All published articles of this journal are available on ScienceDirect.

Producing Sustainable Concrete using Nano Recycled Glass

Abstract

Background:

Many tools and techniques have been recently adopted to develop construction materials that are less harmful and friendlier to the environment. New products can be achieved through the recycling of waste material. Thus, this study aims to use recycled glass bottles as sustainable materials.

Objective:

Our challenge is to use nano glass powder by the addition or replacement of the weight of the cement for producing concrete with enhanced strength.

Methods:

A nano recycled glass powder is prepared by crushing and storming a glass bottle to obtain a Blaine surface area of approximately 28 m2/g and conforming to the chemical requirements for natural pozzolana class N, according to ASTM C618. The outcome of using nano recycled glass for theaddition and replacement of ordinary Portland cement weight on the compressive and flexural strengths of concrete at 7, 28, and 90 days is investigated.

Results:

The concrete mixes with 2.5%, 5%, 7.5%, and 10% replacements of cement by nano recycled glass powder show improvements in compressive and flexural strengths of up to 12.77% and 7.66%, respectively, at 28 days. Meanwhile, mixes with the addition of 5% nano glass powder show best improvements in compressive and flexural strengths of up to 11.49% and 7.46%, respectively.

1. INTRODUCTION

The emission of carbon dioxide and the reduction in raw materials is important in the production of cement. Thus, the use of recycled material as a replacement for cement can be a good solution to eliminate pollution and a good way to dispose wastes [1-4]. Shruthi et al. found that the addition of 15% glass powder with a size less than 90 μm, which acts as a filler and pozzolanic material, enhances strength [3]. Islam et al. studied the 0% - 25% replacements of cement while the cement + glass ratio is kept constant for all replacement levels. The optimum glass content is 20% for concrete mix with a slight increase in compressive strength of up to 2% at 90 days compared with the control concrete specimen [4]. Mohammad et al. investigated the replacements of cement by glass powder with 5%, 10%, 15%, 20%, 25%, and 30% in the concrete mix. They found that 20% replacement of cement by glass powder shows higher compressive and flexural strengths of up to 18% and 27%, respectively, compared with the reference mix at 28 days. They also found that waste glass powder of less than 75 μm exhibits higher strength than the counterpart of 90 - 150 μm [5]. Al-Zubaidi et al. used different waste glasses (neon, brown, and green glasses) as a replacement of cement weight with 11%, 13%, and 15% for each type of glass. They found that the compressive and flexural strengths have maximum results at 13% replacement of weight of cement by neon glass [6]. The addition or replacement of nano-silica by the weight of cement is a new technology in concrete construction [7-9]. The results of nanomaterial addition to concrete show improvements in mechanical and transport properties, especially for the blend of silica nanoparticles and silica fume [10, 11]. The mechanism of the reaction between the Portland cement and nano-silica is the same as a pozzolanic reaction but with a higher rate. The high fineness with high silica content accelerates hydration between calcium hydroxides; the reason is that silicate hydration of cement with nano-silica forms an additional cementitious gel, which results in the densification of microstructure in cement mortar and concrete [12-17]. The use of a combination of colloidal silica and superplasticizer has the same effectiveness as the use of nano-silica (7% as substitution of additives) in enhancing compressive strength in self-consolidation concrete [18]; the high amount of C–S–H formation in normal and self-consolidation concretes introduces more mechanical and durability requirements [18]. The substitution of around 5% glass powder (specific surface area of 800 m2/kg) for cement leads to the best results of compressive strength [12]. The current study focuses on the combination of using recycled glass waste as sustainable material (natural pozzolana) [19-22] after converting it to nano size distribution for activating its effect on the strength properties with minimum cost.

2. MATERIALS AND METHODS

2.1. Materials

The Ordinary Portland Cement (OPC-Type I) known as (Al Mass) was used in this study. The properties of the cement are presented in Table 1. The properties of the fine aggregate (river sand) with fineness modulus = 2.9 and the crushed coarse aggregate (gravel) of 19 mm nominal maximum size are presented in Tables 2 and 3, respectively. The tests were conducted in the Construction Material Lab in the Civil Engineering Department of the University of Baghdad. The raw material of the west glass bottle was transformed to nanopowder by the process presented in Fig. (1). The properties are presented in Table 4.

| Tests | Results | Limits | ||

| ASTM.C150 [23] | IQS. NO.5 [24] | |||

| Chemical Analysis | CaO, % | 61.5 | — | — |

| SiO2, % | 20.5 | — | — | |

| A2O3, % | 4.40 | — | — | |

| Fe2O3, % | 4.20 | — | — | |

| SO3, % | 2.22 | Max. 2.8 if C3A ≥ 8% | Max. 2.8 if C3A ≥ 5% | |

| MgO, % | 2.60 | Max. 6.0 | Max. 5.0 | |

| L.O.I., % | 2.80 | Max. 3.0 | Max. 4.0 | |

| I.R., % | 0.50 | Max. 0.75 | Max. 1.5 | |

| Blaine Surface Area (m2/kg) | 340 | Min. 280 | Min. 230 | |

| Soundness (Autoclave) % | 0.3 | Max. 0.8 | Max. 0.8 | |

| Vicat’s Setting |

Initial set (min) Final set (min) |

75 425 |

Min. 45 Max. 375 |

Min. 45 Max. 600 |

| Compressive Strength (MPa) | 3 days 7 days |

17.2 25.6 |

Min. 12 Min. 19 |

Min. 15 Min. 23 |

| Tests | Passing (%) | IQS NO.45 (Zone 2) [25] | ASTM Specification C33 [26] | |

| Sieve Size (mm) | 10.0 | 100 | 100 | 100 |

| 4.75 | 96 | 90 – 100 | 95 – 100 | |

| 2.36 | 80 | 75 – 100 | 80 – 100 | |

| 1.18 | 62 | 55 – 90 | 50 – 85 | |

| 0.60 | 42 | 35 – 59 | 25 – 60 | |

| 0.30 | 21 | 8 – 30 | 5 – 30 | |

| 0.15 | 2 | 0 – 10 | 0 – 10 | |

| Material finer than 75 µm | 2.5 | Max. 5 | Max. 5 | |

| Sulfate-SO3 (%) | 0.22 | Max. 0.5 | — | |

| Absorption (%) | 1.02 | — | — | |

Table 3.

| Tests | Passing (%) |

IQS NO.45 (20–5) mm [25] |

ASTM Specification C33 [26] | |

| Sieve Size (mm) | 37.5 | 100 | 100 | 100 |

| 19 | 96 | 95 – 100 | 90 – 100 | |

| 9.5 | 38 | 30 – 60 | 20 – 55 | |

| 5 | 4 | 0–10 | 0 – 10 | |

| Material finer than 75 µm (%) | 1.05 | Max. 3 | Max. 1 | |

| Sulfate-SO3 (%) | 0.03 | Max. 0.1 | — | |

| Absorption (%) | 0.85 | — | — | |

| Tests | Nano glass powder | ASTM C618 N[27] | |

| Chemical Analysis % |

SiO2 | 72.8 | Min. 70% of (SiO2 + Al2O3 + Fe2O3) |

| A2O3 | 4.5 | ||

| Fe2O3 | 1.22 | ||

| CaO | 10 | — | |

| MgO | 4.37 | — | |

| SO3 | 0.34 | Max. 4% | |

| L.O.I. | 3.8 | Max. 10% | |

| Strength activity index (%)ASTM C311 [28] | 85 | Min. 75% | |

| Specific gravity | 2.23 | — | |

| Fineness: amount retained when wet sieving at 45 µm (%) | 0 | Max. 34 | |

2.2. Concrete Mixes and Tests

The reference concrete mix was designed to provide a compressive strength of 35 MPa for samples in the cylinder at 28 days, according to the ACI 211.1 [29]. The mixed content was in a ratio of (380:685:1010:205) kg/m3 of cement, river sand, crushed gravel, and water for reference concrete mix (Mrf.). Eight other mixes were prepared by the replacement (4 mixes) and addition (4 mixes) of cement by nano glass powder with 2.5%, 5%, 7.5%, and 10%. Table 5 presents the mix proportion with slump test results according to ASTM C143 [30]. The mixing process of the concrete mix was achieved according to ASTM C192 [31]. The compressive strength test was made according to ASTM C39/C39 M [32] using (150 × 300) mm cylinder. The flexural strength test was performed according to ASTM C78 [33] and the prisms of 100 mm × 100 mm × 300 mm were used.

3. RESULTS AND DISCUSSION

3.1. Compressive Strength

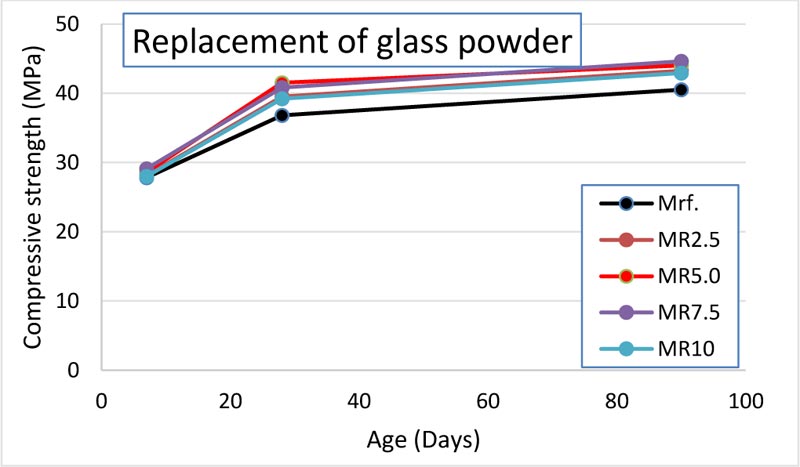

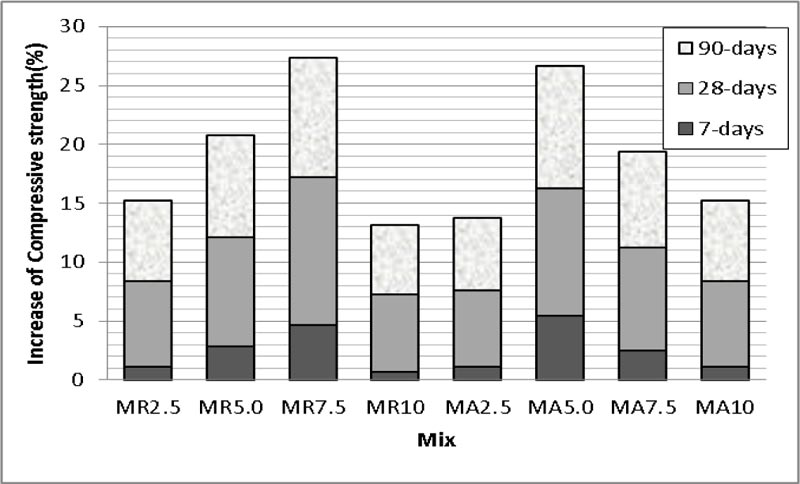

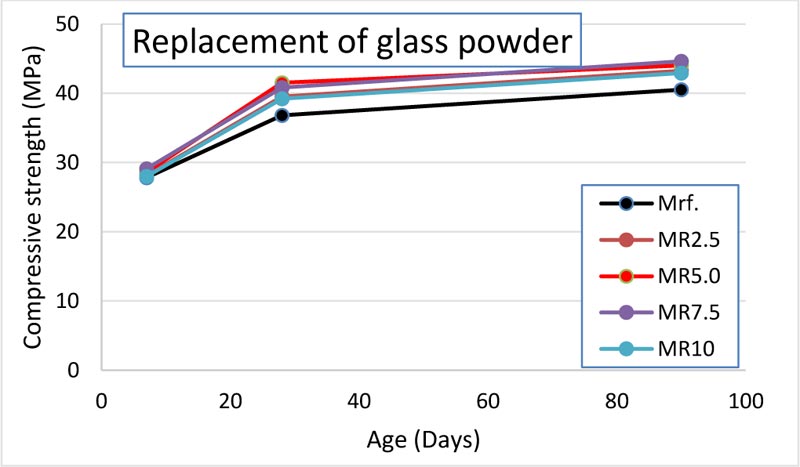

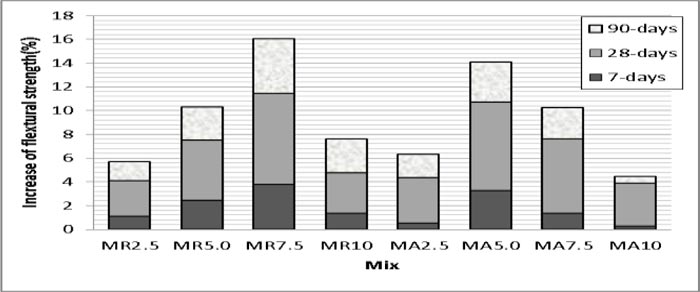

The compressive strength lab results are presented in Table 6. Fig. (2) shows the effect of nano glass powder replacement of cement at 7, 28, and 90 days. A slight enhancement is observed at 7 days. This result may be attributed to the nature of glass powder reaction, which is slower than those of other pozzolana types [34-36]. Better results are observed at 28 and 90 days. The cumulative percentage increase is shown in Fig. (3) As observed, the compressive strength increases with the rise in the percentage replacement of cements for all ages. The 7.5% replacement shows best compressive strengths of up to 4.68%, 12.5%, and 10.12% at 7, 28, and 90 days, respectively. The results show that it is a good way for the liquidation of west material and recycling in concrete construction. The replacement of nano glass powder is more significant than the addition. The reason is that the former gives better results and is a good way to reduce the consumption of cement, which decreases the effect of its manufacture on pollution. Fig. (4) presents the additions of nano glass powder with 2.5%, 5%, 7.5%, and 10%. The compressive strength results show an improvement with more water demand solved by increasing water range; this reduces admixture to maintain slump requirements of design that is due to high fineness and particle behavior [37-39]. The 5% addition of nano glass powder shows optimum improvements in compressive strength of up to 5.4%, 10.86%, and 10.37% at 7, 28, and 90 days, respectively, as presented in the cumulative percentage increase in Fig. (3). The improvement in compressive strength of replacement and addition of recycled nano glass powder is attributed to high fineness. Thus, better filling between cement paste and aggregate and better pozzolanic silica reaction (SiO2 = 72.8% from glass powder and Ca (OH)2 from hydrated cement) are necessary to produce extra gel filling pores with better microstructure of concrete [12-17].

3.2. Flexural Strength

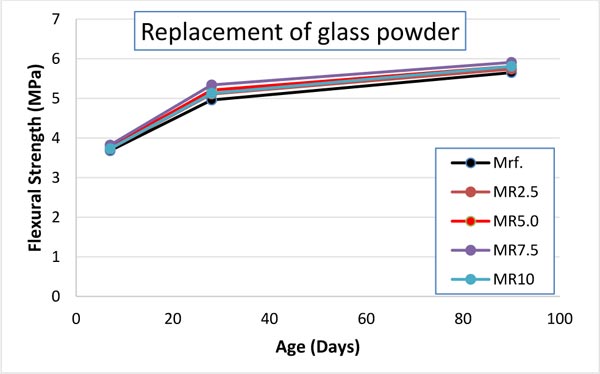

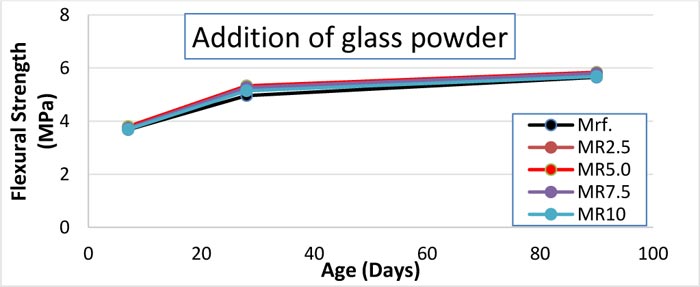

The flexural strength results are compatible with the compressive strength results, as presented in Table 6. Fig. (5 and 6) show the improvement in the results for replacement and addition, respectively. Cumulative increases for replacement and addition of nano glass powder are presented in Fig. (7) The figure shows that the best replacement results are obtained for 7.5% replacement and 5% addition of mixes. Therefore, the replacements are a good way to improve concrete quality with less cement content [40]. The acceptable strength activity index equal to 85%, according to ASTM 618 [27], with high fineness is the main contributor to the improvement in strength in the concrete mix with workability adjusted by superplasticizer [2]. Compressive and flexural strengths presented in Fig. (8) have a good correlation with a high R2 of 0.988.

Table 5.

| Mix ID | Cement (kg/m3) | Glass powder (kg/m3) | SP L/100 kg of cement | Slump (mm) |

| Mrf. | 380 | — | 0.5 | 86 |

| MR 2.5 | 370.5 | 9.5 | 0.5 | 84 |

| MR 5.0 | 361 | 19 | 0.6 | 88 |

| MR 7.5 | 351.5 | 28.5 | 0.65 | 87 |

| MR 10 | 342 | 38 | 0.7 | 90 |

| MA2.5 | 380 | 9.5 | 0.55 | 85 |

| MA5.0 | 380 | 19 | 0.7 | 87 |

| MA7.5 | 380 | 28.5 | 0.85 | 86 |

| MA10 | 380 | 38 | 0.9 | 88 |

| Mix ID | Compressive Strength (N/mm2) | Flexural Strength (N/mm2) | ||||

| 7 days | 28 days | 90 days | 7 days | 28 days | 90 days | |

| Mrf. | 27.8 | 36.8 | 40.5 | 3.68 | 4.96 | 5.65 |

| MR 2.5 | 28.1 | 39.5 | 43.25 | 3.72 | 5.11 | 5.74 |

| MR 5.0 | 28.6 | 41.5 | 44.0 | 3.77 | 5.21 | 5.81 |

| MR 7.5 | 29.1 | 40.8 | 44.6 | 3.82 | 5.34 | 5.91 |

| MR 10 | 28.0 | 39.2 | 42.9 | 3.73 | 5.13 | 5.81 |

| MA 2.5 | 28.1 | 39.2 | 43.0 | 3.70 | 5.15 | 5.76 |

| MA 5.0 | 29.3 | 40.8 | 44.7 | 3.80 | 5.33 | 5.84 |

| MA 7.5 | 28.5 | 40.0 | 43.8 | 3.73 | 5.27 | 5.80 |

| MA 10 | 28.1 | 39.5 | 43.25 | 3.69 | 5.14 | 5.68 |

CONCLUSION

- Sustainable concrete can be produced using nano glass powder as recycled replacements of cement weight of up to 2.5%, 5%, 7.5%, and 10%, with good workability and better strength.

- The additions of nano glass powder to concrete mix with 2.5%, 5%, 7.5%, and 10% as a percentage of cement weight show improvements in compressive and flexural strengths with more demand of water.

- The concrete mix with 7.5% replacement of cement by nano recycled glass powder shows improvements in compressive and flexural strengths of up to 12.77% and 7.66%, respectively, at 28 days.

- The concrete mix containing the 5% addition by weight of cement of nano recycled glass powder shows improvements in compressive and flexural strengths of up to 11.49% and 7.46%, respectively, at 28 days.

- The mixes with replacement of cement exhibit significant improvements in compressive and flexural strengths with less consumption of cement and environmental pollution.

CONSENT FOR PUBLICATION

Not applicable.

AVAILABILITY OF DATA AND MATERIALS

Not applicable.

FUNDING

None.

CONFLICT OF INTEREST

The authors declare no conflict of interest, financial or otherwise.

ACKNOWLEDGEMENTS

Declared none.