of slurry; as a result, the concrete compactness decreases as the internal defects increase. In this manner, micro cracks and pores are likely to appear [15], especially when the amount of basalt fiber dosage is large. When a certain proportion of the fiber dosage fraction is attained, the change in the fiber content is not the main factor of the strength of concrete, and the strength of its matrix gradually becomes the main factor that influences the strength of concrete. This situation causes a slight loss of concrete strength.

3.2. Analysis of Basalt Fiber-Reinforced Concrete Impact Toughness Test

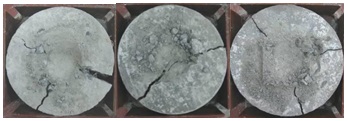

Due to the bridging effect in the crack between the fibers, which begins after the cracks formed, the crack extension in the basalt fiber-reinforced concrete is delayed. The basalt fiber, which is removed to consume a certain amount of energy, causes some changes in the form of destruction, compared with the ordinary concrete test blocks. The basalt fiber-reinforced concrete failure pattern is damaged without fragments after cleft. It maintains the integrity of the original concrete, only appears many cracks and molting. Therefore, the mixed fiber changes the concrete brittle failure to a ductile failure pattern. The ordinary concrete failure pattern is shown in Fig. (4), and the basalt-fiber reinforced concrete failure pattern is shown in Fig. (5).

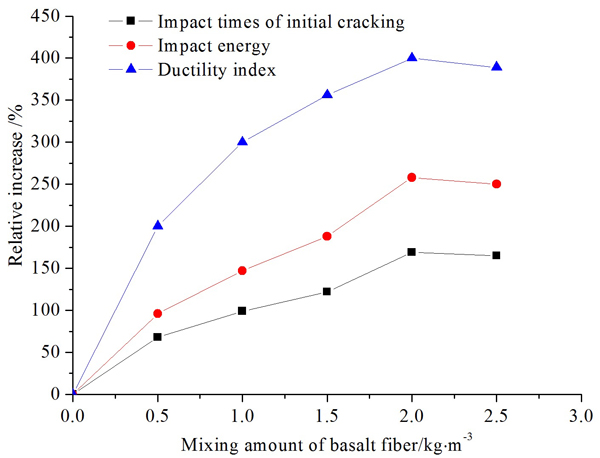

The results of the impact behavior test on basalt fiber-reinforced concrete are shown in Table 5 and Fig. (6).

| NO. | Basalt fiber dosage (kg/m3) |

Initial-crack impact cycle number Nc |

Relative increase /% |

Fracture impact cycle number Nf |

Impact energy W /N·m |

Relative increase /% |

Ductility Index λ |

Relative increase /% |

|---|---|---|---|---|---|---|---|---|

| H0 | 0 | 68 | 0 | 74 | 1491 | 0 | 0.09 | 0 |

| H1 | 0.5 | 114 | 68 | 145 | 2922 | 96 | 0.27 | 200 |

| H2 | 1 | 135 | 99 | 183 | 3688 | 147 | 0.36 | 300 |

| H3 | 1.5 | 151 | 122 | 213 | 4293 | 188 | 0.41 | 356 |

| H4 | 2 | 183 | 169 | 265 | 5341 | 258 | 0.45 | 400 |

| H5 | 2.5 | 180 | 165 | 259 | 5220 | 250 | 0.44 | 389 |

The test results indicate that the mixture of basalt fiber significantly improves the shock resistance of the concrete. Due to the brittleness of ordinary concrete, a fissure quickly runs through the cross-section after its initial crack. Thus, the initial-crack impact cycle number does not substantially differ from the fracture impact cycle number.

As shown in Table 5 and Fig. (6), the initial-crack impact cycle number of the basalt fiber reinforced concrete increases by 60% ~ 170%, and the impact energy increases by 90% ~ 260%.

As a reflection of the energy consumption and deformation capacity of concrete when its matrix cracks, the ductility index is critical to the security of concrete structures. As shown in Table 5 the ductility index λ of basalt fiber reinforced concrete increases by a factor of 2 ~ 4.

Regardless of the initial crack cycle number, impact energy or ductility index, if a certain degree of the dosage of basalt fiber is attained, a declining trend was observed in the experiment. Therefore, an optimal range of fiber content is determined.

Under impact loads, a crack in ordinary concrete indicates damage; however, the basalt fiber-reinforced concrete is “slightly cracked but not damaged”, which exhibits an acceptable degree of toughness. Damage to concrete is a process in which cracks gradually extend and expand. After the addition of fiber, which is fine and larger than the surface area, the fiber number per unit volume in concrete is large, and a homogeneous network system with a three-dimensional disordered distribution of fiber is established. The absorption of kinetic energy when concrete is being impacted enables this system to reduce the stress concentration of the crack tip inside the concrete, which effectively hinders the rapid development of the crack in the concrete and effectively prevents damage to the concrete. Therefore, under impact load, the most significant contribution of basalt fiber to the concrete matrix is an improvement in toughness under impact loads.

CONCLUSION

In this paper, the mechanical properties of concrete that is reinforced by chopped basalt fiber were investigated and a comparative analysis of the study results was performed. The following conclusions are formed:

- The addition of basalt fiber can effectively increase the compressive strength, splitting the tensile and flexural strength (especially splitting tensile and flexural strength) of the concrete; values of 9.9%, 37.5% and 44.2% are attained;

- After mixing concrete with basalt fiber, the initial crack impact cycle number of the concrete improves by 60% ~ 170%, the impact energy improves by 90% ~ 260%, and the ductility index increases by a minimum of two times, compared with ordinary concrete. Thus, we can deduce that adding basalt fibers to ordinary concrete can significantly improve the impact resistance and toughness of concrete, which affects its strengthening and toughening; and

- The fiber content has a significant impact on the mechanical behavior of concrete. According to the experimental results of this paper, the optimal basalt fiber content of C30 concrete ranges from 1.5 ~ 2 kg/m3. If the basalt fiber content exceeds this range, a declining trend is observed for the concrete strength and impact properties.

CONFLICT OF INTEREST

The author confirms that this article content has no conflict of interest.

ACKNOWLEDGEMENTS

The authors acknowledge the financial support by the Natural Science Project of Colleges and Universities in the Anhui province of China (KJHS2016B11), the Science and Technology Planning Project of Department of Housing and Urban-rural development of the Anhui province of China (2017YF-12) and the Science and Technology Planning Project of Huangshan city of the Anhui province of China (2015Z-03).