REVIEW ARTICLE

Durability Phenomena of Bitumen and Bituminous Pavement Materials

Abdullahi Ali Mohamed1, Soon Yee Wong1, Lau Teck Leong1, Mohd Ahmadullah Farooqi2, Ramadhansyah Putra Jaya3, *, Zaid Hazim Al-Saffar4, Haryati Yaacob5

Article Information

Identifiers and Pagination:

Year: 2021Volume: 15

First Page: 279

Last Page: 289

Publisher ID: TOCIEJ-15-279

DOI: 10.2174/1874149502115010279

Article History:

Received Date: 2/12/2020Revision Received Date: 16/5/2021

Acceptance Date: 31/5/2021

Electronic publication date: 30/09/2021

Collection year: 2021

open-access license: This is an open access article distributed under the terms of the Creative Commons Attribution 4.0 International Public License (CC-BY 4.0), a copy of which is available at: https://creativecommons.org/licenses/by/4.0/legalcode. This license permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Abstract

The durability of asphaltic mixtures, in addition to traffic loading, is greatly influenced by the extremes environmental parameters. For instance, at higher temperatures, bitumen becomes soft, thereby reducing the stiffness of asphalt mixtures and making them vulnerable to rutting. On the other hand, at lower temperatures, the stiffness of bitumen is increased, reducing the flexibility of asphaltic concrete and rendering it prone to fatigue failure. Therefore, this evaluation is an extensive research study on the durability of binder and asphalt mixture with their phenomena. Besides that, this paper intends to delve into the various testing methods and measures adopted to evaluate aging and slowing it down. It also presents a critical review of these methods and proposes a future course of action to better address aging issues. According to the evaluation, the behavior of bitumen on the basis of its source varies; when it is mixed with bitumen modifiers, aggregates, and other filler materials, its behavior becomes even more complex. Hence the understanding of the phenomenon of aging is important and the significance cannot be overemphasized. Extensive research work has been done over the last seven decades to evolve the understanding of short- and long-term aging and to improve the durability of asphaltic mixtures. Generally, the aging of bitumen under the influence of both environment and traffic is irreversible as well as inevitable. Apart from entailing hefty maintenance budgets, it remains a challenge to the researchers to slow down aging.

1. INTRODUCTION

The durability of a road surface material is inevitably affected by environmental factors, such as precipitation, temperature, air, and ultraviolet rays [1]. Rises in temperatures decrease the stiffness of bitumen and consequently make pavement more vulnerable to rutting. On the contrary, lower temperatures can increase the stiffness of bitumen and paves the way to inducing fatigue failure in pavements. The resulting cracks in the pavement surface may adversely affect the long-term performance of the asphalt mixture. Studies have been carried out to better understand the factors responsible for short- and long-term aging [2]. In fact, age hardening is predominantly associated with the loss of volatile constituents in bitumen during 1) mixing and construction stages, and 2) life span of pavement through progressive oxidation of the bitumen. The former is designated as short-term aging, while the latter as long-term aging. Both the short and long-term aging tend to cause a surge in viscosity of bitumen and consequent stiffening of the mixture. Subsequently, the pavement mixture tends to become brittle and susceptible to crumbling and cracking. The aging process of bituminous mixtures is potentially irreversible, which consequently reduces the durability of pavements [3]. This paper intends to review the available literature on the broad topic of bitumen aging and assembles the current understanding of bitumen aging and measures to slow down the consequences of bitumen aging in pavement mixtures.

2. RHEOLOGICAL PROPERTIES OF BITUMEN

The main constituents of pavement mixture include coarse and fine aggregates, mineral fillers, and a relatively small proportion of bitumen. However, this small amount of bitumen has a profound impact on the overall performance of pavement [4]. Bitumen is a viscoelastic material generally derived from crude oil or obtained from its natural deposits, like the Pitch Lake, which is considered as the largest natural deposit of asphalt in the world, situated at La Brea in southwest Trinidad. The chemical composition of bitumen is complex, often depends on its sources, consisting mainly of carbon (80-88%) and hydrogen (8-12%). Other elements, such as sulphur (0-9%), oxygen (0-2%), and nitrogen (0-2%), as well as some trace minerals like vanadium, nickel, and manganese, may also be present [4]. The level of performance of road throughout the service life has a close correlation with the properties of bitumen used in the asphaltic mixtures. The rheological weaknesses of the conventional bitumen have generated an interest of researchers to evaluate the factors that contribute towards short- and long-term aging [5]. The properties of bitumen are usually affected by the presence of oxygen, ultraviolet radiation, and temperature and pressure extremes. These external factors cause it to harden or soften and eventually affect its durability [6]. Empirical properties testing such as penetration, ductility, ring and ball methods are inadequate in evaluating the changes in property due to aging [7]. In fact, over the last two decades, bitumen aging has been described by the rheological parameters, namely, complex modulus (G*) and phase angle (δ), as a function of loading frequency and prevailing temperature. It’s a unique behavior of bitumen that its mechanical response is dependent on loading time and temperature. In the 1950s, a viscoelastic description of the behavior of bitumen was given, and the term stiffness was adopted to describe the mechanical behavior of pure bitumen as a function of temperature and loading time [8]. The Strategic Highway Research Program (SHRP) originally conceived the notion of characterizing bitumen through rheological properties in response to a perception from the highway industry that the quality of paving-grade bitumen had, in many cases, declined to an unacceptable level. Because of this perception, the primary objective of the SHRP was to develop performance-based specifications [9]. It can, hence, be concluded that, in particular, complex modulus (G*) is a major indicator of the mechanical behavior and performance of bitumen. The dynamic (oscillatory) shear rheometer (DSR) is considered to be a useful technique to explain the uniqueness of the behavior of bitumen. In the shear mode under dynamic testing, G* and δ were measured, in which G* represents the total resistance to deformation when sheared repeatedly, while the phase angle (δ) represents the magnitude of deformation [2]. Naturally, the higher value of G* represents better resistance to deformation and a lower value of δ reflects better elasticity of bitumen. The study of these parameters is useful because they have the potential to predict pavement performance, such as rutting resistance (G*sinδ) and fatigue (G*sinδ). The general relationship of elastic modulus E and shear modulus (G*) is as shown in Eq. (1):

Where,

E = Elastic stiffness modulus for asphalt mixture,

μ = Poisons ratio,

G* = Complex modulus

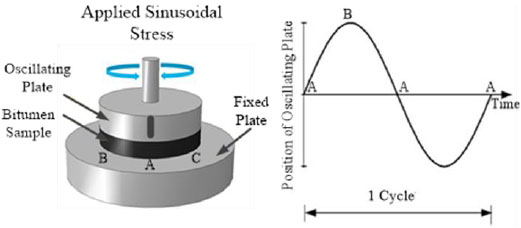

The value of Poisons ratio (μ) is driven by the compressibility of the material. It may be assumed to be 0.5 for pure bitumen, while less than 0.5 for bituminous mixtures. Consequently, new tests based on fundamental properties were needed. The SHRP developed techniques to characterize binders according to their stiffness, relaxation ability, and failure properties. The SHRP techniques have been widely reported in the literature for the last two decades and are specified in AASHTO T315-02 [10]. A type of test to measure the shear modulus of bitumen uses a fixed lower plate and oscillating upper plate in which shear force is applied to the specimen, as shown in Fig. (1) [1].

The SHRP researchers conducted strain sweeps to determine the maximum strain values that could be used in the frequency sweep tests to generate data in the linear region [7]. The methodology required monitoring the absolute value of the complex modulus (G*) as the strain increased; if (G*) did not drop more than 0.95% of its initial value, linearity conditions were considered to be valid. This condition is also a part of the AASHTO specification on Dynamic Shear Rheometer (DSR), and the same approach is adopted by AASHTO T315-02 [10]. The DSR specifications are now being implemented as a part of the Superpave specification in various countries. Using oscillatory shear measurements, both the base and modified bitumen have been investigated under stress- and strain-controlled conditions. The changes in properties have been measured using DSR [11]. There are several major distress modes of road pavement related to the properties of bitumen [12]. Frequent problems of road pavement include rutting, fatigue cracking, and thermal cracking [4], among many others. The performance of bituminous mixtures in service is significantly affected by the rheological properties and chemical composition of bitumen. Numerous researchers have studied the relationship between the rheological characteristics of bitumen and its field performance [13-16]. The rheological characteristics of bitumen, its field performance, and the importance of understanding the rheological behavior of bitumen have also been emphasized [4]. Most of the earlier research was unfortunately limited to studying the aging process and not on how to improve aging resistance. However, some researchers tried antioxidant compounds to improve the aging resistance of bitumen [17-20]. Next, the relative advantages of the wet versus the dry methods are still being researched, although modified bitumen produced through either the wet or the dry process has demonstrated improved performance as compared to unmodified bitumen. Superpave standards are relatively novel and may need further improvement in some areas [21]. Another point of particular concern is the testing of long-term aging, which is carried out at pressures and temperatures well in excess of the usual road-aging conditions. These elevated temperature and pressure conditions affect the mechanics of oxidative hardening of the binder, which leads to physical properties that may be unlikely to obtain at road aging conditions [22]. AASHTO R30-02 requires bitumen mixtures to be conditioned at 135°C for 4 hours prior to compaction, for short-term aging, and for long-term aging, at 85°C for 120 hours in an oven [10]. The conditioning procedure has been designed to simulate the aging that the asphalt mixture suffers during 5-10 years of its design life [6]. Studies have been focused to determine chemical, rheological, elastic, and thermal properties as well as sensitivity to heat, UV, and oxidation of bitumen with and without additives [23].

|

Fig. 1. Schematic Representation of Dynamic Shear Rheometer (DSR) test. |

3. BITUMEN AGING MECHANISMS

The primary bitumen aging mechanism takes place in the pug mill or drum mixer where heated aggregate is mixed with hot bitumen [6]. At this stage, substantial rheological changes take place during this short mixing period. The factor that contributes to the age-hardening of bituminous mixtures during mixing is the volatilization of light asphalt components [24]. This phenomenon occurs when the temperature increases during the production, storage, transport and placing of bitumen, in which loss in weight of bitumen occurs on account of evaporation. Bitumen reacts with atmospheric oxygen, and Ultraviolet (UV) radiation and the rate of this reaction depends on the amount of reactive hydrocarbons present, which varies depending upon the type and the source of bitumen [25]. Oxidative age-hardening of bitumen significantly contributes to pavement embrittlement, which in the case of bitumen mixtures, evidently leads to excessive pavement cracking [25]. Steric-hardening is the isothermal, reversible, and time-dependent hardening phenomenon always observed in bitumen that has been heated to become a free-flowing liquid and then allowed to cool down at room temperature. Steric-hardening occurs when molecules in a randomly oriented complex mixture reorganize themselves upon cooling over time and form an organized mixture of molecules [6]. The effects of steric-hardening, otherwise termed as physical hardening, include increased viscosity and a slight contraction in volume [24]. Steric-hardening can be reversed through heat or mechanical work since it only entails structural reorganization of the molecule as a result of variation in temperature [25]. Volatilization and oxidation processes are, however, irreversible as they are prompted by chemical changes [26]. The above facts have only emerged from the research outcomes within the last four decades; however, to simulate aging, laboratory methods have been focusing only on volatilization and oxidation as the two dominant factors of aging [6].

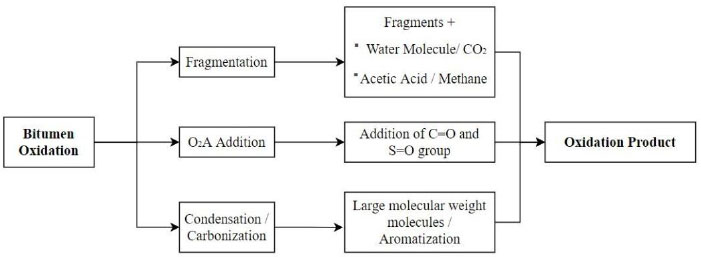

The reaction process is governed by the reactive hydrocarbons present in bitumen, and that is dependent on the type and source of bitumen [27]. One can explain the overall oxidative aging with three different types of phenomena: (i) fragmentation, (ii) oxygen addition, and (iii) condensation or carbonization, as shown in Fig. (2). In fragmentation, the molecules are broken down into smaller fragments, while methane, acetic acid, carbon dioxide, and water are evolved as by-products. In fact, these by-products are volatile in nature, and they evaporate over time. The oxygen addition phenomenon causes the formation of carbonyl (C=O) and sulfonyl (S=O) groups in the matrix. In the condensation or carbonization process, the molecules havinghigh molecular weight and aromatic molecules (benzylic carbon group) are produced. The presence of these heavy molecules coupled with the loss of volatile molecules, on account of fragmentation, reduces the mobility and increases the bitumen’s viscosity [28]. Moreover, the fine filler particles in the asphalt mixture may potentially expedite the overall aging process.

|

Fig. (2). Possible mechanism of oxidative aging. |

Bitumen behaves as a Newtonian fluid when mixed with mineral aggregates at high temperatures. The linear viscoelastic region depicts its resistance to traffic loads [29]. It has been reported that pavement defects, like rutting at elevated temperatures, crack development, and propagation in the low-temperature region may not only be attributed to traffic loading but also due to the thermal vulnerability of bitumen [30]. The high-temperature specification parameter for evaluating rutting resistance in asphalt pavements developed during the SHRP is a ratio of the complex modulus and the phase angle (G*sinδ). It was studied whether the (G*sinδ) ranks the binders in the same way as did laboratory mixture test for rutting [31]. Three different machines were used to test rutting, namely, French Pavement Tester, Hamburg Wheel Tester and Georgia Loaded Wheel Tester (GLWT). The study concluded that the GLWT device provided a good relationship with (G*sinδ) of the bitumen as compared to the other two devices, which showed a slightly higher rutting value. The selection of specification criteria to ensure satisfactory resistance to fatigue cracking is perhaps the most difficult challenge presented by the new binder specification. It is stated that the current definition of fatigue failure is not adequate and that the existing measuring system for binder properties is based on assumptions and simplifications that result in misinterpretation of pavement conditions and other factors like traffic speed, traffic volume, pavement structure, and heating-cooling cycles [11]. The dissipated energy approach was applied to fatigue, and the parameter G*sinδ) was identified as an indicator of fatigue resistance [19]. Traditionally, the aging potentials of bitumen mixtures have been investigated by the aging of bitumen under suitable means and evaluating the change in its physical properties. This approach does not account for the effect of aggregate packing, air-voids, and mixture morphology and may yield inappropriate results. A more pragmatic approach is to subject asphalt-aggregate mixtures to aging conditions and measure the physical properties of the aged mixtures, not bitumen alone. It was claimed that bitumen oxidation was represented accurately by the growth in the infrared carbonyl peak, although this growth represents only a small portion of the spectral change during oxidation [32].

4. CONTROLLED OXIDATIVE AGING BY DIFFUSION PROCESS

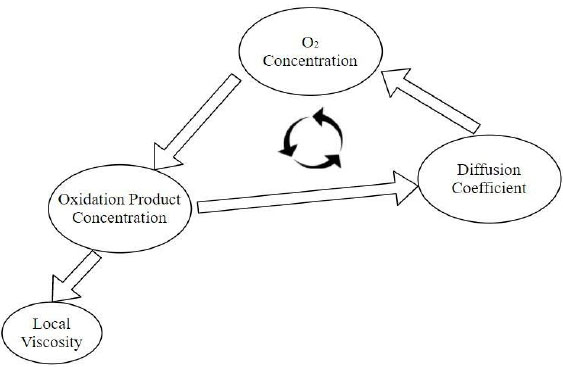

The concentration of oxygen in the bitumen matrix is dependent on the diffusivity value of bitumen and the diffusivity of bitumen keeps changing as oxidative aging progresses [33]. The oxidation product and the oxygen diffusivity of bitumen are, thus, inter-dependent, as shown in Fig. (3). It depicts that the diffusion coefficient continuously varies, and this variation continues until all the reactive hydrocarbons in the bitumen are exhausted, or the supply of oxygen is ended. In this process, the viscosity of bitumen increases with the increasing oxidation product concentration within the bitumen matrix.

|

Fig. (3). Schematic of diffusion-controlled oxidation process [33]. |

5. INVESTIGATION ON BINDER STUDIES

Binders that are resistant to aging or changes in physical properties during long-term service may be described as durable. It is desirable to understand the thermo-mechanical behavior of bitumen before using it as a binder for pavement construction. In field applications, pavement layers are exposed to atmospheric extremes, and the binder comes in contact with oxygen. The reaction of the bitumen with oxygen changes its composition and renders it to be susceptible to wear and moisture damage. The effect of compositional change in the binder is reflected in the increased hardening of the binder, which in turn increases stiffness and viscosity. Various methods have been proposed to imitate the effect of aging and predict the in-situ behavior of bitumen. The commonly used bitumen aging tests to simulate short-term aging are the Thin-Film Oven (TFO) and the Rolling Thin-Film Oven (RTFO) tests. The SHRP binder specification includes 1% RTFOT mass loss limit, which was set to avoid performance problems and not intended as an environmental exposure limit. A review was done dealing specifically with laboratory binder aging and summarizes the methods used together with the test used to evaluate the extent of aging [34] is as shown in Table 1.

| Aging Method | Evaluation Method | References |

|---|---|---|

| For 18, 24 hrs, 325οF (163οC) Mixture aged for 30 min, 149οC |

Change in weight, penetration of residue Recovered asphalt - change in penetration |

[38] |

| Ottawa Sand mixture, oven aging, outdoor exposure | Change in mix properties, abrasion, strength | [39] |

| Mixture oven aging 30 min 163οC | Recovered asphalt - penetration, ductility, softening point | [40] |

| Ultraviolet and infrared Weathering |

Penetration, Softening point Ductility | [41] |

In a study to evaluate procedures to retard oxidative hardening of asphaltic surfacing in South Africa, an approach similar to that first adopted by [35] was incorporated [36]. A two-stage procedure with extended RTFOT aging was utilized initially, for 8 hours followed by pressure oxidation at 300 psi and 65°C for 96 hours. The evaluation of the extent of asphalt aging was done by sliding plate micro viscometer at a shear rate of 0.05 sec-1 and 45°C. The film thickness was reduced to 100 microns and the exposure time was increased to 24 hrs [36]. It is also reported that the viscosity of a typical asphalt volatile fraction is 11 centistokes at 60°C [37-41].

Calculations, which used this viscosity value with a standard viscosity blending algorithm suggested that 1% volatilization increased asphalt viscosity by about 20%. A test method termed as German Rotating Flask Test (GRFT) has also been developed in Germany as an alternative to the TFOT and RTFOT tests [42]. In the GRFT method, 100 g of bitumen is placed in a 500 ml round-bottomed flask. The flask is connected to a rotating evaporation apparatus, which is operated at 20 rpm with the flask immersed in an oil bath at 165°C for 2.5hrs and a 500 ml/min airflow over the asphalt. In an interesting study, bitumen aging results from a controlled environment room have been compared with the two popular methods of aging, namely, a short-term RTFOT and a long-term aging PAV test. The controlled environment room is maintained at 60°C, 1 atmospheric pressure, and 50% relative humidity in an attempt to closely simulate the actual road-aging conditions. For short-term and long-term aging, RTFOT with a new air-blowing procedure and PAV test were performed, respectively. All the samples, before placing in the environmental room for aging, were RTFOT short-term aged to compensate for hot-mix process aging. It was found that 38 days of aging of 1 mm thick films at 60°C and 1 atm of air is approximately equivalent to 20 hr in the PAV in 3.2 mm thick films at 100°C [22]. The exposure of both ultraviolet (UV) and infrared (IR) lights for aging thin bitumen films in TFOT containers has also been reported [34]. A parallel study was also conducted using a weatherometer to age 100 micron thick films of asphalt. A temperature of 65°C was used, a 102-minute cycle of UV followed by 18 min of UV and water spray (300 psi). Samples were aged for time periods of 32.5 hrs, 73.5 hrs, 7 days, and 14 days [36]. The results showed that the oxidation levels and changes in high-molecular-weight constituents were analogous with the other aging procedures. It was also found that very little hardening occurs when void content is below 5% [43]. However, at void contents greater than 5%, penetration decreases, showing the oxidation of bitumen. The results of the penetration test study on the recovered asphalt with air void contents ranging from 3% to 12%. Pressure oxidation to age bitumen on Fraass test plaques has also been done [44]. Samples were subjected to 100 psi oxygen pressure at 60°C for 2 and 5 days. The advantage of this aging approach was that the aged bitumen is in the container used for the test method to evaluate the extent of aging. The asphalt film on a Fraass plaque was 0.5 mm thick, which is much thicker than that used in any of the thin film tests described earlier. The effect of long-term aging on the rheological properties of polymer modified and neat bitumen has also been studied [45, 46]. Modifiers included di-block poly (styrene-b butadiene) rubber, triblock poly (styrene-b-butadiene-b-styrene), and vehicle tire rubber. Bitumen aging was done either at 60°C in a controlled environment room or at 100°C in a pressure aging vessel. In the study, dynamic shear and extensional properties were investigated. The polymer modification resulted in improved value of complex modulus at high temperatures, decreased value of complex modulus at low temperatures, and improved ductility. Oxidative aging decreased asphalt temperature sensitivity, damaged the polymer network in the binders and lowered the effectiveness of polymer additives in improving ductility.

A different sustainable technology implementation was the use of crumbed rubber (waste tyre) as a binder for bitumen modification. Many field studies have been conducted using crumbed rubber to improve bitumen performance [46-49]. The application of rubberized bitumen realized many advantages ranging from improving bitumen resistance to rutting due to high viscosity, better resilience due to higher softening point, lower fatigue/reflection cracking, and improved temperature insensitivity [50]. An investigation was done on rubberized bitumen binder in which samples were prepared by mixing bitumen 80/100 penetration grade with CRM (8% and 16% by binder weight) passing 30 mesh sieve in a propeller mixer at 180°C for one hour at a velocity of 200rpm [51]. The results were encouraging as they showed that the use of rubberized bitumen binder reduced the aging effect on physical and rheological properties of the bitumen binder as established through the lower aging index of viscosity, lower aging index G*sinδ at 76°C, and increase in tanδ with increased crumb rubber modifier content. In addition, the results showed that the softening point increment (ΔS) and Penetration Aging Ratio (PRA) of the rubberized bitumen binder declined significantly due to crumb rubber modification. This crumbed rubber modifier also increased the stiffness of the bitumen binder and lowered G*sinδ at 31°C after PAV aging indicated fatigue resistance.

Another study was conducted for binder characterization of Reactive and Activated Rubber (RAR) modified asphalt with dosages 5, 10, 15, 20, 25%, and its rheological performance was compared with two base virgin binders (VG-30, VG-40) and one crumb rubber modified bitumen (C60 binder). A significant contribution of this study was that the addition of RAR to the base increased viscosity at higher temperatures and reduced viscosity at lower temperatures. The addition of RAR to both the virgin binders showed higher G*sinδ values at low frequencies, demonstrating that the RAR has more rutting resistance than both virgin binders and C60 binders. It also raised the upper-performance grade (PG) temperature to a higher grade (76-82°C) than the base binder making these binders well suited to reduce their potential to rutting [52].

6. INVESTIGATION OF MIXTURE STUDIES

It has been identified that modelling the effects of short- and long-term aging of asphalt-aggregate mixtures is important, and it should be performed under conditions that closely simulate the actual in-situ conditions to obtain the field behavior [53]. Researchers from as early as 1903 have been performing a penetration test on the bitumen recovered before and after extended heating of mixtures [34]. Several standard procedures have been mentioned for extracting and recovering asphalt from mixtures [34]. An extensive study was performed in which 12,000 specimens of Ottawa sand and different type of asphalt mixes were made and aging tests were done with ultraviolet light, and some with extended exposure to heat and air [39, 40, 54]. In a study, the effect of hydrated lime on oxidative hardening of bituminous mixtures is evaluated [25]. An oven aging procedure on 25 mm by 40 mm diameter samples was used. It was established that the change in resilient modulus (measured with a diametral test configuration) of lime-treated mixtures was lesser than non-treated mixtures by the aging process. A different study was performed to evaluate the aging of bitumen, and hydrated lime was observed to slow down the aging process [55]. Another study on bitumen aging in the vicinity of the ocean was performed [56]. In this study, the tests were conducted for 4 and 7 days in a dry atmosphere and an atmosphere of 80% relative humidity. Asphalt was recovered for viscosity determination from 100 mm samples cored from laboratory-produced slabs. Also, the samples were weighed before and after aging, and the weight loss indicated a loss of volatile portion. Finally, beam samples were cut from the slabs and the shrinkage during the aging test was determined. An investigation was carried out using forced-draft oven-aging to simulate short-term hardening [57]. It compared the initial and final penetration and viscosity ratios of each of the bitumen samples for both field and laboratory aging programs. The laboratory method involved oven heating of loose mixture samples for time periods of 8, 16, 24 and 36 hours at a temperature of 135°C. Long-term aging was also investigated in which a forced-draft oven was used with the following procedure [57].

- Six compacted specimens were placed in the oven at 60°C for 2 days, and then three specimens were removed.

- The temperature of the three samples was increased to 107°C from 60°C, and the remaining three specimens were aged for 5 days.

Also, a pressure oxidation treatment was investigated, with three compacted specimens conditioned for 5 to 10 days at 60°C and 100 psi. It was found that indirect tensile strength values were higher for the oven-aged mixtures and failure strains were lower than for pressure-oxidized mixtures implying that the oven-aging was more severe. Initial and recovered asphalt properties were also shown, indicating that the oven aging was more severe for one mixture but less severe for the other two. The effect of UV-radiation was investigated on mixtures obtained from laboratory prepared slabs and freshly constructed field projects and used 54 hours of UV exposure [56]. In another study, dense mixes prepared with asphalt binder film thickness ranging from about 4 to 13 microns, were subjected to accelerated aging using SHRP procedures to simulate both short and long-term aging [58]. The aged compacted mix was tested for tensile strength, tensile strain at failure, and resilient modulus. The aged bitumen was recovered and tested for penetration, viscosity, complex modulus and phase angle. Aging indices were obtained from these tests, and the relationship between film thickness and the aged bituminous mixtures properties were determined using regression analysis. It was found that accelerated aging would occur if the asphalt binder film thickness was less than 9-10 microns in asphalt paving mixture compacted to 8% air void content. The effect of gradation of aggregates on bitumen aging was investigated in a study in which continuous and gap-graded mixtures, the loose asphalt mixtures, were aged at 135°C prior to compaction [53].

7. AGING OF BITUMEN MODIFIED WITH NANO MATERIALS

Nanomaterials have been utilized in many ways to increase the performance of asphalt binder materials. Carbon Nanofibers (CNFs), carbon nanoparticles have been used, and data collected from these studies show that fatigue life and rutting resistance of CNF modified binders have been enhanced [59]. Nano-SiO2 (silicon dioxide) and Styrene-Butadiene-Styrene (SBS) have also been used to improve the performance of asphalt pavement [60, 61]. Other nanomaterials have also been successfully used for improving asphalt binder performance. In a study, the effect of two nanomaterials: (1) Non-modified Nanoclay (NMN) and (2) Polymer modified Nanoclay (PMN) on the aging of bitumen was investigated [62]. The experiment was performed using an asphalt graded PG 58-34 from a project site in Gladstone, Michigan, as a control asphalt. This control asphalt was pre-modified with Acrylonitrile Butadiene Styrene (ABS) to improve the compatibility between the asphalt and polymer and meet the low temperature grade requirement. It was then mixed with PMN or NMN with concentrations of 2% and 4% by weight of controlled asphalt, respectively. This modified asphalt binder was then mixed at temperature 130°C in a high shear mixing component at 4000 rpm. All samples were mixed for 2 hours before superpave binder tests of asphalt binder. It was found that the addition of NMN into control asphalt binder resulted in an increase in viscosity, while the addition of PMN to asphalt binder resulted in a decrease in viscosity. The shear modulus of NMN modified asphalt binder was found to have higher complex modulus than control asphalt binder, while that of PMN modified asphalt binder was found to be on a lower side before or after the RTFO- and PAV-aging process. The PMN was found to influence in other circumstances like improving recovery ability of asphalt binder and also improves the high-temperature properties of unaged, RTFO-aged, and PAV-aged asphalt binders. Bending Beam Rheometer (BBR) results showed that the stiffness values of NMN and PMN modified asphalt binders’ approach to that of control asphalt binder.

8. AGING OF BITUMEN MODIFIED WITH GRAPHITE NANO PLATES

In a different study, considering the unique properties of graphite materials, asphalt was modified using multilayer graphite Nano plates to improve the high and low-temperature performance of the asphalt modified binder. The modified asphalt binder was tested on several parameters, such as viscosity, complex shear modulus, thermal cracking temperature, aging index, and electromagnetic radiation absorption. The viscosity and complex shear modulus of graphite-modified asphalt binders were tested at varying temperatures. The result showed an increase in viscosity as well as mixing and compaction temperatures of modified asphalt binder, thus, indicating an improvement in high-temperature performance in modified asphalt binder. The cracking temperature of the modified asphalt binder also improved, and the stress relaxation of the modified asphalt binder was enhanced, and the resistance to low-temperature thermal cracking also improved. Due to the increase in the ratio of aging groups (C=O) in modified asphalt binder, moisture susceptibility and high-temperature performance improved. Control asphalt and modified asphalt binder were compared using UV-V in a spectrometer with different wavelengths. Results showed that modified asphalt binder develops an ability to absorb more radiation than control asphalt, showing the capacity of modified asphalt binder to work better under low-temperature conditions [61].

9. VISCOUS-FLOW ACTIVATION ENERGY OF BITUMEN

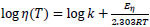

To identify viscous flow properties of an asphalt material, viscosity is one of the most important indicators [63]. When asphalt flows, the internal frictional resistance between asphalt molecules comes into action, reflecting the role of viscosity in asphalt. It is generally considered that the viscosity of asphalt represents the degree of its molecular association. The viscosity of any polymer material mirrors its chemical composition vis-à-vis molecular weight. The higher the molecular weight, the higher the viscosity. Since asphalt aging comprises fracture, polymerization and restructuring of the chemical bonds, which will inevitably lead to changes in viscosity of the material. These changes in viscosity would reflect the colloidal solubility of asphaltene in bitumen. Some authors [64] have suggested that an increase in the content of asphaltene is the main reason for the increase of asphalt viscosity, while others [65] have considered that the viscosity of asphalt reflects the content of hydroxy compound. All of these factors show that the change in viscosity represents the viscous flow properties. As the temperature increases, the thermal motion in the molecules surges, causing the intermolecular distance to increase in the material. This increase in intermolecular distance creates a hole within the material and as the energy increases, the hole gets bigger. This hole creates a gap, which allows molecular chain segments to move easily inside the material, thereby reducing intermolecular interaction and also a reduction in viscosity. The relationship between polymer melting viscosity and temperature can be described using the Arrhenius equation, which is as follows:

Where,

η(T) is the viscosity at temperature T/Pa.s,

K is the material constant,

T is the thermodynamic temperature/K,

R is the universal gas constant = 8.314 J. mol-1.K-1, Eη is the viscous flow activation energy/ J.mol-1

This equation is modified by taking logarithms on both sides of the equations:

Depending upon the viscosity at different temperatures, the curve between logηT and 1T can be obtained. The slope of the curve is the coefficient of 1T, which is equal to the value of Eη/ 2.303 R, and then the viscous flow activation energy Eη is calculated.

9.1. Effect of Aging on Viscous Flow Activation Energy of Bitumen

Viscous flow activation energy (Eη) is the minimum energy when a set of molecules or flow unit moves from its original position towards the hole (See Section 10, for the definition of the hole), overcoming an energy barrier during the process of polymer material flow [66]. That is why Eη can depict the susceptibility of viscosity to change with temperature. Flow unit of polymer material is a chain segment that is why Eη is mainly related to molecular chain structure. There can be two types of polymer materials, the one which is highly rigid and has strong polarity molecular chains. This material has high viscous flow activation energy and requires high temperature to flow. The other material can have a linear flexible molecular chain, which has low Eη flowing at low temperature. In this study, a significant influence of aging on the viscous flow properties of asphalt has been reported. Parameters like viscous flow energy (Eη) and G*sinδ increased while tanδ decreased with the age and the difference in the increased rate of Eη reflects the differences in anti-aging properties of asphalt. However, there is no correlation between these parameters. Both the viscosity and viscous flow energy (Eη) also increased after aging [66].

10. ATOMIC FORCE MICROSCOPIC (AFM) STUDY OF BITUMEN

It is always worthwhile to study material at its micro- or nano-scale level and predict the corresponding macro-scale behavior. On similar lines, bitumen has also been studied at the microscale level using Atomic Force Microscopic (AFM), as shown in Fig. (4), to understand the underlying mechanics that define the behavior of bitumen especially physicochemical changes that occur due to aging. From the experiments conducted on different types of bitumen, it was apparent that the variation in micro-structures on the bitumen surfaces, observed under the AFM due to an increase in temperature correlated positively with the DSC test results. The appearance and disappearance of the micro-structures corresponded with the crystallization temperature range and melting temperature range, respectively [67]. Furthermore, AFM and differential scanning calorimetry (DSC) were utilized to determine the effect of three different exposures; namely, UV and air, only UV, and only air on the surface of bitumen. It was observed that irrespective of the type of bitumen, the proportion of microstructure on the surface reduced with the degree and time of exposure. It was also concluded that out of all the exposures, UV radiation brought about more aging than oxidation. Also, depending on the type of bitumen and exposure, it was found that a water-soluble thin film is formed over the surface of bitumen due to exposure, which verifies a strong correlation between aging and damage due to exposure to moisture [3].

|

Fig. (4). The AFM image of bitumen before (left) and after (right) aging condition. |

|

Fig. 5. 3D Digital Sample of Dense-Graded Asphalt Concrete. |

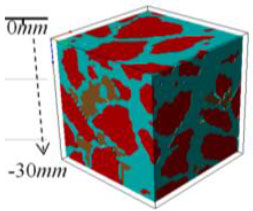

11. FINITE ELEMENT ANALYSIS OF OXIDATIVE AGING

The influence of diffusion-controlled oxidative aging has been investigated using the Finite Element Method (FEM) through simulation of the diffusion-reaction process on samples of different asphalt mixture morphologies. In this study, two samples of asphalt concrete: one dense and one open-graded, were taken. These samples were imaged using MicroCT scanning and segmented. Next, surface generation and discretization into finite elements were done using Simpleware software. The 3D digital sample of bitumen is as shown in Fig. (5).

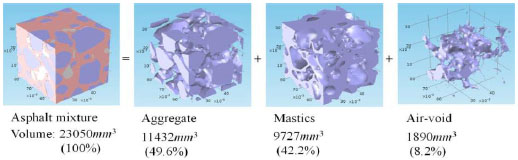

The resolution was 59 microns, which was very fine and would be computationally expensive, hence, by using upscaling, it was increased to 400 microns. Finally, FE analysis was done using COMSOL Multiphysics software. The boundary conditions were taken in such a way that the top surface is exposed to a continuous air supply with an oxygen concentration of 0.81 mol/m3. The interconnectedness of the air voids leads to easier exposure to oxygen, leading to faster aging of bitumen. These samples, being three-phased, contained aggregate, mastic, and air voids. The sample and its disjointed phases or volume fractions of each phase are as shown in Fig. (6). From this figure, it can be observed that air voids are mainly located in center. If the air voids were located within the top surface, which is exposed to the atmosphere, oxidative aging would take place quickly. However, aging cannot be accurately predicted based on only air voids. To determine short-term and long-term viscosity a model, considering factors like mixture morphology, temperature, time, and depth have been proposed. This model discussed elsewhere [68] predicts the long-term aging of bitumen fairly accurately.

|

Fig. (6). Disjointed 3-Phases of Dense-Graded Asphalt Concrete Sample [3]. |

12. DISCUSSION

Numerous physical properties of bitumen, like adhesion, elasticity, viscosity, or stiffness are directly related to the microstructural phase behavior [69]. Probably one of the most interesting areas to explore further is to investigate bitumen at micro-scale and meso-scale levels using its digital samples to decipher the microstructural phase change behavior and its nuances. The most versatile method to develop a digital sample is using X-ray Micro Computed Tomography (Micro CT). It is a powerful non-invasive scanning modality. In addition to computational procedures, the same digital sample may be further used for other morphological and morphometrical studies on bitumen samples conveniently.

Long-term aging of bitumen is of paramount importance, and the tests available to evaluate aging are generally based on creating artificially severe conditions, mostly with temperature and pressure-controlled environments. It has been investigated that bitumen aging at lower temperature and pressure is basically different from aging at elevated temperature and pressure. The former may be appreciated to simulate the actual field conditions more closely [70-72]. Also, the thermo-rheological performance of bitumen mainly depends on its chemical structure and intermolecular microstructures. It is important to study the conditions in which microstructural features appear and disappear due to time-temperature-pressure variations. Hence, developing frameworks to deduce the macroscopic response of bitumen on the basis of micro-scale investigations would be worthwhile.

CONCLUSION

The aging behavior of asphalt, when used in pavement construction, has been a major factor distressing the durability of asphalt pavement. Both traffic and exposure to environmental extremes are responsible for the onset of aging. Numerous researches have been underway to understand the exact mechanism of the inception of aging. Naturally, the next step is to employ innovative methods to age bitumen under laboratory settings to evaluate the effect of constituents added to slow down aging. The addition of graphite nano plate in bitumen has also been found to improve low-temperature thermal cracking as well as the high-temperature performance of bitumen. Furthermore, graphite nanoplate modified bitumen absorbed UV radiations better than its unmodified version. Mixing polymer-modified nanoclay has also been found promising, but it is yet to be thoroughly tested. Nanomaterials like Carbon nanofibers (CNFs) have been found to enhance fatigue life and improved rutting resistance. On the testing front, alternative test methods like German Rotating Flask Test and weatherometer, among others, have also been tested and correlated with the existing short- and long-term testing methods.

The range of effects of environmental factors on the aging of asphalt mixture is significantly dependent on the physicochemical characteristics of bitumen as well as the morphology of the asphaltic mixture. It is appreciable to conclude that assessment of the collective effect of compactness of aggregate, porosity, distribution, and interconnected network of air void is a fundamental necessity. A rudimentary approach involving micro-scale understanding of both bitumen and its mixes is potentially the way to understand the physicochemical behavior better and to predict their individual long-term performance under different field conditions. This approach can be followed by studying microstructural dilatancy using micro-computed tomography (Micro-CT) and Nano-CT scanning modalities.

CONSENT FOR PUBLICATION

Not applicable

FUNDING

None.

CONFLICT OF INTEREST

The authors declare no conflict of interest, financial or otherwise.

ACKNOWLEDGEMENTS

The support provided by the Malaysian Ministry of Higher Education, the University of Nottingham Malaysia and Universiti Malaysia Pahang in the form of a research grant for this study are highly appreciated.