RESEARCH ARTICLE

Performance Improvement of Hot Mix Asphalt and Warm Mix Asphalt using RAP and Evotherm Additive

Ivan Imanuel1, *, Bambang Sugeng Subagio1

Article Information

Identifiers and Pagination:

Year: 2023Volume: 17

E-location ID: e187414952304120

Publisher ID: e187414952304120

DOI: 10.2174/18741495-v17-e230420-2022-79

Article History:

Received Date: 5/12/2022Revision Received Date: 13/03/2023

Acceptance Date: 27/03/2023

Electronic publication date: 06/06/2023

Collection year: 2023

open-access license: This is an open access article distributed under the terms of the Creative Commons Attribution 4.0 International Public License (CC-BY 4.0), a copy of which is available at: https://creativecommons.org/licenses/by/4.0/legalcode. This license permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Abstract

Background:

The application of warm mix asphalt (WMA) technology has challenges related to permanent deformation, while the use of reclaimed asphalt pavement (RAP) tends to shorten the fatigue life of the pavement. RAP is known to improve the mixture’s resistance to permanent deformation, thus the combination of RAP and WMA is mutually beneficial.

Aim:

The main purpose of this research is to measure the stiffness, permanent deformation, and fatigue performance of WMA which was added with RAP and Evotherm.

Methods:

The research conducted laboratory experiments of asphalt mixtures using various contents of reclaimed asphalt, Evotherm additive, and mixing temperatures. The tests include penetration and viscosity tests of asphalt binder, along with mechanical properties of asphalt mixture, such as resilient modulus, fatigue life at 20°C, and permanent deformation test at 60°C.

Results:

The results of the resilient modulus test with UMATTA at three temperatures show an increase in WMA stiffness with the addition of RAP. The results of the permanent deformation test using the Hamburg Wheel Tracking Device show that RAP added with Evotherm improved the resistance of WMA to permanent deformation.

Conclusion:

The results of the fatigue test using Beam Fatigue Apparatus show that WMA added with 30% RAP had the longest fatigue life. The main finding in this research is that the WMA-RAP mixture has good performance related to stiffness, permanent deformation, and fatigue. This research also concludes that Evotherm can be used as a rejuvenating agent with 30% RAP used in WMA.

1. INTRODUCTION

The use of environmental-friendly materials in asphalt mixtures has increased in recent years. Warm Mix Asphalt (WMA) and reclaimed asphalt pavement (RAP) are two of the technologies considered to have a better impact on the environment. Other materials such as polymers and recycled concrete aggregates have also been used to produce eco-friendly and strong asphalt mixtures [1]. There are organic-based additives such as bio-asphalt [2] and cassava peels [3] that provide alternatives for sustainable asphalt pavement materials.

WMA reduces the mixing and compacting temperatures of asphalt, so it conserves the energy and emission of asphalt mixture production. The advantages of WMA compared to hot mix asphalt (HMA) include reduced asphalt aging due to oxidation, savings in the cost of fuel and emissions, and slower temperature reduction [4]. Reduction in mixing temperature also reduces the short-term aging process that has an important role in asphalt moisture susceptibility [5]. RAP is a used asphalt material that is recovered and reapplied on road pavement. The purpose of RAP is to reduce new materials used in the pavement industry [6].

Despite having several advantages, the application of warm mix asphalt (WMA) technology still has its challenges, especially its susceptibility to permanent deformation. On the other hand, WMA generally has lower resistance to rutting than HMA, as reported by Bonaquist [7]. Vargas-Nordcbeck and Timm [8] also stated that permanent deformation tends to be higher on WMA. Sanchez-Alonso et al. [9] showed that the increase in rut depth as the temperature of the asphalt mixture decreases is the result of a large number of voids in the mix. On the other hand, mixtures incorporating RAP often face a decreased fatigue life [10-12]. This is caused by the aging process of the RAP binder, which is one of the most determining factors of fatigue [13]. Although WMA and RAP individually have disadvantages, the combination of the two is somewhat promising.

To improve the warm mix asphalt’s resistance to permanent deformation, some researchers found the use of reclaimed asphalt pavement (RAP) as one of the solutions. Nejad et al. [14] found that the use of RAP up to 60% increased asphalt viscosity and improved the rutting characteristics of WMA. Xuan Lu and Saleh [15] stated that RAP on WMA made the mixture stiffer and increased resistance to permanent deformation. The research conducted by Yousefi et al. [16] showed that RAP asphalt that had undergone aging made the warm mix asphalt stiffer and resistant to permanent deformation. The combination of RAP and WMA in the pavement is beneficial in terms of environment, cost, and fatigue [17, 18].

This research aims to measure the performance of WMA with RAP and Evotherm M1 using Universal Materials Testing Apparatus (UMATTA) to evaluate the mixture stiffness, Hamburg Wheel Tracking Device (HWTD) to evaluate the mixture resistance to permanent deformation, and Beam Fatigue Apparatus (BFA) to measure the fatigue performance of the mixture. Evotherm is one of the warm mix asphalt additives which is largely used in the United States [19]. The decrease in the viscosity of asphalt with Evotherm causes the mixing temperature to decrease but the potential for ruts to increase [20]. With RAP content of fewer than 50%, Evotherm can also be used as a rejuvenator [21]. Therefore, this paper seeks to evaluate the combination of WMA and RAP using Evotherm as the only additive used to reduce mix temperature and rejuvenate the aged RAP binder. The result is expected to increase mixture performance, both resistance to permanent deformation and fatigue.

2. TEST METHOD

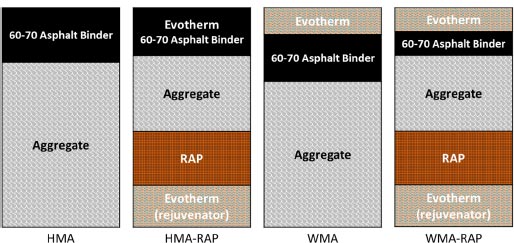

Evotherm functions both as warm mix asphalt additives and RAP rejuvenator. To evaluate the performance improvement of the mixture, four types of the mixture were made: HMA, WMA, WMA-RAP, and HMA-RAP, with compositions as shown in Fig. (1). RAP contents used in this research were 30% and 35% by the weight of the mixture.

The amount of Evotherm required in the WMA was determined based on the Saybolt Furol kinematic viscosity test at temperatures of 120°C, 140°C, and 160°C. RAP was also added with Evotherm to rejuvenate the asphalt contained in it. The asphalt mixture gradation in this research was the Asphalt Concrete-Binder Course (AC-BC). The optimum asphalt content (OAC) in the mixture was determined with the Marshall method, based on the 2018 Bina Marga General Specifications in Indonesia [22].

The performance of the asphalt mixture at OAC includes the parameters of the resilient modulus, permanent deformation, and fatigue. The resilient modulus test used the UMATTA tool, referring to ASTM D4123 [23] and AASHTO TP 31 [24] at temperatures of 25°C, 40°C, and 55°C. A permanent deformation test used the HWTD tool, referring to AASHTO T 324 [25] at a temperature of 60°C and immersed with a maximum number of passes of 10,000. Considering that RAP tends to be prone to fatigue, it was tested using a BFA tool, referring to AASHTO T 321 [26] at a temperature of 20°C. The fatigue test used the stress-controlled method with 3 variations of stress that produced strains close to 300, 400, and 500 με. The UMATTA, HWTD, and BFA tools can be seen in Fig. (2).

|

Fig. (1). Illustration of the types of mixture. |

|

Fig. (2). Tests of Asphalt Mixture with UMATTA, HWTD, and BFA. |

3. EFFECTS OF EVOTHERM ON ASPHALT AND RAP

Evotherm is used to decrease pen 60/70 asphalt viscosity and increase the penetration value of RAP asphalt. As shown in Table 1, asphalt viscosity decreases with the addition of 0.5%-2% Evotherm, but at 2.5% the viscosity increases again. The lowest mixing temperature was reached on asphalt with 2% Evotherm, which was 147°C. The difference between HMA and WMA mixing temperature was 12°C, less significant than another study conducted by Zeng et al. [27]. Therefore, the content of Evotherm in WMA used in this research was 2% by asphalt weight.

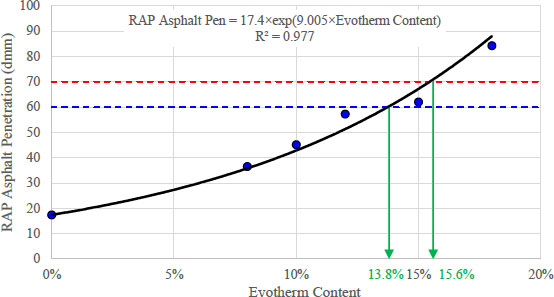

The penetration value of RAP asphalt increased exponentially with the addition of Evotherm from the initial 17.4 dmm as shown in Fig. (3). To achieve a penetration value between 60-70, an Evotherm content of 15% by RAP weight was used. The Evotherm content is less compared to another rejuvenator, Reclamite [28], but they have a similar working temperature. Since the asphalt content in RAP was 5.37%, the Evotherm content as a rejuvenator was 0.948% by RAP weight.

4. DESIGN OF MIXTURE

The asphalt mixture design process using the Marshall method produced optimum asphalt content and density for HMA, WMA, WMA-RAP 30%, and WMA-RAP 35%, as shown in Table 2. The use of Pen 60/70 asphalt on the mixture with RAP decreased significantly because RAP itself contains asphalt. The increase in Evotherm content on WMA-RAP 30% and WMA-RAP 35% was for rejuvenating the RAP asphalt. The asphalt mixture for the permanent deformation test was made at a density to produce a void content in the mixture of 7%.

| Working Temperature | Without Evotherm | +0.5% Evotherm | +1.0% Evotherm | +1.5% Evotherm | +2.0% Evotherm | + 2.5% Evotherm |

|---|---|---|---|---|---|---|

| Mixing Temperature (170 cSt) |

158.6 °C | 158.4 °C | 153.2 °C | 148.8 °C | 147.0 °C | 150.1 °C |

| Compaction Temperature (280 cSt) |

148.2 °C | 145.3 °C | 142.7 °C | 136.9 °C | 137.5 °C | 139.3 °C |

|

Fig. (3). Effects of evotherm on RAP asphalt penetration. |

Table 2. Asphalt mixture design parameters.

| Mixture Type | HMA | HMA-RAP 30% | HMA-RAP35% | WMA | WMA-RAP 30% | WMA-RAP 35% |

|---|---|---|---|---|---|---|

| Pen 60/70 Asphalt Content | 5.13% | 3.29% | 3.04% | 5.05% | 3.88% | 3.76% |

| Evotherm Content | - | 0.28% | 0.33% | 0.10% | 0.36% | 0.41% |

| Mixture Density for UMATTA and BFA tests (g/cm3) | 2.434 | 2.410 | 2.395 | 2.427 | 2.432 | 2.417 |

| Mixture Density for HWTD test (g/cm3) | 2.339 | 2.330 | 2.326 | 2.337 | 2.372 | 2.375 |

| Mixture Type | Resilient Modulus (MPa) | ||

|---|---|---|---|

| 25°C | 40°C | 55°C | |

| HMA | 3176 | 606 | 246 |

| HMA-RAP 30% | 5493 | 1053 | 378 |

| HMA-RAP 35% | 5906 | 1562 | 451 |

| WMA | 3039 | 454 | 182 |

| WMA-RAP 30% | 5138 | 962 | 381 |

| WMA-RAP 35% | 3992 | 777 | 273 |

5. UMATTA TEST RESULTS

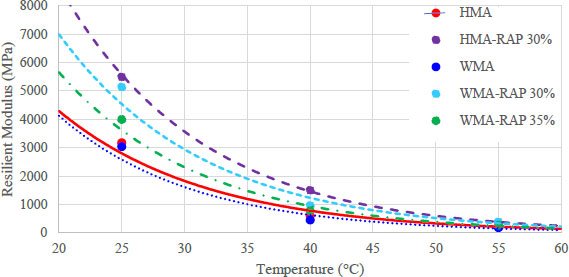

The results of the asphalt mixture resilient modulus test can be seen in Table 3. The resilient modulus at 25°C is the highest while the modulus at 55°C is the lowest. The relationship between resilient modulus and temperature is exponential. The presence of RAP on HMA makes the stiffness of HMA-RAP 35% higher than other mixtures, even though the RAP asphalt has been rejuvenated with Evotherm.

On the other hand, the resilient modulus of WMA is lower than that of HMA due to the presence of Evotherm which softens the asphalt. The addition of 30% RAP and Evotherm increased the resilient modulus of WMA which means that the mixture has a higher stiffness, even stiffer than HMA. The addition of 35% RAP and Evotherm also increased the resilient modulus of WMA, but not as much as the resilient modulus of the mixture with 30% RAP. It confirms that RAP increases the stiffness of the mixture [16, 29]. This stiffness of the mixture has the potential for better resistance to permanent deformation than WMA.

Fig. (4) shows that the resilient modulus has an inverse relationship with temperature and a positive relationship with RAP content. The mathematical model of resilient modulus is as follows:

MR = C (725 x %RAP + 28400) × exp (-0.088 × T), R2 = 0.995 (1)

where:

MR = resilient modulus of the mixture (MPa)

C = mixture coefficient (HMA = 1, WMA = 0,8)

%RAP = RAP content (%)

T = mixture temperature (°C)

|

Fig. (4). Relationship between resilient modulus and temperature. |

| Parameter | Unit | Test Result | |||

|---|---|---|---|---|---|

| HMA | WMA | WMA-RAP 30% | WMA-RAP 35% | ||

| Passes | - | 10000 | 8906 | 10000 | 10000 |

| Total Rut Depth | mm | 7.82 | 20.00 | 7.08 | 11.49 |

| Creeping Slope | mm/ 1000 passes |

0.431 | 1.074 | 0.513 | 0.725 |

| SIP Depth | mm | 3.38 | 2.40 | 5.94 | 10.03 |

| Number of passes at SIP | passes | 4704 | 981 | 7918 | 9174 |

| Stripping Slope | mm/ 1000 passes | 0.903 | 2.221 | 0.558 | 1.785 |

6. HAMBURG WHEEL TRACKING TEST RESULTS

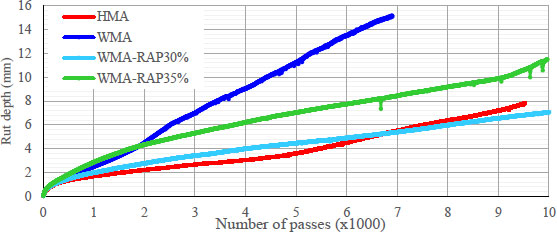

The permanent deformation test using HWTD results is provided in Table 4. A total rut depth on HMA is 7.82 mm with a creeping slope of 0.431 mm/1000 passed and a stripping slope of 0.903 mm/1000 passed. Vulnerability to permanent deformation was seen in WMA mixtures with higher total rut depth, creeping slope, and stripping slope than other asphalt mixtures. The addition of 30% RAP and Evotherm on WMA reduced rut depth, creeping slope, and stripping slope to lower than HMA. Meanwhile, rut depth, creeping slope, and stripping slope on WMA-RAP 35% were lower than WMA, but still higher than HMA.

When compared to HMA, stripping occured faster on WMA. This can be seen in Fig. (5), where the stripping inflection point (SIP) of WMA is lower than HMA. The higher value of SIP on WMA-RAP 30% and WMA-RAP 35% shows that the addition of RAP content increases the resistance of WMA to stripping. The decrease in stiffness and resistance to permanent deformation in WMA-RAP 35% compared to WMA-RAP 30% might occur due to the addition of Evotherm in the mixture, thus it softens the asphalt and the mixture. The presence of Evotherm reduces the asphalt's resistance to permanent deformation [30]. Therefore, it is necessary to limit the use of Evotherm and RAP content not more than 30% in warm mix asphalt to maintain its performance related to permanent deformation.

7. BEAM FATIGUE APPARATUS TEST RESULTS

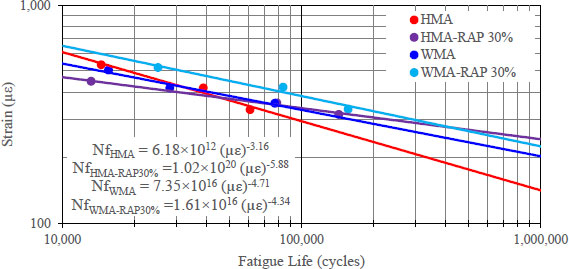

As shown in Fig. (6), fatigue resistance has an inverse relationship with the applied load (strain). HMA and WMA-RAP 30% have a steeper slope than HMA-RAP30% and WMA. They tend to have less sensitivity to strain level change. Even though HMA-RAP30% is stiffer than HMA, it still has more fatigue resistance at the low strain level. WMA-RAP 30% has the highest fatigue life. This shows that Evotherm plays a role in increasing the mixture’s resistance to fatigue. It also confirms a previous study that the use of RAP of 30% is advantageously related to the improvement of the mixture performances [31].

8. DISCUSSION

From the test results above, it can be noticed that Evotherm as WMA additives can reduce the mixing temperatures from 159°C to 147°C. As a rejuvenating agent, the evotherm can increase the asphalt penetration from 17.4 dmm to 63 dmm. These results conclude that Evotherm can work both as WMA additive and rejuvenating agents in asphalt mixtures.

|

Fig. (5). Relationship between rut depth and number of passes. |

|

Fig. (6). Fatigue test S-N curve. |

The modulus resilient tests show that the stiffness of the mixture increases with the addition of RAP and decreases when using WMA. The combination of WMA and RAP in asphalt mixtures provides a balanced stiffness level with a value slightly higher than HMA conventional mixtures. This means there is a potential improvement in resistance to permanent deformation that was confirmed in Hamburg Wheel Tracking Test.

Most materials have a reverse relationship between the resistance to permanent deformation and fatigue life. However, the beam fatigue apparatus test results proved the combination of WMA and RAP using Evotherm has the highest fatigue life. This means that the WMA with 30% RAP should be more economical, long-lasting, and environmental-friendly when applied on road pavements.

The test results are limited by the number of variations provided regarding the RAP source, RAP content, and testing conditions. The test condition used in this research reflects the extreme condition in Indonesia, such as 20°C for the fatigue test and 60°C for the permanent deformation test. There is a possibility to increase RAP content that still has low permanent deformation and high fatigue life. The authors suggest more research be conducted, including field trials to generate more sufficient conclusions on this matter.

CONCLUSION

This research found a better understanding of the use of Evotherm and RAP in warm mix asphalt as follows:

a. Evotherm can decrease the mixing temperature of Pen 60/70 asphalt from 159°C to 147°C with a content of 2% by asphalt weight and can rejuvenate RAP asphalt from 17.4 dmm with a content of 15% by RAP asphalt weight.

b. HMA-RAP mixture type has the highest stiffness, meanwhile, WMA has the lowest stiffness. WMA-RAP has a higher stiffness than conventional HMA.

c. WMA’s low resistance to permanent deformation can be increased most significantly with the addition of 30% rejuvenated RAP to be better than conventional HMA.

d. WMA-RAP 30% mixture has the best fatigue resistance, which shows that the balance between Evotherm dosage and RAP on this mixture improves its resistance to fatigue.

e. The combination of WMA and 30 RAP has the best performance regarding permanent deformation and fatigue compared to other types of mixtures tested.

LIST OF ABBREVIATIONS

| WMA | = Warm mix asphalt |

| RAP | = Reclaimed asphalt pavement |

| HMA | = Hot mix asphalt |

CONSENT FOR PUBLICATION

Not applicable.

AVAILABILITY OF DATA AND MATERIAL

All the data and supportive information are provided within the article.

FUNDING

None.

CONFLICT OF INTEREST

The authors declare no conflict of interest financial or otherwise.

ACKNOWLEDGEMENTS

Declared none.

REFERENCES

| [1] | S.J.A. Al-Hasan, R. Balamuralikrishnan, and M. Altarawneh, "Eco-friendly asphalt approach for the development of sustainable roads", J. Hum. Earth, Future, vol. 1, no. 3, pp. 97-111, 2020. |

| [2] | O.J. Aladegboye, O.D. Oguntayo, E. Al-Ihekwaba, T.E. Daniel, P.C. Chiadighikaobi, and P. Ng’andu, "Evaluation of volumetric properties of cassava peel ash modified asphalt mixtures", Eng. J., vol. 8, no. 10, pp. 2110-2124, 2022. |

| [3] | A.V.R. Sihombing, B.S. Subagio, E.S. Hariyadi, and A. Yamin, "Development of resilient modulus model proposed for bio-asphalt as modifier in asphalt concrete containing reclaimed asphalt pavement", J. Geomate , vol. 19, no. 71, pp. 130-136, 2020. |

| [4] | R.B. Mallick, and T. El-Korchi, Pavement Engineering: Principles and Practice.. CRC Press: Boca Raton, 2017. |

| [5] | Z.T. Al-Fayyadh, and H. Al-Mosawe, "The effect of short-term aging on warm mix asphalt moisture performance", Eng. J., vol. 8, no. 12, pp. 2789-2802, 2022. |

| [6] | Nordic Road Forum (NVF), Sustainable Asphalt, Available from: http://www.eapa.org/userfiles/2/Publications/NVF_en.pdf |

| [7] | R. Bonaquist, "Mix design practices for warm mix asphalt, NCHRP Report 691", Transport. Res. Board, 2011. |

| [8] | A. Vargas-Nordcbeck, and D. H. Timm, "Rutting characterization of warm mix asphalt and high RAP mixtures", Road Mater, vol. 13, no. S1, pp. 1-20, 2012. |

| [9] | E. Sanchez-Alonso, A. Vega-Zamanillo, M.A. Calzada-Perez, and D. Castro-Fresno, "Effect of warm additives on rutting and fatigue behaviour of asphalt mixtures", Constr. Build. Mater., vol. 47, pp. 240-244, 2013. |

| [10] | Q. Ma, Z. Guo, P. Guo, L. Sun, F. Yang, and H. Li, "Research on fatigue prediction model of asphalt mixture with high RAP content", Sustainability, vol. 13, no. 14, p. 7995, 2021. |

| [11] | S. Tang, R.C. Williams, and A.A. Cascione, "Reconsideration of the fatigue tests for asphalt mixtures and binders containing high percentage RAP", Int. J. Pavement Eng., vol. 18, no. 5, pp. 443-449, 2017. |

| [12] | M.S. Oliveira, M.M. Farias, and J.P.S. Silva, "Fatigue analysis of hot recycled asphalt mixtures with RAP incorporation", Case Stud. Constr, vol. 16, p. e01132, 2022. |

| [13] | W.S. Mogawer, A. Austerman, R. Roque, S. Underwood, L. Mohammad, and J. Zou, "Ageing and rejuvenators: Evaluating their impact on high RAP mixtures fatigue cracking characteristics using advanced mechanistic models and testing methods", Road Mater, vol. 16, no. S2, pp. 1-28, 2015. |

| [14] | F. Moghadas Nejad, A. Azarhoosh, G.H. Hamedi, and H. Roshani, "Rutting performance prediction of warm mix asphalt containing reclaimed asphalt pavements", Road Mater. Pavement Des., vol. 15, no. 1, pp. 207-219, 2014. |

| [15] | D.X. Lu, and M. Saleh, "Laboratory evaluation of warm mix asphalt incorporating high RAP proportion by using evotherm and sylvaroad additives", Constr. Build. Mater., vol. 114, pp. 580-587, 2016. |

| [16] | A. Yousefi, A. Behnood, A. Nowruzi, and H. Haghshenas, "Performance evaluation of asphalt mixtures containing warm mix asphalt (WMA) additives and reclaimed asphalt pavement (RAP)", Constr. Build. Mater., vol. 268, p. 121200, 2021. |

| [17] | F.R.G. Padula, S. Nicodemos, J.C. Mendes, R. Willis, and A. Taylor, "Evaluation of fatigue performance of high RAP-WMA mixtures", Int. J. Pavement Res. Technol., vol. 12, no. 4, pp. 430-434, 2019. |

| [18] | C. Hettiarachchi, X. Hou, J. Wang, and F. Xiao, "A comprehensive review on the utilization of reclaimed asphalt material with warm mix asphalt technology", Constr. Build. Mater., vol. 227, p. 117096, 2019. |

| [19] | G.C. Hurley, and B.D. Prowell, "Evaluation of Evotherm for use in warm mix asphalt", NCAT Report, vol. 2, pp. 15-35, 2006. |

| [20] | M. Bazzaz, M.K. Darabi, D.N. Little, and N. Garg, "Effect of evotherm-M1 on properties of asphaltic materials used at NAPMRC testing facility", J. Test. Eval., vol. 48, no. 3, p. 20190446, 2020. |

| [21] | J. Yu, Y. Guo, L. Peng, F. Guo, and H. Yu, "Rejuvenating effect of soft bitumen, liquid surfactant, and bio-rejuvenator on artificial aged asphalt", Constr. Build. Mater., vol. 254, p. 119336, 2020. |

| [22] | Indonesian Directorate General of Highways. General Spesifications 2018 Revision 2 for Road and Bridge. 2020. |

| [23] | ASTM D4123-82, Standard Test Method for Indirect Tension Test for Resilient Modulus of Bituminous Mixtures. ASTM International (ASTM), 2020. |

| [24] | AASHTO TP 31, Standard Test Method for Determining the Resilient Modulus of Bituminous Mixtures by Indirect Tension. ASTM International (ASTM), 2020. |

| [25] | AASHTO T324-04, Standard Method of Test for Hamburg Wheel-Track Testing of Compacted Hot-Mix Asphalt (HMA). American Association of State Highway and Transportation Officials (AASHTO) , 2020. |

| [26] | AASHTO T321-11, Standard Method of Test for Determining the Fatigue Life of Compacted Asphalt Mixtures Subjected to Repeated Flexural Bending. American Association of State Highway and Transportation Officials (AASHTO), 2020. |

| [27] | M. Zeng, C. Wu, and J. Zhang, "Determining mixing and compaction temperatures of evotherm® warm mix asphalt using 100% reclaimed asphalt pavement", Int. J. Pavement Res. Technol., vol. 7, no. 6, 2014. |

| [28] | R.T. Bethary, B.S. Subagio, H. Rahman, and N. Suaryana, "Effect of Recycled Materials on Marshall Performance on Hot-mix Asphalt Mixture", IOP Conference Materials Series: materials Science & Engineering , p. 012048, 2019. |

| [29] | D.X. Lu, M. Saleh, and N.H.T. Nguyen, "Effect of rejuvenator and mixing methods on behaviour of warm mix asphalt containing high RAP content", Constr. Build. Mater., vol. 197, pp. 792-802, 2019. |

| [30] | Q. Li, G. Sun, Y. Lu, Y. Meng, S. Luo, and L. Gao, "Effects of warm-mix asphalt technologies and modifiers on pavement performance of recycled asphalt binders", J. Clean. Prod., vol. 282, p. 125435, 2021. |

| [31] | I. Maha, B. S. Subagio, F. Effendhi, and H. Rahman, "Performance of warm mix asphalt concrete binder course (AC-BC) with reclaimed asphalt pavement", J. East. Asia Soc. Transp. Studies, vol. 10, pp. 590-1597, 2015. |